ASTM C1240-03

(Specification)Standard Specification for Use of Silica Fume for Use as a Mineral Admixture in Hydraulic-Cement Concrete, Mortar, and Grout

Standard Specification for Use of Silica Fume for Use as a Mineral Admixture in Hydraulic-Cement Concrete, Mortar, and Grout

SCOPE

1.1 This specification covers silica fume for use in concrete and other systems containing hydraulic cement.

1.2 In the cases of slurried or densified silica fume, perform the tests on the raw silica fume from which these products have been made.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portions, Sections 10-19, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Read the material safety data sheets for materials used.

1.5 The text of this standard references notes and footnotes that provide explanatory information. These notes and footnotes (excluding those in tables) shall not be considered as requirements of this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1240 – 03

Standard Specification for

Use of Silica Fume as a Mineral Admixture in Hydraulic-

1

Cement Concrete, Mortar, and Grout

This standard is issued under the fixed designation C 1240; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * C 183 Practice for Sampling and the Amount of Testing of

2

Hydraulic Cement

1.1 This specification covers silica fume for use in concrete

C 185 Test Method for Air Content of Hydraulic Cement

and other systems containing hydraulic cement.

2

Mortar

1.2 In the cases of slurried or densified silica fume, perform

2

C 219 Terminology Relating to Hydraulic Cement

the tests on the raw silica fume from which these products have

C 311 Test Methods for Sampling and Testing Fly Ash or

been made.

Natural Pozzolans for Use as a Mineral Admixture in

1.3 The values stated in SI units are to be regarded as the

3

Portland-Cement Concrete

standard. The values given in parentheses are for information

C 430 Test Method for Fineness of Hydraulic Cement by

only.

2

the 45-μm (No. 325) Sieve

1.4 The following safety hazards caveat pertains only to the

C 441 Test Method for Effectiveness of Pozzolans or

test methods portions, Sections 10-19, of this specification:

Ground Blast-Furnace Slag in Preventing Excessive Ex-

This standard does not purport to address all of the safety

3

pansion of Concrete Due to the Alkali-Silica Reaction

concerns, if any, associated with its use. It is the responsibility

C 670 Practice for Preparing Precision and Bias Statements

of the user of this standard to establish appropriate safety and

3

for Test Methods for Construction Materials

health practices and determine the applicability of regulatory

C 1005 Specification for Reference Masses and Devices for

limitations prior to use. Read the material safety data sheets for

Determining Mass and Volume for Use in the Physical

materials used.

2

Testing of Hydraulic Cements

1.5 The text of this standard references notes and footnotes

C 1012 Test Method for Length Change of Hydraulic-

that provide explanatory information. These notes and foot-

2

Cement Mortars Exposed to a Sulfate Solution

notes (excluding those in tables) shall not be considered as

C 1069 Test Method for Specific Surface Area of Alumina

requirements of this standard.

4

or Quartz by Nitrogen Adsorption

2

2. Referenced Documents C 1437 Test Method for Flow of Hydraulic Cement Mortar

2.1 ASTM Standards:

3. Terminology

C 109/C 109M Test Method for Compressive Strength of

3.1 Definitions:

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

2 3.1.1 silica fume—very fine pozzolanic material, composed

Specimens)

mostly of amorphous silica produced by electric arc furnaces as

C 114 Test Methods for Chemical Analysis of Hydraulic

2 a byproduct of the production of elemental silicon or ferro-

Cement

silicon alloys (also known as condensed silica fume and

C 125 Terminology Relating to Concrete and Concrete

3 microsilica).

Aggregates

3.1.2 Other terms in this specification are defined in Termi-

C 157/C 157M Test Method for Length Change of Hard-

3 nologies C 125 and C 219.

ened Hydraulic-Cement, Mortar, and Concrete

4. Ordering Information

1

This specification is under the jurisdiction of ASTM Committee C09 on 4.1 The purchaser shall specify any optional chemical or

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

physical requirements.

C09.24 on Supplementary and Cementitious Materials.

Current edition approved Jan. 10, 2003. Published March 2003. Originally

approved in 1993. Last previous edition approved in 2001 as C 1240-01.

2

Annual Book of ASTM Standards, Vol 04.01.

3 4

Annual Book of ASTM Standards, Vol 04.02. Annual Book of ASTM Standards, Vol 15.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C1240–03

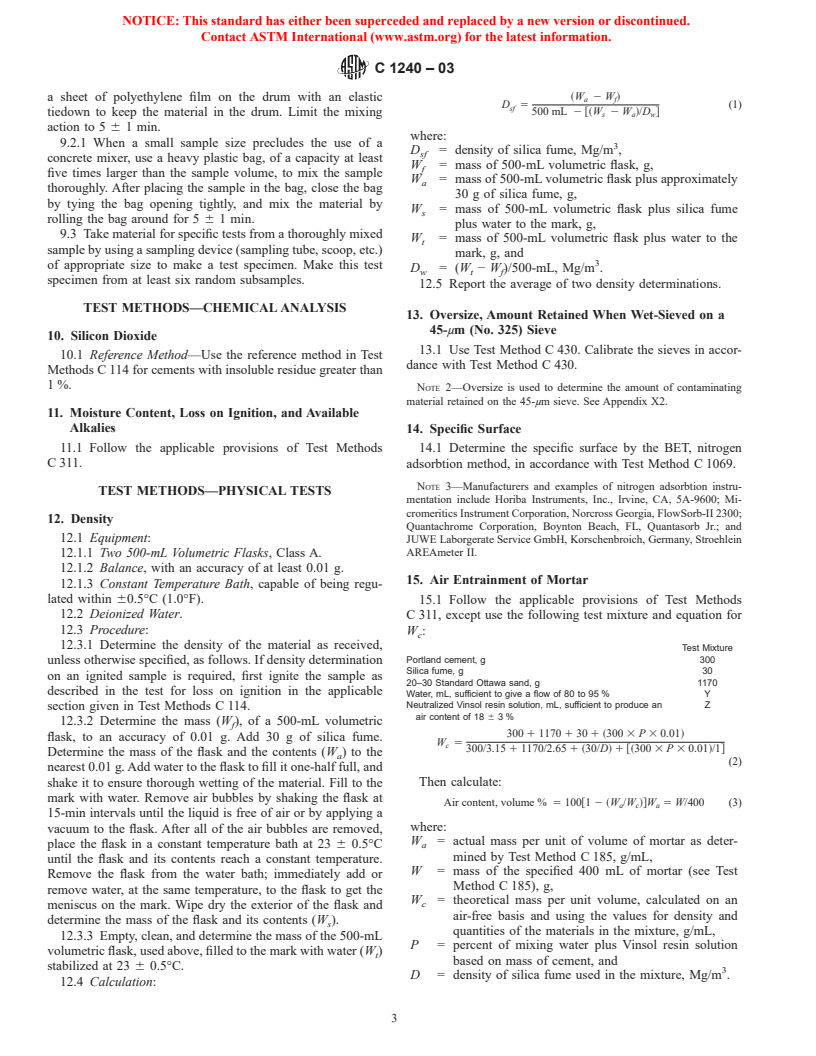

TABLE 2 Physical Requirements

5. Chemical Composition

Oversize:

5.1 Silica fume shall conform to the requirements for

A

Percent retained on 45-μm (No. 325), max, % 10

chemical composition prescribed in Table 1.

Percent retained on 45-μm (No. 325), max variation from 5

B

average, percentage points

C

6. Physical Requirements Accelerated pozzolanic strength activity index:

With portland cement at 7 days, min percent of control 105

6.1 Silica fum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.