ASTM F18-12

(Specification)Standard Specification and Test Method for Evaluation of Glass-to-Metal Headers Used in Electron Devices

Standard Specification and Test Method for Evaluation of Glass-to-Metal Headers Used in Electron Devices

SCOPE

1.1 This specification and test method cover acceptance requirements for headers used in electron devices and describes procedures for determining conformance to these requirements.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method (Sections 7-13) described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F18 −12

Standard Specification and Test Method for

Evaluation of Glass-to-Metal Headers Used in Electron

1

Devices

ThisstandardisissuedunderthefixeddesignationF18;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Acceptance Requirements

4.1 The headers shall conform to the requirements as

1.1 This specification and test method cover acceptance

specified in 4.1.1 and 4.1.2 when tested in accordance with the

requirementsforheadersusedinelectrondevicesanddescribes

prescribed methods of test (Sections 5-13).

procedures for determining conformance to these require-

4.1.1 Visual:

ments.

4.1.1.1 Cracksaroundtheleadshallberestrictedaxiallyand

1.2 The values stated in inch-pound units are to be regarded

radially to one lead diameter. Specimens showing any other

as standard. The values given in parentheses are mathematical

type of crack shall be rejected.

conversions to SI units that are provided for information only

4.1.1.2 The glass shall be free of inclusions exceeding one

and are not considered standard.

half of the smallest lead diameter. Gas bubbles entirely

enclosed by glass are permissible up to a diameter not

1.3 The following safety hazard caveat pertains only to the

exceeding that of the smallest lead.

testmethod(Sections7-13)describedinthisspecification. This

4.1.1.3 Metallic parts shall be as free of draw lines or

standard does not purport to address all of the safety concerns,

grooves longer (by visual estimate) than one half of the seal

if any, associated with its use. It is the responsibility of the user

length as best commercial practice will permit.

of this standard to establish appropriate safety and health

4.1.1.4 In the case of clear glass seals, reference is made to

practices and determine the applicability of regulatory limita-

the seal area only.

tions prior to use.

4.1.1.5 In the case of opaque glass seals, reference is made

to any portion of the exposed metal parts.

2. Terminology

4.1.2 Leak:

2.1 Definitions of Terms Specific to This Standard:

4.1.2.1 Withtheheadersealedtothemassspectrometerleak

2.1.1 The header may be described as an external metal

detector,thenumberofdetectableleaksinasamplelotshallbe

memberofcylindrical,oval,orothershapeintowhichissealed

less than the limit agreed upon between the purchaser and the

one or more wire leads or metal tubulations through a glass

seller.

medium. The metal parts may be plated or unplated and the

TEST METHODS

glass may be clear or opaque.

5. Apparatus

3. Significance and Use

5.1 Microscope, of 10 power magnification, unless other-

3.1 This standard covers procedures for conducting me-

wise specified, in combination with suitable incandescent

chanical and vacuum leak tests on glass-to-metal headers and

white light source.

is suitable for quality control and research and development

use.

5.2 Mass Spectrometer Leak Detector, adjusted to respond

toatracergassuchasheliumandcapableofdetectingleaksof

3.2 Thisstandardissuitableforassessingboththequalityof

−9

10 mL/s at standard temperature and pressure.

materials as well as the manufacturing techniques used.

3

5.3 Hood, having a volume of approximately 250 cm (2.5

–4 3

×10 m ), to cover the test specimen completely with the

tracer gas. (The hood should be flushed with the tracer gas for

1

This specification and test method are under the jurisdiction of ASTM

at least 10 s).

Committee F01 on Electronics and are the direct responsibility of Subcommittee

F01.03 on Metallic Materials.

5.4 Fixture, suitable for making a seal between the header

Current edition approved Feb. 1, 2012. Published March 2012. Originally

under test and the lead detector. A suggested jig is shown in

approved in 1961 as F18 – 61T. Last previous edition approved in 2006 as F18 –

64 (2006). DOI: 10.1520/F0018-12. Fig. 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

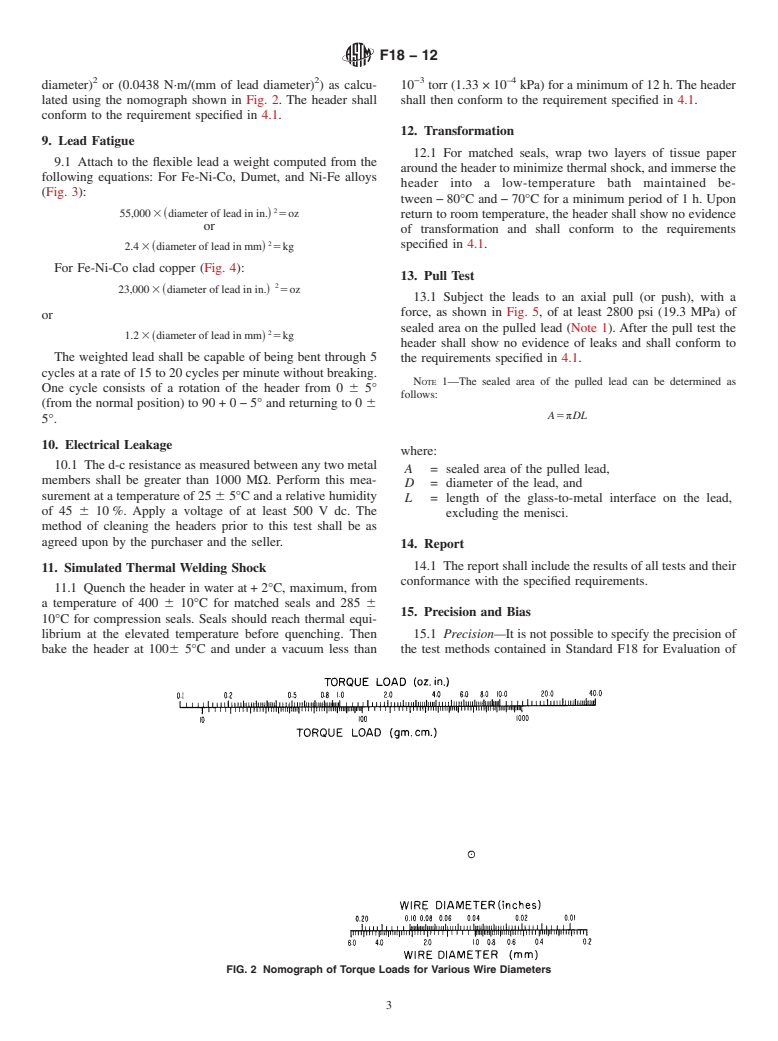

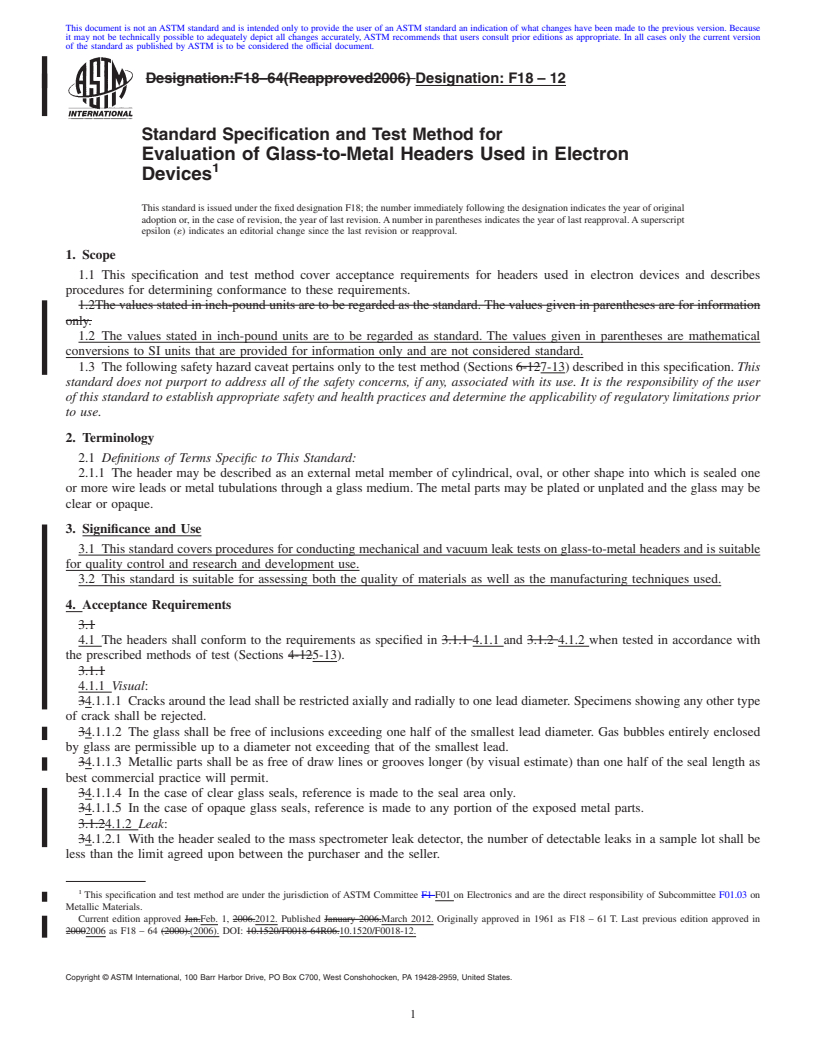

F18−12

FIG. 1 Fixture for Making a Seal Between the Header Under Test and the Leak Detector

5.5 Bath, two constant temperature water baths, and an unless otherwise specified. Lead dimensions referred to are

immersion bath maintained at a temperature of − 80°C nominal dimensions agreed upon between the purchaser and

to−70°C. the seller.

5.6 Torque Fixture, capable of holding the header in a fixed

7. Thermal Shock

position and capable of rotating a lead about its axis.

7.1 Withtheheaderatroomtemperatureimmerseitinwater

5.7 Bending Fixture, capable of rotating the header through

heldat98°C,minimum,for1min;andquenchinwaterat1°C,

anarcof90,+0−5°, about an axis of the

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F18–64(Reapproved2006) Designation: F18 – 12

Standard Specification and Test Method for

Evaluation of Glass-to-Metal Headers Used in Electron

1

Devices

ThisstandardisissuedunderthefixeddesignationF18;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification and test method cover acceptance requirements for headers used in electron devices and describes

procedures for determining conformance to these requirements.

1.2The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 Thefollowingsafetyhazardcaveatpertainsonlytothetestmethod(Sections6-127-13)describedinthisspecification. This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Terminology

2.1 Definitions of Terms Specific to This Standard:

2.1.1 The header may be described as an external metal member of cylindrical, oval, or other shape into which is sealed one

or more wire leads or metal tubulations through a glass medium. The metal parts may be plated or unplated and the glass may be

clear or opaque.

3. Significance and Use

3.1 This standard covers procedures for conducting mechanical and vacuum leak tests on glass-to-metal headers and is suitable

for quality control and research and development use.

3.2 This standard is suitable for assessing both the quality of materials as well as the manufacturing techniques used.

4. Acceptance Requirements

3.1

4.1 The headers shall conform to the requirements as specified in 3.1.1 4.1.1 and 3.1.2 4.1.2 when tested in accordance with

the prescribed methods of test (Sections 4-125-13).

3.1.1

4.1.1 Visual:

34.1.1.1 Cracks around the lead shall be restricted axially and radially to one lead diameter. Specimens showing any other type

of crack shall be rejected.

34.1.1.2 The glass shall be free of inclusions exceeding one half of the smallest lead diameter. Gas bubbles entirely enclosed

by glass are permissible up to a diameter not exceeding that of the smallest lead.

34.1.1.3 Metallic parts shall be as free of draw lines or grooves longer (by visual estimate) than one half of the seal length as

best commercial practice will permit.

34.1.1.4 In the case of clear glass seals, reference is made to the seal area only.

34.1.1.5 In the case of opaque glass seals, reference is made to any portion of the exposed metal parts.

3.1.24.1.2 Leak:

34.1.2.1 With the header sealed to the mass spectrometer leak detector, the number of detectable leaks in a sample lot shall be

less than the limit agreed upon between the purchaser and the seller.

1

This specification and test method are under the jurisdiction of ASTM Committee F1 F01 on Electronics and are the direct responsibility of Subcommittee F01.03 on

Metallic Materials.

Current edition approved Jan.Feb. 1, 2006.2012. Published January 2006.March 2012. Originally approved in 1961 as F18 – 61T. Last previous edition approved in

20002006 as F18 – 64 (2000).(2006). DOI: 10.1520/F0018-64R06.10.1520/F0018-12.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

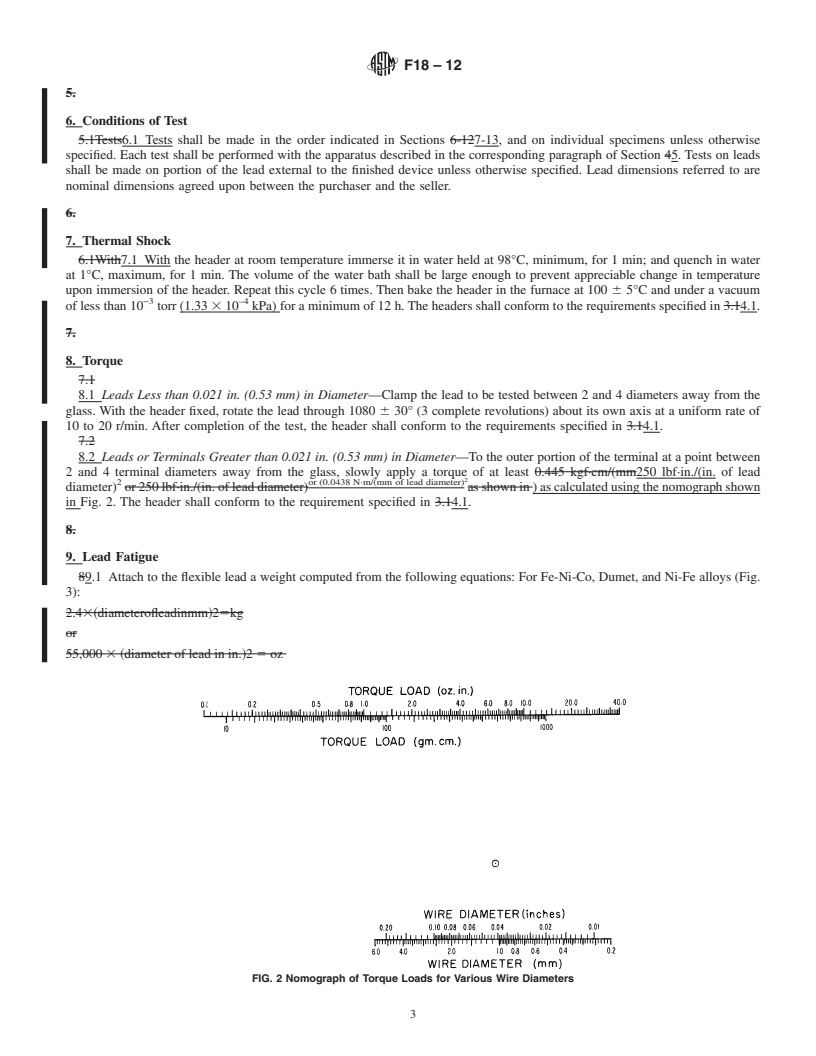

F18–12

TEST METHODS

4.

5. Apparatus

4.1

5.1 Microscope, of 10 power magnification, unless otherwise specified, in combination with suitable incandescent white light

source.

4.2

−9

5.2 Mass Spectrometer Leak Detector,adjustedtorespondtoatracergassuchasheliumandcapableofdetectingleaksof10

mL/s at standard temperature and pressure.

4.3

3 –4 3

5.3 Hood, having a volume of approximately 250 cm (2.5 3 10 m ), to cover the test specimen completely with the tracer

gas. (The hood should be flushed with the tracer gas for at least 10 s).

4.45.4 Fixture, suitable for making a seal between the header under test and the lead detector.Asuggested jig is shown in Fig.

1.

4.5

5.5 Bath, two constant temperature water baths, and an immersio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.