ASTM D245-06(2011)

(Practice)Standard Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber

Standard Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber

SIGNIFICANCE AND USE

Need for Lumber Grading:

Individual pieces of lumber, as they come from the saw, represent a wide range in quality and appearance with respect to freedom from knots, cross grain, shakes, and other characteristics. Such random pieces likewise represent a wide range in strength, utility, serviceability, and value. One of the obvious requirements for the orderly marketing of lumber is the establishment of grades that permit the procurement of any required quality of lumber in any desired quantity. Maximum economy of material is obtained when the range of quality-determining characteristics in a grade is limited and all pieces are utilized to their full potential. Many of the grades are established on the basis of appearance and physical characteristics of the piece, but without regard for mechanical properties. Other grades, called structural or stress grades, are established on the basis of features that relate to mechanical properties. The latter designate near-minimum strength and near-average stiffness properties on which to base structural design.

The development of this practice is based on extensive research covering tests of small clear specimens and of full-sized structural members. Detailed studies have included the strength and variability of clear wood, and the effect on strength from various factors such as density, knots (See Terminology D9), and other defects, seasoning, duration of stress, and temperature.

How Visual Grading is Accomplished— Visual grading is accomplished from an examination of all four faces and the ends of the piece, in which the location as well as the size and nature of the knots and other features appearing on the surfaces are evaluated over the entire length. Basic principles of structural grading have been established that permit the evaluation of any piece of stress-graded lumber in terms of a strength ratio for each property being evaluated. The strength ratio of stress-graded lumber is the hypothetical ratio of the str...

SCOPE

1.1 This practice (1,2) covers the basic principles for establishing related unit stresses and stiffness values for design with visually-graded solid sawn structural lumber. This practice starts with property values from clear wood specimens and includes necessary procedures for the formulation of structural grades of any desired strength ratio.

1.2 The grading provisions used as illustrations herein are not intended to establish grades for purchase, but rather to show how stress-grading principles are applied. Detailed grading rules for commercial stress grades which serve as purchase specifications are established and published by agencies which formulate and maintain such rules and operate inspection facilities covering the various species.

1.3 The material covered in this practice appears in the following order:

Section Scope 1 Significance and Use3 Basic Principles of Strength Ratios4 Estimation and Limitation of Growth Characteristics5 Allowable Properties for Timber Design6 Modification of Allowable Properties for Design Use7 Example of Stress-Grade Development8

1.4 The values given in parentheses are provided for information purposes only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D245 − 06 (Reapproved 2011)

Standard Practice for

Establishing Structural Grades and Related Allowable

Properties for Visually Graded Lumber

This standard is issued under the fixed designation D245; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2 3

1.1 This practice (1,2) covers the basic principles for 2.1 ASTM Standards:

establishing related unit stresses and stiffness values for design D9 Terminology Relating to Wood and Wood-Based Prod-

with visually-graded solid sawn structural lumber. This prac- ucts

tice starts with property values from clear wood specimens and D143 Test Methods for Small Clear Specimens of Timber

includes necessary procedures for the formulation of structural D2555 PracticeforEstablishingClearWoodStrengthValues

grades of any desired strength ratio. E105 Practice for Probability Sampling of Materials

IEEE/ASTM SI-10 Practice for Use of the International

1.2 The grading provisions used as illustrations herein are

System of Units (SI) (the Modernized Metric System)

not intended to establish grades for purchase, but rather to

show how stress-grading principles are applied. Detailed grad-

3. Significance and Use

ing rules for commercial stress grades which serve as purchase

3.1 Need for Lumber Grading:

specifications are established and published by agencies which

3.1.1 Individual pieces of lumber, as they come from the

formulate and maintain such rules and operate inspection

saw, represent a wide range in quality and appearance with

facilities covering the various species.

respect to freedom from knots, cross grain, shakes, and other

1.3 The material covered in this practice appears in the

characteristics. Such random pieces likewise represent a wide

following order:

range in strength, utility, serviceability, and value. One of the

Section

obvious requirements for the orderly marketing of lumber is

Scope 1

the establishment of grades that permit the procurement of any

Significance and Use 3

required quality of lumber in any desired quantity. Maximum

Basic Principles of Strength Ratios 4

Estimation and Limitation of Growth Characteristics 5

economy of material is obtained when the range of quality-

Allowable Properties for Timber Design 6

determining characteristics in a grade is limited and all pieces

Modification of Allowable Properties for Design Use 7

are utilized to their full potential. Many of the grades are

Example of Stress-Grade Development 8

established on the basis of appearance and physical character-

1.4 The values given in parentheses are provided for infor-

istics of the piece, but without regard for mechanical proper-

mation purposes only.

ties. Other grades, called structural or stress grades, are

1.5 This standard does not purport to address all of the

established on the basis of features that relate to mechanical

safety concerns, if any, associated with its use. It is the

properties. The latter designate near-minimum strength and

responsibility of the user of this standard to establish appro-

near-average stiffness properties on which to base structural

priate safety and health practices and determine the applica-

design.

bility of regulatory limitations prior to use.

3.1.2 Thedevelopmentofthispracticeisbasedonextensive

research covering tests of small clear specimens and of

full-sized structural members. Detailed studies have included

This practice is under the jurisdiction of ASTM Committee D07 on Wood and

is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered

the strength and variability of clear wood, and the effect on

Wood Products.

Current edition approved Oct. 1, 2011. Published October 2011. Originally

approved in 1926. Last previous edition approved in 2006 as D245 – 06. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D0245-06R11. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to references at the end of this Standards volume information, refer to the standard’s Document Summary page on

practice. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D245 − 06 (2011)

strength from various factors such as density, knots (See ciency in some particulars, it offers the advantage of a more

Terminology D9), and other defects, seasoning, duration of simple system of grades of stress-graded lumber.

stress, and temperature.

3.4 Essential Elements in a Stress-Grade Description:

3.4.1 Astress grade formulated by this practice contains the

3.2 How Visual Grading is Accomplished— Visual grading

following essential elements:

is accomplished from an examination of all four faces and the

3.4.2 Agrade name that identifies the use-class as described

ends of the piece, in which the location as well as the size and

in 3.3.

natureoftheknotsandotherfeaturesappearingonthesurfaces

3.4.3 A description of permissible growth characteristics

are evaluated over the entire length. Basic principles of

that affect mechanical properties. Characteristics that do not

structural grading have been established that permit the evalu-

affect mechanical properties may also be included.

ation of any piece of stress-graded lumber in terms of a

3.4.4 One or more allowable properties for the grade related

strength ratio for each property being evaluated. The strength

to its strength ratio.

ratio of stress-graded lumber is the hypothetical ratio of the

strength property being considered compared to that for the

4. Basic Principles of Strength Ratios

material with no strength-reducing characteristic. Thus a piece

of stress-graded lumber with a strength ratio of 75 % in

4.1 General Considerations:

bending would be expected to have 75 % of the bending

4.1.1 Strength ratios associated with knots in bending mem-

strength of the clear piece. In effect, the strength ratio system

bers have been derived as the ratio of moment-carrying

of visual structural grading is thus designed to permit practi-

capacity of a member with cross section reduced by the largest

cally unlimited choice in establishing grades of any desired

knot to the moment-carrying capacity of the member without

quality to best meet production and utilization requirements.

defect.This gives the anticipated reduction in bending strength

due to the knot. For simplicity, all knots on the wide face are

3.3 Classification of Stress-Graded Lumber:

treated as being either knots along the edge of the piece (edge

3.3.1 The various factors affecting strength, such as knots,

knots) or knots along the centerline of the piece (centerline

deviations of grain, shakes, and checks, differ in their effect,

knots).

depending on the kind of loading and stress to which the piece

4.1.2 Strength ratios associated with slope of grain in

is subjected. Stress-graded lumber is often classified according

bending members, and in members subjected to compression

to its size and use. Four classes are widely used, as follows:

parallel to grain, were obtained, experimentally (3).

3.3.1.1 Dimension Lumber—Pieces of rectangular cross

4.1.3 Strength ratios associated with shakes, checks, and

section, from nominal 2 to 4 in. thick and 2 or more in. wide,

splits are assumed to affect only horizontal shear in bending

graded primarily for strength in bending edgewise or flatwise,

members. These strength ratios were derived, as for knots, by

but also frequently used where tensile or compressive strength

assuming that a critical cross section is reduced by the amount

is important. Dimension lumber covers many sizes and end

of the shake, or by an equivalent split or check.

uses.Lumbergradedforspecificendusesmaydictateaspecial

4.1.4 Strength ratios associated with knots in compression

emphasis in grading and require an identifying grade name.

members have been derived as the ratio of load-carrying

NOTE 1—For example, in NorthAmerican grading under theAmerican

capacity of a member with cross section reduced by the largest

Lumber Standards Committee, stress graded dimension lumber categories

knot to the load-carrying capacity of the member without

that reflect end use include Light Framing, Structural Light Framing,

defect. No assumption of combined compression and bending

Structural Joists and Planks, and Studs.

is made.

3.3.1.2 Beams and Stringers—Pieces of rectangular cross

4.1.5 Tensile strength of lumber has been related to bending

section, 5 in. nominal and thicker, nominal width more than 2

strength and bending strength ratio from experimental results

in. greater than nominal thickness, graded for strength in

(4).

bending when loaded on the narrow face.

4.1.6 Strength in compression perpendicular to grain is little

3.3.1.3 Posts and Timbers—Pieces of square or nearly

affected in lumber by strength-reducing characteristics, and

squarecrosssection,5by5in.,nominaldimensionsandlarger,

strength ratios of 100 % are assumed for all grades.

nominal width not more than 2 in. greater than nominal

4.1.7 Modulus of elasticity of a piece of lumber is known to

thickness, graded primarily for use as posts or columns.

be only approximately related to bending strength ratio. In this

3.3.1.4 Stress-Rated Boards—Lumber less than 2 in. nomi-

standard, the relationship between full-span, edgewise bending

nal in thickness and 2 in. or wider nominal width, graded

modulus of elasticity and strength ratio was obtained experi-

primarily for mechanical properties.

mentally.

3.3.2 The assignment of names indicating the uses for the 4.1.8 In developing a stress-grade rule, economy may be

various classes of stress-graded lumber does not preclude their served by specifying strength ratios such that the allowable

use for other purposes. For example, posts and timbers may stresses for shear and for extreme fiber in bending will be in

give service as beams. The principles of stress grading permit balance, under the loading for which the members are de-

theassignmentofanykindofallowablepropertiestoanyofthe signed.

classes of stress-graded lumber, whether graded primarily for 4.1.9 A strength ratio can also be associated with specific

that property or not. Recommendations for allowable proper- gravity. Three selection classes called dense, close grain, and

ties may include all properties for all grades or use classes. medium grain are described herein, based on experimental

While such universal application may result in loss of effi- findings (5).

D245 − 06 (2011)

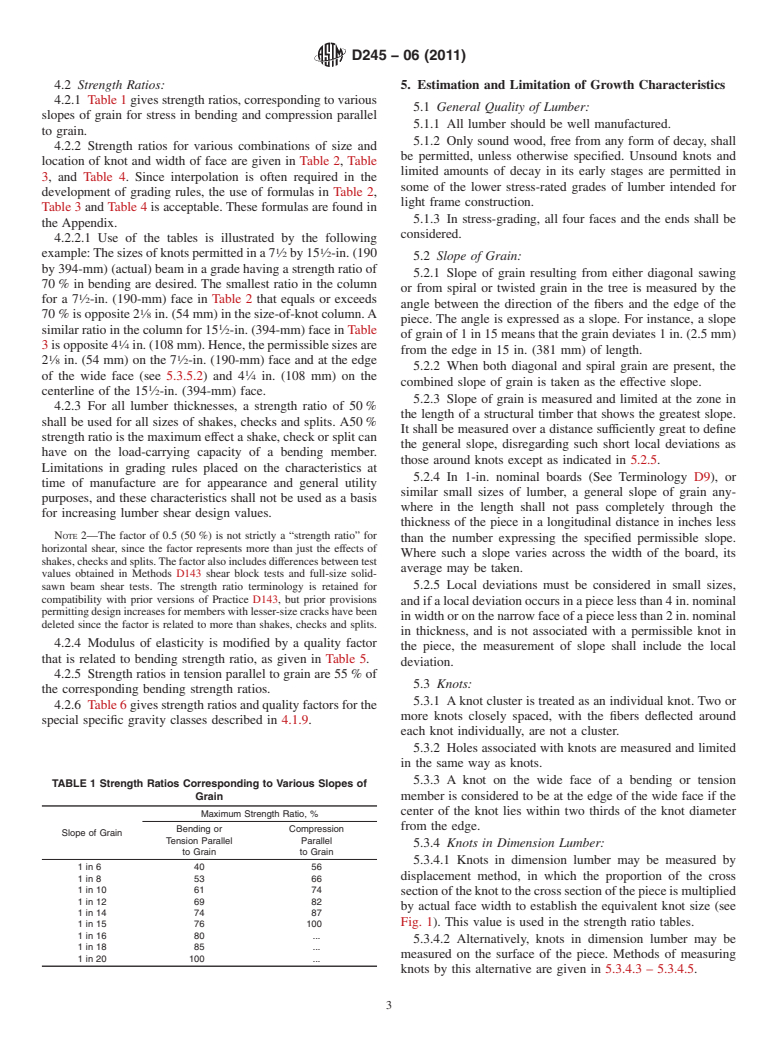

4.2 Strength Ratios: 5. Estimation and Limitation of Growth Characteristics

4.2.1 Table 1 gives strength ratios, corresponding to various

5.1 General Quality of Lumber:

slopes of grain for stress in bending and compression parallel

5.1.1 All lumber should be well manufactured.

to grain.

5.1.2 Only sound wood, free from any form of decay, shall

4.2.2 Strength ratios for various combinations of size and

be permitted, unless otherwise specified. Unsound knots and

location of knot and width of face are given in Table 2, Table

limited amounts of decay in its early stages are permitted in

3, and Table 4. Since interpolation is often required in the

some of the lower stress-rated grades of lumber intended for

development of grading rules, the use of formulas in Table 2,

light frame construction.

Table 3 and Table 4 is acceptable. These formulas are found in

5.1.3 In stress-grading, all four faces and the ends shall be

the Appendix.

considered.

4.2.2.1 Use of the tables is illustrated by the following

1 1

example:Thesizesofknotspermittedina7 ⁄2by15 ⁄2-in.(190

5.2 Slope of Grain:

by 394-mm) (actual) beam in a grade having a strength ratio of

5.2.1 Slope of grain resulting from either diagonal sawing

70 % in bending are desired. The smallest ratio in the column

or from spiral or twisted grain in the tree is measured by the

fora7 ⁄2-in. (190-mm) face in Table 2 that equals or exceeds

angle between the direction of the fibers and the edge of the

70 % is opposite 2 ⁄8 in. (54 mm) in the size-of-knot column.A

piece. The angle is expressed as a slope. For instance, a slope

similar ratio in the column for 15 ⁄2-in. (394-mm) face in Table

of grain of 1 in 15 means that the grain deviates 1 in. (2.5 mm)

3isopposite4 ⁄4in.(108mm).Hence,thepermissiblesizesare

from the edge in 15 in. (381 mm) of length.

1 1

2 ⁄8 in. (54 mm) on the 7 ⁄2-in. (190-mm) face and at the edge

5.2.2 When both diagonal and spiral grain are present, the

of the wide face (see 5.3.5.2) and 4 ⁄4 in. (108 mm) on the

combined slope of grain is taken as the effective slope.

centerline of the 15 ⁄2-in. (394-mm) face.

5.2.3 Slope of grain is measured and limited at the zone in

4.2.3 For all lumber thicknesses, a strength ratio of 50 %

the length of a structural timber that shows the greatest slope.

shall be used for all sizes of shakes, checks and splits. A50 %

It shall be measured over a distance sufficiently great to define

strength ratio is the maximum effect a shake, check or split can

the general slope, disregarding such short local deviations as

have on the load-carrying capacity of a bending member.

those around knots except as indicated in 5.2.5.

Limitations in grading rules placed on the characteristics at

5.2.4 In 1-in. nominal boards (See Terminology D9), or

time of manufacture are for appearance and general utility

similar small sizes of lumber, a general slope of grain any-

purposes, and these characteristics shall not be used as a basis

where in the length shall not pass completely through the

for increasing lumber shear design values.

thickness of the piece in a longitudinal distance in inches less

NOTE 2—The factor of 0.5 (50 %) is not strictly a “strength ratio” for

than the number expressing the specified permissible slope.

horizontal shear, since the factor represents more than just the effects of

Where such a slope varies across the width of the board, its

shakes,checksandsplits.Thefactoralsoincludesdifferencesbetweentest

average may be taken.

values obtained in Methods D143 shear block tests and full-size solid-

5.2.5 Local deviations must be considered in small sizes,

sawn beam shear tests. The strength ratio terminology is retained for

compatibility with prior versions of Practice D143, but prior provisions

andifalocaldeviationoccursinapiecelessthan4in.nominal

permittingdesignincreasesformemberswithlesser-sizecrackshavebeen

inwidtho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.