ASTM D5853-95(2000)e1

(Test Method)Standard Test Method for Pour Point of Crude Oils

Standard Test Method for Pour Point of Crude Oils

SCOPE

1.1 This test method covers two procedures for the determination of the pour point temperatures of crude oils down to -36oC. One method provides a measure of the maximum (upper) pour point temperature (Procedure A) and is described in 9.1; the other method provides a measure of the minimum (lower) pour point temperature (Procedure B) and is described in 9.2.

1.2 The use of this test method is limited to use for crude oils. Pour point temperatures of other petroleum products can be determined by Test Method D97.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D5853–95 (Reapproved 2000)

Designation: 441/99

Standard Test Method for

Pour Point of Crude Oils

This standard is issued under the fixed designation D5853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warning notes were placed in the text editorially in December 2000.

1. Scope 3. Terminology

1.1 This test method covers two procedures for the deter- 3.1 Definitions of Terms Specific to This Standard:

mination of the pour point temperatures of crude oils down 3.1.1 pour point, n—thelowesttemperatureatwhichmove-

to−36°C. One method provides a measure of the maximum ment of the test specimen is observed under the conditions of

(upper) pour point temperature (ProcedureA) and is described the test.

in 9.1; the other method provides a measure of the minimum 3.1.2 maximum (upper) pour point, n—the pour point ob-

(lower) pour point temperature (Procedure B) and is described tained after the test specimen has been subjected to a pre-

in 9.2. scribed treatment designed to enhance gelation of wax crystals

1.2 The use of this test method is limited to use for crude and solidification of the test specimen.

oils. Pour point temperatures of other petroleum products can 3.1.3 minimum (lower) pour point, n—the pour point ob-

be determined by Test MethodD97. tained after the test specimen has been subjected to a pre-

1.3 This standard does not purport to address all of the scribed treatment designed to delay gelation of wax crystals

safety concerns, if any, associated with its use. It is the and solidification of the test specimen.

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.For specific hazard 4.1 Afterpreliminaryheating,thetestspecimeniscooledat

statements, see Section 7. a specified rate and examined at intervals of 3°C for flow

characteristics. The lowest temperature at which movement of

2. Referenced Documents

the test specimen is observed is recorded as the pour point.

2.1 ASTM Standards:

2 5. Significance and Use

D97 Test Method for Pour Point of Petroleum Products

D130 TestMethodforDetectionofCopperCorrosionfrom 5.1 The pour point of a crude oil is an index of the lowest

temperature of handleability for certain applications.

Petroleum Products by the Copper Strip Tarnish Test

D323 Test Method for Vapor Pressure of Petroleum Prod- 5.2 Thisistheonlypourpointmethodspecificallydesigned

for crude oils.

ucts (Reid Method)

D4057 Practice for Manual Sampling of Petroleum and 5.3 The maximum and minimum pour point temperatures

provideatemperaturewindowwhereacrudeoil,dependingon

Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and its thermal history, might appear in the liquid as well as the

solid state.

Petroleum Products

E1 Specification for ASTM Thermometers 5.4 The test method can be used to supplement other

measurements of cold flow behavior. It is especially useful for

E77 Test Method for Inspection and Verification of Ther-

mometers the screening of the effect of wax interaction modifiers on the

flow behavior of crude oils.

This test method is under the jurisdiction of ASTM Committee D02 on

6. Apparatus

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

6.1 Pour Point Test Apparatus Assembly (see Fig. 1):

D02.07 on Flow Properties.

Current edition approved Oct. 10, 1995. Published December 1995.

6.1.1 Test Jar, cylindrical, of clear glass, flat bottomed,

Annual Book of ASTM Standards, Vol 05.01.

outside diameter 33.2 to 34.8 mm, and height 115 to 125 mm.

Annual Book of ASTM Standards, Vol 05.02.

4 Theinsidediameterofthejarcanrangefrom30.0to32.4mm,

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D5853–95 (2000)

NOTE 1—All dimensions are stated in millimetres.

FIG. 1 Apparatus for Pour Point Test

within the constraint that the wall thickness shall be no greater rubber, leather, or other material that is sufficiently elastic to

than 1.6 mm. The jar shall have a line to indicate a sample cling to the test jar and hard enough to hold its shape. Its

height 54 6 3 mm above the inside bottom. The inside of the purpose is to prevent the test jar from touching the jacket.

test jar (up to the mark) shall be visibly clean and free of

6.1.7 Cooling Bath or Baths,ofatypesuitableforobtaining

scratches.

the required temperatures. The size and shape of the bath are

6.1.2 Thermometers, having ranges shown in the following

options, but a support to hold the jacket firmly in a vertical

table and conforming to the requirements prescribed in Speci-

position is essential. The bath temperature shall be monitored

ficationE1 for thermometers:

by means of the appropriate thermometer (6.1.2) or any other

Thermometer

temperature measuring device capable of measuring and dis-

Number

Thermometer Temperature Range

playing the designated temperature with the required precision

ASTM IP

and accuracy. The required bath temperatures shall either be

High cloud and pour −38 to +50°C 5C 1C

maintained by refrigeration or by suitable freezing mixtures

Low cloud and pour −80 to +20°C 6C 2C

(Note 1) and shall maintain the designated temperatures to

Melting point +32 to +127°C 61C 63C

within6 1.5°C.

6.1.2.1 Since separation of liquid column thermometers

NOTE 1—The cooling mixtures commonly used are as follows :

occasionally occurs and may escape detection, the ice point of

the thermometers shall be checked prior to the test and used For Temperatures

Down To

only if they are accurate within6 1°C (seeTest MethodE77).

Ice and water 9°C

6.1.3 Cork, to fit the test jar, center bored for the test

Crushed ice and sodium chloride crystals −12°C

Crushed ice and calcium chloride crystals −27°C

thermometer.

Acetone or petroleum naphtha (see Section 7) −57°C

6.1.4 Jacket, watertight, cylindrical, metal, flat bottomed,

chilled in a covered metal beaker with an

115 6 3 mm depth, with inside diameter of 44.2 to 45.8 mm.

ice-salt mixture to −12°C and then with

enough solid carbon dioxide to give the

It shall be supported in a vertical position in the cooling bath

desired temperature.

(6.1.7) so that no more than 25 mm projects out of the cooling

medium. The jacket shall be capable of being cleaned. 6.2 Water Bath—The size and shape of the bath are op-

6.1.5 Disk, cork or felt, 6 mm thick to fit loosely inside the tional,butasupporttoholdthetestjarimmersedinthebathto

jacket. above the sample height in the test jar and in a firm vertical

6.1.6 Gasket, to fit snugly around the outside of the test jar position is required. The required bath temperature may be

and loosely inside the jacket. The gasket shall be made of maintained by any suitable means, provided the temperature

e1

D5853–95 (2000)

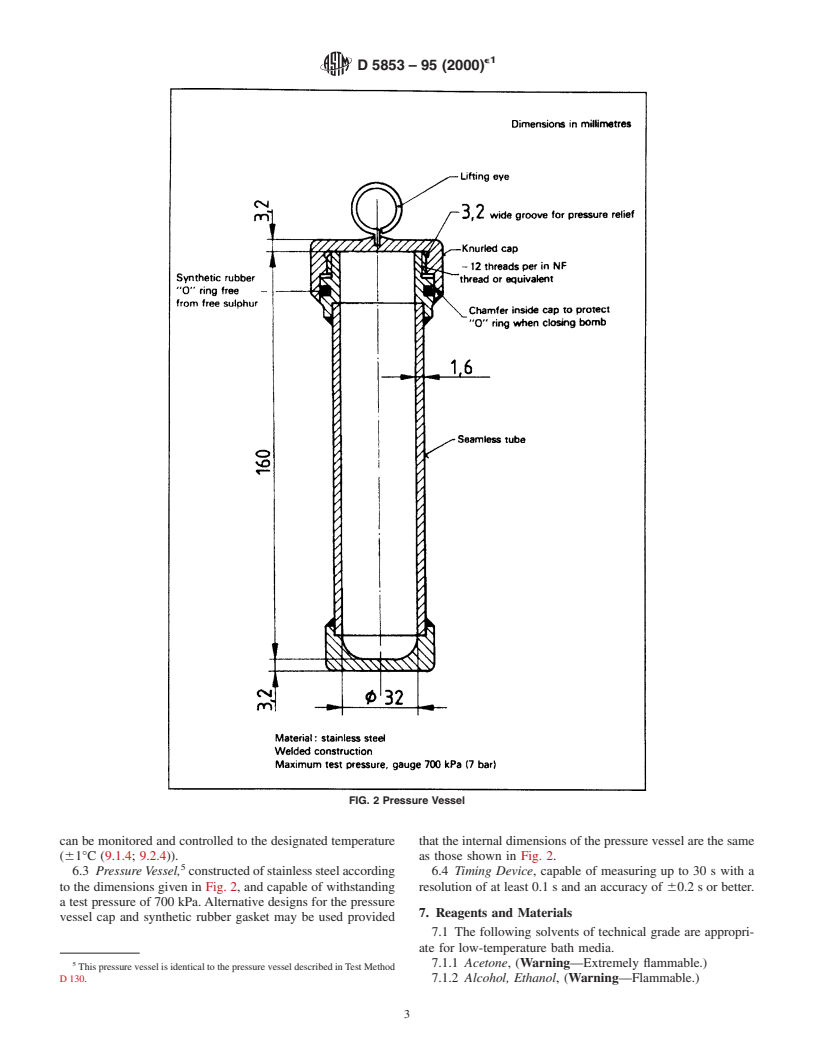

FIG. 2 Pressure Vessel

can be monitored and controlled to the designated temperature thattheinternaldimensionsofthepressurevesselarethesame

(61°C (9.1.4; 9.2.4)). as those shown in Fig. 2.

6.3 Pressure Vessel, constructedofstainlesssteelaccording 6.4 Timing Device, capable of measuring up to 30 s with a

to the dimensions given in Fig. 2, and capable of withstanding resolution of at least 0.1 s and an accuracy of 60.2 s or better.

a test pressure of 700 kPa.Alternative designs for the pressure

7. Reagents and Materials

vessel cap and synthetic rubber gasket may be used provided

7.1 The following solvents of technical grade are appropri-

ate for low-temperature bath media.

7.1.1 Acetone,(Warning—Extremely flammable.)

ThispressurevesselisidenticaltothepressurevesseldescribedinTestMethod

D130. 7.1.2 Alcohol, Ethanol,(Warning—Flammable.)

e1

D5853–95 (2000)

7.1.3 Alcohol, Methanol,(Warning—Flammable. Vapor 9.1.4 If the expected pour point is greater than 36°C, heat

harmful.) the sample to 9°C above the expected pour point. If the

expected pour point is less than 36°C, heat the sample to a

7.1.4 Petroleum Naphtha,(Warning—Combustible. Vapor

harmful.) temperatureof45 61°C.Maintainthewaterbath(6.2)toheat

the sample at 48 6 1°C or at a temperature 12°C higher than

NOTE 2—Typical petroleum naptha used for cleaning purposes areVM

the expected pour point, whichever is higher.

and P napthas.

9.1.4.1 As soon as the test specimen has reached the

7.2 Toluene, technical grade (Warning—Flammable.Vapor

required temperature, remove the cork carrying the thermom-

harmful.).

eter and stir the test specimen gently with a spatula or similar

7.3 Solid Carbon Dioxide,(Warning—Extremely cold

device. Put the cork carrying the thermometer back in place

(−78.5°C).)

(see 9.1.2).

9.1.5 Ensure that the disk, gasket, and the inside of the

8. Sampling, Test Samples, and Test Specimens

jacket are clean and dry. Place the disk in the bottom of the

jacket. Place the disk and jacket in the cooling medium a

NOTE 3—Samplingisdefinedasallstepsrequiredtoobtainaportionof

minimum of 10 min before the test jar is inserted. The use of

thecontentsofanypipe,tank,orothersystemandtoplacethesampleinto

a jacket cover, while the empty jacket is cooling, is permitted.

the laboratory test container.

Remove the test jar from the water bath and dry with a tissue.

8.1 Laboratory Sample—It is essential that the sample

Place the gasket around the test jar, 25 mm from the bottom.

received by the laboratory is representative of the batch or lot

Insert the test jar into the jacket in the first bath maintained at

of crude oil from which it was taken. Practices D4057 and

21°C and commence observations for pour point. Never place

D4177 provide guidance for obtaining such representative

a test jar directly into the cooling medium.

samples.

9.1.6 Exercise care not to disturb the mass of test specimen

8.2 Preparation of Test Samples—The pour point of crude

nor permit the thermometer to shift in the test specimen; any

oils is very sensitive to trace amounts of high melting waxes.

disturbance of the spongy network of wax crystals will lead to

Exercise meticulous care to ensure such waxes, if present, are

a lower pour point and erroneous results (Note 5).

either completely melted or, if volatility constraints prevent

heating to complete melting, homogeneously suspended in the NOTE 6—With dark colored materials, such as crude oils, it is imprac-

tical to observe, in the test jar, the onset of crystallization and network

sample (Appendix X1). Inspect the walls of the original

formation in the test specimen. Hence, it is presumed that network

container to ensure that no high melting point material is left

formation will begin at the very early stages of the cooling sequence.

sticking to the wall.

9.1.7 Pour points are expressed in temperatures which are

NOTE 4—It is not possible to define universal mandatory rules for the

positive or negative multiples of 3°C. Begin to examine the

preparation of crude oil test samples. Guidelines for sample handling for

appearance of the test specimen when the temperature of the

the most common situations are given in Appendix X1.

test specimen is 9°C above the expected pour point (estimated

9. Procedure

as a multiple of 3°C).At each test thermometer reading which

isamultipleof3°Cbelowthestartingtemperature,removethe

9.1 Procedure A for Maximum (Upper) Pour Point:

test jar from the jacket.When necessary, remove moisture that

9.1.1 Pour the test sample into the test jar to the level mark.

limits visibility of the test specimen by wiping the surface of

If necessary, reheat the test sample to a temperature at least

the test jar with a clean cloth moistened in alcohol at

20°Cabovetheexpectedpourpoint(8.2andAppendixX1)but

approximately the temperature of the test specimen in the jar.

not higher than a temperature of 60°C (Warning—The vapor

Then tilt the jar just enough to ascertain whether there is

pressure of crude oils at temperatures higher than 60°C will

movement of the test specimen in the jar. When movement is

usuallyexceed100kPa.Underthesecircumstancesthesample

observed, immediately return the test jar into the jacket. The

container may rupture. Opening of the container may induce

complete operation of removal and replacement shall require

foaming with resultant loss of sample and possible injury to

not more than 3 s.

personnel.).

9.1.7.1 If the test specimen has not ceased to flow when its

9.1.2 Immediately close the test jar with the cork carrying

temperature has reached 30°C, transfer the test jar to the next

the high cloud and pour thermometer, or, if the expected pour

lower temperature bath per the following schedule:

pointisabove36°C,themeltingpointthermometer.Adjustthe

(a) If the test specimen is at+30°C, move to 0°C bath;

positionofthecorkandthermometersothecorkfitstightly,the

(b) If the test specimen is at+9°C, move to−18°C bath;

thermometer and the jar are coaxial, and the thermometer bulb

(c) If the test specimen is at−9°C, move to−33°C bath;

is immersed to a depth that places the beginning of the

and

capillary 3 mm below the surface of the test specimen.

(d) If the test specimen is at−24°C, move to−51°C bath.

9.1.3 Keep the test jar with the test specimen at room

temperature (between 18 and 24°C) for at least 24 h. 9.1.7.2 Assoonasthetestspecimeninthejardoesnotflow

when tilted, hold the jar in a horizontal position for 5 s, as

NOTE 5—The pour point of a crude oil is dependent on the state of

shown by an accurate timing device (6.4) and observe care-

crystallization of the wax in the test specimen. In crude oils, achieving

fully. If the test specimen shows any movement, replace the

equilibrium between crystallized wax and dissolved wax is a rather slow

test jar immediately in the jacket and repeat a test for flow at

process. However, experience has shown that in a majority of cases, such

an equilibrium is reached within 24 h. the next temperature, 3°C lower.

e1

D5853–95 (2000)

9.1.8 Continue in this manner until a point is reached at positionofthecorkandthermometersothecorkfitstightly,the

which the test specimen shows no movement when the test jar thermometer and the jar are coaxial, and the thermometer bulb

is held in a horizontal position for 5 s. Record the observed is immersed to a depth which places the beginning of the

reading of the test temperature. capillary 3 mm below the surface of the test specimen.

9.2.6 Proceed as desc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.