ASTM D88-94(1999)

(Test Method)Standard Test Method for Saybolt Viscosity

Standard Test Method for Saybolt Viscosity

SCOPE

1.1 This test method covers the empirical procedures for determining the Saybolt Universal or Saybolt Furol viscosities of petroleum products at specified temperatures between 21 and 99°C (70 and 210°F). A special procedure for waxy products is indicated. Note 1-Test Methods D445 and D2170 are preferred for the determination of kinematic viscosity. They require smaller samples and less time, and provide greater accuracy. Kinematic viscosities may be converted to Saybolt viscosities by use of the tables in Practice D2161. It is recommended that viscosity indexes be calculated from kinematic rather than Saybolt viscosities.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation: D 88 – 94 (Reapproved 1999) Highway and Transportation Officials Standard

AASHTO No: T72

Method 304—Federal Test

Method Standard No. 791b

Replaces Method 4285 of Federal Test

Method Standard No. 141A

Standard Test Method for

Saybolt Viscosity

ThisstandardisissuedunderthefixeddesignationD 88;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 445 Test Method for Kinematic Viscosity of Transparent

and Opaque Liquids (and the Calculation of Dynamic

1.1 This test method covers the empirical procedures for

Viscosity)

determining the Saybolt Universal or Saybolt Furol viscosities

D 2161 Practice for Conversion of Kinematic Viscosity to

of petroleum products at specified temperatures between 21

Saybolt Universal Viscosity or to Saybolt Furol Viscosity

and 99°C (70 and 210°F). A special procedure for waxy

D 2170 Test Method for Kinematic Viscosity of Asphalts

products is indicated.

(Bitumens)

NOTE 1—Test Methods D 445 and D 2170 are preferred for the deter-

D 4057 Practice for Manual Sampling of Petroleum and

mination of kinematic viscosity. They require smaller samples and less

Petroleum Products

time, and provide greater accuracy. Kinematic viscosities may be con-

D 4177 Practice for Automatic Sampling of Petroleum and

verted to Saybolt viscosities by use of the tables in Practice D 2161. It is

Petroleum Products

recommended that viscosity indexes be calculated from kinematic rather

than Saybolt viscosities. E 1 Specification for ASTM Thermometers

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

1.2 The values stated in SI units are to be regarded as the

poses

standard.

E 102 Test Method for Saybolt Furol Viscosity of Bitumi-

1.3 This standard does not purport to address all of the

nous Materials at High Temperatures

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions:

bility of regulatory limitations prior to use.

3.1.1 Furol—an acronym of “Fuel and road oils.”

3.1.2 Saybolt Furol viscosity—the corrected efflux time in

2. Referenced Documents

seconds of 60 mLof sample flowing through a calibrated Furol

2.1 ASTM Standards:

orifice under specified conditions. The viscosity value is

D 93 Test Methods for Flash Point by Pensky-Martens

2 reported in Saybolt Furol seconds, abbreviated SFS, at a

Closed Tester

specified temperature.

D 117 Guide to Test Methods and Specifications for Elec-

3 3.1.3 Saybolt Universal viscosity—the corrected efflux time

trical Insulating Oils of Petroleum Origin

in seconds of 60 mL of sample flowing through a calibrated

D 140 Practice for Sampling Bituminous Materials

4 Universal orifice under specified conditions. The viscosity

D 244 Test Methods for Emulsified Asphalts

value is reported in Saybolt Universal seconds, abbreviated

SUS, at a specified temperature.

4. Summary of Test Method

ThistestmethodisunderthejurisdictionofASTMCommitteeD-8onRoofing,

Waterproofing, and Bituminous Materials and is the direct responsibility of

4.1 The efflux time in seconds of 60 mL of sample, flowing

Subcommittee D08.05 on Solvent-Bearing Bituminous Compounds for Roofing and

through a calibrated orifice, is measured under carefully

Waterproofing.

Current edition approved Sept. 15, 1994. Published November 1994. Originally

published as D 88 – 21 T. In 1923, combined with former Methods D 47. Last

1 5

previous edition D 88 – 81 (1987)e . Annual Book of ASTM Standards, Vol 05.02.

2 6

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 14.03.

3 7

Annual Book of ASTM Standards, Vol 10.03. Annual Book of ASTM Standards, Vol 14.02.

4 8

Annual Book of ASTM Standards, Vol 04.03. Annual Book of ASTM Standards, Vol 04.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D88

controlled conditions. This time is corrected by an orifice 6.3 Thermometer Support, as shown in Fig. 3.

factor and reported as the viscosity of the sample at that

6.4 Saybolt Viscosity Thermometers, as listed in Table 1, for

temperature.

reading the temperature of the sample. Each thermometer shall

conform to the requirements listed in Specification E 1 for that

5. Significance and Use

ASTM Thermometer Number.

5.1 This test method is useful in characterizing certain

6.5 Bath Thermometers—Saybolt Viscosity thermometers,

petroleum products, as one element in establishing uniformity

or any other temperature-indicating means of equivalent accu-

of shipments and sources of supply.

racy.

5.2 SeeGuideD 117forapplicabilitytomineraloilsusedas

6.6 Filter Funnel, as shown in Fig. 4, equipped with

electrical insulating oils.

interchangeable 150-µm (No. 100) and 75-µm (No. 200)

5.3 The Saybolt Furol viscosity is approximately one tenth

wire-cloth inserts meeting the requirements of Specification

the Saybolt Universal viscosity, and is recommended for

characterization of petroleum products such as fuel oils and E 11 with respect to the wire cloth.

other residual materials having Saybolt Universal viscosities

6.7 Receiving Flask, as shown in Fig. 5.

greater than 1000 s.

6.8 Timer, graduated in tenths of a second, and accurate to

5.4 Determination of the Saybolt Furol viscosity of bitumi-

within 0.1 % when tested over a 60-min interval. Electric

nous materials at higher temperatures is covered by Test

timers are acceptable if operated on a controlled frequency

Method E 102.

circuit.

6. Apparatus

7. Sampling

6.1 Saybolt Viscometer and Bath, as shown in Fig. 1 and

7.1 SamplethematerialinaccordancewithPracticesD 140,

described in Annex A1.

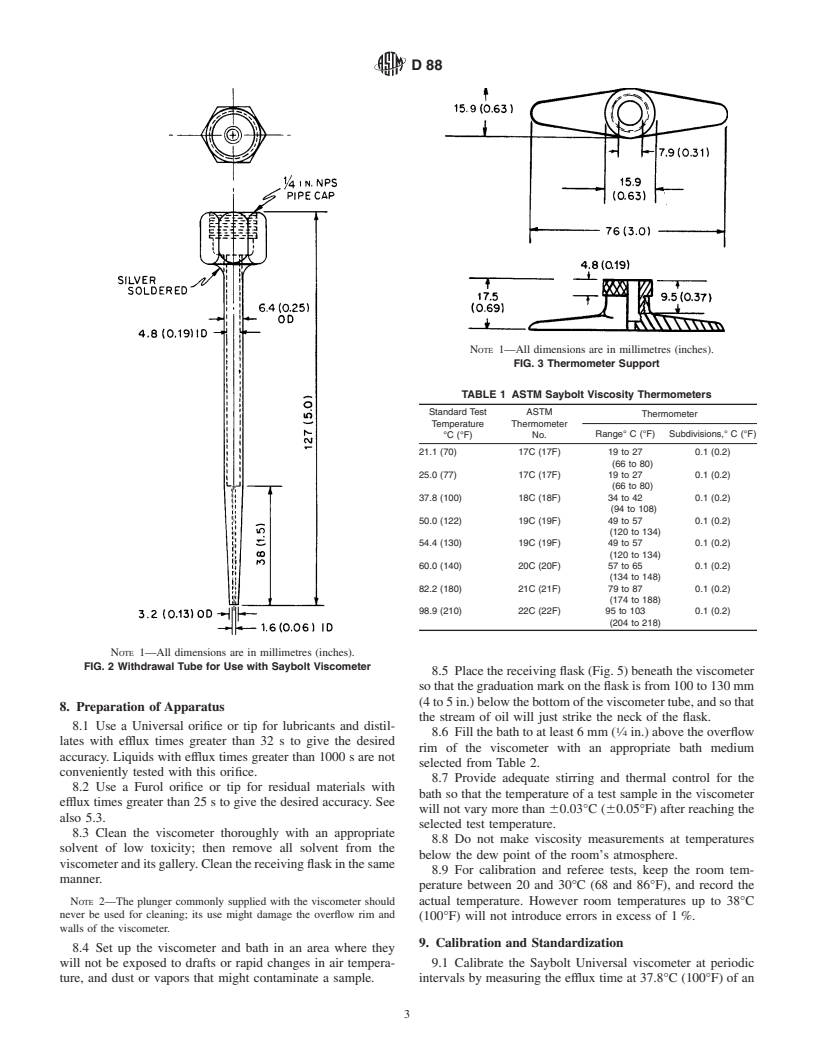

6.2 Withdrawal Tube, as shown in Fig. 2. D 4057, or D 4177, as appropriate.

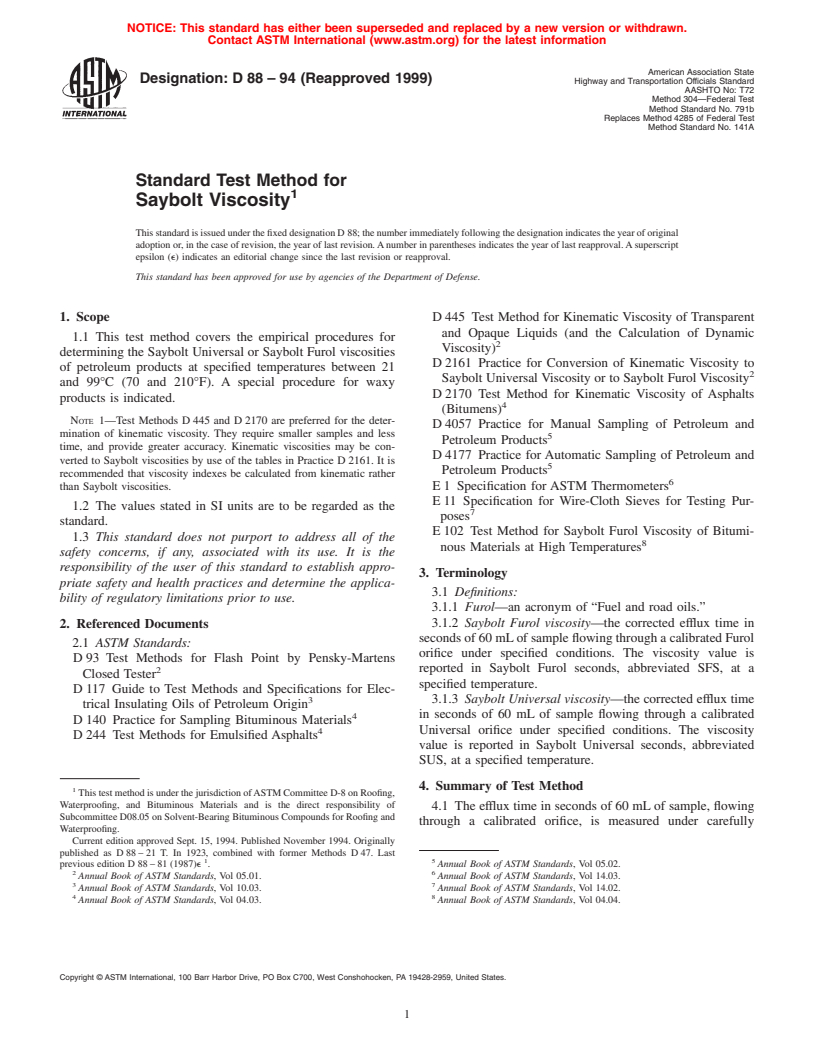

NOTE 1—All dimensions are in millimetres (inches).

FIG. 1 Saybolt Viscometer with Universal and Furol Orifice

D88

NOTE 1—All dimensions are in millimetres (inches).

FIG. 3 Thermometer Support

TABLE 1 ASTM Saybolt Viscosity Thermometers

Standard Test ASTM

Thermometer

Temperature Thermometer

Range° C (°F) Subdivisions,° C (°F)

°C (°F) No.

21.1 (70) 17C (17F) 19 to 27 0.1 (0.2)

(66to80)

25.0 (77) 17C (17F) 19 to 27 0.1 (0.2)

(66to80)

37.8 (100) 18C (18F) 34 to 42 0.1 (0.2)

(94 to 108)

50.0 (122) 19C (19F) 49 to 57 0.1 (0.2)

(120 to 134)

54.4 (130) 19C (19F) 49 to 57 0.1 (0.2)

(120 to 134)

60.0 (140) 20C (20F) 57 to 65 0.1 (0.2)

(134 to 148)

82.2 (180) 21C (21F) 79 to 87 0.1 (0.2)

(174 to 188)

98.9 (210) 22C (22F) 95 to 103 0.1 (0.2)

(204 to 218)

NOTE 1—All dimensions are in millimetres (inches).

FIG. 2 Withdrawal Tube for Use with Saybolt Viscometer

8.5 Place the receiving flask (Fig. 5) beneath the viscometer

so that the graduation mark on the flask is from 100 to 130 mm

(4to5in.)belowthebottomoftheviscometertube,andsothat

8. Preparation of Apparatus

the stream of oil will just strike the neck of the flask.

8.1 Use a Universal orifice or tip for lubricants and distil-

8.6 Fill the bath to at least 6 mm ( ⁄4 in.) above the overflow

lates with efflux times greater than 32 s to give the desired

rim of the viscometer with an appropriate bath medium

accuracy. Liquids with efflux times greater than 1000 s are not

selected from Table 2.

conveniently tested with this orifice.

8.7 Provide adequate stirring and thermal control for the

8.2 Use a Furol orifice or tip for residual materials with

bath so that the temperature of a test sample in the viscometer

efflux times greater than 25 s to give the desired accuracy. See

will not vary more than 60.03°C (60.05°F) after reaching the

also 5.3.

selected test temperature.

8.3 Clean the viscometer thoroughly with an appropriate

8.8 Do not make viscosity measurements at temperatures

solvent of low toxicity; then remove all solvent from the

below the dew point of the room’s atmosphere.

viscometeranditsgallery.Cleanthereceivingflaskinthesame

8.9 For calibration and referee tests, keep the room tem-

manner.

perature between 20 and 30°C (68 and 86°F), and record the

NOTE 2—The plunger commonly supplied with the viscometer should actual temperature. However room temperatures up to 38°C

never be used for cleaning; its use might damage the overflow rim and

(100°F) will not introduce errors in excess of 1 %.

walls of the viscometer.

9. Calibration and Standardization

8.4 Set up the viscometer and bath in an area where they

will not be exposed to drafts or rapid changes in air tempera- 9.1 Calibrate the Saybolt Universal viscometer at periodic

ture, and dust or vapors that might contaminate a sample. intervals by measuring the efflux time at 37.8°C (100°F) of an

D88

NOTE 1—All dimensions are in millimetres (inches).

FIG. 4 Filter Funnel for Use with Saybolt Viscometer

appropriate viscosity oil standard, following the procedure 9.3 Calibrate the Saybolt Furol viscometer at 50.0°C

given in Section 10. See Annex A2 for viscosity oil standards (122°F) in the same manner as above, using a viscosity oil

available. standard having a minimum efflux time of 90 s.

9.2 The efflux time of the viscosity oil standard shall equal 9.4 Viscometers or orifices requiring corrections greater

the certified Saybolt viscosity value. If the efflux time differs than 1.0 % sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.