ASTM E1654-94(1999)

(Guide)Standard Guide for Measuring Ionizing Radiation-Induced Spectral Changes in Optical Fibers and Cables for Use in Remote Raman FiberOptic Spectroscopy

Standard Guide for Measuring Ionizing Radiation-Induced Spectral Changes in Optical Fibers and Cables for Use in Remote Raman FiberOptic Spectroscopy

SCOPE

1.1 This guide covers the method for measuring the real time, in situ radiation-induced alterations to the Raman spectral signal transmitted by a multimode, step index, silica optical fiber. This guide specifically addresses steady-state ionizing radiation (that is, alpha, beta, gamma, protons, etc.) with appropriate changes in dosimetry, and shielding considerations, depending upon the irradiation source.

1.2 The test procedure given in this guide is not intended to test the other optical and non-optical components of an optical fiber-based Raman sensor system, but may be modified to test other components in a continuous irradiation environment.

1.3 The values in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1654 – 94 (Reapproved 1999)

Standard Guide for

Measuring Ionizing Radiation-Induced Spectral Changes in

Optical Fibers and Cables for Use in Remote Raman

FiberOptic Spectroscopy

This standard is issued under the fixed designation E1654; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-STD-2196-(SH) Glossary of Fiber Optic Terms

1.1 This guide covers the method for measuring the real

3. Terminology

time,insituradiation-inducedalterationstotheRamanspectral

3.1 Definitions—Refer to the following documents for the

signal transmitted by a multimode, step index, silica optical

definition of terms used in this guide: MIL-STD-2196-(SH)

fiber. This guide specifically addresses steady-state ionizing

and E1614.

radiation (that is, alpha, beta, gamma, protons, etc.) with

appropriatechangesindosimetry,andshieldingconsiderations,

4. Significance and Use

depending upon the irradiation source.

4.1 Ionizing environments will affect the performance of

1.2 The test procedure given in this guide is not intended to

optical fibers/cables being used to transmit spectroscopic

test the other optical and non-optical components of an optical

information from a remote location. Determination of the type

fiber-based Raman sensor system, but may be modified to test

and magnitude of the spectral variations or interferences

other components in a continuous irradiation environment.

produced by the ionizing radiation in the fiber, or both, is

1.3 The values in SI units are to be regarded as standard.

necessary for evaluating the performance of an optical fiber

1.4 This standard does not purport to address all of the

sensor system.

safety concerns, if any, associated with its use. It is the

4.2 The results of the test can be utilized as a selection

responsibility of the user of this standard to establish appro-

criteria for optical fibers used in optical fiber Raman spectro-

priate safety and health practices and determine the applica-

scopic sensor systems.

bility of regulatory limitations prior to use.

NOTE 1—The attenuation of optical fibers generally increases when

2. Referenced Documents

theyareexposedtoionizingradiation.Thisisdueprimarilytothetrapping

ofradiolyticelectronsandholesatdefectsitesintheopticalmaterials,that

2.1 ASTM Standards:

is, the formation of color centers. The depopulation of these color centers

E 1614 Guide for Procedure for Measuring Ionizing

by thermal or optical (photobleaching) processes, or both, causes recov-

Radiation-InducedAttenuation in Silica-Based Optical Fi-

ery, usually resulting in a decrease in radiationinduced attenuation.

bers and Cables for Use in Remote Fiber-Optic Spectros-

Recovery of the attenuation after irradiation depends on many variables,

copy and Broadband Systems

including the temperature of the test sample, the composition of the

2.2 EIA Standards:

sample, the spectrum and type of radiation employed, the total dose

applied to the test sample, the light level used to measure the attenuation,

2.2.1 Test or inspection requirements include the following

and the operating spectrum. Under some continuous conditions, recovery

references:

is never complete.

EIA-455-57 Optical Fiber End Preparation and Examina-

tion

5. Apparatus

EIA-455-64 Procedure for Measuring Radiation-Induced

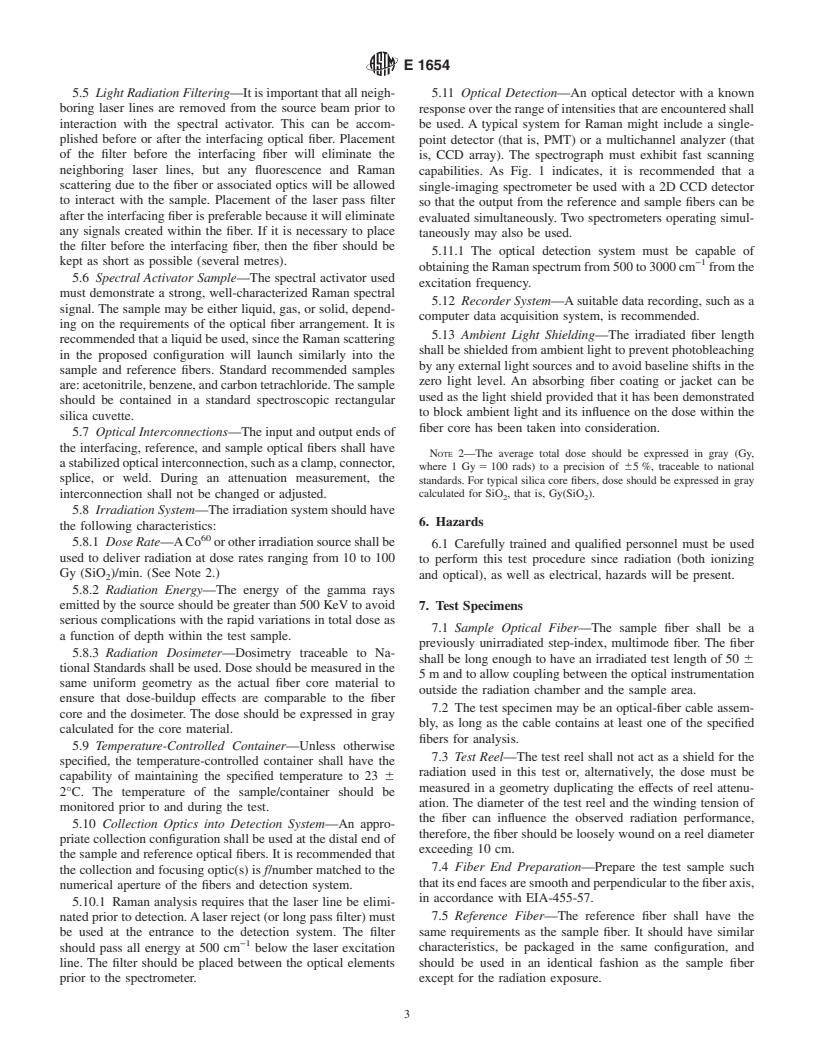

3 5.1 ThetestschematicisshowninFig.1.Thefollowinglist

Attenuation in Optical Fibers and Cables

identifies the equipment necessary to accomplish this test

2.3 Military Standard:

procedure.

5.2 Light Source—A laser source shall be used for the

Ramananalysis,andthewavelengthmustbechosensothatthe

This guide is under the jurisdiction of ASTM Committee E-13 on Molecular

Spectroscopy and is the direct responsibility of Subcommittee E13.09 on Fiber

fluorescentsignalsfromtheopticalcomponents(especiallythe

Optics in Molecular Spectroscopy.

spectralactivatorsampleandopticalfibers)areminimized,and

Current edition approved Dec. 15, 1994. Published February 1995.

Annual Book of ASTM Standards, Vol 03.06.

Available from Electronic Industry Association, Engineering Dept., 2001 4

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Pennsylvania Ave., NW, Washington, DC 20006.

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1654

FIG. 1 Test Configuration

sothatthewavelengthcorrespondstothespectralsensitivityof trograph, detector). The minimal requirement for these ele-

the detection scheme. Typically, the wavelength range ex- ments shall be that the numerical aperture of the components

ploited spans from 0.4 to 1.06 µm. The laser source must have are matched for efficient coupling. Optics may also be neces-

sufficient power to obtain the desired minimum signal-to-noise sary to enhance the interaction of the input light with the

ratio (S/N) (see 10.3). spectral activator.

5.3 Focusing/Collection Optics—A number of optical ele- 5.4 Interfacing Optical Fiber—The primary requirement of

ments are needed for the launch and collection of light the interfacing optical fiber is to provide the minimum power

radiation into and from the optical fibers (interfacing, sample to the activator sample at the proper wavelength(s). The fiber

and reference), and other instrumentation (light source, spec- lengthmaybeadjustedsothatthepowerrequirementsaremet.

E 1654

5.5 Light Radiation Filtering—Itisimportantthatallneigh- 5.11 Optical Detection—An optical detector with a known

boring laser lines are removed from the source beam prior to responseovertherangeofintensitiesthatareencounteredshall

interaction with the spectral activator. This can be accom-

be used. A typical system for Raman might include a single-

plished before or after the interfacing optical fiber. Placement point detector (that is, PMT) or a multichannel analyzer (that

of the filter before the interfacing fiber will eliminate the

is, CCD array). The spectrograph must exhibit fast scanning

neighboring laser lines, but any fluorescence and Raman

capabilities. As Fig. 1 indicates, it is recommended that a

scattering due to the fiber or associated optics will be allowed

single-imaging spectrometer be used with a 2D CCD detector

to interact with the sample. Placement of the laser pass filter

so that the output from the reference and sample fibers can be

aftertheinterfacingfiberispreferablebecauseitwilleliminate

evaluated simultaneously. Two spectrometers operating simul-

any signals created within the fiber. If it is necessary to place

taneously may also be used.

the filter before the interfacing fiber, then the fiber should be

5.11.1 The optical detection system must be capable of

−1

kept as short as possible (several metres).

obtainingtheRamanspectrumfrom500to3000cm fromthe

5.6 Spectral Activator Sample—The spectral activator used

excitation frequency.

must demonstrate a strong, well-characterized Raman spectral

5.12 Recorder System—Asuitable data recording, such as a

signal. The sample may be either liquid, gas, or solid, depend-

computer data acquisition system, is recommended.

ing on the requirements of the optical fiber arrangement. It is

5.13 Ambient Light Shielding—The irradiated fiber length

recommendedthataliquidbeused,sincetheRamanscattering

shall be shielded from ambient light to prevent photobleaching

in the proposed configuration will launch similarly into the

byanyexternallightsourcesandtoavoidbaselineshiftsinthe

sample and reference fibers. Standard recommended samples

zero light level. An absorbing fiber coating or jacket can be

are:acetonitrile,benzene,andcarbontetrachloride.Thesample

used as the light shield provided that it has been demonstrated

should be contained in a standard spectroscopic rectangular

to block ambient light and its influence on the dose within the

silica cuvette.

fiber core has been taken into consideration.

5.7 Optical Interconnections—Theinputandoutputendsof

the interfacing, reference, and sample optical fibers shall have

NOTE 2—The average total dose should be expressed in gray (Gy,

astabilizedopticalinterconnection,suchasaclamp,connector,

where 1 Gy 5100 rads) to a precision of 65%, traceable to national

splice, or weld. During an attenuation measurement, the

standards. For typical silica core fibers, dose should be expressed in gray

interconnection shall not be changed or adjusted. calculated for SiO , that is, Gy(SiO ).

2 2

5.8 Irradiation System—Theirradiationsystemshouldhave

6. Hazards

the following characteristics:

5.8.1 Dose Rate—ACo orotherirradiationsourceshallbe

6.1 Carefully trained and qualified personnel must be used

used to deliver radiation at dose rates ranging from 10 to 100

to perform this test procedure since radiation (both ionizing

Gy (SiO )/min. (See Note 2.)

and optical), as well as electrical, hazards will be present.

5.8.2 Radiation Energy—The energy of the gamma rays

emitted by the source should be greater than 500 KeVto avoid

7. Test Specimens

serious complications with the rapid variations in total dose as

7.1 Sample Optical Fiber—The sample fiber shall be a

a function of depth within the test sample.

previously unirradiated step-index, multimode fiber. The fiber

5.8.3 Radiation Dosimeter—Dosimetry traceable to Na-

shall be long enough to have an irradiated test length of 50 6

tionalStandardsshallbeused.Doseshouldbemeasuredinthe

5 m and to allow coupling between the optical instrumentation

same uniform geometry as the actual fiber core material to

outside the radiation chamber and the sample area.

ensure that dose-buildup effects are comparable to the fiber

7.2 The test specimen may be an optical-fiber cable assem-

core and the dosimeter. The dose should be expressed in gray

bly, as long as the cable contains at least one of the specified

calculated for the core material.

fibers for analysis.

5.9 Temperature-Controlled Container—Unless otherwise

7.3 Test Reel—The test reel shall not act as a shield for the

specified, the temperature-controlled container shall have the

radiation used in this test or, alternatively, the dose must be

capability of maintaining the specified temperature to 23 6

measured in a geometry duplicating the effects of reel attenu-

2°C. The temperature of the sample/container should be

ation. The diameter of the test reel and the winding tension of

monitored prior to and during the test.

the fiber can influence the observed radiation performance,

5.10 Collection Optics into Detection System—An appro-

therefore, the fiber should be loosely wound on a reel diameter

priatecol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.