ASTM D3489-96

(Test Method)Standard Test Methods for Rubber--Microcellular Urethane

Standard Test Methods for Rubber--Microcellular Urethane

SCOPE

1.1 These methods cover the preparation of a standard-size test sample and basic tests for physical property determinations of microcellular urethane rubber.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1- There is no similar or equivalent ISO standard to these test methods.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3489 – 96

Standard Test Methods for

Rubber—Microcellular Urethane

This standard is issued under the fixed designation D 3489; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1630 Test Method for Rubber Property—Abrasion Resis-

tance (Footwear Abrader)

1.1 These test methods cover the preparation of a standard-

D 1938 Test Method for Tear Propagation Resistance of

size test sample and basic tests for physical property determi-

Plastic Film and Thin Sheeting by a Single-Tear Method

nations of microcellular urethane rubber.

D 2240 Test Method for Rubber Property—Durometer

1.2 The values stated in SI units are to be regarded as the

Hardness

standard. The values given in parentheses are for information

D 2584 Test Method for Ignition Loss of Cured Reinforced

only.

Resins

1.3 This standard does not purport to address all of the

D 2632 Test Method for Rubber Property—Resilience by

safety concerns, if any, associated with its use. It is the

Vertical Rebound

responsibility of the user of this standard to establish appro-

D 3040 Practice for Preparing Precision Statements for

priate safety and health practices and determine the applica-

Standards Related to Rubber and Rubber Testing

bility of regulatory limitations prior to use.

D 3137 Test Method for Rubber Property—Hydrolytic Sta-

NOTE 1—There is no similar or equivalent ISO standard to these test 3

bility

methods.

D 3574 Test Methods for Flexible Cellular Materials—Slab,

Bonded, and Molded Urethane Foams

2. Referenced Documents

D 3768 Test Method for Microcellular Urethanes—Flexural

2.1 ASTM Standards:

Recovery

D 256 Test Method for Determining the Pendulum Impact

D 3769 Test Method for Microcellular Urethanes—High-

Resistance of Notched Specimens of Plastics

Temperature Sag

D 395 Test Methods for Rubber Property—Compression

Set

3. Terminology

D 412 Test Methods for Vulcanized Rubber and Thermo-

3.1 Description of Term Specific to This Standard:

plastic Rubbers and Thermoplastic Elastomers—

3.1.1 microcellular urethane—a rubber material made by

Tension

the interaction of a polyol and an organic isocyanate, having

D 573 Test Method for Rubber—Deterioration in an Air

cell diameters in the range from 0.0001 to 0.001 mm, with a

Oven

3 3

minimum density of 160 kg/m (10 lb/ft ).

D 575 Test Methods for Rubber Properties in Compression

D 624 Test Method for Tear Strength of Conventional

4. Significance and Use

Vulcanized Rubber and Thermoplastic Elastomers

4.1 Tests made on materials herein prescribed can be of

D 790 Test Methods for Flexural Properties of Unreinforced

considerable value in comparing physical properties of differ-

and Reinforced Plastics and Electrical Insulating Materi-

ent materials, in controlling manufacturing processes, and as a

als

basis for writing specifications.

D 1044 Test Method for Resistance of Transparent Plastics

4.2 Before proceeding with these test methods, reference

to Surface Abrasion

should be made to the specification of the material being tested.

D 1052 Test Method for Measuring Rubber Deterioration—

Any test specimen preparation, conditioning, or dimensions, or

Cut Growth Using Ross Flexing Apparatus

combination thereof, and testing parameters covered in the

materials specification shall take precedence over those men-

These test methods are under the jurisdiction of ASTM Committee D-20 on tioned in these test methods. If there are no material specifi-

Plastics and are the direct responsibility of Subcommittee D20.22 on Cellular

cations, then the default conditions apply.

Materials—Plastics and Elastomers.

Current edition approved July 10, 1996. Published September 1996. Originally

published as D 3489 – 76. Last previous edition D 3489 – 85 (1990).

This revision includes addition of the following: an ISO equivalency statement,

a material specifications statement, and a keywords section. Also, this revision now Annual Book of ASTM Standards, Vol 08.02.

references another ASTM test method for the Ash Test. Discontinued—see 1987 Annual Book of ASTM Standards, Vols 09.01 and

Annual Book of ASTM Standards, Vol 08.01. 09.02.

3 6

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 09.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

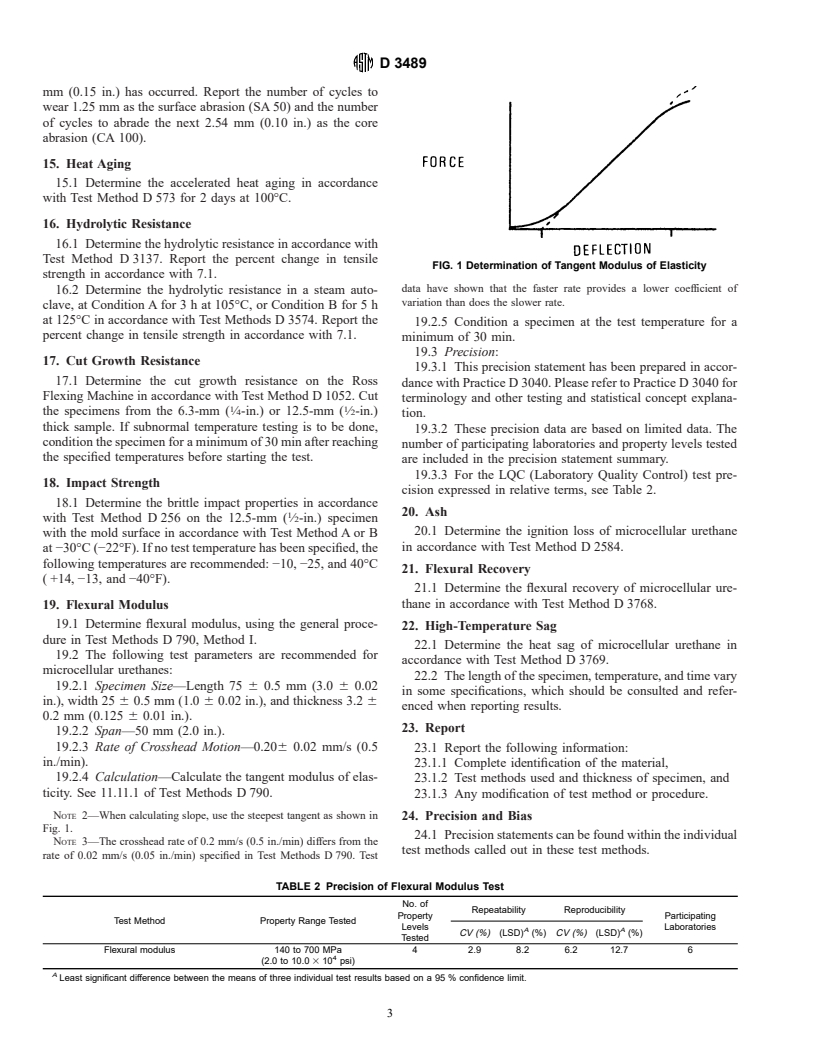

D 3489

5. Sampling ( ⁄8-in.) sample, retaining the molded surface.

8.2 Determine the split tear strength in accordance with Test

5.1 Test samples can be made in any suitable mold. The

Method D 1938. Cut the specimen from the 3.15-mm ( ⁄8-in.)

following three sizes are recommended (length, width, and

1 sample. The direction of tear shall include both molded

thickness): 305 by 152 by 3.15 mm (12 by 6 by ⁄8 in.), 305 by

surfaces.

152 by 6.3 mm (12 by 6 by ⁄4 in.), and 305 by 152 by 12.5 mm

1 8.3 Determine the block tear in accordance with Test

(12 by 6 by ⁄2 in.).

Methods D 3574, except the specimen shall be 19.0 mm (0.75

5.2 The procedure used to prepare the test sample relating to

in.) wide by 12.5 mm (0.5 in.) thick. The tear direction shall be

component ratios, temperature, mixing direction, mold tem-

through the core retaining both molded surfaces.

perature, and curing conditions shall conform to the manufac-

turer’s recommendations.

9. Hardness

5.3 The test sample shall be allowed to age a minimum of

9.1 Determine the hardness in accordance with Test Method

48 h before testing, at 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

D 2240 on the 6.3-mm ( ⁄4-in.) thick sample. Report the initial

relative humidity.

and 5-s drift value. If the determination is to be made at

6. Density

subnormal temperatures, condition the instrument at the same

6.1 Procedure—Section density can be determined on any temperature. To prevent moisture from damaging the instru-

thickness of molded material. The minimum specimen size ment, it is advisable to place the tester directly in a desiccator

3 3

shall be 8.19 cm (0.5 in. ). Weigh and measure the volume of after removing from the cold box.

the specimen. Calculate the density as follows:

10. Compression Set

W

Density, kg/m 5

10.1 Determine the compression set in accordance with Test

V

Methods D 395, Method B, using 22 h at 70°C (158°F). Cut the

where:

specimen from the 12.5-mm (0.5-in.) sample, retaining the

W 5 mass of specimen, kg, and

molded surfaces.

V 5 volume of specimen, m .

6.2 Report—Report the following information:

11. Compression Deflection

6.2.1 Density, to the nearest 1.6 kg/m , and

11.1 Determine the compression deflection at 25 % deflec-

6.2.2 Thickness.

tion in accordance with Test Methods D 575. Cut the specimen

from the 12.5-mm (0.5-in.) sample, retaining the molded

7. Tensile Properties

surfaces. The sample is not preflexed. The initial compression

7.1 Determine the tensile properties in accordance with Test

value is reported.

Methods D 412. Cut tension specimens using the Die A or any

other suitable die in accordance with Test Methods D 412 from

12. Resilience

1 1

the 3.15-mm ( ⁄8-in.) or 6.3-mm ( ⁄4-in.) test sample. Retain the

12.1 Determine the resilience by vertical rebound test in

molded surfaces.

accordance with Test Method D 2632. Cut the specimen from

7.2 Precision—These precision statements were prepared i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.