ASTM D3603-07

(Test Method)Standard Test Method for Rust-Preventing Characteristics of Steam Turbine Oil in the Presence of Water (Horizontal Disk Method)

Standard Test Method for Rust-Preventing Characteristics of Steam Turbine Oil in the Presence of Water (Horizontal Disk Method)

SIGNIFICANCE AND USE

Horizontal metal surfaces, on which water droplets tend to be retained, are more prone to rusting and corrosion than vertical or sloping surfaces. This test method is therefore more discriminating than Test Method D 665 (Procedure A), since it gives a separate evaluation of the oil on a horizontal and a vertical surface. The test method indicates the ability of oils to prevent rusting and corrosion of all ferrous surfaces in steam turbines under full flow and quasi-static conditions. It is used for specification of new oils.

SCOPE

1.1 This test method covers the ability of steam-turbine oils to prevent the rusting of horizontal and vertical ferrous surfaces when water becomes mixed with the oil.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3603 − 07

StandardTest Method for

Rust-Preventing Characteristics of Steam Turbine Oil in the

1

Presence of Water (Horizontal Disk Method)

This standard is issued under the fixed designation D3603; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope Plate, 19Cr - 9.2Ni

BS 970:Part 1:1983 Specification for wrought steels for

1.1 This test method covers the ability of steam-turbine oils

mechanical and allied engineering purposes. General in-

topreventtherustingofhorizontalandverticalferroussurfaces

spection and testing procedures and specific requirements

when water becomes mixed with the oil.

5

for carbon, carbon manganese, alloy and stainless steels

1.2 The values stated in SI units are to be regarded as

BS 871:1981 Specification for abrasive papers and cloths

standard. The values given in parentheses are for information

3. Summary of Test Method

only.

1.3 This standard does not purport to address all of the 3.1 The test method involves completely immersing a hori-

zontal steel disk and vertical steel cylinder in a stirred mixture

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- of 275 mL of the oil under test and 25 mL of distilled water

(water conforming to Specification D1193, Type II) at a

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. temperature at 60°C (140°F).

3.2 The horizontal specimen allows water to puddle on the

2. Referenced Documents

surface, and the vertical specimen is continually washed with

2

the oil-water mixture during the test.

2.1 ASTM Standards:

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

3.3 The test is run for 6 h and the specimens are evaluated.

Finished

A240/A240M Specification for Chromium and Chromium- 4. Significance and Use

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

4.1 Horizontal metal surfaces, on which water droplets tend

Vessels and for General Applications

to be retained, are more prone to rusting and corrosion than

D91 Test Method for Precipitation Number of Lubricating

vertical or sloping surfaces. This test method is therefore more

Oils

discriminating than Test Method D665 (Procedure A), since it

D665 Test Method for Rust-Preventing Characteristics of

gives a separate evaluation of the oil on a horizontal and a

Inhibited Mineral Oil in the Presence of Water

vertical surface. The test method indicates the ability of oils to

D1193 Specification for Reagent Water

prevent rusting and corrosion of all ferrous surfaces in steam

E1 Specification for ASTM Liquid-in-Glass Thermometers

turbines under full flow and quasi-static conditions. It is used

for specification of new oils.

2.2 Other Standards:

3

IP 60/80 Specification for Petroleum Spirit

5. Apparatus

SAE 30304 Steel, Corrosion-Resistant, Sheet, Strip, and

5.1 Oil Bath—A thermostatically controlled liquid bath

capable of maintaining a temperature in the oil sample of 60 6

1°C (140 6 2°F). The bath shall have a cover with holes to

1

This test method is under the jurisdiction of ASTM Committee D02 on

accommodate the test beakers.

Petroleum Products and Lubricantsand is the direct responsibility of D02.C0.02 on

Corrosion and Water/Air Separability.

NOTE 1—The bath used for Test Method D665 may be used with slight

Current edition approved May 1, 2007. Published May 2007. Originally

modification, that is, the centers of the beaker holes are moved from 6.4

approved in 1977. Last previous edition approved in 2002 as D3603–93(2002).

1 23

mm to 18.3 mm ( ⁄4 to ⁄32 in.) from the axes of the stirrers.

DOI: 10.1520/D3603-07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from SAE World Headquarters, 400 Commonwealth Drive,

the ASTM website. Warrendale, PA 15096-0001.

3 5

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, BSI, British Standards, 389 Chiswick High Road, London W4 4AL, United

U.K., http://www.energyinst.org.uk. Kingdom.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3603 − 07

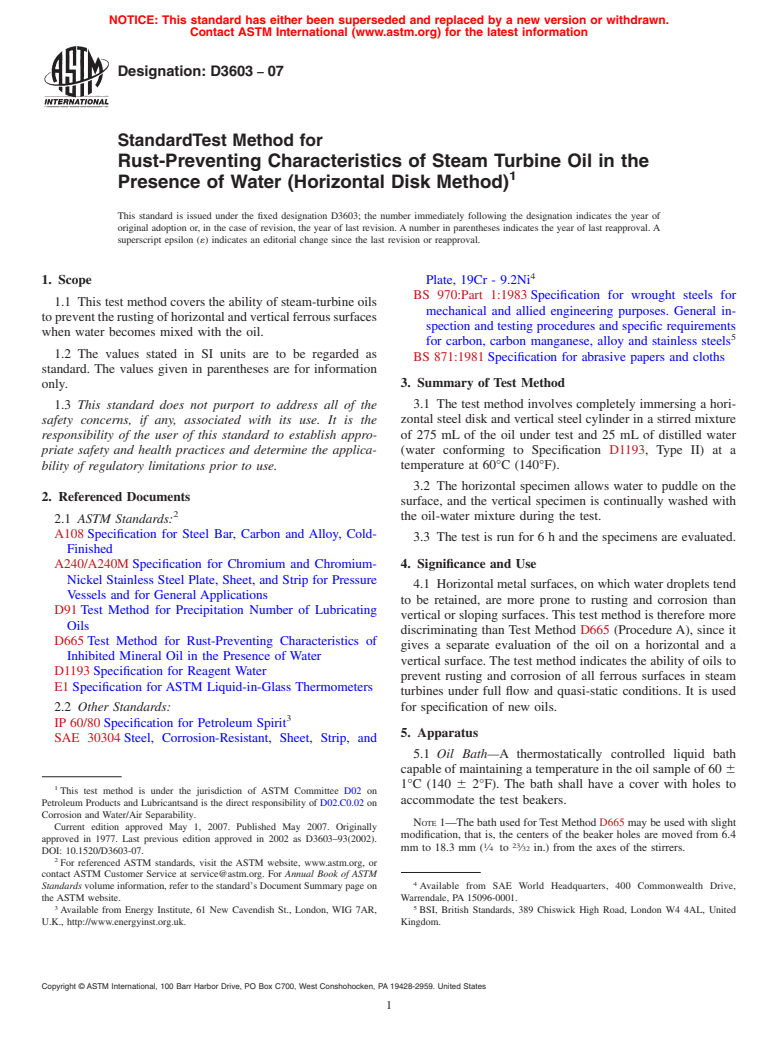

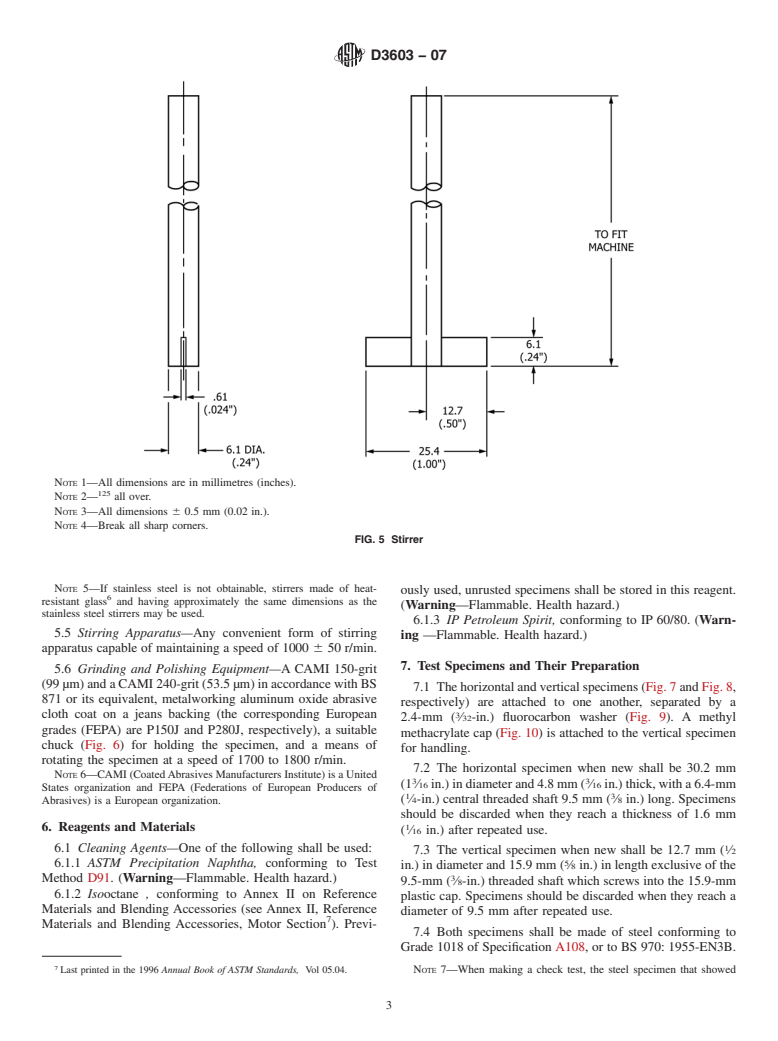

NOTE 1—All dimensions are in millimetres (inches).

NOTE 1—All dimensions are in millimetres (inches).

FIG. 2 Beaker Cover

FIG. 1 Rusting Test Apparatus

NOTE 2—To indicate the temperature, a thermometer conforming to the

requirem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.