ASTM D523-89(1999)

(Test Method)Standard Test Method for Specular Gloss

Standard Test Method for Specular Gloss

SIGNIFICANCE AND USE

Gloss is associated with the capacity of a surface to reflect more light in some directions than in others. The directions associated with mirror (or specular) reflection normally have the highest reflectances. Measurements by this test method correlate with visual observations of surface shininess made at roughly the corresponding angles.

5.1.1 Measured gloss ratings by this test method are obtained by comparing the specular reflectance from the specimen to that from a black glass standard. Since specular reflectance depends also on the surface refractive index of the specimen, the measured gloss ratings change as the surface refractive index changes. In obtaining the visual gloss ratings, however, it is customary to compare the specular reflectances of two specimens having similar surface refractive indices. Since the instrumental ratings are affected more than the visual ratings by changes in surface refractive index, non-agreement between visual and instrumental gloss ratings can occur when high gloss specimen surfaces differing in refractive index are compared.

Other visual aspects of surface appearance, such as distinctness of reflected images, reflection haze, and texture, are frequently involved in the assessment of gloss (1), (6), (7). Test Method E 430 includes techniques for the measurement of both distinctness-of-image gloss and reflection haze. Test Method D 4039 provides an alternative procedure for measuring reflection haze.

Little information about the relation of numerical-to-perceptual intervals of specular gloss has been published. However, in many applications the gloss scales of this test method have provided discriminations between coated specimens that have agreed well with visual discriminations of gloss (10).

When specimens differing widely in perceived gloss or color, or both, are compared, nonlinearity may be encountered in the relationship between visual gloss difference ratings and instrumental gloss reading differences.

SCOPE

1.1 This test method covers the measurement of the specular gloss of nonmetallic specimens for glossmeter geometries of 60, 20, and 85° (1-7).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D523–89(Reapproved1999)

Standard Test Method for

Specular Gloss

This standard is issued under the fixed designation D 523; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope reflected from a standard surface under the same geometric

conditions. For the purpose of measuring specular gloss, the

1.1 Thistestmethodcoversthemeasurementofthespecular

standard surface is polished glass.

gloss of nonmetallic specimens for glossmeter geometries of

2 3.1.2 specular gloss—the relative luminous reflectance fac-

60, 20, and 85° (1-7).

tor of a specimen in the mirror direction.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

4. Summary of Test Method

information only.

4.1 Measurements are made with 60, 20, or 85° geometry

1.3 This standard does not purport to address all of the

(8, 9). The geometry of angles and apertures is chosen so that

safety concerns, if any, associated with its use. It is the

these procedures may be used as follows:

responsibility of the user of this standard to establish appro-

4.1.1 The 60° geometry is used for intercomparing most

priate safety and health practices and determine the applica-

specimens and for determining when the 20° geometry may be

bility of regulatory limitations prior to use.

more applicable.

2. Referenced Documents 4.1.2 The 20° geometry is advantageous for comparing

specimens having 60° gloss values higher than 70.

2.1 ASTM Standards:

4.1.3 The 85° geometry is used for comparing specimens

D 823 Practices for Producing Films of Uniform Thickness

for sheen or near-grazing shininess. It is most frequently

of Paint, Varnish, and Related Products on Test Panels

applied when specimens have 60° gloss values lower than 10.

D 3964 Practice for Selection of Coating Specimens for

Appearance Measurements

5. Significance and Use

D 3980 Practice for Interlaboratory Testing of Paint and

4 5.1 Gloss is associated with the capacity of a surface to

Related Materials

reflect more light in some directions than in others. The

D 4039 Test Method for Reflection Haze of High-Gloss

3 directions associated with mirror (or specular) reflection nor-

Surfaces

mally have the highest reflectances. Measurements by this test

E97 Test Method for Directional Reflectance Factor, 45-

method correlate with visual observations of surface shininess

deg 0-deg, of Opaque Specimens by Broad-Band Filter

5 made at roughly the corresponding angles.

Reflectometry

5.1.1 Measured gloss ratings by this test method are ob-

E 430 Test Method for Measurement of Gloss of High-

3 tained by comparing the specular reflectance from the speci-

Gloss Surfaces by Goniophotometry

men to that from a black glass standard. Since specular

3. Terminology reflectance depends also on the surface refractive index of the

specimen, the measured gloss ratings change as the surface

3.1 Definitions:

refractive index changes. In obtaining the visual gloss ratings,

3.1.1 relative luminous reflectance factor—the ratio of the

however, it is customary to compare the specular reflectances

luminous flux reflected from a specimen to the luminous flux

of two specimens having similar surface refractive indices.

Since the instrumental ratings are affected more than the visual

This test method is under the jurisdiction of ASTM Committee E12 on Color

ratings by changes in surface refractive index, non-agreement

and Appearance and is the direct responsibility of Subcommittee E12.03 on

between visual and instrumental gloss ratings can occur when

Geometry.

high gloss specimen surfaces differing in refractive index are

Current edition approved March 31, 1989. Published May 1989. Originally

e1

compared.

published as D 523 – 39 T. Last previous edition D 523 – 85 .

The boldface numbers in parentheses refer to the list of references at the end of

5.2 Other visual aspects of surface appearance, such as

this test method.

distinctness of reflected images, reflection haze, and texture,

Annual Book of ASTM Standards, Vol 06.01.

4 are frequently involved in the assessment of gloss (1), (6), (7).

Discontinued; see 1997 Annual Book of ASTM Standards, Vol 06.01.

Discontinued; see 1992 Annual Book of ASTM Standards, Vol 14.02. Test Method E 430 includes techniques for the measurement of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D523–89 (1999)

both distinctness-of-image gloss and reflection haze. Test 6.2.1 The important geometric dimensions of any specular-

Method D 4039 provides an alternative procedure for measur- gloss measurement are:

ing reflection haze. 6.2.1.1 Beam axis angle(s), usually 60, 20, or 85°.

5.3 Little information about the relation of numerical-to- 6.2.1.2 Accepted angular divergences from principal rays

perceptual intervals of specular gloss has been published. (degree of spreading or diffusion of the reflected beam).

However, in many applications the gloss scales of this test

NOTE 1—The parallel-beam glossmeters possess the better uniformity

method have provided discriminations between coated speci-

of principle-ray angle of reflection, but the converging-beam glossmeters

mensthathaveagreedwellwithvisualdiscriminationsofgloss

possess the better uniformity in extent of angular divergence accepted for

(10).

measurement.

NOTE 2—Polarization—An evaluation of the impact of polarization on

5.4 When specimens differing widely in perceived gloss or

gloss measurement has been reported (11). The magnitude of the polar-

color, or both, are compared, nonlinearity may be encountered

ization error depends on the difference between the refractive indices of

in the relationship between visual gloss difference ratings and

specimen and standard, the angle of incidence, and the degree of

instrumental gloss reading differences.

polarization. Because the specimen and standard are generally quite

similar optically, measured gloss values are little affected by polarization.

6. Apparatus

6.3 Vignetting—There shall be no vignetting of rays that lie

6.1 Instrumental Components—The apparatus shall consist

within the field angles specified in Table 1.

of an incandescent light source furnishing an incident beam,

6.4 Spectral Conditions—Results should not differ signifi-

means for locating the surface of the specimen, and a receptor

cantly from those obtained with a source-filter photocell

located to receive the required pyramid of rays reflected by the

combination that is spectrally corrected to yield CIE luminous

specimen. The receptor shall be a photosensitive device re-

efficiency with CIE source C. Since specular reflection is, in

sponding to visible radiation.

general, spectrally nonselective, spectral corrections need to be

6.2 Geometric Conditions—The axis of the incident beam

applied only to highly chromatic, low-gloss specimens upon

shallbeatoneofthespecifiedanglesfromtheperpendicularto

agreement of users of this test method.

the specimen surface. The axis of the receptor shall be at the

6.5 Measurement Mechanism—The receptor-measurement

mirror reflection of the axis of the incident beam. The axis of

mechanism shall give a numerical indication that is propor-

the incident beam and the axis of the receptor shall be within

tional to the light flux passing the receptor field stop with

0.1°ofthenominalvalueindicatedbythegeometry.Withaflat

61 % of full-scale reading.

piece of polished black glass or other front-surface mirror in

the specimen position, an image of the source shall be formed 7. Reference Standards

at the center of the receptor field stop (receptor window). The

7.1 Primary Standards—Highlypolished,plane,blackglass

lengthoftheilluminatedareaofthespecimenshallbenotmore

with a refractive index of 1.567 for the sodium D line shall be

than one third of the distance from the center of this area to the

assigned a specular gloss value of 100 for each geometry. The

receptor field stop. The dimensions and tolerance of the source

gloss value for glass of any other refractive index can be

and receptor shall be as indicated in Table 1. The angular

computed from the Fresnel equation (5). For small differences

dimensions of the receptor field stop are measured from the

inrefractiveindex,however,theglossvalueisalinearfunction

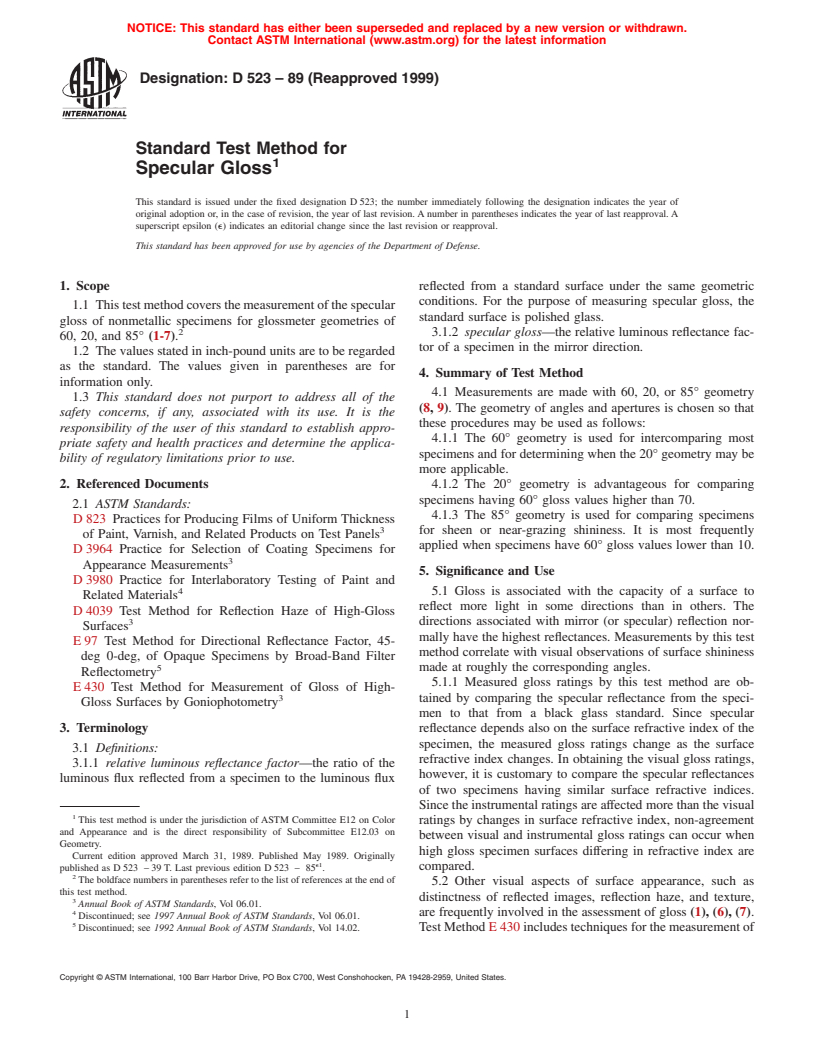

receptor lens in a collimated-beam-type instrument, as illus-

of index, but the rate of change of gloss with index is different

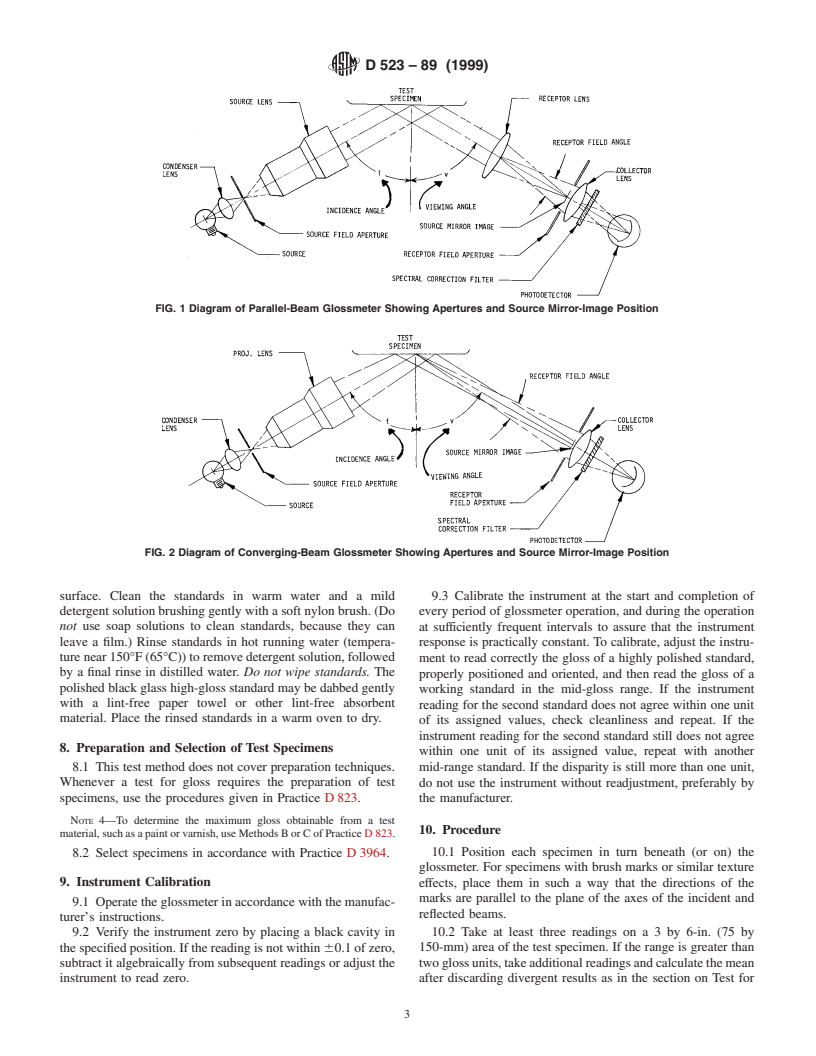

trated in Fig. 1, and from the test surface in a converging-

for each geometry. Each 0.001 increment in refractive index

beam-type instrument, as illustrated in Fig. 2. See Fig. 1 and

produces a change of 0.27, 0.16, and 0.016 in the gloss value

Fig. 2 for a generalized illustration of the dimensions. The

assigned to a polished standard for the 20, 60, and 85°

tolerances are chosen so that errors in the source and receptor

geometries, respectively. For example, glass of index 1.527

apertures do not produce an error of more than one gloss unit

would be assigned values of 89.2, 93.6, and 99.4, in order of

at any point on the scale (5).

increasing geometry.

NOTE 3—Polished black glass has been reported to change in refractive

index with time largely due to chemical contamination (10). The original

TABLE 1 Angles and Relative Dimensions of Source Image and

values can be restored by optical polishing with cerium oxide.Awedge of

Receptors

high-purity quartz provides a more stable reference standard than glass.

In Plane of Perpendicular to

Measurement Plane of Measurement

7.2 Working Standards—Ceramic tile, depolished ground

Relative Relative

opaque glass, emery paper, and other semigloss materials

u,° 2 tan u/2 u,° 2tan u/2

Dimension Dimension

having hard and uniform surfaces are suitable when calibrated

Source image 0.75 0.0131 0.171 2.5 0.0436 0.568

against a primary standard on a glossmeter known to meet the

Tolerance 6 0.25 0.0044 0.057 0.5 0.0087 0.114

requirements of this test method. Such standards should be

60° receptor 4.4 0.0768 1.000 11.7 0.2049 2.668 checked periodically for constancy by comparing with primary

Tolerance6 0.1 0.0018 0.023 0.2 0.0035 0.046

standards.

7.3 Store standards in a closed container when not in use.

20° receptor 1.8 0.0314 0.409 3.6 0.0629 0.819

Tolerance 6 0.05 0.0009 0.012 0.1 0.0018 0.023 Keep them clean and away from any dirt that might scratch or

mar their surfaces. Never place standards face down on a

85° receptor 4.0 0.0698 0.909 6.0 0.1048 1.365

surface that may be dirty or abrasive.Always hold standards at

Tolerance6 0.3 0.0052 0.068 0.3 0.0052 0.068

thesideedgestoavoidgettingoilfromtheskinonthestandard

D523–89 (1999)

FIG. 1 Diagram of Parallel-Beam Glossmeter Showing Apertures and Source Mirror-Image Position

FIG. 2 Diagram of Converging-Beam Glossmeter Showing Apertures and Source Mirror-Image Position

surface. Clean the standards in warm water and a mild 9.3 Calibrate the instrument at the start and completion of

detergent solution brushing gently with a soft nylon brush. (Do every period of glossmeter operation, and during the operation

not use soap solutions to clean standards, because they can

at sufficiently frequent intervals to assure that the instrument

leave a film.) Rinse standards in hot running water (tempera- response is practically constant. To calibrate, adjust the instru-

turenear150°F(65°C))toremovedetergentsolution,followed

ment to read correctly the gloss of a highly polished standard,

by a final rinse in distilled water. Do not wipe standards. The

properly positioned and oriented, and then read the gloss of a

polished black glass high-gloss standard may be dabbed gently

working standard in the mid-gloss range. If the instrument

with a lint-free paper towel or other lint-free absorbent

reading for the second standard does not agree within one unit

material. Place the rinsed standards in a warm oven to dry.

of its assigned values, check cleanliness and repeat. If the

instrument reading for the second standard still does not agree

8. Preparation and Selection of Test Specimens

within one unit of its assigned value, repeat with another

8.1 This test method does not cover preparation techniques. mid-range standard. If the disparity is still more than one unit,

Whenever a test for gloss requires the preparation of test do not use the instrument without readjustment, preferably by

specimens, use the procedures given in Practice D 823. the manufacturer.

NOTE 4—To determine the maximum gloss obtainable from a test

10. Procedure

material,suchasapaintorvarnish,useMethodsBorCofPracticeD 823.

10.1 Position each specimen in turn beneath (or on) the

8.2 Select specimens in accordance with Practice D 3964.

glossmeter. For specimens with brush marks or similar texture

9. Instrument Calibration

effects, place them in such a way that the directions of the

marks are parallel to the plane of the axes of the incident and

9.1 Operate the glossmeter in accordance with the manufac-

reflected beams.

turer’s instructions.

10.2 Take at least three readings ona3by 6-in. (75 by

9.2 Verify the instrument zero by placing a black cavity in

the specified position. If the reading is not within 60.1 of zero, 150-mm) area of the test specimen. If the range is greater than

twoglossunits,takeadditionalreadingsandcalculatethemean

subtract it algebraically from subsequent readings or adjust the

instrument to read zero. after discarding divergent results as in the section on Test for

D523–89 (1999)

Outliers of Practice D 3980. For larger specimens, take a 13. Precision

proportionately greater number of readings.

13.1 On the basis of studies of this test method by several

laboratories in which single determinations were made on

11. Diffuse Correction

different days on several ceramic tiles and painted panels

11.1 Apply diffuse corrections only upon agreement be-

differing in visually perceived gloss, the pooled within-

tween the producer and the user. To apply the correction,

laboratory and between-laboratories standard deviations were

subtract it from the glossmeter reading. To measure the

found to be those shown in Table 3. Based on these standard

correction, illuminate the specimen perpendicularly and view

deviations,thefollowingcriteriashouldbeusedforjudgingthe

at the incident angle with the receiver aperture specified in 6.2

acceptability of results at the 95 % confidence level:

for the corresponding geometry. To compute

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.