ASTM D2818-79(1983)

(Specification)Specification for Perforated Homogeneous Bituminized Fiber Pipe for Airport and Highway Drainage (Withdrawn 1990)

Specification for Perforated Homogeneous Bituminized Fiber Pipe for Airport and Highway Drainage (Withdrawn 1990)

General Information

Standards Content (Sample)

I ASTM DE'BLB 77 W 0759530 flfl?347A A = -- -

Designation: D 2818 - 79 (Res

Standard Specification for

PERFORATED, HOMOGENEOUS BITUMINIZED FIBER

PIPE FOR AIRPORT AND HIGHWAY DRAINAGE'

This standard is issued under the fixed designafionIl 281s; the number immediately following fhe designationindicates the

year of original adoption or, in the case of revision, the year of last rev¡sion.-Anumber in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

4. Chemical and Physical Requirements

1. scope

4.1 Chemical Resistance-The specimen

1.1 This specification covers homogeneous

shall show no evidence of chemical reaction or

perforated bituminized fiber pipe, couplings,

deterioration of impregnant.

joints, and fittings used in subsurface airport,

4.2 Water Absorption-The maximum water

highway, and similar drainage.

absorption shall be 2 % of the original weight,

1.2 The values stated in SI units are to be

regarded as the standard. calculated to the nearest 0.1 %.

4.3 Kerosine Resistance-Specimens shaU

2. Applicable Document

meet the dry crushing strength requirements

specified in Table 1.

2. í ASTMStandard

4.4 Heat Resistance-The heat shall not

D 23 14 Methods of Testing Homogeneous Bi-

cause a weight loss over 1 % in the specimen

tuminized Fiber Pipe'

due to exudation of the impregnant.

3. Materials and, Manufacture

4.5 Resistance to Flartening-The decrease

in diameter shall be not more than 3 %.

3.1 Pipe shall be composed of a reinforcing

4.6 Crushing Strengths-The requirements

interwoven fibrous structure thoroughly im-

for dry and wet crushing strengths are given in

pregnated with a durable bituminous com-

Table 1.

pound. The wall of the pipe shall be without

seams or laminations and the bore shall have

5. Dimensions

a smooth surface free from obstructions and

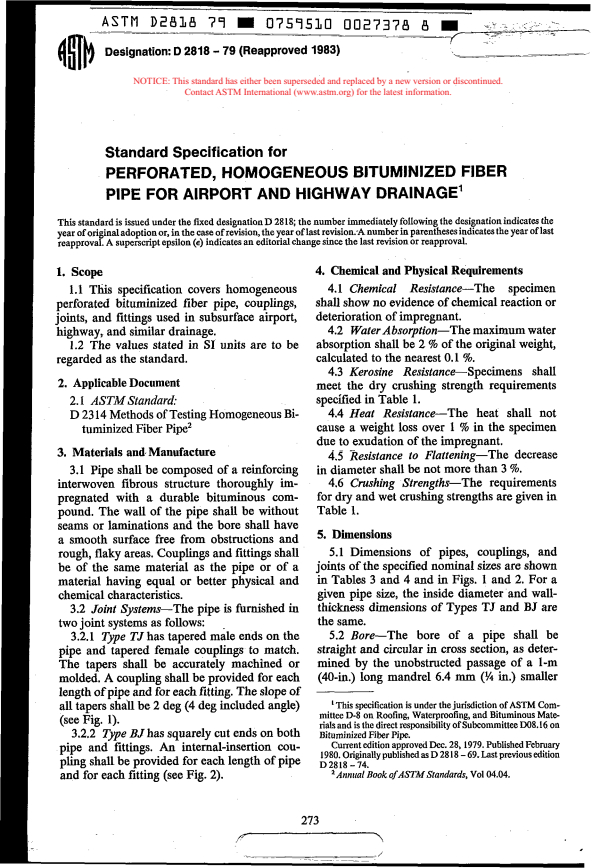

5.1 Dimensions of pipes, couplings, and

rough, flaky areas. Couplings and fittings shall

joints of the specified nominal sizes are shown

be of the same material as the pipe or of a

in Tables 3 and 4 and in Figs. 1 and 2. For a

material having equal or better physical and

given pipe size, the inside diameter and wall-

chemical characteristics.

thickness dimensions of Types TJ and BJ are

3.2 Joint Systems-The pipe is furnished in

the same.

two joint systems as follows:

5.2 Bore-The bore of a pipe shall be

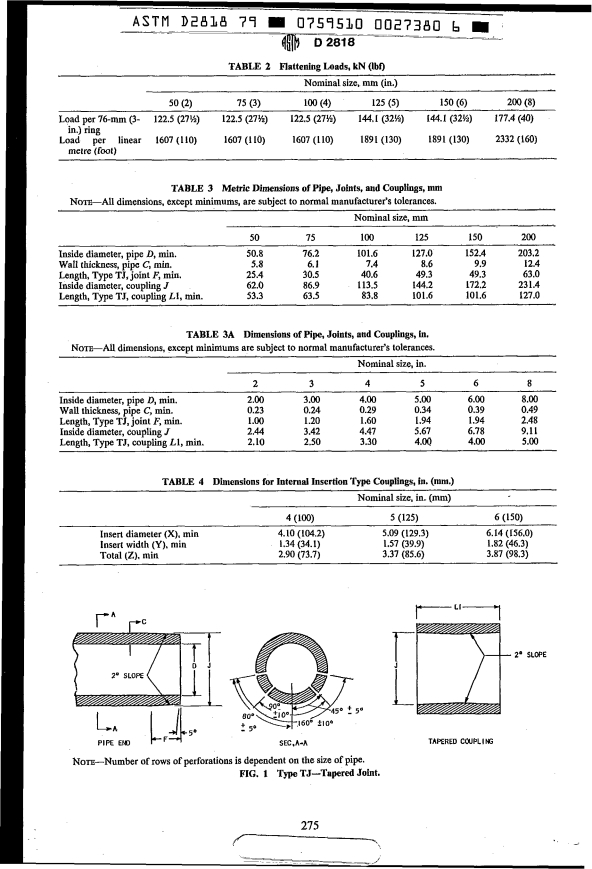

3.2.1 Type TJ has tapered male ends on the

straight and circular in cross section, as deter-

pipe and tapered female couplings to match.

mined by the unobstructed passage of a 1-m

The tapers shall be accurately machined or

(40-in.) long mandrel 6.4 mm (Y4 in.) smaller

molded. A coupling shall be provided for each

length of pipe and for each fitting. The slope of

'This specification is under the jurisdiction of ASTM Com-

ail tapers shall be 2 deg (4 deg included angle)

mittee D8 on Roofing, Waterproofing, and Bituminous Mate

(see Fig. 1).

rials and is the direct responsibility of Subcommittee W8.16 on

3.2.2 Type BJ has squarely cut ends on both Bituminized Fiber Pipe.

Current edition approved Dec. 28,1979. Published February

pipe and fittings. An intemal-insertion cou-

1980.OriginaUypublishedasD2818-69.Lastpreviousedition

pling shall be provided for each length of pipe

D 2818 - 74.

Anniral Book of ASTM Sfandards, Vol 04.04.

and for each fitting (see Fig. 2).

273

---------------------- Page: 1 ----------------------

.O7575110 0027377 T

~~

ASTM D2BLB 77 II

D 2818

_.

4m

than nominal diameter of the pipe. 8. Inspection

5.3 Length-Overall lengfh of the pipe shall

8.1 Inspection of the material shaU be agreed

be 1.5, 2.4, or 3.0 m (5, 8, or 10 ft), depending

upon between the purchaser and the supplier

on manufacturer's standard practice. A toler-

as part of the purchase contract.

ance of f25 mm (I 1 in.) shall be permitted.

Up to 20 % shorter lengths than the manufac- 9. Rejection and Rehearing

turer's standard may be suppled, but no length

9.1 Material that fails to conform to the

shorter than 1.2 m (4 ft) shall be furnished.

requirements of this specification may be re-

5.4 Pegoraïians-The perforations shall be

jected, Rejection should be reported to the

circular in shape and arranged in parallel rows

producer or supplier promptly and in writing.

along the axis of the pipe. They shall be 7.9 I:

In case of dissatisfaction with the results of the

1.6 mm (%6 f %is in.) in diameter and spaced

test, the producer or supplier may make claim

approximately 76 mm (3 in.) center to center

for a rehearing.

along the rows. The rows of perforations shall

9.2 If 20 % or less of the test spechens fail

be arranged in two equal groups placed sym-

to meet any of the test rquirements, then the

metrically on each side of a lower segment

supplier will be allowed to retest on two addi-

corresponding to the flow be of the pipe. Pipe

tional specimens for each specimen that fail

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.