ASTM C680-89(2002)

(Practice)Standard Practice for Determination of Heat Gain or Loss and the Surface Temperatures of Insulated Pipe and Equipment Systems by the Use of a Computer Program

Standard Practice for Determination of Heat Gain or Loss and the Surface Temperatures of Insulated Pipe and Equipment Systems by the Use of a Computer Program

SCOPE

1.1 The computer programs included in this practice provide a calculational procedure for predicting the heat loss or gain and surface temperatures of insulated pipe or equipment systems. This procedure is based upon an assumption of a uniform insulation system structure, that is, a straight run of pipe or flat wall section insulated with a uniform density insulation. Questions of applicability to real systems should be resolved by qualified personnel familiar with insulation systems design and analysis. In addition to applicability, calculational accuracy is also limited by the range and quality of the physical property data for the insulation materials and systems.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 680 – 89 (Reapproved 2002)

Standard Practice for

Determination of Heat Gain or Loss and the Surface

Temperatures of Insulated Pipe and Equipment Systems by

the Use of a Computer Program

This standard is issued under the fixed designation C 680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope X3.5 Flow Chart Symbols and Their Usage in Information

Processing

1.1 The computer programs included in this practice pro-

X3.9 Standard for Fortran Programming Language

vide a calculational procedure for predicting the heat loss or

gain and surface temperatures of insulated pipe or equipment

3. Terminology

systems. This procedure is based upon an assumption of a

3.1 Definitions—For definitions of terms used in this prac-

uniform insulation system structure, that is, a straight run of

tice, refer to Terminology C 168.

pipe or flat wall section insulated with a uniform density

3.2 Symbols:Symbols—The following symbols are used in

insulation. Questions of applicability to real systems should be

the development of the equations for this practice. Other

resolved by qualified personnel familiar with insulation sys-

symbols will be introduced and defined in the detailed descrip-

tems design and analysis. In addition to applicability, calcula-

tion of the development.

tional accuracy is also limited by the range and quality of the

physical property data for the insulation materials and systems.

where:

1.2 This standard does not purport to address all of the 2 2

h = surface coefficient, Btu/(h·ft ·°F) (W/(m ·K))

safety concerns, if any, associated with its use. It is the

k = thermal conductivity, Btu·in./(h·ft ·°F)(W/(m·K))

responsibility of the user of this standard to establish appro-

k = constant equivalent thermal conductivity introduced

a

priate safety and health practices and determine the applica-

by the Kirchhoff transformation, Btu·in./(h·ft ·F)

bility of regulatory limitations prior to use.

(W/(m·K))

Q = total time rate of heat flow, Btu/h (W)

t

2. Referenced Documents

Q = time rate of heat flow per unit length, Btu/h·ft (W/m)

l

2.1 ASTM Standards:

q = time rate of heat flow per unit area, Btu/(h·ft )

2 2

C 168 Terminology Relating to Thermal Insulation (W/m )

2 2

C 177 Test Method for Steady-State Heat Flux Measure- R = thermal resistance, (°F·h·ft )/Btu (K·m /W)

r = radius, in. (m)

ments and Thermal Transmission Properties by Means of

t = local temperature, °F (K)

the Guarded Hot Plate Apparatus

t = temperature of inner surface of the insulation, °F (K)

i

C 335 Test Method for Steady-State Heat Transfer Proper-

t = temperature of ambient fluid and surroundings, °F

a

ties of Horizontal Pipe Insulation

(K)

C 518 Test Method for Steady-State Heat Flux Measure-

x = distance in direction of heat flow (thickness), in. (m)

ments and Thermal Transmission Properties by Means of

the Heat Flow Meter Apparatus

C 585 Practice for Inner and Outer Diameters of Rigid

4. Summary of Practice

Thermal Insulation for Nominal Sizes of Pipe and Tubing

2 4.1 The procedures used in this practice are based upon

(NPS System)

standard steady-state heat transfer theory as outlined in text-

E 691 Practice for Conducting an Interlaboratory Study to

3 books and handbooks. The computer program combines the

Determine the Precision of a Test Method

functions of data input, analysis, and data output into an

2.2 ANSI Standards:

easy-to-use, interactive computer program. By making the

program interactive, little operator training is needed to per-

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

form fast, accurate calculations.

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

4.2 The operation of the computer program follows the

Measurement.

Current edition approved Jan. 27, 1989. Published May 1989. Originally

e1

published as C 680 – 71. Last previous edition C 680 – 82 .

2 4

Annual Book of ASTM Standards, Vol 04.06. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Annual Book of ASTM Standards, Vol 14.02. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 680 – 89 (2002)

procedure listed below: this change is generally continuous and can be mathematically

4.2.1 Data Input—The computer requests and the operator

approximated. In the cryogenic region where one or more

inserts information that describes the system and operating components of the air condense, a more detailed mathematical

environment. The data include:

treatment may be required. For those insulations that depend

4.2.1.1 Analysis Identification. on high molecular weight, that is, fluorinated hydrocarbons, for

4.2.1.2 Date.

their insulating effectiveness, gas condensation will occur at

4.2.1.3 Ambient Temperature. higher temperatures and produce sharp changes of conductivity

4.2.1.4 Surface coefficient or ambient wind speed, insula-

in the moderate temperature range. For this reason, it is

tion system surface emittance, and orientation.

necessary to consider the temperature conductivity dependence

4.2.1.5 System Description—Layer number, material, and

of an insulation system when calculating thermal performance.

thicknesses.

The use of a single value thermal conductivity at the mean

4.2.2 Analysis—Once input data is entered, the program

temperature will provide less accurate predictions, especially

calculates the surface coefficients (if not entered directly) and

when bridging regions where strong temperature dependence

the layer resistances, then uses that data to calculate the heat

occurs.

losses and surface temperatures. The program continues to

5.6 The use of this practice by both manufacturers and users

repeat the analysis using the previous temperature data to

of thermal insulations will provide standardized engineering

update the estimates of layer resistance until the temperatures

data of sufficient accuracy for predicting thermal insulation

at each surface repeat with a specified tolerance.

performance.

4.2.3 Once convergence of the temperatures is reached, the

5.7 Computers are now readily available to most producers

program prints a table giving the input data, the resulting heat

and consumers of thermal insulation to permit the use of this

flows, and the inner surface and external surface temperatures.

practice.

5. Significance and Use

5.8 Two separate computer programs are described in this

practice as a guide for calculation of the heat loss or gain, and

5.1 Manufacturers of thermal insulations express the perfor-

surface temperatures, of insulated pipe and equipment systems.

mance of their products in charts and tables showing heat gain

The range of application of these programs and the reliability

or loss per lineal foot of pipe or square foot of equipment

of the output is a primary function of the range and quality of

surface. These data are presented for typical operating tem-

the input data. Both programs are intended for use with an

peratures, pipe sizes, and surface orientations (facing up, down,

“interactive” terminal. With this system, intermediate output

or horizontal) for several insulation thicknesses. The insulation

guides the user to make programming adjustments to the input

surface temperature is often shown for each condition, to

parameters as necessary. The computer controls the terminal

provide the user with information on personnel protection or

interactively with program-generated instructions and ques-

surface condensation. Additional information on effects of

wind velocity, jacket emittance, and ambient conditions may tions, prompting user response. This facilitates problem solu-

tion and increases the probability of successful computer runs.

also be required to properly select an insulation system. Due to

the infinite combinations of size, temperature, humidity, thick-

5.8.1 Program C 608E is designed for an interactive solu-

ness, jacket properties, surface emittance, orientation, ambient

tion of equipment heat transfer problems.

conditions, etc., it is not practical to publish data for each

5.8.2 Program C 608P is designed for interactive solution of

possible case.

piping-system problems. The subroutine SELECT has been

5.2 Users of thermal insulation, faced with the problem of

written to provide input for the nominal iron pipe sizes as

designing large systems of insulated piping and equipment,

shown in Practice C 585, Tables 1 and 3. The use of this

encounter substantial engineering costs to obtain the required

program for tubing-systems problems is possible by rewriting

thermal information. This cost can be substantially reduced by

subroutine SELECT such that the tabular data contain the

both the use of accurate engineering data tables, or by the use

appropriate data for tubing rather than piping systems (Practice

of available computer analysis tools, or both.

C 585, Tables 2 and 4).

5.3 The use of analysis procedures described in this practice

5.8.3 Combinations of the two programs are possible by

can also apply to existing systems. For example, C 680 is

using an initial selector program that would select the option

referenced for use with Procedures C 1057 and C 1055 for burn

being used and elimination of one of the k curve and surface

hazard evaluation for heated surfaces. Infrared inspection or in

coefficient subroutines that are identical in each program.

situ heat flux measurements are often used in conjunction with

5.8.4 These programs are designed to obtain results identi-

C 680 to evaluate insulation system performance and durability

cal to the previous batch program of the 1971 edition of this

on operating systems. This type analysis is often made prior to

practice. The only major changes are the use of an interactive

system upgrades or replacements.

terminal and the addition of a subroutine for calculating surface

5.4 The calculation of heat loss or gain and surface tem-

coefficient.

perature of an insulated system is mathematically complex and

because of the iterative nature of the method, is best handled by 5.9 The user of this practice may wish to modify the data

computers. input and report sections of the computer program presented

5.5 The thermal conductivity of most insulating materials here to fit individual needs. Also, additional calculations may

changes with mean temperature. Since most thermal insulating be desired to include other data such as system costs or

materials rely on enclosed air spaces for their effectiveness, economic thickness. No conflict with this method in making

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 680 – 89 (2002)

these modifications exists, provided that the user has demon- composite (multiple-layer) cases and supplemented with pro-

strated compatibility. Compatibility is demonstrated using a vision for heat flow from the outer surface by convection or

series of test cases covering the range for which the new radiation, or both.

method is to be used. For those cases, results for the heat flow 6.3 Equations—Case 1, Slab Insulation:

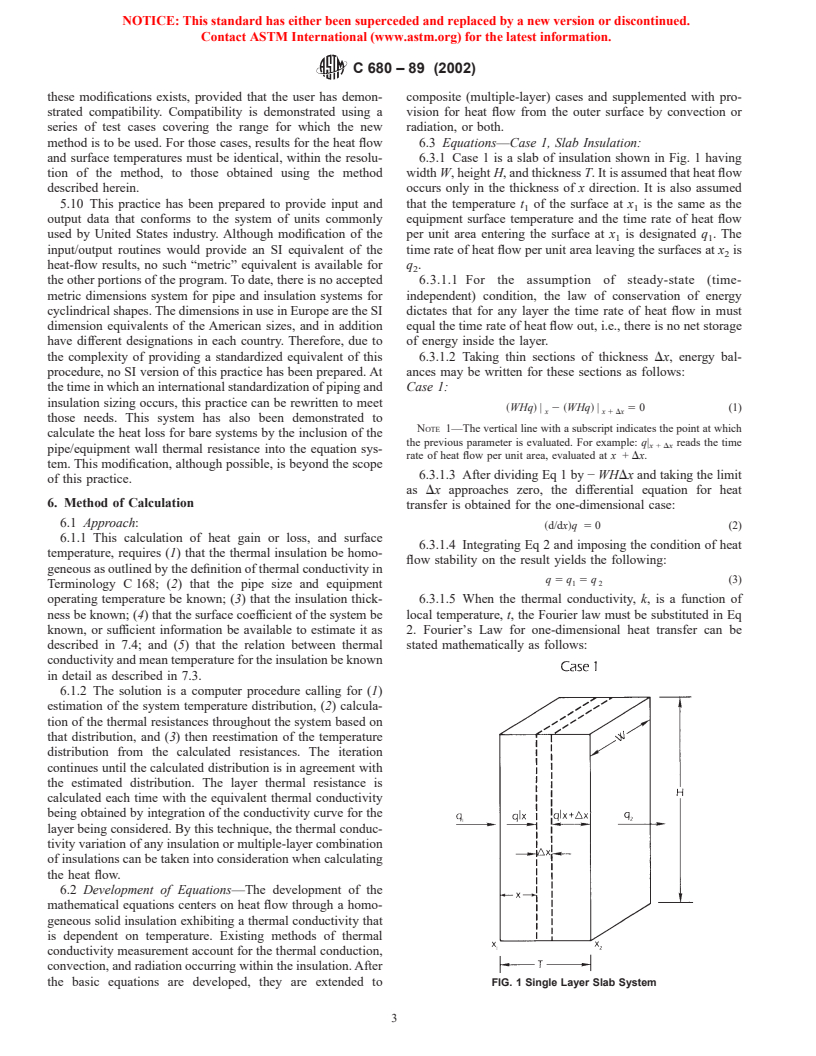

and surface temperatures must be identical, within the resolu- 6.3.1 Case 1 is a slab of insulation shown in Fig. 1 having

tion of the method, to those obtained using the method width W, height H, and thickness T. It is assumed that heat flow

described herein. occurs only in the thickness of x direction. It is also assumed

5.10 This practice has been prepared to provide input and that the temperature t of the surface at x is the same as the

1 1

output data that conforms to the system of units commonly equipment surface temperature and the time rate of heat flow

used by United States industry. Although modification of the per unit area entering the surface at x is designated q . The

1 1

input/output routines would provide an SI equivalent of the time rate of heat flow per unit area leaving the surfaces at x is

heat-flow results, no such “metric” equivalent is available for q .

the other portions of the program. To date, there is no accepted 6.3.1.1 For the assumption of steady-state (time-

metric dimensions system for pipe and insulation systems for independent) condition, the law of conservation of energy

cyclindrical shapes. The dimensions in use in Europe are the SI dictates that for any layer the time rate of heat flow in must

dimension equivalents of the American sizes, and in addition equal the time rate of heat flow out, i.e., there is no net storage

have different designations in each country. Therefore, due to of energy inside the layer.

the complexity of providing a standardized equivalent of this 6.3.1.2 Taking thin sections of thickness Dx, energy bal-

procedure, no SI version of this practice has been prepared. At ances may be written for these sections as follows:

the time in which an international standardization of piping and Case 1:

insulation sizing occurs, this practice can be rewritten to meet

~WHq! | 2 ~WHq! | 5 0 (1)

x x1Dx

those needs. This system has also been demonstrated to

NOTE 1—The vertical line with a subscript indicates the point at which

calculate the heat loss for bare systems by the inclusion of the

the previous parameter is evaluated. For example: q| reads the time

x+ Dx

pipe/equipment wall thermal resistance into the equation sys-

rate of heat flow per unit area, evaluated at x + Dx.

tem. This modification, although possible, is beyond the scope

6.3.1.3 After dividing Eq 1 by − WHDx and taking the limit

of this practice.

as Dx approaches zero, the differential equation for heat

6. Method of Calculation

transfer is obtained for the one-dimensional case:

6.1 Approach:

~d/dx!q 5 0 (2)

6.1.1 This calculation of heat gain or loss, and surface

6.3.1.4 Integrating Eq 2 and imposing the condition of heat

temperature, requires (1) that the thermal insulation be homo-

flow stability on the result yields the following:

geneous as outlined by the definition of thermal conductivity in

q 5 q 5 q (3)

1 2

Terminology C 168; (2) that the pipe size and equipment

operating temperature be known; (3) that the insulation thick- 6.3.1.5 When the thermal conductivity, k, is a function of

ness be known; (4) that the surface coefficient of the system be

local

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.