ASTM D4683-10

(Test Method)Standard Test Method for Measuring Viscosity of New and Used Engine Oils at High Shear Rate and High Temperature by Tapered Bearing Simulator Viscometer at 150 °C

Standard Test Method for Measuring Viscosity of New and Used Engine Oils at High Shear Rate and High Temperature by Tapered Bearing Simulator Viscometer at 150 <span class='unicode'>°</span>C

SIGNIFICANCE AND USE

Viscosity values at the shear rate and temperature of this test method have been indicated to be related to the viscosity providing hydrodynamic lubrication in automotive and heavy duty engines in severe service.

The viscosities of engine oils under such high temperatures and shear rates are also related to their effects on fuel efficiency and the importance of high shear rate, high temperature viscosity has been addressed in a number of publications and presentations.

SCOPE

1.1 This test method covers the laboratory determination of the viscosity of engine oils at 150 °C and 1.0·106 s−1 using a viscometer having a slightly tapered rotor and stator called the Tapered Bearing Simulator (TBS) Viscometer.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4683 − 10

StandardTest Method for

Measuring Viscosity of New and Used Engine Oils at High

Shear Rate and High Temperature by Tapered Bearing

1

Simulator Viscometer at 150 °C

This standard is issued under the fixed designation D4683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

3

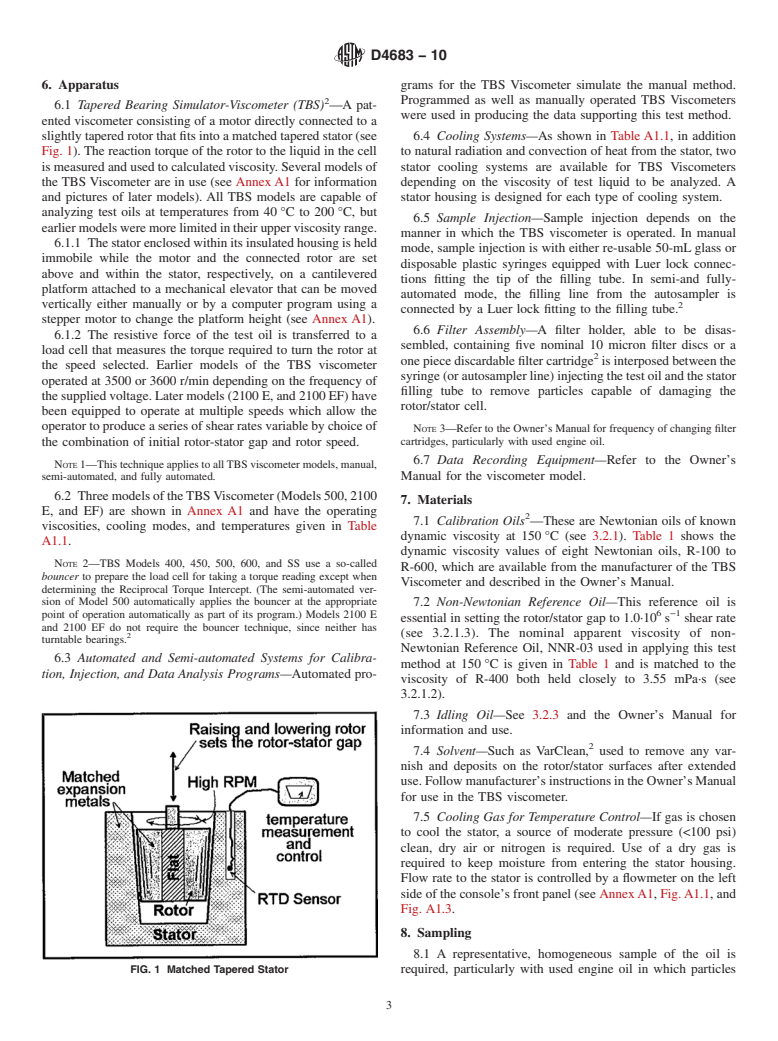

1.1 This test method covers the laboratory determination of 2.1 ASTM Standards:

6 −1

the viscosity of engine oils at 150°C and 1.0·10 s using a D4741Test Method for Measuring Viscosity at High Tem-

viscometer having a slightly tapered rotor and stator called the peratureandHighShearRatebyTapered-PlugViscometer

2

Tapered Bearing Simulator (TBS) Viscometer. D5481Test Method for Measuring Apparent Viscosity at

High-TemperatureandHigh-ShearRatebyMulticellCap-

1.2 TheNewtoniancalibrationoilsusedtoestablishthistest

illary Viscometer

method range from approximately 1.2 mPa·s to 7.7 mPa·s at

150°C.

3. Terminology

1.3 The non-Newtonian reference oil used to establish the

3.1 Definitions:

6 −1

shear rate of 1.0·10 s for this test method has a viscosity

3.1.1 density—massperunitvolumeofthetestliquid.InSI,

closely held to 3.55 mPa·s at 150°C.

the unit of density is the kilogram per cubic metre, but, for

1.4 Manual, semi-automated, and fully automated viscom- practicaluse,asubmultipleismoreconvenient.Thus,gramper

cubic centimetre is customarily used and is equivalent to

eters were used in developing the precision statement for this

3 3

test method. 10 kg/m .

3.1.2 Newtonian oil or fluid—oil or liquid that at a given

1.5 Applicationtopetroleumproductsotherthanengineoils

temperature exhibits a constant viscosity at all shear rates or

has not been determined in preparing the viscometric informa-

shear stresses.

tion for this test method.

3.1.3 non-Newtonian oil or fluid—oil or liquid that exhibits

1.6 The values stated in SI units are to be regarded as

aviscositythatvarieswithchangingshearstressandshearrate.

standard. No other units of measurement are included in this

standard. 3.1.4 shear rate—velocity gradient in liquid flow in milli-

1.6.1 This test method uses the milliPascal·second (mPa·s)

metres per second per millimetre (mm/s per mm). The SI unit

-1

astheunitofviscosity.Thisunitisequivalenttothecentipoise for shear rate is reciprocal seconds, s .

(cP).

3.1.5 shear stress—force per unit area causing liquid flow.

1.7 This standard does not purport to address all of the The unit area noted is the area over which viscous shear is

safety concerns, if any, associated with its use. It is the

being caused.

responsibility of the user of this standard to establish appro-

3.1.6 viscosity—ratio of applied shear stress and the result-

priate safety and health practices and determine the applica-

ing rate of shear. It is sometimes called the coefficient of

bility of regulatory limitations prior to use.

dynamic or absolute viscosity (in contrast to kinematic viscos-

ity). This coefficient is a measure of the resistance to flow of

1

This test method is under the jurisdiction of ASTM Committee D02 on

the liquid. In the SI the unit of viscosity is the Pascal·second

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

(Pa·s), often conveniently expressed as milliPascal·second

D02.07 on Flow Properties.

(mPa·s), or as the English system equivalent, the centipoise

Current edition approved Oct. 1, 2010. Published November 2010. Originally

approved in 1987. Last previous edition approved in 2009 as D4683–09. DOI:

(cP).

10.1520/D4683-10.

2

The sole source of supply of the apparatus known to the committee at this time

3

is Tannas Co., 4800 James Savage Rd., Midland, MI 48642. If you are aware of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

alternative suppliers, please provide this information to ASTM International contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Headquarters.Your comments will receive careful consideration at a meeting of the Standards volume information, refer to the standard’s Document Summary page on

1

responsible technical committee, which you may attend. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4683 − 10

3.1.6.1 apparent viscosity—viscosity of a non-Newtonian 3.2.7 reciprocaltorqueintersection,1/Tj—desiredshearrate

liquid det

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4683–09 Designation:D4683–10

Standard Test Method for

Measuring Viscosity of New and Used Engine Oils at High

Shear Rate and High Temperature by Tapered Bearing

1

Simulator Viscometer at 150°C

This standard is issued under the fixed designation D4683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

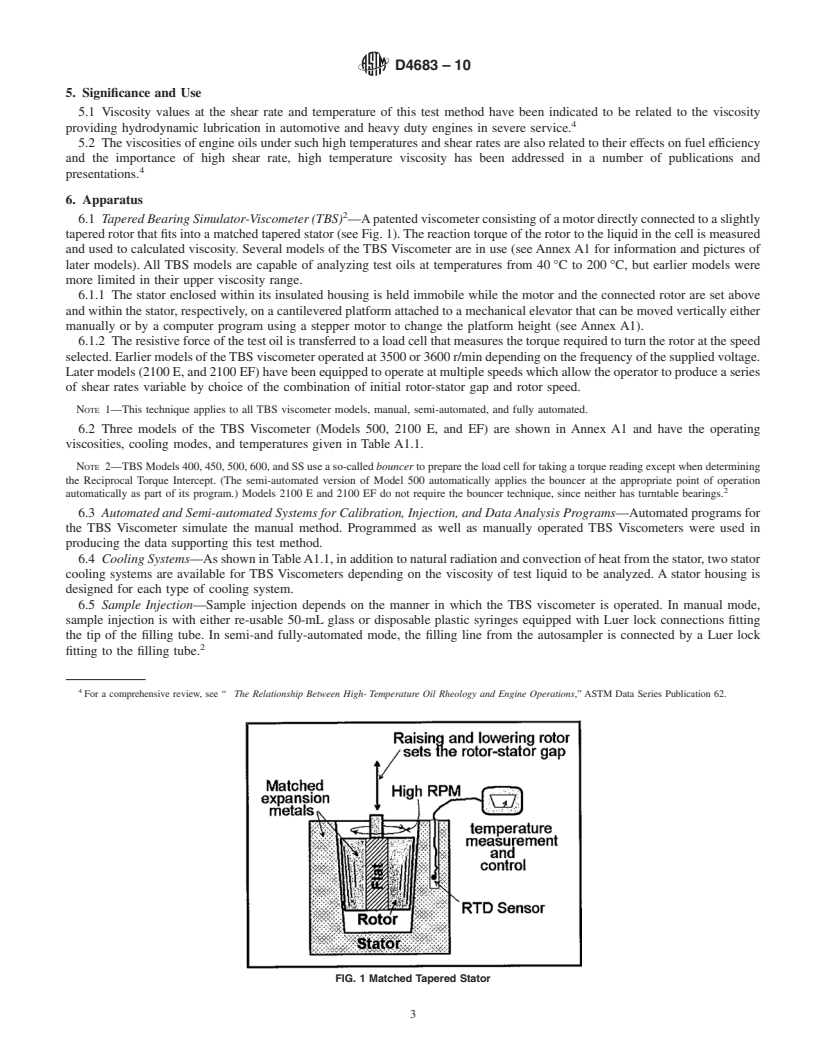

1. Scope*

6 −1

1.1 This test method covers the laboratory determination of the viscosity of engine oils at 150°C and 1.0·10 s using a

2

viscometer having a slightly tapered rotor and stator called the Tapered Bearing Simulator (TBS) Viscometer.

1.2 The Newtonian calibration oils used to establish this test method range from approximately 1.2 mPa·s to 7.7 mPa·s at

150°C.

6 −1

1.3 The non-Newtonian reference oil used to establish the shear rate of 1.0·10 s for this test method has a viscosity closely

held to 3.55 mPa·s at 150°C.

1.4 Manual, semi-automated, and fully automated viscometers were used in developing the precision statement for this test

method.

1.5 Application to petroleum products other than engine oils has not been determined in preparing the viscometric information

for this test method.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 ThistestmethodusesthemilliPascal·second(mPa·s)astheunitofviscosity.Thisunitisequivalenttothecentipoise(cP).

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D4741 Test Method for Measuring Viscosity at High Temperature and High Shear Rate by Tapered-Plug Viscometer

D5481 Test Method for Measuring Apparent Viscosity at High-Temperature and High-Shear Rate by Multicell Capillary

Viscometer

3. Terminology

3.1 Definitions:

3.1.1 density—massperunitvolumeofthetestliquid.InSI,theunitofdensityisthekilogrampercubicmetre,but,forpractical

3 3

use, a submultiple is more convenient. Thus, gram per cubic centimetre is customarily used and is equivalent to 10 kg/m .

3.1.2 Newtonian oil or fluid—oil or liquid that at a given temperature exhibits a constant viscosity at all shear rates or shear

stresses.

3.1.3 non-Newtonian oil or fluid—oil or liquid that exhibits a viscosity that varies with changing shear stress and shear rate.

3.1.4 shear rate—velocitygradientinliquidflowinmillimetrespersecondpermillimetre(mm/spermm).TheSIunitforshear

-1

rate is reciprocal seconds, s .

3.1.5 shear stress—force per unit area causing liquid flow. The unit area noted is the area over which viscous shear is being

caused.

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.07 on

Flow Properties.

Current edition approved JulyOct. 1, 2009.2010. Published November 2009.2010. Originally approved in 1987. Last previous edition approved in 20042009 as

D4683–04.D4683–09. DOI: 10.1520/D4683-109.

2

ThesolesourceofsupplyoftheapparatusknowntothecommitteeatthistimeisTannasCo.,4800JamesSavageRd.,Midland,MI48642.Ifyouareawareofalternative

suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical

committee, which you may attend.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4683–10

3.1.6 viscosity—ratio of applied shear stress and the resulting rate of shear. It is sometimes called the coefficient of dynamic

or absolute viscosity (in contrast to kinematic viscosity). This coefficient is a measure of the resistance to flow of the liquid. In

the SI the unit of visc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.