ASTM E1640-99

(Test Method)Standard Test Method for Assignment of the Glass Transition Temperature By Dynamic Mechanical Analysis

Standard Test Method for Assignment of the Glass Transition Temperature By Dynamic Mechanical Analysis

SCOPE

1.1 This test method covers the assignment of a glass transition temperature (Tg) of materials using dynamic mechanical analyzers.

1.2 This test method is applicable to thermoplastic polymers, thermoset polymers, and partially crystalline materials which are thermally stable in the glass transition region.

1.3 The applicable range of temperatures for this test method is dependent upon the instrumentation used, but, in order to encompass all materials, the minimum temperature should be about -150°C.

1.4 This test method is intended for materials having an elastic modulus in the range of 0.5 MPa to 100 GPa.

1.5 Electronic instrumentation or automated data analysis and data reduction systems or treatments equivalent to this test method may also be used. Note 1-The user bears the responsibility for determining the precision, accuracy, and validity of the techniques and measurements made using dynamic mechanical analyzers in accordance with this standard. If disputes arise, only the manual procedures described in this standard are to be considered valid.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 1640 – 99

Standard Test Method for

Assignment of the Glass Transition Temperature By

Dynamic Mechanical Analysis

This standard is issued under the fixed designation E 1640; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the assignment of a glass

E 1142 Terminology Relating to Thermophysical Proper-

transition temperature (Tg) of materials using dynamic me-

ties

chanical analyzers.

E 1356 Test Method for Glass Transition Temperatures by

1.2 This test method is applicable to thermoplastic poly-

Differential Scanning Calorimetry or Differential Thermal

mers, thermoset polymers, and partially crystalline materials

Analysis

which are thermally stable in the glass transition region.

E 1363 Test Method for Temperature Calibration of Ther-

1.3 The applicable range of temperatures for this test

momechanical Analyzers

method is dependent upon the instrumentation used, but, in

E 1545 Test Method for the Determination of Glass Transi-

order to encompass all materials, the minimum temperature

tion Temperatures by Thermomechanical Analysis

should be about −150°C.

2.2 Other Standard:

1.4 This test method is intended for materials having an

SRM 18R-94 Recommended Method for Glass Transition

elastic modulus in the range of 0.5 MPa to 100 GPa.

Temperature (Tg) Determination by DMA of Oriented

1.5 Electronic instrumentation or automated data analysis

Fiber-Resin Composites

and data reduction systems or treatments equivalent to this test

method may also be used.

3. Terminology

NOTE 1—The user bears the responsibility for determining the preci-

3.1 Definition:

sion, accuracy, and validity of the techniques and measurements made

3.1.1 Specific technical terms used in this document are

using dynamic mechanical analyzers in accordance with this standard. If

defined in Terminology D 4092 and E 1142.

disputes arise, only the manual procedures described in this standard are

3.1.2 dynamic mechanical analyzer—any of various com-

to be considered valid.

mercial or experimental devices used to study the viscoelastic

1.6 This standard does not purport to address all of the

response of a specimen under a forced or free resonant

safety concerns, if any, associated with its use. It is the

oscillatory load. The force may be applied in torsion, flexure,

responsibility of the user of this standard to establish appro-

or a combination of tension and compression.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

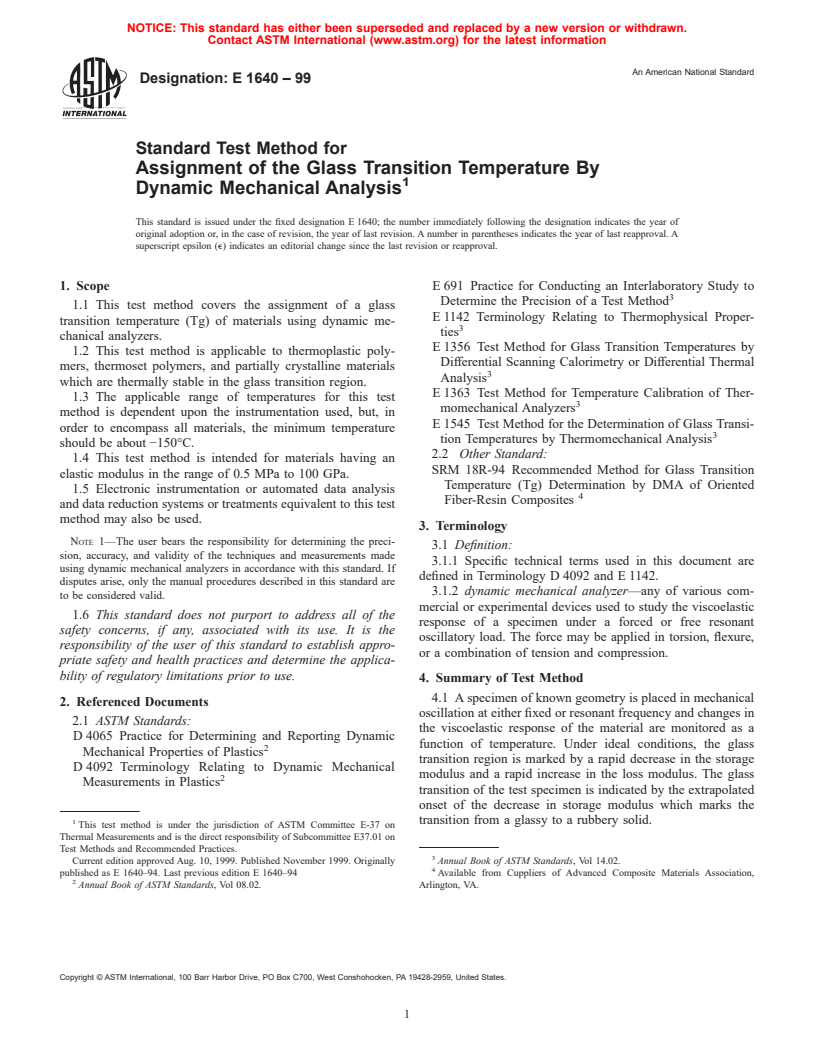

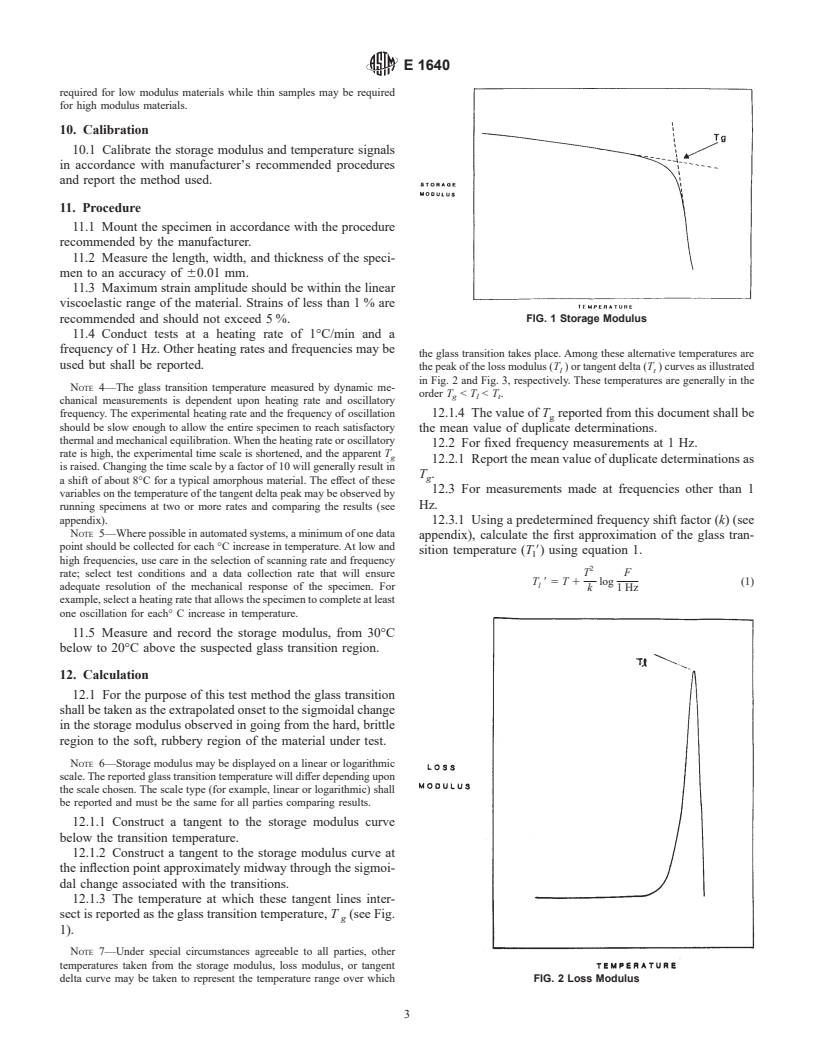

4. Summary of Test Method

4.1 A specimen of known geometry is placed in mechanical

2. Referenced Documents

oscillation at either fixed or resonant frequency and changes in

2.1 ASTM Standards:

the viscoelastic response of the material are monitored as a

D 4065 Practice for Determining and Reporting Dynamic

function of temperature. Under ideal conditions, the glass

Mechanical Properties of Plastics

transition region is marked by a rapid decrease in the storage

D 4092 Terminology Relating to Dynamic Mechanical

modulus and a rapid increase in the loss modulus. The glass

Measurements in Plastics

transition of the test specimen is indicated by the extrapolated

onset of the decrease in storage modulus which marks the

1 transition from a glassy to a rubbery solid.

This test method is under the jurisdiction of ASTM Committee E-37 on

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on

Test Methods and Recommended Practices.

Current edition approved Aug. 10, 1999. Published November 1999. Originally Annual Book of ASTM Standards, Vol 14.02.

published as E 1640–94. Last previous edition E 1640–94 Available from Cuppliers of Advanced Composite Materials Association,

Annual Book of ASTM Standards, Vol 08.02. Arlington, VA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1640

5. Significance and Use 7.2.1 Clamps, a clamping arrangement that permits gripping

of the specimen. Samples may be mounted by clamping at both

5.1 This test method can be used to locate the glass

ends (most systems), one end (for example, torsional pendu-

transition region and assign a glass transition temperature of

lum), or neither end (free bending between knife edges).

amorphous and semi-crystalline materials.

7.2.2 Oscillatory Stress (Strain), for applying an oscillatory

5.2 Dynamic mechanical analyzers monitor changes in the

deformation (strain) or oscillatory stress to the specimen. The

viscoelastic properties of a material as a function of tempera-

deformation may be applied and then released, as in freely

ture and frequency, providing a means to quantify these

vibrating devices, or continuously applied, as in forced vibra-

changes. In ideal cases, the temperature of the onset of the

tion devices.

decrease in storage modulus marks the glass transition.

7.2.3 Detector, for determining the dependent and indepen-

5.3 A glass transition temperature ( T ) is useful in charac-

g

dent experimental parameters, such as force (or stress), dis-

terizing many important physical attributes of thermoplastic,

placement (or strain), frequency, and temperature. Tempera-

thermosets (see SRM 18R-94), and semi-crystalline materials

tures should be measurable with an accuracy of 60.5°C, force

including their thermal history, processing conditions, physical

to 61 %, and frequency to 60.1 Hz.

stability, progress of chemical reactions, degree of cure, and

7.2.4 Temperature Controller and Oven, for controlling the

both mechanical and electrical behavior. T may be determined

g

specimen temperature, either by heating, cooling (in steps or

by a variety of techniques and may vary in accordance with the

ramps), or by maintaining a constant experimental environ-

technique.

ment. The temperature programmer shall be sufficiently stable

5.4 This test method is useful for quality control, specifica-

to permit measurement of specimen temperature to 60.5°C.

tion acceptance, and research.

The precision of the required temperature measurement is

61.0°C.

6. Interferences

7.2.5 Output Device, capable of displaying the storage

6.1 Because the specimen size will usually be small, it is

modulus (either linearly or logarithmically) on the Y axis

essential that each specimen be homogeneous and/or represen-

increasing in the upward direction and temperature on the X

tative of the material as a whole.

axis increasing to the right.

6.2 An increase or decrease in heating rates from those

NOTE 2—Some instruments suitable for this test may display only

specified may alter results.

linear or logarithm storage modulus while others may display either linear

6.3 A transition temperature is a function of the experimen-

and/or logarithm storage modulus. Care must be taken to use the same

tal frequency, therefore the frequency of test must always be

modulus scale when comparing unknown specimens, and in the compari-

specified. (The transition temperature increases with increasing

son of results from one instrument to another.

frequency.) Extrapolation to a common frequency may be

7.3 Nitrogen, Helium or other gas supplied for purging

accomplished using a predetermined frequency shift factor or

purposes.

assuming the frequency shift factor of about 8°C per decade of

5 7.4 Calipers or other length measuring device capable of

frequency.

measuring dimensions (or length within)6 0.01 mm.

7. Apparatus

8. Precautions

7.1 The function of the apparatus is to hold a specimen of

8.1 Toxic and corrosive, or both, effluents may be released

uniform dimension so that the sample acts as the elastic and

when heating some materials and could be harmful to person-

dissipative element in a mechanically oscillated system. Dy-

nel and to apparatus.

namic mechanical analyzers typically operate in one of several

8.2 Multiple Transitions—Under some experimental condi-

modes. See Table 1.

tions it is possible to have transitions secondary to the primary

glass transition. Secondary transitions may be related to the

glass transition of a second polymeric phase, melt processes,

TABLE 1 Modes for Dynamic Mechanical Analyzers

crystallization, chemical reactions, the motion of groups pen-

Mechanical Response

Mode dent to the main backbone or the crankshaft motion of the

Tension Flexural Torsional Compression

polymer backbone.

Free/dec . . X .

Forced/res/CA . X X .

9. Samples

Forced/fix/CA X X X X

Forced/fix/CS X X . X

9.1 Samples may be any uniform size or shape, but are

ordinarily analyzed in rectangular form. If some heat treatment

Free 5 free oscillation; dec 5 decaying amplitude; forced 5 forced oscillation;

CA 5 constant amplitude; res 5 resonant frequency; fix 5 fixed frequency;

is applied to the specimen to obtain this preferred analytical

CS 5 controlled stress.

form, such treatment should be noted in the report.

9.2 Due to the numerous types of dynamic mechanical

analyzers, sample size is not fixed by this method. In many

7.2 The apparatus shall consist of the following:

cases, specimens measuring between 1 3 5 3 20 mm and

1 3 10 3 50 mm are suitable.

NOTE 3—It is important to select a specimen size appropriate for both

Ferry, D. “Viscoelastic Properties of Polymers,” John Wiley & Sons, 1980. the material and the testing apparatus. For example, thick samples may be

E 1640

required for low modulus materials while thin samples may be required

for high modulus materials.

10. Calibration

10.1 Calibrate the storage modulus and temperature signals

in accordance with manufacturer’s recommended procedures

and report the method used.

11. Procedure

11.1 Mount the specimen in accordance with the procedure

recommended by the manufacturer.

11.2 Measure the length, width, and thickness of the speci-

men to an accuracy of 60.01 mm.

11.3 Maximum strain amplitude should be within the linear

viscoelastic range of the material. Strains of l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.