ASTM D4984-06(2015)

(Test Method)Standard Test Method for Carbon Dioxide in Natural Gas Using Length-of-Stain Detector Tubes

Standard Test Method for Carbon Dioxide in Natural Gas Using Length-of-Stain Detector Tubes

SIGNIFICANCE AND USE

5.1 The measurement of carbon dioxide in natural gas is important, because of the gas quality specifications, the corrosive nature of carbon dioxide on pipeline materials, and the affects of carbon dioxide on utilization equipment.

5.2 This test method provides inexpensive field screening of carbon dioxide. The system design is such that it may be used by nontechnical personnel with a minimum of proper training.

SCOPE

1.1 This test method covers a rapid and simple field determination of carbon dioxide in natural gas pipelines. Available detector tubes provide a total measuring range of 100 ppm (parts per million) up to 60 % by volume, although the majority of applications will be on the lower end of this range (that is, under 5 %). At least one manufacturer provides a special kit for measurements from 10 to 100 % CO2, but the normal 100-cc hand pump is not used. See Note 1.

Note 1: High-range carbon dioxide detector tubes will have measuring ranges in percent (%) CO2, and low-range tubes will be in parts per million (ppm). To convert percent to ppm, multiply by 10 000 (1 % = 10 000 ppm).

1.2 The values stated in SI units are regarded as standard. The inch-pound units in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4984 − 06 (Reapproved 2015)

Standard Test Method for

Carbon Dioxide in Natural Gas Using Length-of-Stain

1

Detector Tubes

This standard is issued under the fixed designation D4984; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 Discussion—A detector tube and pump together

form a unit and must be used as such. Each manufacturer

1.1 This test method covers a rapid and simple field deter-

calibrates detector tubes to match the flow characteristics of

mination of carbon dioxide in natural gas pipelines. Available

their specific pump. Crossing brands of pumps and tubes is not

detector tubes provide a total measuring range of 100 ppm

permitted, as considerable loss of system accuracy is likely to

(partspermillion)upto60 %byvolume,althoughthemajority

3

occur.

of applications will be on the lower end of this range (that is,

under 5 %).At least one manufacturer provides a special kit for 3.1.2 gas sampling chamber—any container that provides

measurements from 10 to 100 % CO , but the normal 100-cc for access of the detector tube into a uniform flow of sample

2

hand pump is not used. See Note 1. gas at atmospheric pressure and isolates the sample from the

surrounding atmosphere. A stainless steel needle valve (or

NOTE1—High-rangecarbondioxidedetectortubeswillhavemeasuring

pressure regulator) is placed between the source valve and the

ranges in percent (%) CO , and low-range tubes will be in parts per

2

sampling chamber for the purpose of throttling the sample

million (ppm). To convert percent to ppm, multiply by 10 000

(1%=10000 ppm).

flow. Flow rate should approximate 1 to 2 volume changes per

minute or, at minimum, provide exit gas flow throughout the

1.2 The values stated in SI units are regarded as standard.

detector tube-sampling period.

The inch-pound units in parentheses are for information only.

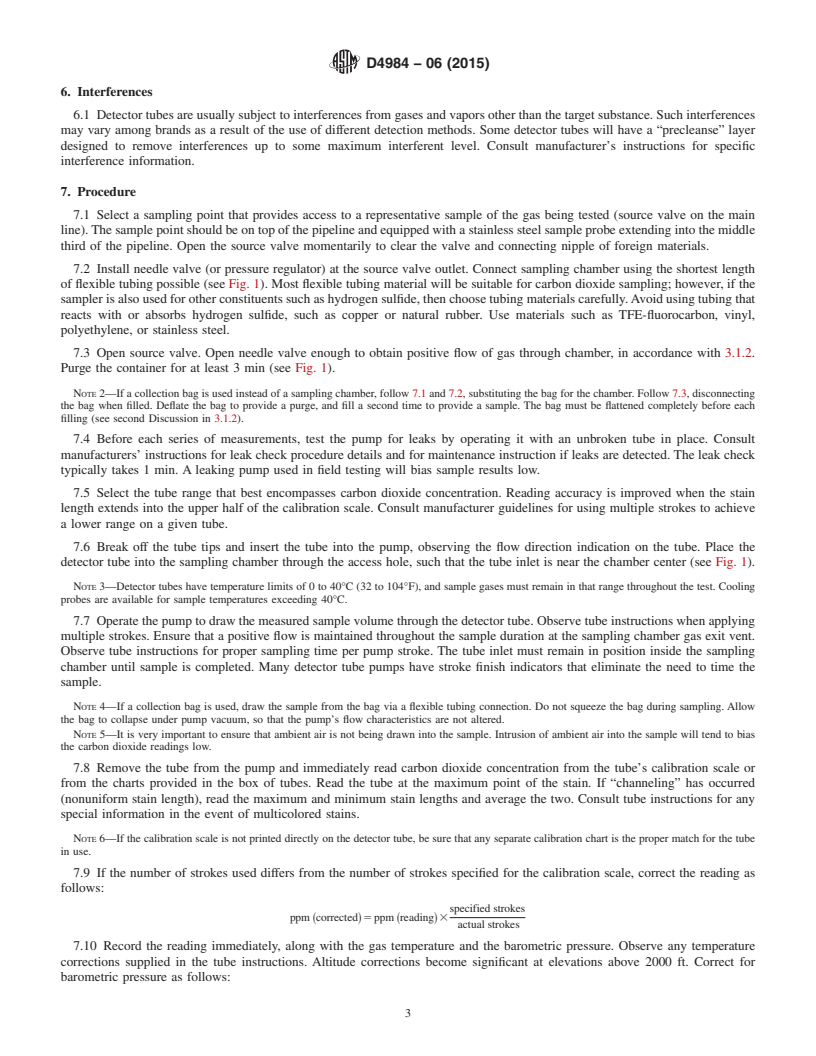

3.1.2.1 Discussion—A suitable sampling chamber may be

1.3 This standard does not purport to address all of the

devised from a polyethylene wash bottle of nominal 500-mL

safety concerns, if any, associated with its use. It is the

(16-oz) or 1-L(32-oz) size. The wash bottle’s internal delivery

responsibility of the user of this standard to establish appro-

tube provides for delivery of sample gas to the bottom of the

priate safety and health practices and determine the applica-

1

bottle.A14.7-mm ( ⁄2-in.) hole cut in the bottle’s cap provides

bility of regulatory limitations prior to use.

access for the detector tube and vent for the purge gas (see Fig.

1). (An alternate flow-through sampler may be fashioned using

2. Referenced Documents

a 1-gal (3.8-L) “zipper”-type food storage bag. The flexible

2.1 Gas Processors Association Standard:

line enters one corner of the bag’s open end and extends to the

2337 Test for Hydrogen Sulfide and Carbon Dioxide in

bottom of the bag. The opposite corner of the bag’s top is

2

Natural Gas Using Length-of-Stain Tubes

sealed shut. The basic procedure for the sampler in Fig. 1

applies.)

3. Terminology

3.1.2.2 Discussion—An alternate sampling container is a

3.1 Definitions of Terms Specific to This Standard:

collection bag made of a material suitable for the collection of

3.1.1 detector tube pump—a hand-operated pump of a

natural gas (for example, polyester film). The sampling bag

piston or bellows type. It must be capable of drawing 100 mL

should have a minimum capacity of 2 L.

per stroke of sample through the detector tube with a volume

3

3.1.3 length-of-stain detector tube—a sealed glass tube with

tolerance of 65 mL. It must be specifically designed for use

break-off tips sized to fit the tube holder of the pump. The

with detector tubes.

reagent layer inside the tube, typically a silica gel substance

coated with the active chemicals, must be specific for carbon

1

This test method is issued under the jurisdiction of ASTM Committee D03 on

dioxide and produce a distinct color change when exposed to a

Gaseous Fuels and is the direct responsibility of Subcommittee D03.07 on Analysis

sample of gas containing carbon dioxide. Any substances

of Chemical Composition of Gaseous Fuels.

known to interfere must be listed in the instructions accompa-

Current edition approved Nov. 1, 2015. Published December 2015. Originally

approved in 1989. Last previous edition approved in 2011 as D4984–06 (2011).

nying the tubes. A calibration scale should be marked directly

DOI: 10.1520/D4984-06R15.

on the tube; however, other markings that provide for easy

2

Available from Gas Processors Association, 6526 East 60th St., Tulsa, OK

interpretation of carbon dioxide content from a separate

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4984 − 06 (Reapproved 2011) D4984 − 06 (Reapproved 2015)

Standard Test Method for

Carbon Dioxide in Natural Gas Using Length-of-Stain

1

Detector Tubes

This standard is issued under the fixed designation D4984; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a rapid and simple field determination of carbon dioxide in natural gas pipelines. Available detector

tubes provide a total measuring range of 100 ppm (parts per million) up to 60 % by volume, although the majority of applications

will be on the lower end of this range (that is, under 5 %). At least one manufacturer provides a special kit for measurements from

10 to 100 % CO , but the normal 100-cc hand pump is not used. See Note 1.

2

NOTE 1—High-range carbon dioxide detector tubes will have measuring ranges in percent (%) CO , and low-range tubes will be in parts per million

2

(ppm). To convert percent to ppm, multiply by 10 000 (1 % = 10 000 ppm).

1.2 The values stated in SI units are regarded as standard. The inch-pound units in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 Gas Processors Association Standard:

2

2337 Test for Hydrogen Sulfide and Carbon Dioxide in Natural Gas Using Length-of-Stain Tubes

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 detector tube pump—a hand-operated pump of a piston or bellows type. It must be capable of drawing 100 mL per stroke

3

of sample through the detector tube with a volume tolerance of 65 mL. It must be specifically designed for use with detector

tubes.

3.1.1.1 Discussion—A detector tube and pump together form a unit and must be used as such. Each manufacturer calibrates

detector tubes to match the flow characteristics of their specific pump. Crossing brands of pumps and tubes is not permitted, as

3

considerable loss of system accuracy is likely to occur.

3.1.2 gas sampling chamber—any container that provides for access of the detector tube into a uniform flow of sample gas at

atmospheric pressure and isolates the sample from the surrounding atmosphere. A stainless steel needle valve (or pressure

regulator) is placed between the source valve and the sampling chamber for the purpose of throttling the sample flow. Flow rate

should approximate 1 to 2 volume changes per minute or, at minimum, provide exit gas flow throughout the detector tube-sampling

period.

1

This test method is issued under the jurisdiction of ASTM Committee D03 on Gaseous Fuels and is the direct responsibility of Subcommittee D03.07 on Analysis of

Chemical Composition of Gaseous Fuels.

Current edition approved Nov. 1, 2011Nov. 1, 2015. Published March 2012December 2015. Originally approved in 1989. Last previous edition approved in 20062011 as

D4984–06. –06 (2011). DOI: 10.1520/D4984-06R11.10.1520/D4984-06R15.

2

Available from Gas Processors Association, 6526 East 60th St., Tulsa, OK 74145.

3

\, First ed., American Industrial Hygiene Association, Akron, OH 44311.

3.1.2.1 Discussion—

A suitable sampling chamber may be devised from a polyethylene wash bottle of nominal 500-mL (16-oz) or 1-L (32-oz) size. The

1

wash bottle’s internal delivery tube provides for delivery of sample gas to the bottom of the bottle. A 14.7-mm ( ⁄2-in.) hole cut

in the bottle’s cap provides access for the detector tube and vent for the purge gas (see Fig. 1). (An alternate flow-through sampler

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4984 − 06 (2015)

FIG. 1 Apparatus Schematic

may be fashioned using a 1-gal (3.8-L) “zipper”-type food storage bag. The flexible line enters one corner of the bag’s open end

and extends to the bottom of the bag. The opposite corner of the bag’s top is sealed shut. The basic procedure for the sampler in

Fig. 1 applies.)

3.1.2.2 Discussion—

An alternate sampling container is a collection bag made of a material suitable for the collection of natural gas (for exam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.