ASTM D3673-89(2016)

(Test Method)Standard Test Methods for Chemical Analysis of Alpha Olefin Sulfonates

Standard Test Methods for Chemical Analysis of Alpha Olefin Sulfonates

SIGNIFICANCE AND USE

33.1 This method is suitable as a quality control test for the measurement of color in alpha olefin sulfonates.

SCOPE

1.1 These test methods cover the chemical analysis of alpha olefin sulfonates. The analytical procedures appear in the following order:

Sections

Moisture by the Distillation Method

4 – 8

Sodium Sulfate

9 – 14

Neutral Oil

15 – 19

Chlorides Calculated as Sodium Chloride (NaCl)

20 – 24

Alkalinity

25 – 29

pH

30 and 31

Determination of Color

32 – 37

Determination of Active Content by Methylene Blue Titration

38 – 47

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precaution statement see 36.1. Material safety data sheets are available for reagents and materials. Review them for hazards prior to usage.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3673 −89 (Reapproved 2016)

Standard Test Methods for

Chemical Analysis of Alpha Olefin Sulfonates

This standard is issued under the fixed designation D3673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Purity of Reagents

1.1 These test methods cover the chemical analysis of alpha 3.1 Reagent-grade chemicals shall be used in all tests.

olefin sulfonates. The analytical procedures appear in the Unless otherwise indicated, it is intended that all reagents shall

following order: conform to the specifications of the Committee on Analytical

Reagents of the American Chemical Society, where such

Sections

Moisture by the Distillation Method 4–8

specifications are available. Other grades may be used, pro-

Sodium Sulfate 9–14

vided it is first ascertained that the reagent is of sufficiently

Neutral Oil 15–19

high purity to permit its use without lessening the accuracy of

Chlorides Calculated as Sodium Chloride (NaCl) 20–24

Alkalinity 25–29

the determination.

pH 30 and 31

3.2 Unless otherwise indicated, references to water shall be

Determination of Color 32–37

Determination of Active Content by Methylene Blue Titration 38–47

understood to mean Type III reagent water conforming to

1.2 The values stated in SI units are to be regarded as Specification D1193.

standard. No other units of measurement are included in this

MOISTURE BY THE DISTILLATION

standard.

METHOD

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Apparatus

responsibility of the user of this standard to establish appro-

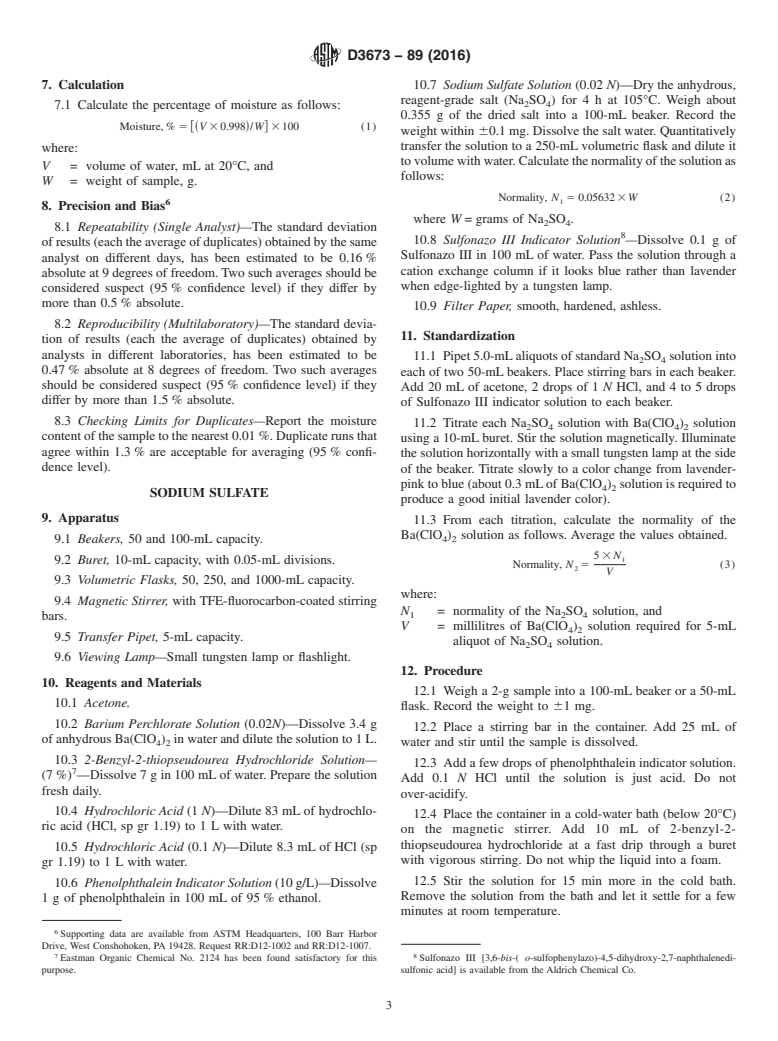

4.1 The apparatus required shall consist of a glass flask

priate safety and health practices and determine the applica-

heated by suitable means and provided with a reflux condenser

bility of regulatory limitations prior to use. For specific

discharging into a trap and connected to the flask. The

precaution statement see 36.1. Material safety data sheets are

connections between the trap and the condenser and flask shall

available for reagents and materials. Review them for hazards

beinterchangeablegroundjoints.Thetrapservestocollectand

prior to usage.

measure the condensed water and to return the solvent to the

flask.Asuitable assembly of the apparatus is illustrated in Fig.

2. Referenced Documents

1.

2.1 ASTM Standards:

4.1.1 Flask, 1-L capacity, either the short-neck, round-

D1172 Guide for pH of Aqueous Solutions of Soaps and

bottom type, or the Erlenmeyer type.

Detergents

4.1.2 Heat Source—Either an oil bath (for example, stearic

D1193 Specification for Reagent Water

acid or paraffin wax) or an electric heater provided with a

D1209 Test Method for Color of Clear Liquids (Platinum-

sliding rheostat or other means of heat control.

Cobalt Scale)

4.1.3 Condenser—A water-cooled glass reflux condenser

D3049 Test Method for Synthetic Anionic Ingredient by

(Fig. 1), having a jacket approximately 15 ⁄4 in. (400 mm) in

Cationic Titration

3 1

length, with an inner tube ⁄8 to ⁄2 in. (9.5 to 12.7 mm) in

outside diameter, and not less than ⁄4 in. (6.35 mm) in inside

diameter. The end of the condenser to be inserted in the trap

These test methods are under the jurisdiction of ASTM Committee D12 on

may be ground off at an angle of 30° from the vertical axis of

Soaps and Other Detergents and are the direct responsibility of Subcommittee

the condenser. When inserted into the trap, the tip of the

D12.12 on Analysis and Specifications of Soaps, Synthetics, Detergents and their

Components.

Current edition approved July 1, 2016. Published August 2016. Originally

approved in 1978. Last previous edition approved in 2009 as D3673 – 89(2009). Reagent Chemicals, American Chemical Society Specifications, American

DOI: 10.1520/D3673-89R16. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3673 − 89 (2016)

4.1.4.1 Trap, 5-mL capacity, subdivided into 0.1-mL divi-

sions with each 1-mL line numbered (5 mL at top). The error

in any indicated capacity may not be greater than 0.05 mL.

4.1.4.2 Trap, 10-mLcapacity, subdivided from 0 to 1 mLin

0.1-mL divisions and from 1 to 10 mL in 0.2-mL divisions.

4.1.4.3 Trap, 25-mLcapacity, subdivided from 0 to 1 mLin

0.1-mL divisions and from 1 to 25 mL in 0.2-mL divisions.

NOTE 1—The condenser and trap should be thoroughly cleaned before

use.

5. Solvent

5.1 Xylene—Saturate xylene with water by shaking with a

small quantity of water and distill. Use the distillate for the

determination.

6. Procedure

6.1 Transfer to the 1000-mLflask (equipped with the size of

the trap specified in 4.1.4) an amount of sample according to

the percentage of moisture expected, as follows:

Weight of Sample

A

Moisture Expected, % to Be Used, g

0to5,incl 50±5

Over 5 to 17, incl 50 ± 5

Over 17 to 30, incl 40 ± 4

Over 30 to 50, incl 30 ± 3

Over 50 to 70, incl 30 ± 3

Over 70 to 85, incl 25 ± 2

A

Weighed to the nearest 0.25 g.

Immediatelyaddabout250mLofxylene.Placeasmall,thin

sheet of long-fiber, chemical-resistant glass wool on the

surface of the xylene. The glass wool should be thoroughly

dried in the oven and held in the desiccator before use.

6.2 Connecttheflaskandreceivertothecondenserandpour

sufficient xylene down the condenser tube to cause a slight

overflowthroughthesidetube.Wraptheflaskandtubeleading

to the receiver with glass wool, so that refluxing will be under

better control.

6.3 Heat the oil bath with a gas burner or other source of

heat, or apply heat directly to the flask with an electric heater

FIG. 1 Assembly of Distillation Apparatus

and distill slowly.The rate at the start should be approximately

condenser shall be about ⁄4 in. (7 mm) above the surface of the

100 drops per minute. When the greater part of the water has

liquid in the trap after the distillation conditions have been

distilled over, increase the distillation rate to 200 drops per

established. Fig. 1 shows a conventional sealed-in type of

minute until no more water is collected. Rinse during the

condenser, but any other condenser fulfilling the detailed

distillation with 5-mL portions of xylene to wash down any

requirements of this paragraph may be used.

moisture adhering to the walls of the condenser. The water in

4.1.4 Trap—For greatest accuracy several trap sizes are

the receiver may be made to separate from the xylene by using

allowable, depending upon the percentage of moisture ex-

aspiralcopperorNichrome wire.Movethewireupanddown

pected:

in the condenser occasionally, thus causing the water to settle

at the bottom of the receiver. Reflux for at least 2 h, and shut

Moisture Expected, % Size of Trap, mL

off the heat at the end of this period.

0to5,incl 5

Over 5 to 17, incl 10

NOTE 2—In especially difficult cases of boil-over, add 10 to 15 mL of

Over 17 to 30, incl 25

oleicacidbeforebeginningthedistillation.Washdownthecondenserwith

Over 30 to 50, incl 25

10 mLof xylene.Adjust the temperature of the distillate to 20°C and read

Over 50 to 70, incl 25

the volume of water.

Over 70 to 85, incl 25

Traps made of well-annealed glass, constructed essentially

as shown in Fig. 1, and graduated to contain one of the

Borosilicate glass has been found satisfactory for this purpose.

following specified volumes at 20°C shall be used: “Nichrome” is a trademark of the Driver-Harris Co.

D3673 − 89 (2016)

7. Calculation 10.7 Sodium Sulfate Solution (0.02 N)—Dry the anhydrous,

reagent-grade salt (Na SO)for4hat 105°C. Weigh about

2 4

7.1 Calculate the percentage of moisture as follows:

0.355 g of the dried salt into a 100-mL beaker. Record the

Moisture,% 5 @ V 30.998 /W# 3100 (1)

~ !

weight within 60.1 mg. Dissolve the salt water. Quantitatively

transfer the solution to a 250-mL volumetric flask and dilute it

where:

tovolumewithwater.Calculatethenormalityofthesolutionas

V = volume of water, mL at 20°C, and

follows:

W = weight of sample, g.

Normality, N 5 0.05632 3 W (2)

6 1

8. Precision and Bias

where W = grams of Na SO .

2 4

8.1 Repeatability (Single Analyst)—The standard deviation

10.8 Sulfonazo III Indicator Solution —Dissolve 0.1 g of

ofresults(eachtheaverageofduplicates)obtainedbythesame

Sulfonazo III in 100 mL of water. Pass the solution through a

analyst on different days, has been estimated to be 0.16 %

cation exchange column if it looks blue rather than lavender

absolute at 9 degrees of freedom.Two such averages should be

when edge-lighted by a tungsten lamp.

considered suspect (95 % confidence level) if they differ by

more than 0.5 % absolute.

10.9 Filter Paper, smooth, hardened, ashless.

8.2 Reproducibility (Multilaboratory)—The standard devia-

11. Standardization

tion of results (each the average of duplicates) obtained by

analysts in different laboratories, has been estimated to be

11.1 Pipet 5.0-mLaliquots of standard Na SO solution into

2 4

0.47 % absolute at 8 degrees of freedom. Two such averages

each of two 50-mL beakers. Place stirring bars in each beaker.

should be considered suspect (95 % confidence level) if they

Add 20 mL of acetone, 2 drops of 1 N HCl, and 4 to 5 drops

differ by more than 1.5 % absolute.

of Sulfonazo III indicator solution to each beaker.

8.3 Checking Limits for Duplicates—Report the moisture

11.2 Titrate each Na SO solution with Ba(ClO ) solution

2 4 4 2

contentofthesampletothenearest0.01 %.Duplicaterunsthat

using a 10-mL buret. Stir the solution magnetically. Illuminate

agree within 1.3 % are acceptable for averaging (95 % confi-

the solution horizontally with a small tungsten lamp at the side

dence level).

of the beaker. Titrate slowly to a color change from lavender-

pink to blue (about 0.3 mLof Ba(ClO ) solution is required to

4 2

SODIUM SULFATE

produce a good initial lavender color).

9. Apparatus

11.3 From each titration, calculate the normality of the

Ba(ClO ) solution as follows. Average the values obtained.

9.1 Beakers, 50 and 100-mL capacity. 4 2

5 3 N

9.2 Buret, 10-mL capacity, with 0.05-mL divisions.

Normality, N 5 (3)

V

9.3 Volumetric Flasks, 50, 250, and 1000-mL capacity.

where:

9.4 Magnetic Stirrer, with TFE-fluorocarbon-coated stirring

N = normality of the Na SO solution, and

1 2 4

bars.

V = millilitres of Ba(ClO ) solution required for 5-mL

4 2

9.5 Transfer Pipet, 5-mL capacity.

aliquot of Na SO solution.

2 4

9.6 Viewing Lamp—Small tungsten lamp or flashlight.

12. Procedure

10. Reagents and Materials

12.1 Weigh a 2-g sample into a 100-mL beaker or a 50-mL

10.1 Acetone.

flask. Record the weight to 61 mg.

10.2 Barium Perchlorate Solution (0.02N)—Dissolve 3.4 g

12.2 Place a stirring bar in the container. Add 25 mL of

of anhydrous Ba(ClO ) in water and dilute the solution to 1 L.

4 2 water and stir until the sample is dissolved.

10.3 2-Benzyl-2-thiopseudourea Hydrochloride Solution—

12.3 Add a few drops of phenolphthalein indicator solution.

(7 %) —Dissolve7gin100mLof water. Prepare the solution

Add 0.1 N HCl until the solution is just acid. Do not

fresh daily.

over-acidify.

10.4 Hydrochloric Acid (1 N)—Dilute 83 mL of hydrochlo-

12.4 Place the container in a cold-water bath (below 20°C)

ric acid (HCl, sp gr 1.19) to 1 L with water.

on the magnetic stirrer. Add 10 mL of 2-benzyl-2-

thiopseudourea hydrochloride at a fast drip through a buret

10.5 Hydrochloric Acid (0.1 N)—Dilute 8.3 mL of HCl (sp

with vigorous stirring. Do not whip the liquid into a foam.

gr 1.19) to 1 L with water.

12.5 Stir the solution for 15 min more in the cold bath.

10.6 Phenolphthalein Indicator Solution(10g/L)—Dissolve

Remove the solution from the bath and let it settle for a few

1 g of phenolphthalein in 100 mL of 95 % ethanol.

minutes at room temperature.

Supporting data are available from ASTM Headquarters, 100 Barr Harbor

Drive, West Conshohoken, PA 19428. Request RR:D12-1002 and RR:D12-1007.

7 8

Eastman Organic Chemical No. 2124 has been found satisfactory for this Sulfonazo III [3,6-bis-( o-sulfophenylazo)-4,5-dihydroxy-2,7-naphthalenedi-

purpose. sulfonic acid] is available from the Aldrich Chemical Co.

D3673 − 89 (2016)

12.6 Filter the solution through filter paper into a 50-mL 16. Reagents

volumetric flask. Wash the filter cake with water. Use the

16.1 Ethanol, freshly boiled, 95 % or higher and neutral to

washes to dilute the solution to volume.

phenolphthalein indicator, conforming to either Formula No.

12.7 Pipet a 5-mL aliquot into a 50-mL beaker. Add 20 mL 3A or No. 30 of the U.S. Bureau of Internal Revenue.

of acetone, 2 drops of 1 N HCl, and 4 to 5 drops of Sulfonazo

16.2 Petroleum Ether, with a distillation range between 30

III indicator solution.

and 60°C or n-pentane having a distillation range between

33°C and 41°C.

12.8 Titrate the solution slowly with 0.02 N Ba(ClO )

4 2

solution. Use magnetic stirring. Illuminate the solution hori-

16.3 Ethanol-Water (1 + 1)—Mix 1 volume of ethanol with

zontally with a small tungsten lamp at the side of the beaker.

1 volume of water.

Titratetoacolorchangefromlavender-pinktoabluecolorthat

16.4 Phenolphthalein Indicator Solution.

persists for 1 min.

16.5 Sodium Hydroxide Solution (0.1N)—Dissolve approxi-

NOTE 3—The titration should be between 1 and 5 mL. If the titration is

mately4gof sodium hydroxide (NaOH) in water and dilute to

greater than 5 mL, use a smaller aliquot of the sample and add water to

1L.

bring the aqueous volume to 5 mL total. If the titration is less than 1 mL,

pipet a 10-mL aliquot into a 100-mL beaker and add 40 mL of acetone, 4

16.6 Sodium Sulfate (Na SO ), anhydrous, crystalline.

2 4

drops of 1 N HCl, and 8 to 10 drops of Sulfonazo III indicator solution.

17. Procedure

13. Calculation

17.1 Introduce into a 250-mL Erlenmeyer flask sample

13.1 Calculate the concentration of Na SO as follows:

2 4

equivalent to 6 to8gof active matter, weighed to the near

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.