ASTM B367-93(2004)

(Specification)Standard Specification for Titanium and Titanium Alloy Castings

Standard Specification for Titanium and Titanium Alloy Castings

SCOPE

1.1 This specification covers titanium and titanium alloy castings intended for general corrosion resistant and industrial applications.

1.2 This specification is intended for use of purchasers and/or producers of reactive metal castings for defining the requirements and assuring the properties of castings for unique corrosion-resistant applications, that is, not for commodity items which must meet all potential purchasers' requirements.

1.2.1 Users are advised to use the specification as a basis for obtaining castings which will meet minimum acceptance requirements established and revised by consensus of the members of the committee.

1.2.2 User requirements considered more stringent may be met by the addition to the purchase order of one or more supplementary requirements, which may include, but are not limited to, those listed in Sections S1 through S8.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 367 – 93 (Reapproved 2004)

Standard Specification for

1

Titanium and Titanium Alloy Castings

This standard is issued under the fixed designation B 367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 120 Test Methods for ChemicalAnalysis of Titanium and

3

Titanium Alloys

1.1 This specification covers titanium and titanium alloy

E 142 Test Method for Controlling Quality of Radiographic

castings intended for general corrosion resistant and industrial

3

Testing

applications.

E 165 Test Method for Liquid Penetrant Examination

1.2 This specification is intended for use of purchasers

E 446 Reference Radiographs for Steel Castings Up to 2 in.

and/or producers of reactive metal castings for defining the

(51 mm) in Thickness

requirements and assuring the properties of castings for unique

E 1409 Test Method for Determination of Oxygen in Tita-

corrosion-resistant applications, that is, not for commodity

nium and Titanium Alloys by the Inert Gas Fusion Tech-

items which must meet all potential purchasers’ requirements.

nique

1.2.1 Usersareadvisedtousethespecificationasabasisfor

E 1447 Test Method for Determination of Hydrogen in

obtaining castings which will meet minimum acceptance

Titanium and Titanium Alloys by the Inert Gas Fusion

requirements established and revised by consensus of the

Thermal Conductivity Method

members of the committee.

1.2.2 User requirements considered more stringent may be

3. Terminology

met by the addition to the purchase order of one or more

3.1 Definitions of Terms Specific to This Standard:

supplementary requirements, which may include, but are not

3.1.1 lot, n—shall consist of all castings of the same design

limited to, those listed in Sections S1 through S8.

produced from the same pour.

1.3 The values stated in inch-pound units are to be regarded

3.1.2 pour, n—shall consist of all material melted and cast

as the standard. The values given in parentheses are for

at one time.

information only.

4. Ordering Information

2. Referenced Documents

2 4.1 Orders for castings to this specification shall include the

2.1 ASTM Standards:

following as required, to describe the requirements adequately:

A 802/A 802M Practice for Steel Castings, Surface Accep-

4.1.1 Description of the castings by pattern number or

tance Standards, Visual Examination

drawing. Dimensional tolerances shall be included on the

E8 Test Methods for Tension Testing of Metallic Materials

casting drawing,

E10 Test Method for Brinell Hardness of Metallic Materi-

4.1.2 Quantity,

als

4.1.3 Grade designation (see Table 1),

E18 Test Methods for Rockwell Hardness and Rockwell

4.1.4 Options in the specification, and

Superficial Hardness of Metallic Materials

4.1.5 Supplementary requirements desired, including the

E29 Practice for Using Significant Digits in Test Data to

standards of acceptance.

Determine Conformance with Specifications

E94 Guide for Radiographic Testing

5. Materials and Manufacture

5.1 Materials for this specification shall be melted by

1

conventional processes used for reactive metals. Typical meth-

This specification is under the jurisdiction of ASTM Committee B10 on

Reactive and Refractory Metals and Alloys and is the direct responsibility of

ods include the consumable electrode and induction-slag,

Subcommittee B10.01 on Titanium.

plasma arc, induction-skull, and electron beam melting pro-

Current edition approved May 1, 2004. Published May 2004. Originally

cesses.

approved in 1961. Last previous edition approved in 1993 as B 367 – 93 (1998).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 367 – 93 (2004)

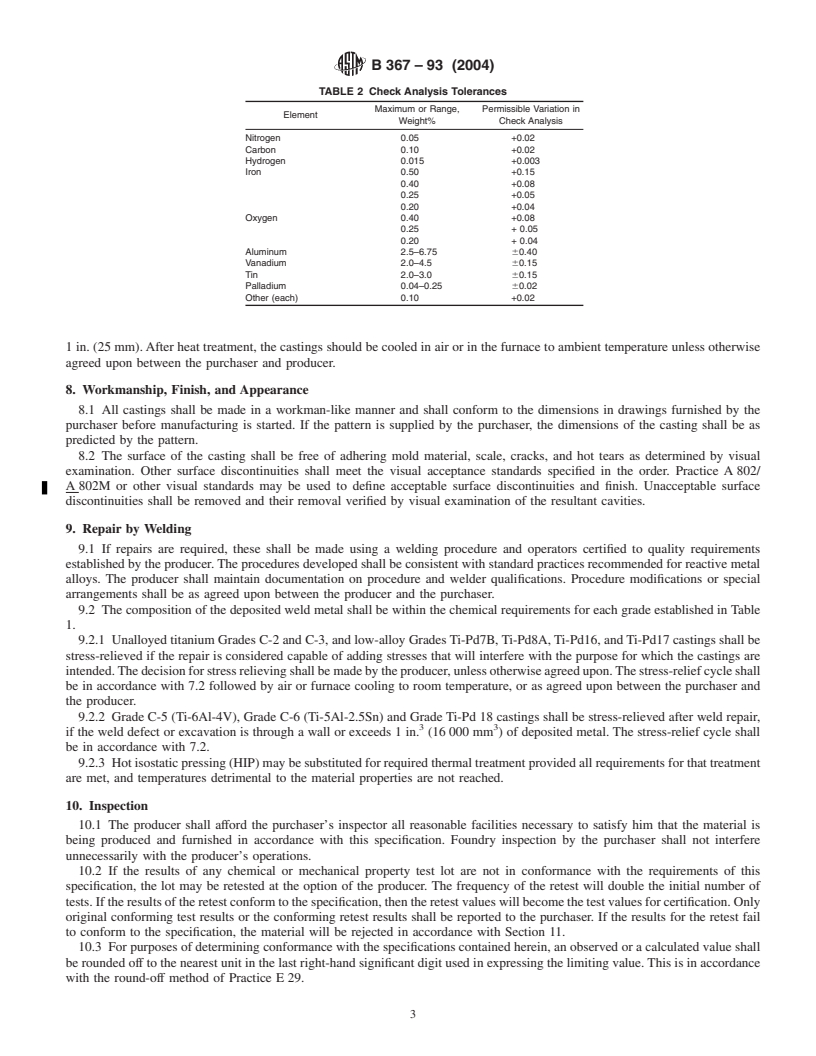

TABLE 1 Chemical Requirements

Composition, Weight %

Element

Grade Grade Grade Grade Grade Grade Grade Grade Grade

C-2 C-3 C-5 C-6 Ti-Pd7B Ti-Pd8A Ti-Pd16 Ti-Pd17 Ti-Pd18

Nitrogen, max 0.05 0.05 0.05 0.05 0.05 0.05 0.03 0.03 0.05

Carbon, max 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10

Hydrogen, max 0.015 0.015 0.015 0.015 0.015 0.015 0.0150 0.0150 0.0150

Iron, max 0.20 0.25 0.40 0.50 0.20 0.25 0.30 0.20 0.25

Oxygen, max 0.40 0.40 0.25 0.20 0.40 0.40 0.18 0.25 0.15

Aluminum . . 5.5–6.75 4.00–6.00 . . . . 2.5–3.5

Vanadium . . 3.5–4.5 . . . . . 2.0–3.0

Tin . . . 2.0–3.0 . . . .

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B367–93(Reapproved1998) Designation: B 367 – 93 (Reapproved 2004)

Standard Specification for

1

Titanium and Titanium Alloy Castings

This standard is issued under the fixed designation B 367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers titanium and titanium alloy castings intended for general corrosion resistant and industrial

applications.

1.2 This specification is intended for use of purchasers and/or producers of reactive metal castings for defining the requirements

and assuring the properties of castings for unique corrosion-resistant applications, that is, not for commodity items which must

meet all potential purchasers’ requirements.

1.2.1 Users are advised to use the specification as a basis for obtaining castings which will meet minimum acceptance

requirements established and revised by consensus of the members of the committee.

1.2.2 User requirements considered more stringent may be met by the addition to the purchase order of one or more

supplementary requirements, which may include, but are not limited to, those listed in Sections S1 through S8.

1.3 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

2. Referenced Documents

2

2.1 ASTM Standards:

A 802/A 802M Practice for Steel Castings, Surface Acceptance Standards, Visual Examination

E 8 Test Methods for Tension Testing of Metallic Materials

E 10 Test Method for Brinell Hardness of Metallic Materials

E 18 Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 94 Guide for Radiographic Testing

3

E 120 Test Methods for Chemical Analysis of Titanium and Titanium Alloys

3

E 142 Test Method for Controlling Quality of Radiographic Testing

E 165 Test Method for Liquid Penetrant Examination

E 446 Reference Radiographs for Steel Castings Up to 2 in. (51 mm) in Thickness

E 1409 Test Method for Determination of Oxygen in Titanium and Titanium Alloys by the Inert Gas Fusion Technique

E 1447 Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by the Inert Gas Fusion Thermal

Conductivity Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lotlot, n—shall consist of all castings of the same design produced from the same pour.

3.1.2 pourpour, n—shall consist of all material melted and cast at one time.

4. Ordering Information

4.1 Orders for castings to this specification shall include the following as required, to describe the requirements adequately:

1

This specification is under the jurisdiction of ASTM Committee B-10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.05 on Castings.

Current edition approved Aug. 15, 1993. Published November 1993. Originally published as B367–61T. Last previous edition B367–87.

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.01 on Titanium.

Current edition approved May 1, 2004. Published May 2004. Originally approved in 1961. Last previous edition approved in 1993 as B 367 – 93 (1998).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 03.01.

3

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 367 – 93 (2004)

4.1.1 Description of the castings by pattern number or drawing. Dimensional tolerances shall be included on the casting

drawing,

4.1.2 Quantity,

4.1.3 Grade designation (see Table 1),

4.1.4 Options in the specification, and

4.1.5 Supplementary requirements desired, including the standards of acceptance.

5. Materials and Manufacture

5.1 Materials for this specification shall be melted by conventional processes used for reactive metals. Typical methods include

the consumable electrode and induction-slag,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.