ASTM B963-11

(Test Method)Standard Test Methods for Oil Content, Oil-Impregnation Efficiency, and Interconnected Porosity of Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle

Standard Test Methods for Oil Content, Oil-Impregnation Efficiency, and Interconnected Porosity of Sintered Powder Metallurgy (PM) Products Using Archimedes<span class='unicode'>’</span> Principle

SIGNIFICANCE AND USE

Oil content values are generally contained in specifications for oil-impregnated PM bearings.

The oil-impregnation efficiency provides an indication of how well the as-received parts had been impregnated.

The desired self-lubricating performance of PM bearings requires a minimum amount of interconnected porosity and satisfactory oil impregnation of the interconnected porosity. A minimum oil content is specified.

The results from these test methods may be used for quality control or compliance purposes.

SCOPE

1.1 This standard describes three related test methods that cover the measurement of physical properties of oil-impregnated powder metallurgy products.

1.1.1 Determination of the volume percent of oil contained in the material.

1.1.2 Determination of the efficiency of the oil-impregnation process.

1.1.3 Determination of the percent interconnected porosity by oil impregnation.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are converted in accordance with IEEE/ASTM SI 10 and are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B963 − 11

StandardTest Methods for

Oil Content, Oil-Impregnation Efficiency, and Interconnected

Porosity of Sintered Powder Metallurgy (PM) Products

1

Using Archimedes’ Principle

This standard is issued under the fixed designation B963; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions of powder metallurgy (PM) terms can be

1.1 This standard describes three related test methods that

found in Terminology B243.Additional descriptive material is

cover the measurement of physical properties of oil-

available in the Related Material section of Vol. 02.05 of the

impregnated powder metallurgy products.

Annual Book of ASTM Standards.

1.1.1 Determination of the volume percent of oil contained

in the material.

4. Summary of Test Method

1.1.2 Determination of the efficiency of the oil-

4.1 Thepartortestspecimenisfirstweighedinair.Itisthen

impregnation process.

oil impregnated to fill the surface-connected porosity and the

1.1.3 Determination of the percent interconnected porosity

specimen is reweighed. The test specimen is then weighed

by oil impregnation.

when immersed in water and its volume calculated based on

1.2 The values stated in SI units are to be regarded as the

Archimedes’ principle. The oil is then removed and the

standard. The values in parentheses are converted in accor-

specimen is reweighed.

dance with IEEE/ASTM SI 10 and are for information only.

4.2 The oil content of an oil-impregnated part or test

1.3 This standard does not purport to address all of the

specimen is then calculated as a percentage of the volume of

safety concerns, if any, associated with its use. It is the

the specimen. This may be done for the as-received and the

responsibility of the user of this standard to establish appro-

fully oil-impregnated specimen.

priate safety and health practices and determine the applica-

4.3 The oil-impregnation effıciencyiscalculatedbydividing

bility of regulatory limitations prior to use.

theas-receivedoilcontentbythefullyimpregnatedoilcontent

and expressing the result as a percentage.

2. Referenced Documents

4.4 The volume percentage of interconnected porosity (as

2

2.1 ASTM Standards:

measured by oil impregnation) is then calculated based on the

B243Terminology of Powder Metallurgy

amount of oil in the fully oil-impregnated specimen.

D1217Test Method for Density and Relative Density (Spe-

cific Gravity) of Liquids by Bingham Pycnometer 5. Significance and Use

D1298Test Method for Density, Relative Density (Specific

5.1 Oil content values are generally contained in specifica-

Gravity), or API Gravity of Crude Petroleum and Liquid

tions for oil-impregnated PM bearings.

Petroleum Products by Hydrometer Method

5.2 The oil-impregnation efficiency provides an indication

2.2 IEEE/ASTM Standard:

of how well the as-received parts had been impregnated.

SI 10American National Standard for Use of the Interna-

5.3 The desired self-lubricating performance of PM bear-

tional System of Units (SI): The Modern Metric System

ings requires a minimum amount of interconnected porosity

and satisfactory oil impregnation of the interconnected poros-

ity. A minimum oil content is specified.

1

These test methods are under the jurisdiction of ASTM Committee B09 on

5.4 The results from these test methods may be used for

Metal Powders and Metal Powder Products and are the direct responsibility of

quality control or compliance purposes.

Subcommittee B09.04 on Bearings.

Current edition approved May 1, 2011. Published May 2011. Last prefious

6. Apparatus

edition approved in 2008 as B963–08. DOI: 10.1520/B0963-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Analytical Balance—Precision single-pan balance that

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

will permit readings within 0.01% of the test specimen mass.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. See Table 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B963 − 11

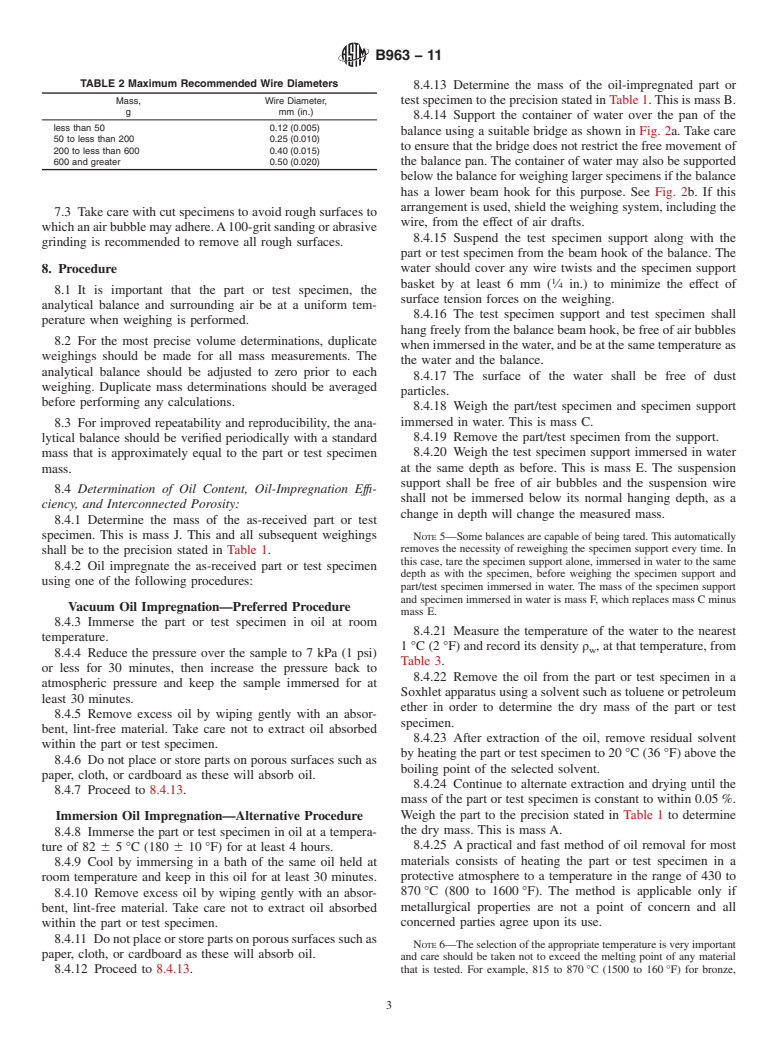

TABLE 1 Balance Sensitivity

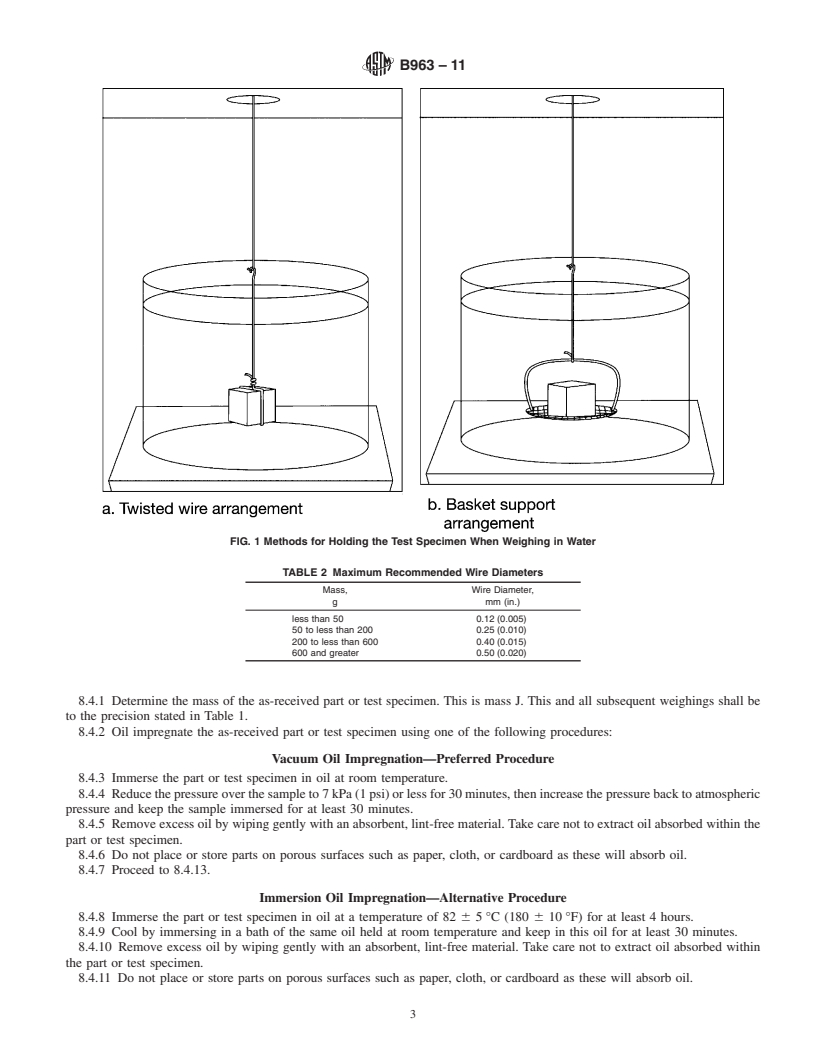

ornichrome—shallbeusedforthebasketandsuspensionwire.

Mass, Balance Sensitivity, The maximum recommended diameter of suspension wire to

g g

be used for various mass ranges is shown in Table 2.

less than 10 0.0001

NOTE 4—For the most precise determinations, it is important that the

10 to less than 100 0.001

massandvolumeofallsupportingwiresimmersedinwaterbeminimized.

100 to less than 1000 0.01

10

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B963–08 Designation:B963–11

Standard Test Methods for

Oil Content, Oil-Impregnation Efficiency, and Interconnected

Porosity of Sintered Powder Metallurgy (PM) Products

1

Using Archimedes’Principle

This standard is issued under the fixed designation B963; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard describes three related test methods that cover the measurement of physical properties of oil-impregnated

powder metallurgy products.

1.1.1 Determination of the volume percent of oil contained in the material.

1.1.2 Determination of the efficiency of the oil-impregnation process.

1.1.3 Determination of the percent interconnected porosity by oil impregnation.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are converted in accordance with

IEEE/ASTM SI 10 and are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B243 Terminology of Powder Metallurgy

D1217 Test Method for Density and Relative Density (Specific Gravity) of Liquids by Bingham Pycnometer

D1298 Test Method for Density, Relative Density (Specific Gravity), orAPI Gravity of Crude Petroleum and Liquid Petroleum

Products by Hydrometer Method

2.2 IEEE/ASTM Standard:

SI 10 American National Standard for Use of the International System of Units (SI): The Modern Metric System

3. Terminology

3.1 Definitions of powder metallurgy (PM) terms can be found in Terminology B243. Additional descriptive material is

available in the Related Material section of Vol. 02.05 of the Annual Book of ASTM Standards.

4. Summary of Test Method

4.1 The part or test specimen is first weighed in air. It is then oil impregnated to fill the surface-connected porosity and the

specimen is reweighed. The test specimen is then weighed when immersed in water and its volume calculated based on

Archimedes’ principle. The oil is then removed and the specimen is reweighed.

4.2 The oil content of an oil-impregnated part or test specimen is then calculated as a percentage of the volume of the specimen.

This may be done for the as-received and the fully oil-impregnated specimen.

4.3 The oil-impregnation effıciency is calculated by dividing the as-received oil content by the fully impregnated oil content and

expressing the result as a percentage.

4.4 Thevolumepercentageof interconnected porosity(asmeasuredbyoilimpregnation)isthencalculatedbasedontheamount

of oil in the fully oil-impregnated specimen.

1

These test methods are under the jurisdiction ofASTM Committee B09 on Metal Powders and Metal Powder Products and are the direct responsibility of Subcommittee

B09.04 on Bearings.

Current edition approved Nov. 1, 2008. Published December 2008. DOI: 10.1520/B0963-08.

Current edition approved May 1, 2011. Published May 2011. Last prefious edition approved in 2008 as B963–08. DOI: 10.1520/B0963-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B963–11

5. Significance and Use

5.1 Oil content values are generally contained in specifications for oil-impregnated PM bearings.

5.2 The oil-impregnation efficiency provides an indication of how well the as-received parts had been impregnated.

5.3 The desired self-lubricating performance of PM bearings requires a minimum amount of interconnected porosity and

satisfactory oil impregnation of the interconnected porosity. A minimum oil content is specified.

5.4 The results from these test methods may be used for quality control or compliance purposes.

6. Apparatus

6.1 Analytical Balance—Precision single-pan balance that will permit readings within 0.01 % of the test specimen mass. See

Table 1.

6.2 Water Container—A glass beaker or other sui

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.