ASTM B341/B341M-00

(Specification)Standard Specification for Aluminum-Coated (Aluminized) Steel Core Wire for Aluminum Conductors, Steel Reinforced (ACSR/AZ)

Standard Specification for Aluminum-Coated (Aluminized) Steel Core Wire for Aluminum Conductors, Steel Reinforced (ACSR/AZ)

SCOPE

1.1 This specification covers round, aluminum-coated steel core wire used for mechanical reinforcement in the manufacture of aluminum conductors, steel reinforced (ACSR).

1.2 This specification covers wire of diameter from 0.0500 to 0.1900 in., inclusive.

1.3 The values stated in inch-pound units are to be regarded as the standard, with the exception of resistivity. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 341/B 341M – 00

Standard Specification for

Aluminum-Coated (Aluminized) Steel Core Wire for

Aluminum Conductors, Steel Reinforced (ACSR/AZ)

This standard is issued under the fixed designation B 341/B 341M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 Quantity of each size,

4.1.2 Wire diameter in inches or millimetres (see 1.2, 13.1),

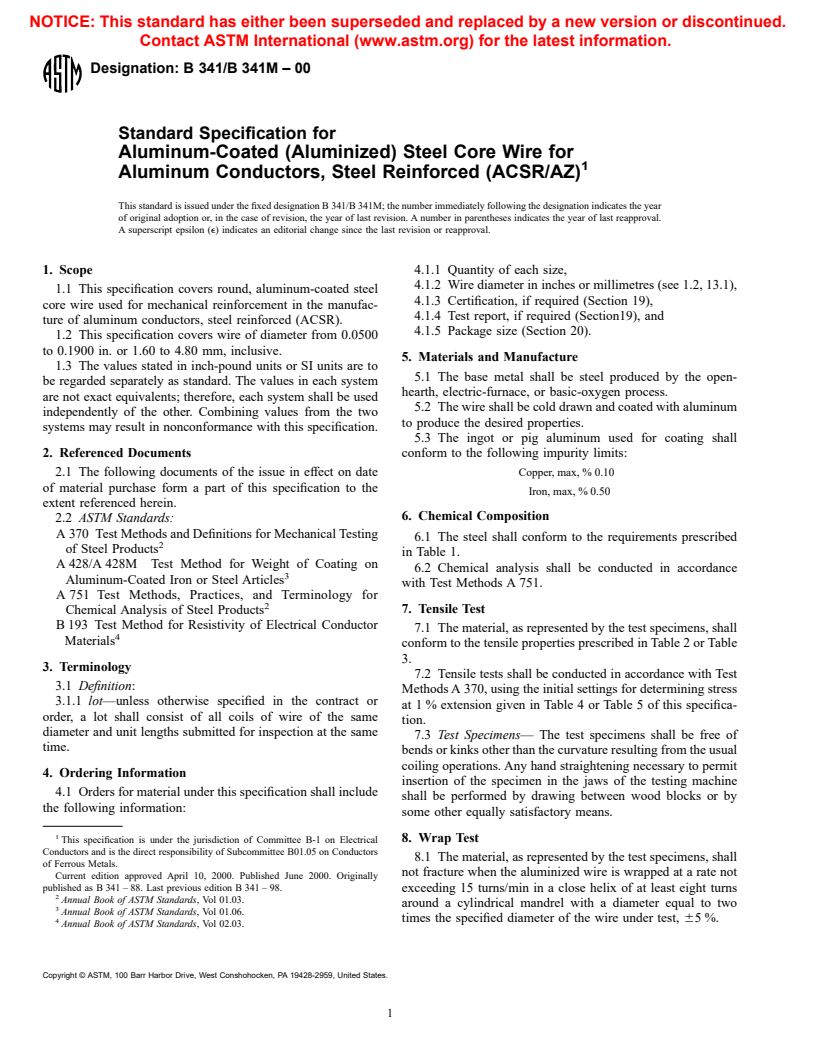

1.1 This specification covers round, aluminum-coated steel

4.1.3 Certification, if required (Section 19),

core wire used for mechanical reinforcement in the manufac-

4.1.4 Test report, if required (Section19), and

ture of aluminum conductors, steel reinforced (ACSR).

4.1.5 Package size (Section 20).

1.2 This specification covers wire of diameter from 0.0500

to 0.1900 in. or 1.60 to 4.80 mm, inclusive.

5. Materials and Manufacture

1.3 The values stated in inch-pound units or SI units are to

5.1 The base metal shall be steel produced by the open-

be regarded separately as standard. The values in each system

hearth, electric-furnace, or basic-oxygen process.

are not exact equivalents; therefore, each system shall be used

5.2 The wire shall be cold drawn and coated with aluminum

independently of the other. Combining values from the two

to produce the desired properties.

systems may result in nonconformance with this specification.

5.3 The ingot or pig aluminum used for coating shall

2. Referenced Documents conform to the following impurity limits:

2.1 The following documents of the issue in effect on date Copper, max, % 0.10

of material purchase form a part of this specification to the

Iron, max, % 0.50

extent referenced herein.

6. Chemical Composition

2.2 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing

6.1 The steel shall conform to the requirements prescribed

of Steel Products

in Table 1.

A 428/A 428M Test Method for Weight of Coating on

6.2 Chemical analysis shall be conducted in accordance

Aluminum-Coated Iron or Steel Articles

with Test Methods A 751.

A 751 Test Methods, Practices, and Terminology for

7. Tensile Test

Chemical Analysis of Steel Products

B 193 Test Method for Resistivity of Electrical Conductor

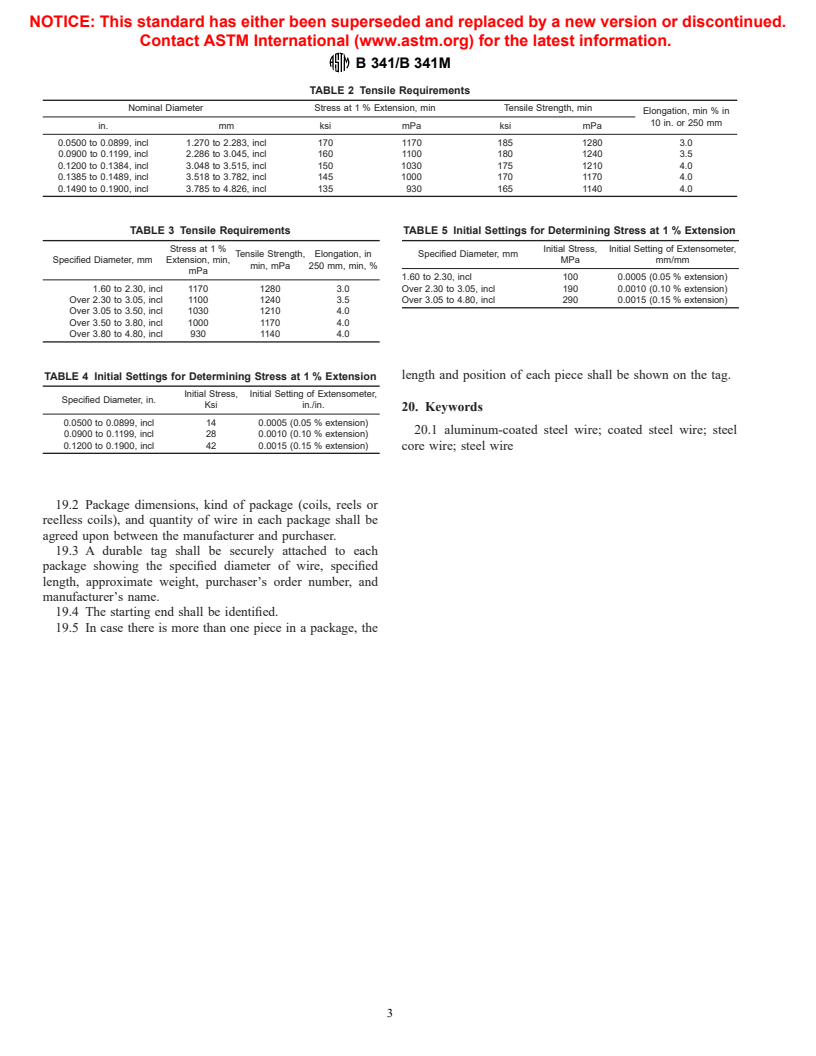

7.1 The material, as represented by the test specimens, shall

Materials

conform to the tensile properties prescribed in Table 2 or Table

3.

3. Terminology

7.2 Tensile tests shall be conducted in accordance with Test

3.1 Definition:

Methods A 370, using the initial settings for determining stress

3.1.1 lot—unless otherwise specified in the contract or

at 1 % extension given in Table 4 or Table 5 of this specifica-

order, a lot shall consist of all coils of wire of the same

tion.

diameter and unit lengths submitted for inspection at the same

7.3 Test Specimens— The test specimens shall be free of

time.

bends or kinks other than the curvature resulting from the usual

coiling operations. Any hand straightening necessary to permit

4. Ordering Information

insertion of the specimen in the jaws of the testing machine

4.1 Orders for material under this specification shall include

shall be performed by drawing between wood blocks or by

the following information:

some other equally satisfactory means.

8. Wrap Test

This specification is under the jurisdiction of Committee B-1 on Electrical

Conductors and is the direct responsibility of Subcommittee B01.05 on Conductors

8.1 The material, as represented by the test specimens, shall

of Ferrous Metals.

not fracture when the aluminized wire is wrapped at a rate not

Current edition approved April 10, 2000. Published June 2000. Originally

published as B 341 – 88. Last previous edition B 341 – 98. exceeding 15 turns/min in a close helix of at least eight turns

Annual Book of ASTM Standards, Vol 01.03.

around a cylindrical mandrel with a diameter equal to two

Annual Book of ASTM Standards, Vol 01.06.

times the specified diameter of the wire under test, 65%.

Annual Book of ASTM Standards, Vol 02.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 341/B 341M

TABLE 1 Chemical Requirements

14. Workmanship, Finish, and Appearance

Element Composition,%

14.1 The aluminum coating shall be reasonably smooth,

Carbon 0.50 to 0.95

continuous, of reasonably uniform thickness, and free of

Manganese 0.50 to 1.30

imperfections not consistent with good commercial practice.

Phosphorus, max 0.040

Sulfur, max 0.050

Silicon 0.10 to 0.35 15. Number of Tests and Retests

15.1 One test specimen shall be taken from each 5000 lb or

2500 kg or fraction thereof in a lot. Each heat in a given lot

9. Coating Test

shall be tested.

9.1 The material, as represented by the test specimens, shall

15.2 Each specimen shall be tested for compliance with

conform to the coating requirements of Table 6 or Table 7, for

Section 7, 8, 10, and 13. At least half of the specimens shall be

the diameter specified.

tested for compliance with Section 9.

9.2 The coating test shall be conducted in accordance with

15.3 Should one or more of the test specimens fail any of

Test Method A 428/A 428M.

the tests specified, the nonconforming coil or coils may be

10. Adherence of Coating Test

removed and the balance of the lot subjected to retests. For

retest purposes, two additional coils for each 5000 lb or 2500

10.1 The material, as represented by the samples, shall be

kg in the lot shall be sampled and tested for the property in

capable of being wrapped in a close helix at a rate not

which the original sample failed to comply.

exceeding 15 turns/min around a cylindrical mandrel having a

15.4 Should any of the retest specimens fail to meet the

diameter as prescribed in Table 8 or Table 9, without cracking

properties specified, the lot represented by the test specimens

or flaking the aluminum coating to such an extent that any

shall be rejected.

aluminum can be removed by rubbing with the bare fingers.

15.5 Instead of rejecting the entire lot as provided in 15.4,

NOTE 1—Loosening or detachment during the adhesion test of super-

the producer may test specimens from every coil in the lot for

ficial, small particles of aluminum formed by mechanical polishing of the

the property in which failure occurred, and reject only the

surface of aluminum-coated wire shall not be considered cause for

nonconforming coils.

rejection.

11. Joints 16. Inspection

11.1 No joints shall be made in the finished wire.

16.1 Unless otherwise specified in the contract or purchase

11.2 Joints may be made at any stage of processing prior to order, the manufacturer shall be responsible for the perfor-

final cold drawing by the electric butt-weld or flash-welding

mance of all inspection and test requirements specified.

process. 16.2 All inspections and tests shall be made at the place of

11.3 Welding equipment and procedure shall be such that it

manufacture unless otherwise especially agreed upon between

can be demonstrated that the tensile strength of a finished wire the manufacturer and the purchaser at the time of the purchase.

specimen containing the welded section shall not be less than

16.3 The manufacturer shall afford the inspector represent-

96 % of the specified minimum stress at 1 % extension.

ing the purchaser all reasonable manufacturer’s facilities to

11.4 A welded section shall not be required to meet the

satisfy him that the material is being furnished in accordance

stress at 1 % extension, elongation, and wrap tests.

with this specification.

12. Density and Resistivity

17. Rejection and Rehearing

12.1 For the purposes of calculating mass per unit length,

17.1 Material that fails to conform to the requirements of

cross-sections, etc., the density of aluminized steel wire shall

this specification shall be rejected. Rejection shall be reported

3 3

(7780 kg/m ).

be taken as 0.281 lb/in.

to the producer or supplier promptly and in writing. In case

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.