ASTM E155-10

(Specification)Standard Reference Radiographs for Inspection of Aluminum and Magnesium Castings

Standard Reference Radiographs for Inspection of Aluminum and Magnesium Castings

SIGNIFICANCE AND USE

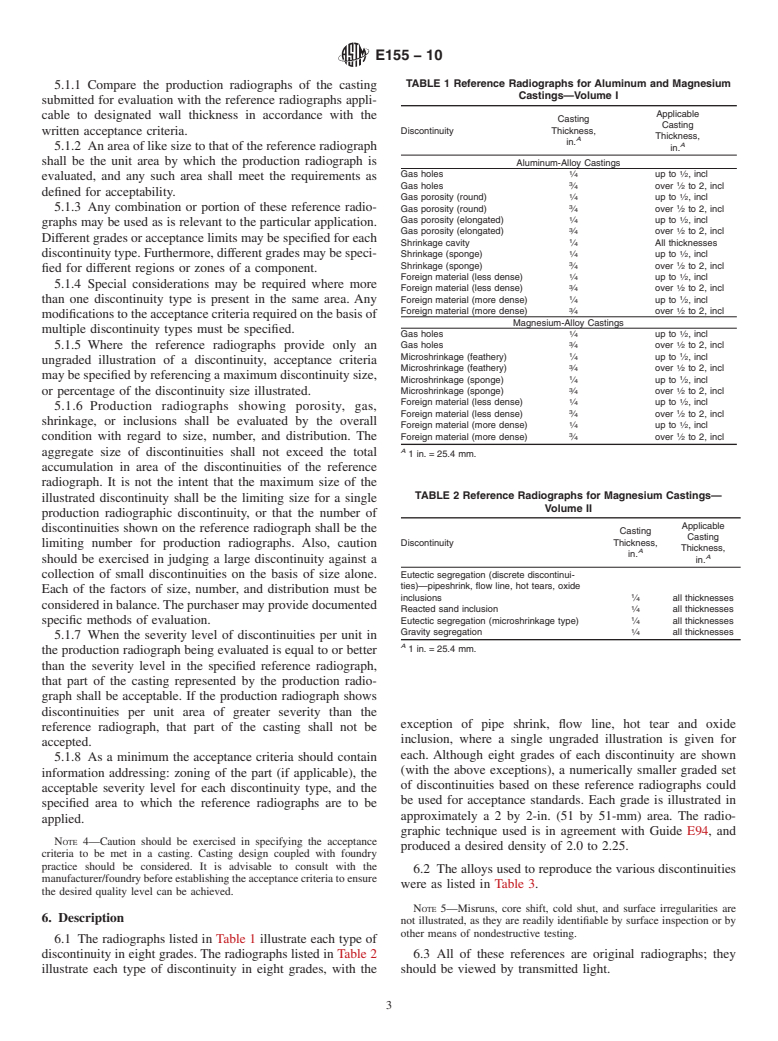

These radiographs are intended for reference only but are so designed that acceptance standards, which may be developed for particular requirements, can be specified in terms of these radiographs. The illustrations are radiographs of castings that were produced under conditions designed to develop the discontinuities. The radiographs of the 1/4-in. (6.35-mm) castings are intended to be used in the thickness range up to and including 1/2 in. (12.7 mm). The radiographs of the 3/4-in. (19.1-mm) castings are intended to be used in the thickness range of over 1/2 in. to and including 2 in. (51 mm). The grouping and system of designations are based on considerations of the best practical means of making these reference radiographs of the greatest possible value.

Film DeteriorationRadiographic films are subject to wear and tear from handling and use. The extent to which the image deteriorates over time is a function of storage conditions, care in handling and amount of use. Reference radiograph films are no exception and may exhibit a loss in image quality over time. The radiographs should therefore be periodically examined for signs of wear and tear, including scratches, abrasions, stains, and so forth. Any reference radiographs which show signs of excessive wear and tear which could influence the interpretation and use of the radiographs should be replaced.

SCOPE

1.1 These reference radiographs illustrate the types and degrees of discontinuities that may be found in aluminum-alloy and magnesium-alloy castings. The castings illustrated are in thicknesses of 1/4 in. (6.35 mm) and 3/4 in. (19.1 mm). The reference radiograph films are an adjunct to this document and must be purchased separately from ASTM International if needed.

1.2 These film reference radiographs are not intended to illustrate the types and degrees of discontinuities found in aluminum-alloy castings when performing digital radiography. If performing digital radiography of aluminum-alloy castings, refer to Digital Reference Image Standard E2422. Magnesium-alloy digital reference images are not currently available from ASTM International.

1.3 This document may be used where no other applicable document exists, for other material thicknesses for which it has been found to be applicable and for which agreement has been reached between the purchaser and the manufacturer.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—Vol I: The set of reference radiographs consists of 13 plates covering discontinuities in aluminum-alloy castings and 10 plates covering discontinuities in magnesium-alloy castings. Each plate is held in an 81/2 by 11-in. (216 by 279-mm) cardboard frame and each plate illustrates eight grades of severity for the discontinuity in approximately a 2 by 2-in. (51 by 51-mm) area. The cardboard frames are contained in a 101/2 by 111/2-in. (267 by 292-mm) ring binder. The reference radiographs are not impacted by this revision. There have been no revisions to the adjunct reference radiographs since original issue. The adjunct reference radiographs of any issue remain valid and may be used to this standard.

Vol. II: The set of reference radiographs consists of four plates covering discontinuities in magnesium-alloy castings only. Each plate is held in an 81/2 by 11-in. (216 by 279-mm) cardboard frame and illustrates eight grades of severity for the discontinuity (with the exception of discrete discontinuities, where only one example of each discontinuity is...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E155 − 10

StandardReference Radiographs for

1

Inspection of Aluminum and Magnesium Castings

This standard is issued under the fixed designation E155; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

These Reference Radiographs have been developed in cooperation with the Quality Control Committee and Aerospace Research and

Testing Committee of the Aerospace Industries Association.

This standard has been approved for use by agencies of the Department of Defense.

1

(51 by 51-mm) area. The cardboard frames are contained in a 10 ⁄2 by

1. Scope

1

11 ⁄2-in. (267 by 292-mm) ring binder. The reference radiographs are not

1.1 These reference radiographs illustrate the types and

impacted by this revision. There have been no revisions to the adjunct

degreesofdiscontinuitiesthatmaybefoundinaluminum-alloy reference radiographs since original issue. The adjunct reference radio-

graphs of any issue remain valid and may be used to this standard.

and magnesium-alloy castings. The castings illustrated are in

Vol.II:Thesetofreferenceradiographsconsistsoffourplatescovering

1 3

thicknesses of ⁄4 in. (6.35 mm) and ⁄4 in. (19.1 mm). The

discontinuities in magnesium-alloy castings only. Each plate is held in an

reference radiograph films are an adjunct to this document and

1

8 ⁄2 by 11-in. (216 by 279-mm) cardboard frame and illustrates eight

must be purchased separately from ASTM International if

grades of severity for the discontinuity (with the exception of discrete

needed. discontinuities, where only one example of each discontinuity is given).

NOTE 2—Reference radiographs applicable to aluminum and magne-

1.2 These film reference radiographs are not intended to

sium die castings up to 1 in. (25 mm) in thickness are contained in

illustrate the types and degrees of discontinuities found in

Reference Radiographs E505.

aluminum-alloy castings when performing digital radiography.

2. Referenced Documents

If performing digital radiography of aluminum-alloy castings,

2

refer to Digital Reference Image Standard E2422. Magnesium-

2.1 ASTM Standards:

alloy digital reference images are not currently available from

E94 Guide for Radiographic Examination

ASTM International.

E505 Reference Radiographs for Inspection of Aluminum

and Magnesium Die Castings

1.3 This document may be used where no other applicable

E1316 Terminology for Nondestructive Examinations

document exists, for other material thicknesses for which it has

E2422 Digital Reference Images for Inspection of Alumi-

been found to be applicable and for which agreement has been

num Castings

reached between the purchaser and the manufacturer.

2.2 ASTM Adjuncts:

1.4 The values stated in inch-pound units are to be regarded

Reference Radiographs for Inspection of Aluminum and

asthestandard.Thevaluesgiveninparenthesesaremathemati-

Magnesium Castings:

cal conversions to SI units that are provided for information 3

Volume I, Aluminum and Magnesium Castings

only and are not considered standard.

4

Volume II, Magnesium Castings

1.5 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 Definitions—Definitions of terms used in this standard

priate safety and health practices and determine the applica-

may be found in Terminology E1316.

bility of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 The terms relating to discontinuities used in these

NOTE 1—Vol I: The set of reference radiographs consists of 13 plates

reference radiographs are described based upon radiographic

covering discontinuities in aluminum-alloy castings and 10 plates cover-

ing discontinuities in magnesium-alloy castings. Each plate is held in an

appearance.

1

8 ⁄2 by 11-in. (216 by 279-mm) cardboard frame and each plate illustrates

eight grades of severity for the discontinuity in approximatelya2by 2-in.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

These reference radiographs are under the jurisdiction of ASTM Committee Standards volume information, refer to the standard’s Document Summary page on

E07 on Nondestructive Testing and are the direct responsibility of Subcommittee the ASTM website.

3

E07.02 on Reference Radiological Images. Available from ASTM International Headquarters. Order Reference Radio-

Current edition approved Sept. 1, 2010. Published September 2010. Originally graph No. ADJE015501.

4

approved in 1960.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E155–05 Designation:E155–10

Standard Reference Radiographs for

1

Inspection of Aluminum and Magnesium Castings

This standard is issued under the fixed designation E155; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

These Reference Radiographs have been developed in cooperation with the Quality Control Committee and Aerospace Research and

Testing Committee of the Aerospace Industries Association.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 These reference radiographs illustrate the types and degrees of discontinuities that may be found in aluminum-alloy and

1 3

magnesium-alloy castings. The castings illustrated are in thicknesses of ⁄4 in. [6.35 mm](6.35 mm) and ⁄4 in. [19.1 mm].(19.1

mm). The reference radiograph films are an adjunct to this document and must be purchased separately fromASTM International

if needed.

1.2 These film reference radiographs are not intended to illustrate the types and degrees of discontinuities found in

aluminum-alloy castings when performing digital radiography. If performing digital radiography of aluminum-alloy castings, refer

to Digital RefererenceReference Image Standard E2422. Magnesium-alloy digital reference images are not currently available

from ASTM International.

1.3 This document may be used where no other applicable document exists, for other material thicknesses for which it has been

found to be applicable and for which agreement has been reached between the purchaser and the manufacturer.

1.4The values stated in inch-pound units are to be regarded as the standard.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—Vol I: The set of reference radiographs consists of 13 plates covering discontinuities in aluminum-alloy castings and 10 plates covering

1

discontinuities in magnesium-alloy castings. Each plate is held in an 8 ⁄2 by 11-in. [216(216 by 279-mm]279-mm) cardboard frame and each plate

illustrates eight grades of severity for the discontinuity in approximately a 2 by 2-in. [51(51 by 51-mm]51-mm) area. The cardboard frames are contained

1 1

ina10 ⁄2 by 11 ⁄2-in. [267 by 292-mm] ring binder. -in. (267 by 292-mm) ring binder. The reference radiographs are not impacted by this revision. There

have been no revisions to the adjunct reference radiographs since original issue. The adjunct reference radiographs of any issue remain valid and may

be used to this standard.

1

Vol. II: The set of reference radiographs consists of four plates covering discontinuities in magnesium-alloy castings only. Each plate is held in an 8 ⁄2

by 11-in. [216(216 by 279-mm]279-mm) cardboard frame and illustrates eight grades of severity for the discontinuity (with the exception of discrete

discontinuities, where only one example of each discontinuity is given).

NOTE 2—Reference radiographs applicable to aluminum and magnesium die castings up to 1 in. [25 mm](25 mm) in thickness are contained in

Reference Radiographs E505.

2. Referenced Documents

2

2.1 ASTM Standards:

E94 Guide for Radiographic Examination

E505 Reference Radiographs for Inspection of Aluminum and Magnesium Die Castings

E1316 Terminology for Nondestructive Examinations

E2422 Digital Reference Images for Inspection of Aluminum Castings

1

These reference radiographs are under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and are the direct responsibility of Subcommittee E07.02

on Reference Radiographs.

´1

Current edition approved Nov. 15, 2005. Published December 2005. Originally approved in 1960. Last previous edition approved in 2005 as E155-00(2005) . DOI:

10.1520/E0155-05.on Reference Radiological Images.

Current edition approved Sept. 1, 2010. Published September 2010. Originally approved in 1960. Last previous edition approved in 2005 as E155 - 05. DOI:

10.1520/E0155-10.

2

For referencedASTM standard

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.