ASTM F1700-04(2010)

(Specification)Standard Specification for Solid Vinyl Floor Tile

Standard Specification for Solid Vinyl Floor Tile

ABSTRACT

This specification establishes the material and performance characteristics that determine serviceability and recommended applicability of solid vinyl floor tiles intended for use in commercial, light commercial, and residential buildings. Floor tiles shall be classified as Class I for monolithic vinyl tiles, Class II for surface-decorated vinyl tiles, and Class III for printed film vinyl tiles. Furthermore, these classes of tiles shall be subgrouped as Type A for tiles with smooth surfaces, and Type B for those with embossed surfaces. The tiles shall be composed of binder, filler, and pigments compounded with suitable lubricants and processing aids, the composition for all of which shall be dictated by their respective classes. When tested, the tiles shall adhere to the following physical requirements: binder content; dimension including size, thickness, squareness, and dimensional stability; residual indentation; flexibility; resistance to chemicals such as white vinegar, rubbing alcohol, white mineral oil, sodium hydroxide solution, hydrochloric acid solution, sulfuric acid solution, household ammonia solution, household bleach, olive oil, kerozene, unleaded gasoline, and phenol; resistance to heat; and resistance to light.

SCOPE

1.1 This specification covers solid vinyl floor tiles that are monolithic, surface decorated or printed, and that have binder contents referenced in Table 1.

1.2 This type of floor covering is intended for use in commercial, light commercial, and residential buildings. General information and performance characteristics which determine serviceability and recommended use are included in this specification.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1700 −04(Reapproved 2010)

Standard Specification for

1

Solid Vinyl Floor Tile

This standard is issued under the fixed designation F1700; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Flooring by Color Change

2 F1515 Test Method for Measuring Light Stability of Resil-

1.1 This specification covers solid vinyl floor tiles that are

ient Flooring by Color Change

monolithic, surface decorated or printed, and that have binder

F1914 Test Methods for Short-Term Indentation and Re-

contents referenced in Table 1.

sidual Indentation of Resilient Floor Covering

1.2 This type of floor covering is intended for use in

F2055 Test Method for Size and Squareness of Resilient

commercial, light commercial, and residential buildings. Gen-

Floor Tile by Dial Gage Method

eral information and performance characteristics which deter-

F2199 Test Method for Determining Dimensional Stability

mine serviceability and recommended use are included in this

of Resilient Floor Tile after Exposure to Heat

specification.

2.2 Other Standards:

1.3 This standard does not purport to address all of the

ANSI/ASQC Z1.4–1993 Sampling Procedures and Tables

4

safety concerns, if any, associated with its use. It is the

for Inspection by Attributes

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Classification

bility of regulatory limitations prior to use.

3.1 The vinyl floor tiles covered by this specification shall

1.4 The values stated in inch-pound units are to be regarded

be classified as follows:

as standard. The values given in parentheses are mathematical

3.1.1 Class I—Monolithic Vinyl Tile.

conversions to SI units that are provided for information only

3.1.1.1 Type A—Smooth Surface.

and are not considered standard.

3.1.1.2 Type B—Embossed Surface.

3.1.2 Class II—Surface-Decorated Vinyl Tile.

2. Referenced Documents

3.1.2.1 Type A—Smooth Surface.

3

2.1 ASTM Standards:

3.1.2.2 Type B—Embossed Surface.

F137 Test Method for Flexibility of Resilient Flooring Ma-

3.1.3 Class III—Printed Film Vinyl Tile.

terials with Cylindrical Mandrel Apparatus

3.1.3.1 Type A—Smooth Surface.

F141 Terminology Relating to Resilient Floor Coverings

3.1.3.2 Type B—Embossed Surface.

F373 Test Method for Embossed Depth of Resilient Floor

3.2 The embossed surfaces may or may not be grouted with

Coverings

ink.

F386 Test Method for Thickness of Resilient Flooring Ma-

terials Having Flat Surfaces

4. Ordering Information

F925 Test Method for Resistance to Chemicals of Resilient

4.1 The purchaser shall state whether this specification is to

Flooring

F1514 TestMethodforMeasuringHeatStabilityofResilient be used, select the preferred options permitted herein, and

include the following contract requirements on the purchase

order:

1

This specification is under the jurisdiction of ASTM Committee F06 on 4.1.1 Title, number, and date of this specification,

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80

4.1.2 Class, type, and pattern number (Section 3),

on Specifications.

4.1.3 Quantity in square feet, pieces, or cartons,

Current edition approved Dec. 1, 2010. Published December 2010. Originally

4.1.4 Size required (Section 6),

approved in 1996. Last previous edition approved in 2004 as F1700–04. DOI:

10.1520/F1700-04R10.

4.1.5 Thickness required (Section 6),

2

For solid vinyl definition, refer to Terminology F141.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 11 West 42nd St., New

the ASTM website. York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1700−04 (2010)

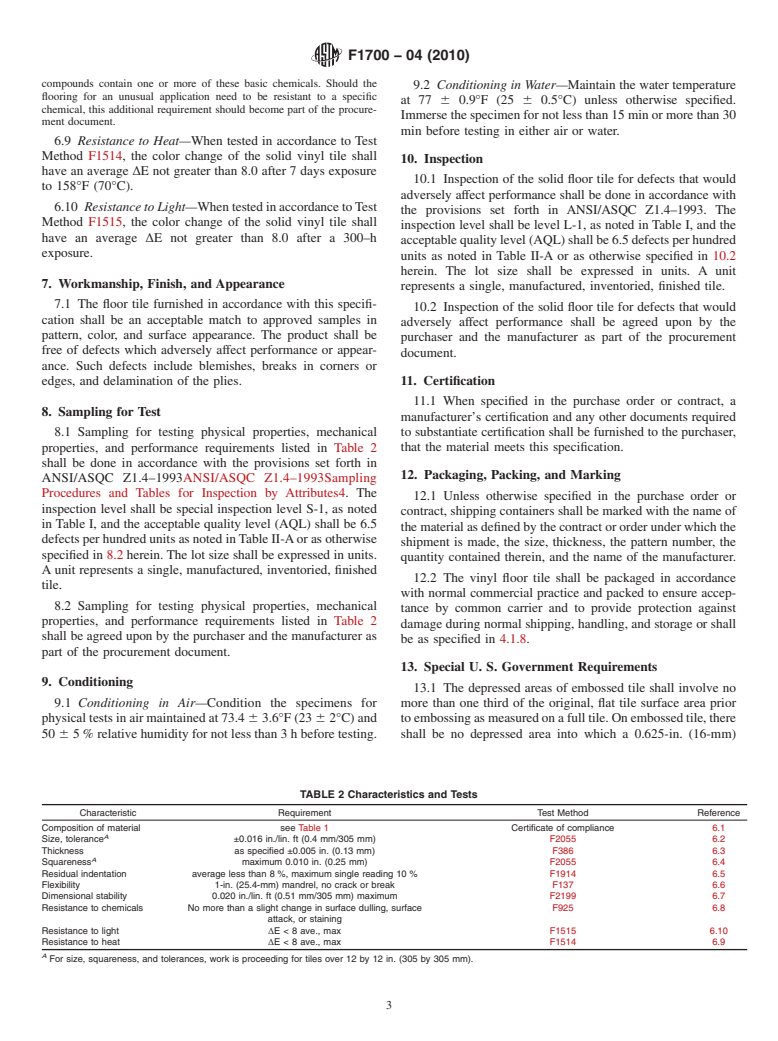

TABLE 1 Minimum Binder Content

layer or base layer. Other base layers may be added. Each ply

Class I Class II Class III or layer will comply with Table 1 for binder content.

Each ply or layer 34 % 34 % . . . 5.5.1 For commercial applications, the wear layer shall be a

Clear wear layer . . . . . . 90 %

minimum of 0.020 in. (0.50 mm) thick.

Intermediate colored layer . . . . . . 34 %

Each base layer . . . . . . 34 %

6. Physical Requirements

6.1 BinderContent—Thebindercontentofeachplyorlayer

shall be determined by statement of formula (Manufactu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.