ASTM D7702/D7702M-14(2021)

(Guide)Standard Guide for Considerations When Evaluating Direct Shear Results Involving Geosynthetics

Standard Guide for Considerations When Evaluating Direct Shear Results Involving Geosynthetics

SIGNIFICANCE AND USE

4.1 The shear strength of soil-geosynthetic interfaces and geosynthetic-geosynthetic interfaces is a critical design parameter for many civil engineering projects, including, but not limited to: waste containment systems, mining applications, dam designs involving geosynthetics, mechanically stabilized earth structures, reinforced soil slopes, and liquid impoundments. Since geosynthetic interfaces often serve as a weak plane on which sliding may occur, shear strengths of these interfaces are needed to assess the stability of earth materials resting on these interfaces, such as a waste mass or ore body over a lining system or the ability of a final cover to remain on a slope. Accordingly, project-specific shear testing using representative materials under conditions similar to those expected in the field is recommended for final design. Shear strengths of geosynthetic interfaces are obtained by either Test Method D5321/D5321M (geosynthetics) or D6243/D6243M (geosynthetic clay liners). This guide touches upon some of the issues that should be considered when evaluating shear strength data. Because of the large number of potential conditions that could exist, there may be other conditions not identified in this guide that could affect interpretation of the results. The seemingly infinite combinations of soils, geosynthetics, hydration and wetting conditions, normal load distributions, strain rates, creep, pore pressures, etc., will always require individual engineering evaluations by qualified practitioners. Along the same lines, the list of references provided in this guide is not exhaustive, nor are the findings and suggestions of any particular reference meant to be considered conclusive. The references and their related findings are presented herein only as examples available in the literature of the types of considerations that others have found useful when evaluating direct shear test results.

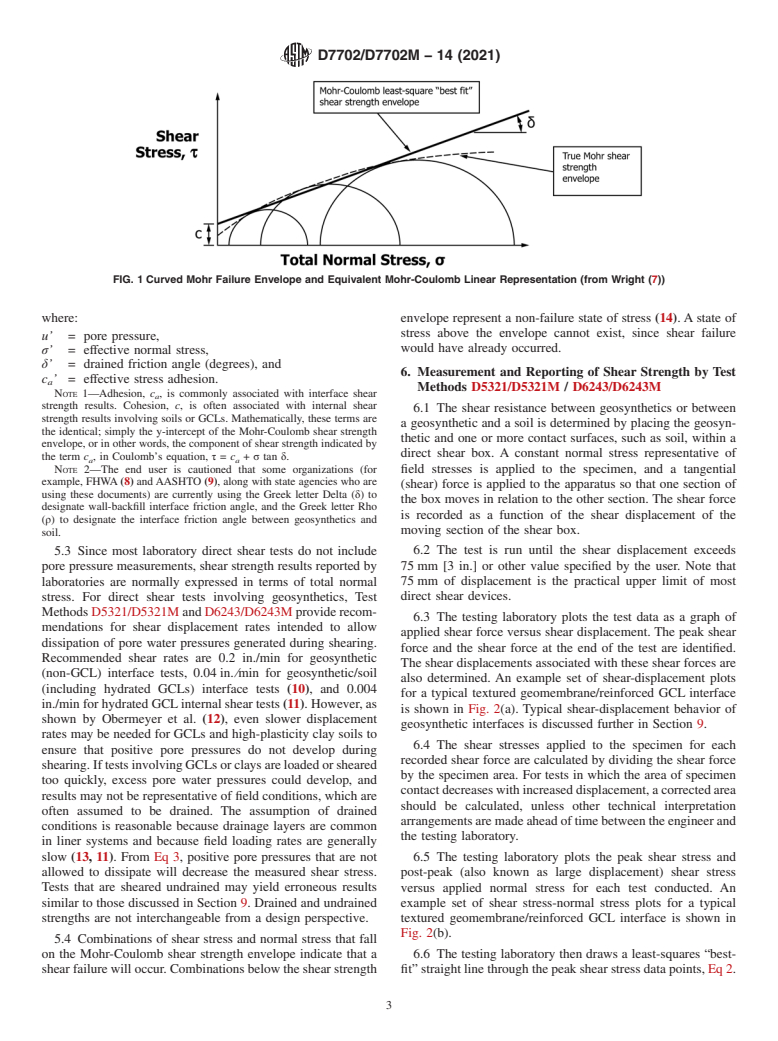

4.2 The figures included in this guide are only examples intended t...

SCOPE

1.1 This guide presents a summary of available information related to the evaluation of direct shear test results involving geosynthetic materials.

1.2 This guide is intended to assist designers and users of geosynthetics. This guide is not intended to replace education or experience and should only be used in conjunction with professional judgment. This guide is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project’s many unique aspects. Not all aspects of this practice may be applicable in all circumstances. The word “Standard” in the title of this document means only that the document has been approved through the ASTM consensus process.

1.3 This guide is applicable to soil-geosynthetic and geosynthetic-geosynthetic direct shear test results, obtained using either Test Method D5321/D5321M or D6243/D6243M.

1.4 This guide does not address selection of peak or large-displacement shear strength values for design. References on this topic include Thiel (1),2 Gilbert (2), Koerner and Bowman (3), and Stark and Choi (4).

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardizatio...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7702/D7702M − 14 (Reapproved 2021)

Standard Guide for

Considerations When Evaluating Direct Shear Results

Involving Geosynthetics

This standard is issued under the fixed designation D7702/D7702M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This guide presents a summary of available information

ization established in the Decision on Principles for the

related to the evaluation of direct shear test results involving

Development of International Standards, Guides and Recom-

geosynthetic materials.

mendations issued by the World Trade Organization Technical

1.2 This guide is intended to assist designers and users of

Barriers to Trade (TBT) Committee.

geosynthetics. This guide is not intended to replace education

or experience and should only be used in conjunction with 2. Referenced Documents

professional judgment. This guide is not intended to represent

2.1 ASTM Standards:

or replace the standard of care by which the adequacy of a

D653 Terminology Relating to Soil, Rock, and Contained

given professional service must be judged, nor should this

Fluids

document be applied without consideration of a project’s many

D4439 Terminology for Geosynthetics

unique aspects. Not all aspects of this practice may be

D5321/D5321M Test Method for Determining the Shear

applicable in all circumstances. The word “Standard” in the

Strength of Soil-Geosynthetic and Geosynthetic-

title of this document means only that the document has been

Geosynthetic Interfaces by Direct Shear

approved through the ASTM consensus process.

D6243/D6243M Test Method for Determining the Internal

1.3 This guide is applicable to soil-geosynthetic and

and Interface Shear Strength of Geosynthetic Clay Liner

geosynthetic-geosynthetic direct shear test results, obtained by the Direct Shear Method

using either Test Method D5321/D5321M or D6243/D6243M.

3. Terminology

1.4 This guide does not address selection of peak or

3.1 Definitions—For definitions of terms relating to soil and

large-displacement shear strength values for design. Refer-

rock, refer to Terminology D653. For definitions of terms

ences on this topic include Thiel (1), Gilbert (2), Koerner and

relating to geosynthetics and GCLs, refer to Terminology

Bowman (3), and Stark and Choi (4).

D4439.

1.5 The values stated in either SI units or inch-pound units

3.2 Definitions of Terms Specific to This Standard:

are to be regarded separately as standard. The values stated in

3.2.1 adhesion, c or c, n—the y-intercept of the Mohr-

each system are not necessarily exact equivalents; therefore, to a

Coulomb shear strength envelope; the component of shear

ensure conformance with the standard, each system shall be

strength indicated by the term c , in Coulomb’s equation, τ =

used independently of the other, and values from the two a

c + σ tan δ.

systems shall not be combined. a

3.2.2 failure envelope, n—curvi-linear line on the shear

1.6 This standard does not purport to address all of the

stress-normal stress plot representing the combination of shear

safety concerns, if any, associated with its use. It is the

and normal stresses that define a selected shear failure criterion

responsibility of the user of this standard to establish appro-

(for example, peak and post-peak). Also referred to as shear

priate safety, health, and environmental practices and deter-

strength envelope.

mine the applicability of regulatory limitations prior to use.

3.2.3 Mohr-Coulomb friction angle δ,n—angle of friction

of a material or between two materials (degrees), the angle

This guide is under the jurisdiction ofASTM Committee D35 on Geosynthetics

defined by the least-squares, “best-fit” straight line through a

and is the direct responsibility of Subcommittee D35.04 on Geosynthetic Clay

Liners.

Current edition approved Aug. 1, 2021. Published August 2021. Originally

approved in 2011. Last previous edition approved in 2014 as D7702_D7702 – 14. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI:10.1520/D7702_D7702M-14R21. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7702/D7702M − 14 (2021)

defined section of the shear strength-normal stress failure infinite combinations of soils, geosynthetics, hydration and

envelope; the component of the shear strength indicated by the wetting conditions, normal load distributions, strain rates,

term δ, in Coulomb’s equation, τ = c + σ tan δ.

creep, pore pressures, etc., will always require individual

engineering evaluations by qualified practitioners. Along the

3.2.4 Mohr-Coulomb shear strength envelope, n—the least-

squares, “best-fit” straight line through a defined section of the same lines, the list of references provided in this guide is not

shear strength-normal stress failure envelope described in the exhaustive, nor are the findings and suggestions of any

equation τ = c + σ tan δ. The envelope can be described for

particular reference meant to be considered conclusive. The

a

any chosen shear failure criteria (for example, peak, post-peak,

references and their related findings are presented herein only

or residual).

as examples available in the literature of the types of consid-

erations that others have found useful when evaluating direct

3.2.5 secant friction angle, δ ,n—(degrees) the angle

sec

defined by a line drawn from the origin to a data point on the shear test results.

shear strength-normal stress failure envelope. Intended to be

4.2 The figures included in this guide are only examples

used only at the shearing normal stress for which it is defined.

intended to demonstrate selected concepts related to direct

3.2.6 shear strength, τ,n—the shear force on a given failure

shear testing of geosynthetics. The values shown in the figures

plane. In the direct shear test it is always stated in relation to

may not be representative and should not be used for design

the normal stress acting on the failure plane. Two different

purposes. Site-specific and material-specific tests should al-

types of shear strengths are often estimated and used in

ways be performed.

standard practice:

3.2.6.1 peak shear strength, n—the largest value of shear

5. Shear Strength Fundamentals

resistance experienced during the test under a given normal

stress. 5.1 Mohr first presented a theory for shear failure, showing

that a material experiences failure at a critical combination of

3.2.6.2 post-peak shear strength, n—the minimum, or

normal and shear stress, and not through some maximum

steady-state value of shear resistance that occurs after the peak

normal or shear stress alone. In other words, the shear stress on

shear strength is experienced.

a given failure plane was shown to be a function of the normal

3.2.6.3 Discussion—Due to horizontal displacement limita-

stress acting on that plane (5):

tions of many commercially available shear boxes used to

τ 5 f~σ! (1)

determine interface shear strength, the post-peak shear strength

is often specified and reported as the value of shear resistance

If a series of shear tests at different values of normal stress

that occurs at 75 mm [3 in.] of displacement. The end user is

is performed, and the stress circle corresponding to failure is

cautioned that the reported value of post-peak shear strength

plotted for each test, at least one point on each circle must

(regardless how defined) is not necessarily the residual shear

represent the normal and shear stress combination associated

strength. In some instances, a post-peak shear strength may not

with failure (6). As the number of tests increases, a failure

be defined before the limit of horizontal displacement is

envelope (line tangent to the failure circles) for the material

reached.

becomes apparent (Fig. 1).

4. Significance and Use

5.2 In general, the failure envelope described by Eq 1 is a

4.1 The shear strength of soil-geosynthetic interfaces and

curved line for many materials (5). For most geotechnical

geosynthetic-geosynthetic interfaces is a critical design param-

engineering problems, the shear stress on the failure plane is

eter for many civil engineering projects, including, but not

approximated as a linear function of the total or effective

limited to: waste containment systems, mining applications,

normal stress within a selected normal stress range, as shown

dam designs involving geosynthetics, mechanically stabilized

in Fig. 1. This linear approximation is known as the Mohr-

earth structures, reinforced soil slopes, and liquid impound-

Coulomb shear strength envelope. In the case of total stresses,

ments. Since geosynthetic interfaces often serve as a weak

the Mohr-Coulomb shear strength envelope is expressed as:

plane on which sliding may occur, shear strengths of these

interfaces are needed to assess the stability of earth materials

τ 5 c 1σ tan δ (2)

a

resting on these interfaces, such as a waste mass or ore body

where:

over a lining system or the ability of a final cover to remain on

τ = shear stress,

a slope. Accordingly, project-specific shear testing using rep-

σ = normal stress,

resentativematerialsunderconditionssimilartothoseexpected

δ = friction angle (degrees), and

in the field is recommended for final design. Shear strengths of

c = adhesion.

a

geosynthetic interfaces are obtained by either Test Method

D5321/D5321M (geosynthetics) or D6243/D6243M (geosyn-

Inthecaseofeffectivestresses,thelinearfailureenvelopeis:

thetic clay liners). This guide touches upon some of the issues

'

τ 5 c 1~σ 2 u! tan δ (3)

a

that should be considered when evaluating shear strength data.

Because of the large number of potential conditions that could

or

exist, there may be other conditions not identified in this guide

'

that could affect interpretation of the results. The seemingly τ 5 c 1σ’ tan δ’

a

D7702/D7702M − 14 (2021)

FIG. 1 Curved Mohr Failure Envelope and Equivalent Mohr-Coulomb Linear Representation (from Wright (7))

where: envelope represent a non-failure state of stress (14). A state of

stress above the envelope cannot exist, since shear failure

u’ = pore pressure,

would have already occurred.

σ’ = effective normal stress,

δ’ = drained friction angle (degrees), and

6. Measurement and Reporting of Shear Strength by Test

c ’ = effective stress adhesion.

a

Methods D5321/D5321M / D6243/D6243M

NOTE 1—Adhesion, c , is commonly associated with interface shear

a

strength results. Cohesion, c, is often associated with internal shear

6.1 The shear resistance between geosynthetics or between

strength results involving soils or GCLs. Mathematically, these terms are

a geosynthetic and a soil is determined by placing the geosyn-

the identical; simply the y-intercept of the Mohr-Coulomb shear strength

thetic and one or more contact surfaces, such as soil, within a

envelope, or in other words, the component of shear strength indicated by

direct shear box. A constant normal stress representative of

the term c , in Coulomb’s equation, τ = c + σ tan δ.

a a

NOTE 2—The end user is cautioned that some organizations (for

field stresses is applied to the specimen, and a tangential

example, FHWA (8) andAASHTO (9), along with state agencies who are

(shear) force is applied to the apparatus so that one section of

using these documents) are currently using the Greek letter Delta (δ)to

the box moves in relation to the other section. The shear force

designate wall-backfill interface friction angle, and the Greek letter Rho

is recorded as a function of the shear displacement of the

(ρ) to designate the interface friction angle between geosynthetics and

moving section of the shear box.

soil.

5.3 Since most laboratory direct shear tests do not include 6.2 The test is run until the shear displacement exceeds

75 mm [3 in.] or other value specified by the user. Note that

pore pressure measurements, shear strength results reported by

laboratories are normally expressed in terms of total normal 75 mm of displacement is the practical upper limit of most

direct shear devices.

stress. For direct shear tests involving geosynthetics, Test

MethodsD5321/D5321MandD6243/D6243Mproviderecom-

6.3 The testing laboratory plots the test data as a graph of

mendations for shear displacement rates intended to allow

applied shear force versus shear displacement. The peak shear

dissipation of pore water pressures generated during shearing.

force and the shear force at the end of the test are identified.

Recommended shear rates are 0.2 in./min for geosynthetic

The shear displacements associated with these shear forces are

(non-GCL) interface tests, 0.04 in.⁄min for geosynthetic/soil

also determined. An example set of shear-displacement plots

(including hydrated GCLs) interface tests (10), and 0.004

for a typical textured geomembrane/reinforced GCL interface

in./min for hydrated GCLinternal shear tests (11). However, as

is shown in Fig. 2(a). Typical shear-displacement behavior of

shown by Obermeyer et al. (12), even slower displacement

geosynthetic interfaces is discussed further in Section 9.

rates may be needed for GCLs and high-plasticity clay soils to

6.4 The shear stresses applied to the specimen for each

ensure that positive pore pressures do not develop during

recorded shear force are calculated by dividing the shear force

shearing.IftestsinvolvingGCLsorclaysareloadedorsheared

by the specimen area. For tests in which the area of specimen

too quickly, excess pore water pressures could develop, and

contactdecreaseswithincreaseddisplacement,acorrectedarea

results may not be representative of field conditions, which are

should be calculated, unless other technical interpretation

often assumed to be drained. The assumption of drained

arrangementsaremadeaheadoftimebetweentheengineerand

conditions is reasonable because drainage layers are common

the testing laboratory.

in liner systems and because field loading rates are generally

slow (13, 11). From Eq 3, positive pore pressures that are not 6.5 The testing laborator

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.