ASTM B367-93(2004)

(Specification)Standard Specification for Titanium and Titanium Alloy Castings

Standard Specification for Titanium and Titanium Alloy Castings

SCOPE

1.1 This specification covers titanium and titanium alloy castings intended for general corrosion resistant and industrial applications.

1.2 This specification is intended for use of purchasers and/or producers of reactive metal castings for defining the requirements and assuring the properties of castings for unique corrosion-resistant applications, that is, not for commodity items which must meet all potential purchasers' requirements.

1.2.1 Users are advised to use the specification as a basis for obtaining castings which will meet minimum acceptance requirements established and revised by consensus of the members of the committee.

1.2.2 User requirements considered more stringent may be met by the addition to the purchase order of one or more supplementary requirements, which may include, but are not limited to, those listed in Sections S1 through S8.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 367 – 93 (Reapproved 2004)

Standard Specification for

Titanium and Titanium Alloy Castings

This standard is issued under the fixed designation B 367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 120 Test Methods for ChemicalAnalysis of Titanium and

Titanium Alloys

1.1 This specification covers titanium and titanium alloy

E 142 Test Method for Controlling Quality of Radiographic

castings intended for general corrosion resistant and industrial

Testing

applications.

E 165 Test Method for Liquid Penetrant Examination

1.2 This specification is intended for use of purchasers

E 446 Reference Radiographs for Steel Castings Up to 2 in.

and/or producers of reactive metal castings for defining the

(51 mm) in Thickness

requirements and assuring the properties of castings for unique

E 1409 Test Method for Determination of Oxygen in Tita-

corrosion-resistant applications, that is, not for commodity

nium and Titanium Alloys by the Inert Gas Fusion Tech-

items which must meet all potential purchasers’ requirements.

nique

1.2.1 Usersareadvisedtousethespecificationasabasisfor

E 1447 Test Method for Determination of Hydrogen in

obtaining castings which will meet minimum acceptance

Titanium and Titanium Alloys by the Inert Gas Fusion

requirements established and revised by consensus of the

Thermal Conductivity Method

members of the committee.

1.2.2 User requirements considered more stringent may be

3. Terminology

met by the addition to the purchase order of one or more

3.1 Definitions of Terms Specific to This Standard:

supplementary requirements, which may include, but are not

3.1.1 lot, n—shall consist of all castings of the same design

limited to, those listed in Sections S1 through S8.

produced from the same pour.

1.3 The values stated in inch-pound units are to be regarded

3.1.2 pour, n—shall consist of all material melted and cast

as the standard. The values given in parentheses are for

at one time.

information only.

4. Ordering Information

2. Referenced Documents

2 4.1 Orders for castings to this specification shall include the

2.1 ASTM Standards:

following as required, to describe the requirements adequately:

A 802/A 802M Practice for Steel Castings, Surface Accep-

4.1.1 Description of the castings by pattern number or

tance Standards, Visual Examination

drawing. Dimensional tolerances shall be included on the

E8 Test Methods for Tension Testing of Metallic Materials

casting drawing,

E10 Test Method for Brinell Hardness of Metallic Materi-

4.1.2 Quantity,

als

4.1.3 Grade designation (see Table 1),

E18 Test Methods for Rockwell Hardness and Rockwell

4.1.4 Options in the specification, and

Superficial Hardness of Metallic Materials

4.1.5 Supplementary requirements desired, including the

E29 Practice for Using Significant Digits in Test Data to

standards of acceptance.

Determine Conformance with Specifications

E94 Guide for Radiographic Testing

5. Materials and Manufacture

5.1 Materials for this specification shall be melted by

conventional processes used for reactive metals. Typical meth-

This specification is under the jurisdiction of ASTM Committee B10 on

Reactive and Refractory Metals and Alloys and is the direct responsibility of

ods include the consumable electrode and induction-slag,

Subcommittee B10.01 on Titanium.

plasma arc, induction-skull, and electron beam melting pro-

Current edition approved May 1, 2004. Published May 2004. Originally

cesses.

approved in 1961. Last previous edition approved in 1993 as B 367 – 93 (1998).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 367 – 93 (2004)

TABLE 1 Chemical Requirements

Composition, Weight %

Element

Grade Grade Grade Grade Grade Grade Grade Grade Grade

C-2 C-3 C-5 C-6 Ti-Pd7B Ti-Pd8A Ti-Pd16 Ti-Pd17 Ti-Pd18

Nitrogen, max 0.05 0.05 0.05 0.05 0.05 0.05 0.03 0.03 0.05

Carbon, max 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

Hydrogen, max 0.015 0.015 0.015 0.015 0.015 0.015 0.0150 0.0150 0.0150

Iron, max 0.20 0.25 0.40 0.50 0.20 0.25 0.30 0.20 0.25

Oxygen, max 0.40 0.40 0.25 0.20 0.40 0.40 0.18 0.25 0.15

Aluminum . . 5.5–6.75 4.00–6.00 . . . . 2.5–3.5

Vanadium . . 3.5–4.5 . . . . . 2.0–3.0

Tin . . . 2.0–3.0 . . . . .

A A B

Palladium . . . . 0.12 min 0.12 min 0.04–0.08 0.04–0.08 0.04–0.08

Other elements 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

C

(each), max

Other elements 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40

C

(total), max

A

Grade TiPd16 and TiPd17—Unalloyed titanium with reduced palladium content to enhance corrosion properties are similar to Grade TiPd, 7B and 8A.

B

Grade 18—Palladium added to titanium alloy 3AI-2.5V to enhance corrosion properties.

C

Need not be reported. By agreement between producer and purchaser, analysis may be required and limits established for elements or compounds not specified in

this table.

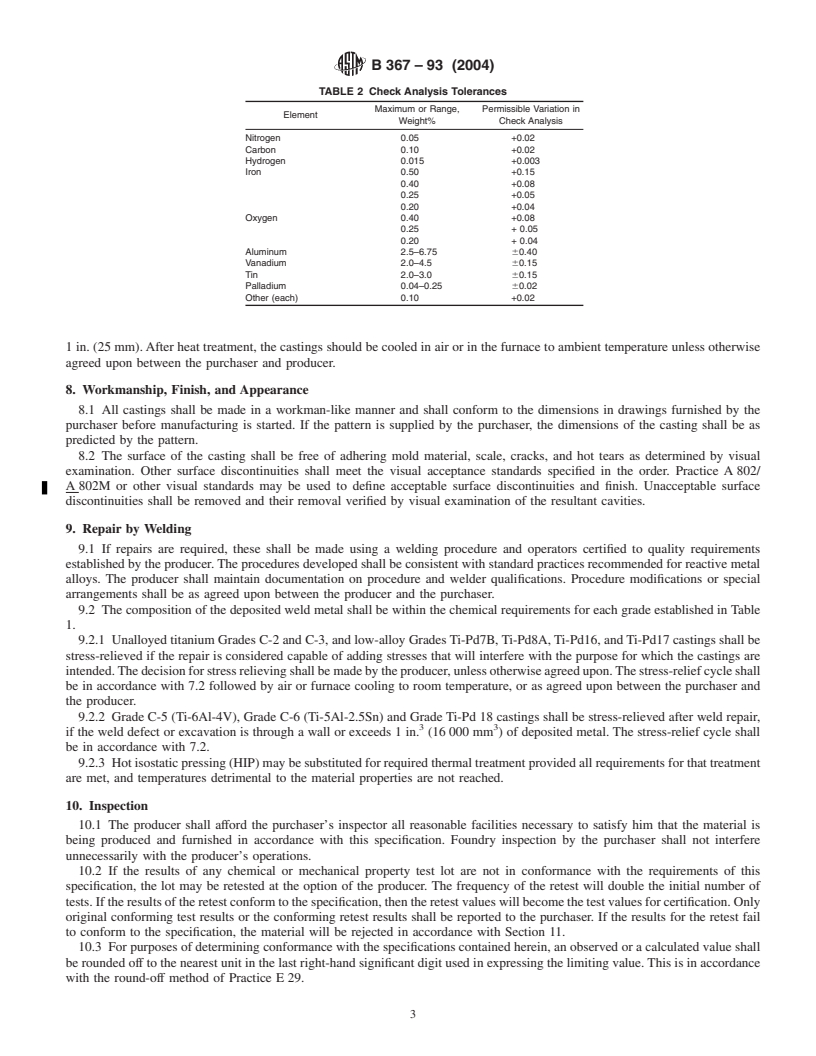

TABLE 2 Check Analysis Tolerances

Maximum or Range, Permissible Variation in

6. Chemical Composition

Element

Weight% Check Analysis

6.1 Pour Analysis—An analysis of each pour shall be made

Nitrogen 0.05 +0.02

by the producer from a sample such as a casting or test bar that

Carbon 0.10 +0.02

Hydrogen 0.015 +0.003

is representative of the pour. The chemical composition deter-

Iron 0.50 +0.15

mined shall conform to the requirements specified for the

0.40 +0.08

relevant grade in Table 1.

0.25 +0.05

0.20 +0.04

6.1.1 The elements listed in Table 1 are intentional alloy

Oxygen 0.40 +0.08

additions or elements which are inherent to the manufacture of

0.25 + 0.05

titanium sponge, ingot or mill product. 0.20 + 0.04

Aluminum 2.5–6.75 60.40

6.1.1.1 Elements other than those listed in Table 1 are

Vanadium 2.0–4.5 60.15

deemed to be capable of occurring in the grades listed in Table Tin 2.0–3.0 60.15

Palladium 0.04–0.25 60.02

1 by and only by way of unregulated or unanalyzed scrap

Other (each) 0.10 +0.02

additions to the ingot melt. Therefore product analysis for

elements not listed in Table 1 shall not be required unless

specified and shall be considered to be in excess of the intent

6.5 Referee Analysis—Intheeventofdisagreementbetween

of this specification.

the producer and purchaser concerning the analysis of any

6.1.2 Elements intentionally added to the melt must be

casting,TestMethodsE 120shallbeusedasarefereechemical

identified, analyzed, and reported in the chemical analysis.

analysis method.

6.2 When agreed upon by the producer and the purchaser

and requested by the purchaser in his written purchase order, 7. Heat Treatment

chemical analysis shall be completed for specific residual

7.1 Unless otherwise specified in the contract, all castings

elements not listed in this specification.

willbesuppliedintheas-castconditionexceptwhenpost-weld

6.3 Product Analysis—Product analysis tolerances do not

heat treatment is required.

broaden the specified heat analysis requirements, but cover

7.2 If post-weld heat treatment is required, it shall consist of

variations between laboratories in the measurement of chemi-

a stress relief performed at 1075 6 25°F (580 6 14°C) for

cal content. The producer shall not ship material which is

Grades C-2, C-3 Ti-Pd7B, Ti-Pd8A, Ti-Pd16 and Ti-Pd17, and

outside the limits specified in Table 1 for the applicable grade.

1200 6 25°F (650 6 14°C) for Grades C-5, C-6, and Ti-Pd18.

Product analysis limits shall be as specified in Table 2. 1

Time at temperature shall be a minimum of ⁄2 h plus an

6.4 Sampling—Samples for chemical analysis may be made additional ⁄2 h at temperature per inch of thickness for section

by the purchaser on a representative casting from any lot. Due sizes greater than 1 in. (25 mm). After heat treatment, the

to the possibility of oxygen or other interstitial contamination, castings should be cooled in air or in the furnace to ambient

samples for oxygen, carbon, hydrogen, and nitrogen analysis temperature unless otherwise agreed upon between the pur-

shall be taken no closer than ⁄4 in. (6.3 mm) to a cast surface chaser and producer.

except that castings too thin for this shall be analyzed on

8. Workmanship, Finish, and Appearance

representative material. The chemical composition determined

shall conform to the analysis in Table 1 within the check 8.1 All castings shall be made in a workman-like manner

analysis variations shown in Table 2 or shall be subject to and shall conform to the dimensions in drawings furnished by

rejection by the purchaser. the purchaser before manufacturing is started. If the pattern is

B 367 – 93 (2004)

supplied by the purchaser, the dimensions of the casting shall 10.2 If the results of any chemical or mechanical property

be as predicted by the pattern. test lot are not in conformance with the requirements of this

specification, the lot may be retested at the option of the

8.2 The surface of the casting shall be free of adhering mold

producer. The frequency of the retest will double the initial

material, scale, cracks, and hot tears as determined by visual

number of tests. If the results of the retest conform to the

examination.Othersurfacediscontinuitiesshallmeetthevisual

specification, then the retest values will become the test values

acceptance standards specified in the order. Practice A 802/

for certification. Only original conforming test results or the

A 802M or other visual standards may be used to define

conforming retest results shall be reported to the purchaser. If

acceptable surface discontinuities and finish. Unacceptable

the results for the retest fail to conform to the specification, the

surface discontinuities shall be removed and their removal

material will be rejected in accordance with Section 11.

verified by visual examination of the resultant cavities.

10.3 For purposes of determining conformance with the

specifications contained herein, an observed or a calculated

9. Repair by Welding

value shall be rounded off to the nearest unit in the last

9.1 If repairs are required, these shall be made using a

right-hand significant digit used in expressing the limiting

welding procedure and operators certified to quality require-

value. This is in accordance with the round-off method of

ments estab

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B367–93(Reapproved1998) Designation: B 367 – 93 (Reapproved 2004)

Standard Specification for

Titanium and Titanium Alloy Castings

This standard is issued under the fixed designation B 367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers titanium and titanium alloy castings intended for general corrosion resistant and industrial

applications.

1.2 This specification is intended for use of purchasers and/or producers of reactive metal castings for defining the requirements

and assuring the properties of castings for unique corrosion-resistant applications, that is, not for commodity items which must

meet all potential purchasers’ requirements.

1.2.1 Users are advised to use the specification as a basis for obtaining castings which will meet minimum acceptance

requirements established and revised by consensus of the members of the committee.

1.2.2 User requirements considered more stringent may be met by the addition to the purchase order of one or more

supplementary requirements, which may include, but are not limited to, those listed in Sections S1 through S8.

1.3 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

2. Referenced Documents

2.1 ASTM Standards:

A 802/A 802M Practice for Steel Castings, Surface Acceptance Standards, Visual Examination

E 8 Test Methods for Tension Testing of Metallic Materials

E 10 Test Method for Brinell Hardness of Metallic Materials

E 18 Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 94 Guide for Radiographic Testing

E 120 Test Methods for Chemical Analysis of Titanium and Titanium Alloys

E 142 Test Method for Controlling Quality of Radiographic Testing

E 165 Test Method for Liquid Penetrant Examination

E 446 Reference Radiographs for Steel Castings Up to 2 in. (51 mm) in Thickness

E 1409 Test Method for Determination of Oxygen in Titanium and Titanium Alloys by the Inert Gas Fusion Technique

E 1447 Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by the Inert Gas Fusion Thermal

Conductivity Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lotlot, n—shall consist of all castings of the same design produced from the same pour.

3.1.2 pourpour, n—shall consist of all material melted and cast at one time.

4. Ordering Information

4.1 Orders for castings to this specification shall include the following as required, to describe the requirements adequately:

This specification is under the jurisdiction of ASTM Committee B-10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.05 on Castings.

Current edition approved Aug. 15, 1993. Published November 1993. Originally published as B367–61T. Last previous edition B367–87.

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.01 on Titanium.

Current edition approved May 1, 2004. Published May 2004. Originally approved in 1961. Last previous edition approved in 1993 as B 367 – 93 (1998).

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 03.01.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 367 – 93 (2004)

4.1.1 Description of the castings by pattern number or drawing. Dimensional tolerances shall be included on the casting

drawing,

4.1.2 Quantity,

4.1.3 Grade designation (see Table 1),

4.1.4 Options in the specification, and

4.1.5 Supplementary requirements desired, including the standards of acceptance.

5. Materials and Manufacture

5.1 Materials for this specification shall be melted by conventional processes used for reactive metals. Typical methods include

the consumable electrode and induction-slag, plasma arc, induction-skull, and electron beam melting processes.

6. Chemical Composition

6.1 Pour Analysis—An analysis of each pour shall be made by the producer from a sample such as a casting or test bar that

is representative of the pour. The chemical composition determined shall conform to the requirements specified for the relevant

grade in Table 1.

6.1.1 TheelementslistedinTable1areintentionalalloyadditionsorelementswhichareinherenttothemanufactureoftitanium

sponge, ingot or mill product.

6.1.1.1 Elements other than those listed in Table 1 are deemed to be capable of occurring in the grades listed in Table 1 by and

only by way of unregulated or unanalyzed scrap additions to the ingot melt. Therefore product analysis for elements not listed in

Table 1 shall not be required unless specified and shall be considered to be in excess of the intent of this specification.

6.1.2 Elements intentionally added to the melt must be identified, analyzed, and reported in the chemical analysis.

6.2 Whenagreeduponbytheproducerandthepurchaserandrequestedbythepurchaserinhiswrittenpurchaseorder,chemical

analysis shall be completed for specific residual elements not listed in this specification.

6.3 Product Analysis—Product analysis tolerances do not broaden the specified heat analysis requirements, but cover variations

between laboratories in the measurement of chemical content. The producer shall not ship material which is outside the limits

specified in Table 1 for the applicable grade. Product analysis limits shall be as specified in Table 2.

6.4 Sampling—Samples for chemical analysis may be made by the purchaser on a representative casting from any lot. Due to

the possibility of oxygen or other interstitial contamination, samples for oxygen, carbon, hydrogen, and nitrogen analysis shall be

taken no closer than ⁄4 in. (6.3 mm) to a cast surface except that castings too thin for this shall be analyzed on representative

material.ThechemicalcompositiondeterminedshallconformtotheanalysisinTable1withinthecheckanalysisvariationsshown

in Table 2 or shall be subject to rejection by the purchaser.

6.5 Referee Analysis—In the event of disagreement between the producer and purchaser concerning the analysis of any casting,

Test Methods E 120 shall be used as a referee chemical analysis method.

7. Heat Treatment

7.1 Unless otherwise specified in the contract, all castings will be supplied in the as-cast condition except when post-weld heat

treatment is required.

7.2 If post-weld heat treatment is required, it shall consist of a stress relief performed at 1075 6 25°F (580 6 14°C) for Grades

C-2, C-3 Ti-Pd7B, Ti-Pd8A, Ti-Pd16 and Ti-Pd17, and 1200 6 25°F (650 6 14°C) for Grades C-5, C-6, and Ti-Pd18. Time at

1 1

temperature shall be a minimum of ⁄2 h plus an additional ⁄2 h at temperature per inch of thickness for section sizes greater than

TABLE 1 Chemical Requirements

Composition, Weight %

Element

Grade Grade Grade Grade Grade Grade Grade Grade Grade

C-2 C-3 C-5 C-6 Ti-Pd7B Ti-Pd8A Ti-Pd16 Ti-Pd17 Ti-Pd18

Nitrogen, max 0.05 0.05 0.05 0.05 0.05 0.05 0.03 0.03 0.05

Carbon, max 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

Hydrogen, max 0.015 0.015 0.015 0.015 0.015 0.015 0.0150 0.0150 0.0150

Iron, max 0.20 0.25 0.40 0.50 0.20 0.25 0.30 0.20 0.25

Oxygen, max 0.40 0.40 0.25 0.20 0.40 0.40 0.18 0.25 0.15

Aluminum . . 5.5–6.75 4.00–6.00 . . . . 2.5–3.5

Vanadium . . 3.5–4.5 . . . . . 2.0–3.0

Tin . . . 2.0–3.0 . . . . .

A A B

Palladium . . . . 0.12 min 0.12 min 0.04–0.08 0.04–0.08 0.04–0.08

Other elements 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

C

(each), max

Other elements 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40

C

(total), max

A

Grade TiPd16 and TiPd17—Unalloyed titanium with reduced palladium content to enhance corrosion properties are similar to Grade TiPd, 7B and 8A.

B

Grade 18—Palladium added to titanium alloy 3AI-2.5V to enhance corrosion properties.

C

Need not be reported. By agreement between producer and purchaser, analysis may be required and limits established for elements or compounds not specified in

this table.

B 367 – 93 (2004)

TABLE 2 Check Analysis Tolerances

Maximum or Range, Permissible Variation in

Element

Weight% Check Analysis

Nitrogen 0.05 +0.02

Carbon 0.10 +0.02

Hydrogen 0.015 +0.003

Iron 0.50 +0.15

0.40 +0.08

0.25 +0.05

0.20 +0.04

Oxygen 0.40 +0.08

0.25 + 0.05

0.20 + 0.04

Aluminum 2.5–6.75 60.40

Vanadium 2.0–4.5 60.15

Tin 2.0–3.0 60.15

Palladium 0.04–0.25 60.02

Other (each) 0.10 +0.02

1 in. (25 mm).After heat treatment, the castings should be cooled in air or in the furnace to ambient temperature unless otherwise

agreed upon between the purchaser and producer.

8. Workmanship, Finish, and Appearance

8.1 All castings shall be made in a workman-like manner and shall conform to the dimensions in drawings furnished by the

purchaser before manufacturing is started. If the pattern is supplied by the purchaser, the dimensions of the casting shall be as

predicted by the pattern.

8.2 The surface of the casting shall be free of adhering mold material, scale, cracks, and hot tears as determined by visual

examination. Other surface discontinuities shall meet the visual acceptance standards specified in the order. Practice A 802/

A 802M or other visual standards may be used to define acceptable surface discontinuities and finish. Unacceptable surface

discontinuities shall be removed and their removal verified by visual examination of the resultant cavities.

9. Repair by Welding

9.1 If repairs are required, these shall be made using a welding procedure and operators certified to quality requirements

established by the producer.The procedures developed shall be consistent with standard practices recommended for reactive metal

alloys. The producer shall maintain documentation on procedure and welder qualifications. Procedure modifications or special

arrangements shall be as agreed upon between the producer and the purchaser.

9.2 The composition of the deposited weld metal shall be within the chemical requirements for each grade established in Table

1.

9.2.1 Unalloyed titanium Grades C-2 and C-3, and low-alloy GradesTi-Pd7B,Ti-Pd8A,Ti-Pd16, andTi-Pd17 castings shall be

stress-relieved if the repair is considered capable of adding stresses that will interfere with the purpose for which the castings are

intended.Thedecisionforstressrelievingshallbemadebytheproducer,unlessotherwiseagreedupon.Thestress-reliefcycleshall

be in accordance with 7.2 followed by air or furnace cooling to room temperature, or as agreed upon between the purchaser and

the producer.

9.2.2 Grade C-5 (Ti-6Al-4V), Grade C-6 (Ti-5Al-2.5Sn) and Grade Ti-Pd 18 castings shall be stress-relieved after weld repair,

3 3

if the weld defect or excavation is through a wall or exceeds 1 in. (16 000 mm ) of deposited metal. The stress-relief cycle shall

be in accordance with 7.2.

9.2.3 Hot isostatic pressing (HIP) may be substituted for required thermal treatment provided all requirements for that treatment

are met, and temperatures detrimental to the material properties are not reached.

10. Inspection

10.1 The producer shall afford the purchaser’s inspector all reasonable facilities necessary to satisfy him that the material is

being produced and furnished in accordance with this specification. Foundry inspection by the purchaser shall not interfere

unnecessarily with the producer’s operations.

10.2 If the results of any chemical or mechanical property test lot are not in conformance with the requirements of this

specification, the lot may be retested at the option of the producer. The frequency of the retest will double the initial number of

tests.Iftheresultsoftheretestconformtothespecification,thentheretestvalueswillbecomethetestvaluesforcertification.Only

original conforming test results or the conforming retest results shall be reported to the purchaser. If the results for the retest fail

to conform to the specification, the material will be rejected in accordance with Section 11.

10.3 For purposes of determining conformance with the specifications contained herein, an observed or a calculated value shall

be rounded off to the nearest unit in the last right-hand significant digit used in expressing the limiting value.This is in accordance

with the round-off method of Practice E 29.

B 367 – 93 (2004)

11. Rejection

11.1 Any rejection based on test reports shall be reported to the producer within 60 days from the receipt of the test reports by

the purchaser.

11.2 Material that shows unacceptable discontinuities as determined by the acceptance standards specified on the order,

subsequent to acceptance at the producer’s works, may be rejected, and the producer shall be notified within 60 days, or as

otherwise agreed upon.

11.3 In the event of disagreement between the producer and the purchaser on the conformance of the material to the

requirements of this specification, a mutually acceptable referee shall perform the tests in question. The referee’s testing shall be

used in determining the conformance of the material to this specification.

12. Product Marking

12.1 Unless otherwise specified, the following shall apply.

12.1.1 Castings shall be marked for material identification with theASTM designation number (Specification B 367) and grade

symbol, that is, C2, C3, C5, C6, Ti-Pd7B, Ti-Pd8A, Ti-Pd16, Ti-Pd17, or Ti-Pd18.

12.1.2 The producer’s name or identification mark and the pattern number shall be cast or stamped using low stress stamps on

all castings. Small size castings may be such that marking must be limited consistent with the available area.

12.1.3 The marking of lot numbers on individual castings shall be agreed upon by the producer and the purchaser.

12.1.4 Marking shall be in such a position as not to injure the usefulness of the casting.

13. Keywords

13.1 castings; corrosion resistant; titanium; titanium alloys

SUPPLEME

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.