ASTM D1000-09

(Test Method)Standard Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

Standard Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

SCOPE

1.1 These test methods cover procedures for testing pressure-sensitive adhesive-coated tapes to be used as electrical insulation. These tapes are classified as follows:

1.1.1 Class 1—Non-elastomeric backings made from materials such as:

Paper, flat or creped, Fabric, uncoated or coated, Cellulose ester films, Polyethylene terephthalate (polyester) films, Fluorocarbon polymer films, Composite filament films, Polyamide films, Polyimide films, and Combinations thereof.

1.1.2 Class 2—Elastomeric backings that are characterized by both high stretch and substantial recovery. These backings are made from materials such as:

Vinyl chloride and co-polymers, Vinylidene chloride and co-polymers, and Polyethylene and co-polymers.

1.2 Laminates of Class 1 and Class 2 backings should be tested according to Class 1 test methods.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards see Section 3.

1.4 The procedures appear in the sections indicated below and in alphabetical order:

Adhesion Strength to Steel and Backing at Room Temperature46-53 Adhesion Strength to Steel and Backing at Low Temperatures46-53 Bond Strength After Solvent Immersion110-115 Breaking Strength and Elongation at Room Temperature37-45 Breaking Strength and Elongation at Low Temperatures37-45 Conditioning6-8 Curling and Twisting140-146 Dielectric Breakdown Voltage83-90 Effect of Accelerated Aging on High-Temperature Tapes97-103 Flagging66-76 Flammability104-109 Hazards/Precautions3 Insulation Resistance at High Humidity91-96 Length of Tape in a Roll28-36 Oil Resistance116-122 Puncture Resistance123-128 Resistance to Accelerated Aging (Heat and Moisture)129-139 Sampling4 Specimen Preparation5 Thermosetting Properties77-82 Thickness21-27 Unwind Force at Room Temperature54-65 Unwind Force at Low Temperatures54-65 Width11-20

Note 1—These procedures apply to both Class 1 and Class 2 tapes except as noted above.

1.5 The values stated in SI units are the standard, unless otherwise noted. If a value for measurement is followed by a value in inch-pound or English units in parentheses, the second value may only be approximate and is for information only. The first stated value is the preferred unit.

Note 2—These test methods are similar to IEC 60454–3, but may differ sometimes in some details.

1.6 This is a fire–test response standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation:D1000–09

Standard Test Methods for

Pressure-Sensitive Adhesive-Coated Tapes Used for

1

Electrical and Electronic Applications

This standard is issued under the fixed designation D1000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

Curling and Twisting 140-146

Dielectric Breakdown Voltage 83-90

1.1 These test methods cover procedures for testing

Effect of Accelerated Aging on High-Temperature Tapes 97-103

pressure-sensitive adhesive-coated tapes to be used as electri-

Flagging 66-76

Flammability 104-109

cal insulation. These tapes are classified as follows:

Hazards/Precautions 3

1.1.1 Class 1—Non-elastomeric backings made from mate-

Insulation Resistance at High Humidity 91-96

rials such as:

Length of Tape in a Roll 28-36

Oil Resistance 116-122

Paper, flat or creped,

Puncture Resistance 123-128

Fabric, uncoated or coated,

Resistance to Accelerated Aging (Heat and Moisture) 129-139

Cellulose ester films,

Sampling 4

Polyethylene terephthalate (polyester) films,

Specimen Preparation 5

Fluorocarbon polymer films,

Thermosetting Properties 77-82

Composite filament films,

Thickness 21-27

Polyamide films,

Unwind Force at Room Temperature 54-65

Polyimide films, and

Unwind Force at Low Temperatures 54-65

Combinations thereof.

Width 11-20

NOTE 1—These procedures apply to both Class 1 and Class 2 tapes

1.1.2 Class 2—Elastomeric backings that are characterized

except as noted above.

by both high stretch and substantial recovery. These backings

1.5 The values stated in SI units are the standard, unless

are made from materials such as:

otherwise noted. If a value for measurement is followed by a

Vinyl chloride and co-polymers,

value in inch-pound or English units in parentheses, the second

Vinylidene chloride and co-polymers, and

Polyethylene and co-polymers.

value may only be approximate and is for information only.

The first stated value is the preferred unit.

1.2 Laminates of Class 1 and Class 2 backings should be

tested according to Class 1 test methods.

NOTE 2—ThesetestmethodsaresimilartoIEC60454–3,butmaydiffer

1.3 This standard does not purport to address all of the

sometimes in some details.

safety concerns, if any, associated with its use. It is the

1.6 This is a fire–test response standard.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

2. Referenced Documents

bility of regulatory limitations prior to use.Forspecifichazards 2

2.1 ASTM Standards:

see Section 3.

A167 Specification for Stainless and Heat-Resisting

1.4 The procedures appear in the sections indicated below

Chromium-Nickel Steel Plate, Sheet, and Strip

and in alphabetical order:

D149 Test Method for Dielectric Breakdown Voltage and

Adhesion Strength to Steel and Backing at Room Temperature 46-53

Dielectric Strength of Solid Electrical Insulating Materials

Adhesion Strength to Steel and Backing at Low Temperatures 46-53

at Commercial Power Frequencies

Bond Strength After Solvent Immersion 110-115

Breaking Strength and Elongation at Room Temperature 37-45 D257 Test Methods for DC Resistance or Conductance of

Breaking Strength and Elongation at Low Temperatures 37-45

Insulating Materials

Conditioning 6-8

D295 Test Methods for Varnished Cotton Fabrics Used for

Electrical Insulation

1

These test methods are under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and are the direct responsibility of

2

Subcommittee D09.07 on Flexible and Rigid Insulating Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 15, 2009. Published November 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

´1

approved in 1948. Last previous edition approved in 2004 as D1000 – 04 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1000-09. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1000–09

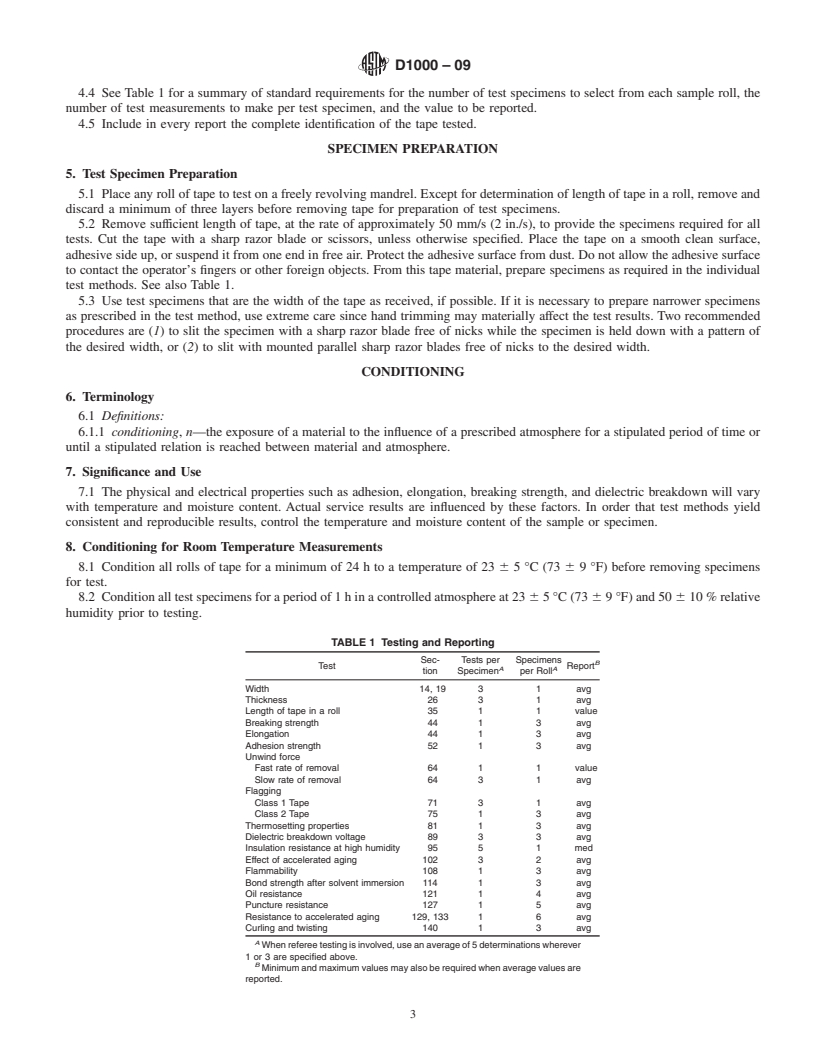

D374 Test Methods for Thickness of Solid Electrical Insu- 4.4 See Table 1 for a summary of standard requirements for

lation the number of test specimens to select from each sample roll,

D1711 Terminology Relating to Electrical Insulation the number of test measurements to make per test specimen

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D1000–04 Designation:D1000–09

Standard Test Methods for

Pressure-Sensitive Adhesive-Coated Tapes Used for

1

Electrical and Electronic Applications

This standard is issued under the fixed designation D1000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Updated research report information in Footnote 6 editorially in October 2008.

1. Scope*

1.1 These test methods cover procedures for testing pressure-sensitive adhesive-coated tapes to be used as electrical insulation.

These tapes are classified as follows:

1.1.1 Class 1—Non-elastomeric backings made from materials such as:

Paper, flat or creped,

Fabric, uncoated or coated,

Cellulose ester films,

Polyethylene terephthalate (polyester) films,

Fluorocarbon polymer films,

Composite filament films,

Polyamide films,

Polyimide films, and

Combinations thereof.

1.1.2 Class 2—Elastomeric backings that are characterized by both high stretch and substantial recovery. These backings are

made from materials such as:

Vinyl chloride and co-polymers,

Vinylidene chloride and co-polymers, and

Polyethylene and co-polymers.

1.2 Laminates of Class 1 and Class 2 backings should be tested according to Class 1 test methods.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazards see Section 3.

1.4 The procedures appear in the sections indicated below and in alphabetical order:

Adhesion Strength to Steel and Backing at Room Temperature 46-53

Adhesion Strength to Steel and Backing at Low Temperatures 46-53

Bond Strength After Solvent Immersion 110-115

Breaking Strength and Elongation at Room Temperature 37-45

Breaking Strength and Elongation at Low Temperatures 37-45

Conditioning 6-8

Curling and Twisting 140-146

Dielectric Breakdown Voltage 83-90

Effect of Accelerated Aging on High-Temperature Tapes 97-103

Flagging 66-76

Flammability 104-109

Hazards/Precautions 3

Insulation Resistance at High Humidity 91-96

Length of Tape in a Roll 28-36

Oil Resistance 116-122

Puncture Resistance 123-128

1

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD09onElectricalandElectronicInsulatingMaterialsandarethedirectresponsibilityofSubcommittee

D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved Sept. 1, 2004. Published September 2004. Originally approved in 1948. Last previous edition approved in 1999 as D1000–99. DOI:

10.1520/D1000-04E01.

´1

Current edition approved Oct. 15, 2009. Published November 2009. Originally approved in 1948. Last previous edition approved in 2004 as D1000 – 04 . DOI:

10.1520/D1000-09.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1000–09

Resistance to Accelerated Aging (Heat and Moisture) 129-139

Sampling 4

Specimen Preparation 5

Thermosetting Properties 77-82

Thickness 21-27

Unwind Force at Room Temperature 54-65

Unwind Force at Low Temperatures 54-65

Width 11-20

NOTE 1—These procedures apply to both Class 1 and Class 2 tapes except as noted above.

1.5 The values stated in SI units are the standard, unless otherwise noted. If a value for measurement is followed by a value

in inch-pound or English units in parentheses, the second value may only be approximate and is for information only. The first

stated value is the preferred unit.

NOTE 2—These test methods are similar to IEC 60454–3, but may differ sometimes in some details.

1.6 This is a fire–test response standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A167 Specification for Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet, and Strip

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D295 Test Methods for Varnished Cotton Fabrics Used for Electrical Insulatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.