ASTM D4252-89(2017)

(Test Method)Standard Test Methods for Chemical Analysis of Alcohol Ethoxylates and Alkylphenol Ethoxylates

Standard Test Methods for Chemical Analysis of Alcohol Ethoxylates and Alkylphenol Ethoxylates

SIGNIFICANCE AND USE

3.1 Alcohol ethoxylates and alkylphenol ethoxylates are important surfactants in household and industrial cleaners. They may be used as either nonionic surfactants or sulfated and used as anionic surfactants. Careful control of the ethoxylate characteristics is desired as variations may result in either desirable or undesirable end-use properties.

SCOPE

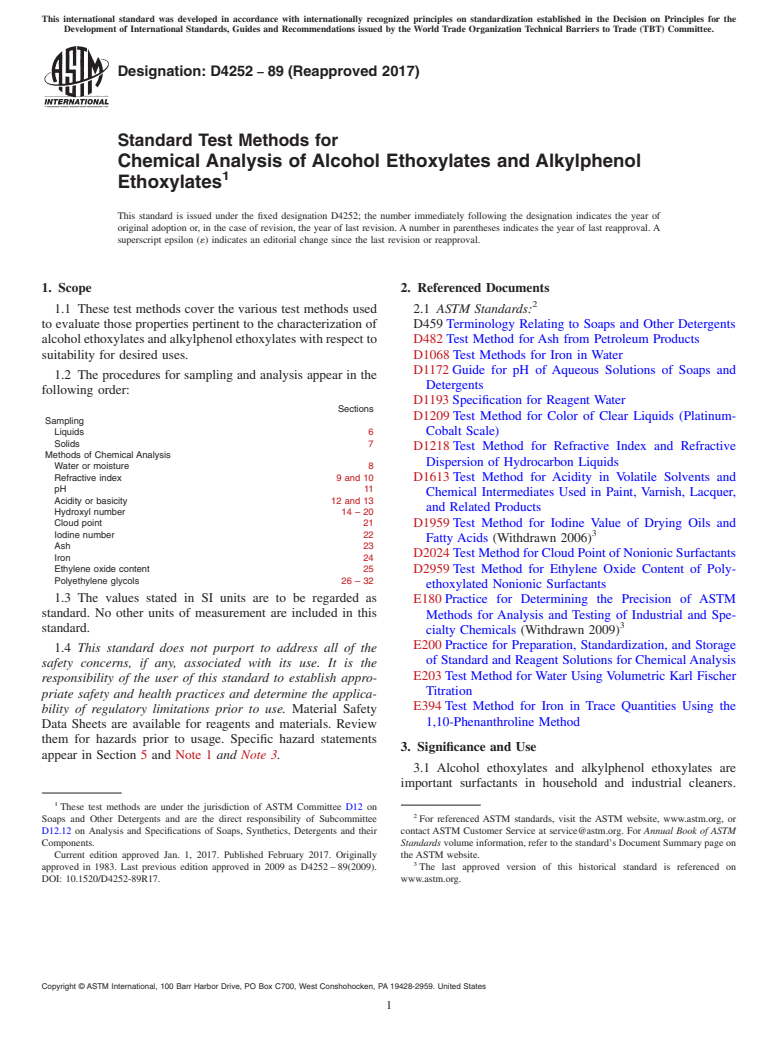

1.1 These test methods cover the various test methods used to evaluate those properties pertinent to the characterization of alcohol ethoxylates and alkylphenol ethoxylates with respect to suitability for desired uses.

1.2 The procedures for sampling and analysis appear in the following order:

Sections

Sampling

Liquids

6

Solids

7

Methods of Chemical Analysis

Water or moisture

8

Refractive index

9 and 10

pH

11

Acidity or basicity

12 and 13

Hydroxyl number

14 – 20

Cloud point

21

Iodine number

22

Ash

23

Iron

24

Ethylene oxide content

25

Polyethylene glycols

26 – 32

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage. Specific hazard statements appear in Section 5 and Note 1 and Note 3.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4252 − 89 (Reapproved 2017)

Standard Test Methods for

Chemical Analysis of Alcohol Ethoxylates and Alkylphenol

Ethoxylates

This standard is issued under the fixed designation D4252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 These test methods cover the various test methods used 2.1 ASTM Standards:

to evaluate those properties pertinent to the characterization of D459 Terminology Relating to Soaps and Other Detergents

alcoholethoxylatesandalkylphenolethoxylateswithrespectto D482 Test Method for Ash from Petroleum Products

suitability for desired uses. D1068 Test Methods for Iron in Water

D1172 Guide for pH of Aqueous Solutions of Soaps and

1.2 The procedures for sampling and analysis appear in the

Detergents

following order:

D1193 Specification for Reagent Water

Sections

D1209 Test Method for Color of Clear Liquids (Platinum-

Sampling

Liquids 6 Cobalt Scale)

Solids 7

D1218 Test Method for Refractive Index and Refractive

Methods of Chemical Analysis

Dispersion of Hydrocarbon Liquids

Water or moisture 8

Refractive index 9 and 10 D1613 Test Method for Acidity in Volatile Solvents and

pH 11

Chemical Intermediates Used in Paint, Varnish, Lacquer,

Acidity or basicity 12 and 13

and Related Products

Hydroxyl number 14–20

Cloud point 21 D1959 Test Method for Iodine Value of Drying Oils and

Iodine number 22

Fatty Acids (Withdrawn 2006)

Ash 23

D2024 Test Method for Cloud Point of Nonionic Surfactants

Iron 24

Ethylene oxide content 25

D2959 Test Method for Ethylene Oxide Content of Poly-

Polyethylene glycols 26–32

ethoxylated Nonionic Surfactants

1.3 The values stated in SI units are to be regarded as

E180 Practice for Determining the Precision of ASTM

standard. No other units of measurement are included in this

Methods for Analysis and Testing of Industrial and Spe-

standard.

cialty Chemicals (Withdrawn 2009)

E200 Practice for Preparation, Standardization, and Storage

1.4 This standard does not purport to address all of the

of Standard and Reagent Solutions for ChemicalAnalysis

safety concerns, if any, associated with its use. It is the

E203 Test Method for Water Using Volumetric Karl Fischer

responsibility of the user of this standard to establish appro-

Titration

priate safety and health practices and determine the applica-

E394 Test Method for Iron in Trace Quantities Using the

bility of regulatory limitations prior to use. Material Safety

1,10-Phenanthroline Method

Data Sheets are available for reagents and materials. Review

them for hazards prior to usage. Specific hazard statements

3. Significance and Use

appear in Section 5 and Note 1 and Note 3.

3.1 Alcohol ethoxylates and alkylphenol ethoxylates are

important surfactants in household and industrial cleaners.

These test methods are under the jurisdiction of ASTM Committee D12 on

Soaps and Other Detergents and are the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

D12.12 on Analysis and Specifications of Soaps, Synthetics, Detergents and their contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Components. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2017. Published February 2017. Originally the ASTM website.

approved in 1983. Last previous edition approved in 2009 as D4252 – 89(2009). The last approved version of this historical standard is referenced on

DOI: 10.1520/D4252-89R17. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4252 − 89 (2017)

Theymaybeusedaseithernonionicsurfactantsorsulfatedand 10. Precision

used as anionic surfactants. Careful control of the ethoxylate

10.1 The following criteria should be used for judging the

characteristics is desired as variations may result in either 5,6

acceptability of results:

desirable or undesirable end-use properties.

10.1.1 Repeatability (Single Analyst)—The standard devia-

tion of results (each the average of duplicates), obtained by the

4. Purity of Reagents

same analyst on different days, has been estimated to be

4.1 Reagent-grade chemicals shall be used in all tests. 0.00021 units absolute at 36 df. Two such averages should be

Unless otherwise indicated, it is intended that all reagents shall considered suspect (95 % confidence level) if they differ by

conform to the specifications of the Committee on Analytical more than 0.00059 units absolute.

Reagents of the American Chemical Society, where such 10.1.2 Reproducibility (Multilaboratory)—The standard de-

specifications are available. Other grades may be used, pro- viation of results (each the average of duplicates), obtained by

vided it is first ascertained that the reagent is of sufficiently analysts in different laboratories, has been estimated to be

high purity to permit its use without lessening the accuracy of 0.00059 units absolute at 7 df. Two such averages should be

the determination. considered suspect (95 % confidence level) if they differ by

more than 0.0020 units absolute.

4.2 Unless otherwise indicated, references to water shall be

10.1.3 Checking Limits for Duplicates—Report the refrac-

understood to mean Type III reagent water conforming to

tive index of the sample to the nearest 0.0001. Duplicate runs

Specification D1193.

that agree within 0.00025 units are acceptable for averaging

(95 % confidence level).

5. Safety Precautions

pH

5.1 All reagents and chemicals should be handled with care.

Before using any chemical, read and follow all safety precau-

11. Procedure

tions and instructions on the manufacturer label. Clean up any

spillimmediately.Forinformationoncleaningupspillsreferto

11.1 Determine the pH in accordance with Test Method

the Laboratory Disposal Manual, Manufacturing Chemists

D1172, except prepare the solution by transferring 1 6 0.001

Association, Washington, DC.

g of the sample to a 100 mL volumetric flask and diluting in

accordance with Test Method D1172. Measure the pH 10 min

SAMPLING

after diluting the sample solution to volume.

6. Liquids

ACIDITY OR BASICITY

6.1 Thoroughly mix the sample before sampling. If a solid

12. Procedure

layer or crystals have formed on the bottom of the bottle, melt

inanovenorwaterbathat55°Candmixwellbeforesampling.

12.1 Determine acidity or basicity in accordance with Test

Method D1613 using a 3+1 solution of isopropyl alcohol and

7. Solids

water as the solvent and a 10-g sample.

7.1 Melt in an oven or water bath at 55°C and mix well

13. Precision

beforesampling.Ifitisnecessarytoheatattemperaturesabove

60°C,replacethegascapwithaninertgas,suchasoxygen-free 13.1 The following criteria should be used for judging the

6,7

nitrogen, helium, or argon before heating.

acceptability of results:

13.1.1 Repeatability (Single Analyst)—The standard devia-

WATER OR MOISTURE

tion of results (each the average of duplicates), obtained by the

same analyst on different days, has been estimated to be 0.017

8. Procedure

meq/100 g at 27 df. Two such averages should be considered

8.1 Determine water or moisture in accordance with Test suspect (95 % confidence level) if they differ by more than

0.049 meq/100 g.

Method E203.

13.1.2 Reproducibility (Multilaboratory)—The standard de-

REFRACTIVE INDEX

viation of results (each the average of duplicates), obtained by

analysts in different laboratories, has been established to be

9. Procedure

0.12 meq/100 g at 5 df. Two such averages should be

9.1 Measure the refractive index at 50°C in accordance with

Test Method D1218.

The precision estimates are based on an interlaboratory study on ALFONIC®

1412-60, MAKON®-10, NEODOL® 25-9, PLURONIC® 25R1, and TERGITOL

15-S-3 by nine laboratories.

4 6

Reagent Chemicals, American Chemical Society Specifications, American Statistical analysis was performed in accordance with Practice E180 for

Chemical Society, Washington, DC. For suggestions on the testing of reagents not developing precision estimates. Data supporting the precision statements are on file

listed by the American Chemical Society, see Analar Standards for Laboratory at ASTM International Headquarters. Request RR: RR:D12-1004.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia The precision estimates are based on an interlaboratory study on ALFONIC®

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, 1412-60, MAKON®-10, NEODOL® 25-9, PLURONIC® 25R1 and TERGITOL®

MD. 15-S-3 by six laboratories.

D4252 − 89 (2017)

considered suspect (95 % confidence level) if they differ by 17.5 Hydrochloric Acid (0.1 N)—Purchase or prepare by

more than 0.44 meq/100 g. diluting 8.3 mL of concentrated hydrochloric acid to 1 L with

distilled water. Standardize and store according to Practice

13.1.3 Checking Limits for Duplicates—Report the acidity

or basicity of the sample to the nearest 0.05 meq/100 g. E200.

Duplicate runs that agree within 0.051 meq/100 g are accept-

17.6 Phenolphthalein Indicator Solution—Dissolve1gof

able for averaging (95 % confidence level).

phenolphthalein in 100 mL of pyridine.

HYDROXYL NUMBER 17.7 Isopropyl Alcohol, A. R.

18. Procedure

14. Terminology

18.1 Weigh into a clean and dry 250-mL Erlenmeyer flask

14.1 Definitions:

with ground glass joint to the nearest 0.1 mg an amount of

14.1.1 hydroxyl number—the number of milligrams of po-

sample calculated by means of the following equation but do

tassium hydroxide equivalent to the hydroxyl content of1gof

not use more than 10 g of sample:

sample.

M

Amount of Sample, g 5 (1)

F 3100

15. Summary of Test Method

where:

15.1 The hydroxyl groups are esterified by reaction with

phthalic anhydride in a pyridine medium at the temperature of M = molecular weight of sample and

reflux of the mixture. After cooling, the excess of phthalic F = number of hydroxyl groups per molecule.

anhydride is hydrolyzed with water and the phthalic acid

18.2 Pipet accurately 25 mL of phthalic anhydride reagent

formed is titrated to the phenolphthalein end point with

into the flask and swirl to effect solution. Add two boiling

standard sodium hydroxide solution. The hydroxyl content is

chips, attach a dry reflux condenser with a ground glass joint

calculated from the difference in titration of the blank and of

fitted with a TFE-fluorocarbon sleeve to the flask, and reflux

the sample solution.

for1honan electric hotplate.

18.3 Turn off the hotplate and insert an insulated pad

16. Apparatus

between the flask and the hot plate. Al

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.