ASTM D6706-01(2007)

(Test Method)Standard Test Method for Measuring Geosynthetic Pullout Resistance in Soil

Standard Test Method for Measuring Geosynthetic Pullout Resistance in Soil

SIGNIFICANCE AND USE

The pullout test method is intended as a performance test to provide the user with a set of design values for the test conditions examined.

5.1.1 The test method is applicable to all geosynthetics and all soils.

5.1.2 This test method produces test data, which can be used in the design of geosynthetic-reinforced retaining walls, slopes, and embankments, or in other applications where resistance of a geosynthetic to pullout under simulated field conditions is important.

5.1.3 The test results may also provide information related to the in-soil stress-strain response of a geosynthetic under confined loading conditions.

The pullout resistance versus normal stress plot obtained from this test is a function of soil gradation, plasticity, as-placed dry unit weight, moisture content, length and surface characteristics of the geosynthetic and other test parameters. Therefore, results are expressed in terms of the actual test conditions. The test measures the net effect of a combination of pullout mechanisms, which may vary depending on type of geosynthetic specimen, embedment length, relative opening size, soil type, displacement rate, normal stress, and other factors.

Information between laboratories on precision is incomplete. In cases of dispute, comparative tests to determine if there is a statistical bias between laboratories may be advisable.

SCOPE

1.1 Resistance of a geosynthetic to pullout from soil is determined using a laboratory pullout box.

1.2 The test method is intended to be a performance test conducted as closely as possible to replicate design or as-built conditions. It can also be used to compare different geosynthetics, soil types, etc., and thereby be used as a research and development test procedure.

1.3 The values stated in SI units are to be regarded as standard. The values stated in parentheses are provided for information only.

This standard may involve hazardous materials, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6706 − 01(Reapproved 2007)

Standard Test Method for

1

Measuring Geosynthetic Pullout Resistance in Soil

This standard is issued under the fixed designation D6706; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 apertures, n—the open spaces in geogrids which

enable soil interlocking to occur.

1.1 Resistance of a geosynthetic to pullout from soil is

3.1.2 atmosphere for testing geosynthetics, n—air main-

determined using a laboratory pullout box.

tained at a relative humidity of 60 6 10 % and a temperature

1.2 The test method is intended to be a performance test

of 21 6 2°C (70 6 4°F).

conducted as closely as possible to replicate design or as-built

3.1.3 cross-machine direction, n—the direction in the plane

conditions. It can also be used to compare different

of the geosynthetic perpendicular to the direction of manufac-

geosynthetics,soiltypes,etc.,andtherebybeusedasaresearch

ture.

and development test procedure.

3.1.4 failure, n—a defined point at which a material ceases

1.3 The values stated in SI units are to be regarded as

to be functionally capable of its intended use.

standard. The values stated in parentheses are provided for

information only. 3.1.5 geosynthetic, n—a planar product manufactured from

polymeric material used with soil, rock, earth, or other geo-

1.4 This standard may involve hazardous materials, and

technical engineering related material as an integral part of a

equipment. This standard does not purport to address all of the

man-made project, structure, or system. (D4439)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1.6 junction, n—the point where geogrid ribs are intercon-

priate safety and health practices and determine the applica-

nected in order to provide structure and dimensional stability.

bility of regulatory limitations prior to use.

3.1.7 machine direction, n—the direction in the plane of the

geosynthetic parallel to the direction of manufacture.

2. Referenced Documents

2

3.1.8 pullout, n—the movement of a geosynthetic over its

2.1 ASTM Standards:

entire embedded length, with initial pullout occurring when the

D123 Terminology Relating to Textiles

back of the specimen moves, and ultimate pullout occurring

D653 Terminology Relating to Soil, Rock, and Contained

when the movement is uniform over the entire embedded

Fluids

length.

D3080 Test Method for Direct Shear Test of Soils Under

3.1.9 pullout force, (kN),n—force required to pull a geo-

Consolidated Drained Conditions

D4354 Practice for Sampling of Geosynthetics for Testing synthetic out of the soil during a pullout test.

D4439 Terminology for Geosynthetics

3.1.10 pullout resistance, (kN/m),n—the pullout force per

width of geosynthetic measured at a specified condition of

3. Terminology

displacement.

3.1 Definitions of Terms Specific to This Standard:

3.1.11 rib, n—the continuous elements of a geogrid which

are either in the machine or cross-machine direction as

1

This test method is under the jurisdiction of ASTM Committee D35 on

manufactured.

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani-

cal Properties.

3.1.12 ultimate pullout resistance, (kN/m),n—the maxi-

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

mum pullout resistance measured during a pullout test.

in 2001. Last previous edition approved in 2001 as D6706–01. DOI: 10.1520/

D6706-01R07.

3.1.13 wire gage, n—a displacement gage consisting of a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

non extensible wire attached to the geosynthetic and monitored

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

by connection to a dial extensometer, or electronic displace-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ment transducer.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

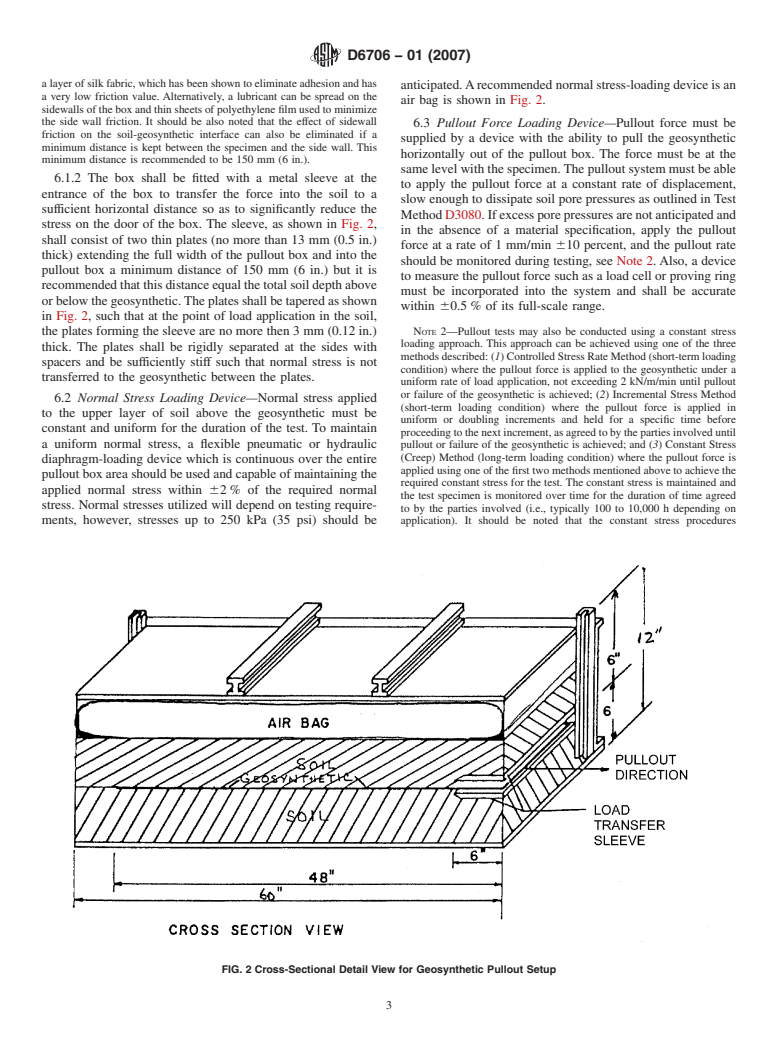

---------------------- Page: 1 ----------------------

D6706 − 01 (2007)

3.2 For definitions of other terms used in this test method pullout mechanisms, which may vary depending on type of

refer to Terminology D123, D653, and D4439. geosynthetic specimen, embedment length, relative opening

size, soil type, displacement rate, normal stress, and other

4. Summary of Test Method

factors.

4.1 Inthismethod,ageosyntheticisembeddedbetweentwo

5.3 Information between laboratories on precision is incom-

layers of soil, horizontal force is applied to the geosynthetic

ple

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.