ASTM F377-03

(Practice)Standard Practice for Calibration of Braking/Tractive Measuring Devices for Testing Tires

Standard Practice for Calibration of Braking/Tractive Measuring Devices for Testing Tires

SIGNIFICANCE AND USE

Calibration is essential in the use of various test platforms and devices to insure that the test results generated by these test devices are accurate, repeatable and meaningful. This standard gives the necessary instructions for the calibration of all of the test devices cited in the Scope.

SCOPE

1.1 This practice gives procedures for the calibration of:reference load cellscalibration platform systems by using a reference load cellstatic calibration of braking/tractive force on locked wheels of tire test trailers, instrumented vehicles, and laboratory tire testing machines by using the calibration platform system as a calibration fixture.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:F377–03

Standard Practice for

Calibration of Braking/Tractive Measuring Devices for

1

Testing Tires

ThisstandardisissuedunderthefixeddesignationF377;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Practice

1.1 This practice gives procedures for the calibration of: 4.1 Reference-load cells shall be calibrated using proce-

reference load cells dures and equipment traceable to the National Institute of

calibration platform systems by using a reference load cell Standards and Technology (NIST), or appropriate national

staticcalibrationofbraking/tractiveforceonlockedwheels standards organization.

of tire test trailers, instrumented vehicles, and laboratory tire

NOTE 1—Practice E74 may be used as an alternative method for

testing machines by using the calibration platform system as a

load-cell calibration.

calibration fixture.

4.2 Thecalibratedreference-loadcellisusedtocalibratethe

1.2 The values stated in SI units are to be regarded as

calibration-platform systems or used as the longitudinal force

standard. The values in parentheses are for information only.

sensor. The tire test trailer, instrumented vehicle, or laboratory

1.3 This standard does not purport to address all of the

tire testing machine is calibrated with the platform.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 Calibration is essential in the use of various test plat-

bility of regulatory limitations prior to use.

forms and devices to insure that the test results generated by

thesetestdevicesareaccurate,repeatableandmeaningful.This

2. Referenced Documents

standard gives the necessary instructions for the calibration of

2

2.1 ASTM Standards:

all of the test devices cited in the Scope.

E74 Practice of Calibration of Force-Measuring Instru-

ments for Verifying the Force Indication of Testing Ma-

6. Apparatus

chines

6.1 The calibration system consists of the following basic

F538 Terminology Relating to the Characteristics and Per-

components:

formance of Tires

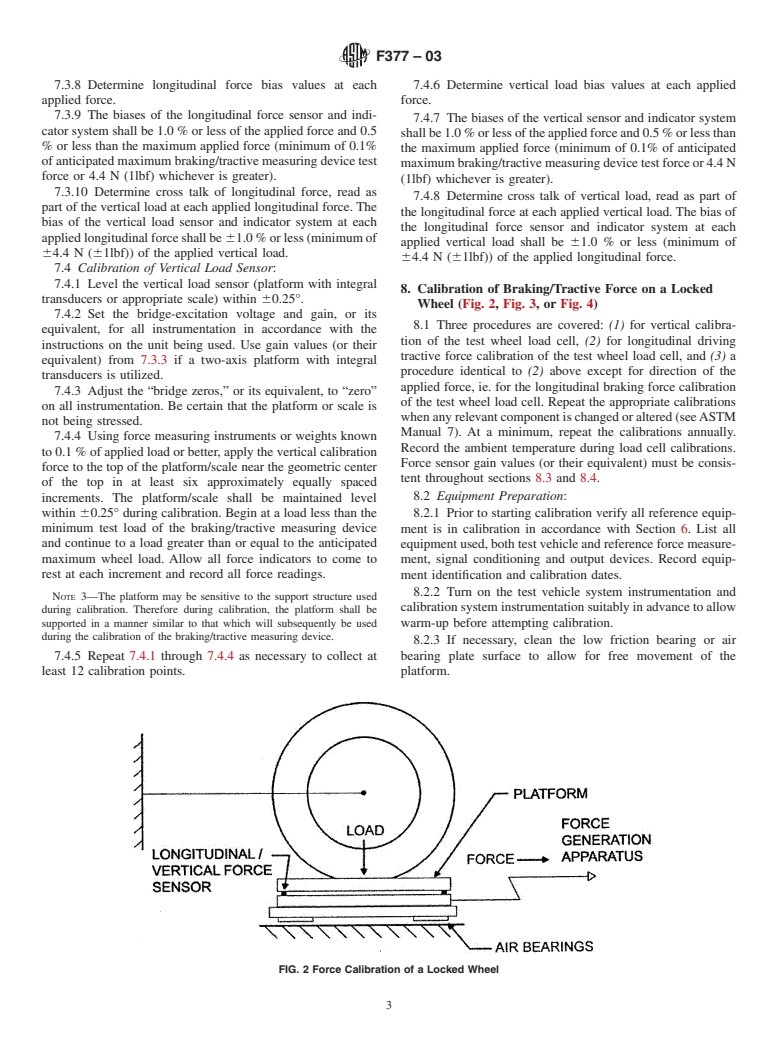

6.1.1 Platform—The platform on which the test wheel is

placed shall have a flat high friction top surface. The platform

3. Terminology

shall be of sufficient dimensions to support the entire tire

3.1 Definitions:

contact patch throughout the calibration process.Alow friction

3.2 bias, n—the difference between the average measured

bearing (an air bearing is recommended) permitting free

test result and the accepted reference value; it measures in an

horizontal motion and capable of sustaining a vertical load

inverse manner the accuracy of a test.

equal to the largest anticipated wheel load shall support the

3.3 longitudinal force, [F], of a tire, n—the component of

platform. The longitudinal movement shall be sufficient to

the tire force vector in the X’ direction.

obtain the necessary required force levels. The platform may

3.4 vertical load, n—the normal reaction of the tire on the

also be instrumented with integrated transducers (Force Sen-

road which is equal to the negative of normal force.

sors) to measure vertical and longitudinal forces.

6.1.2 Force Generation Apparatus—A system, capable of

developing a longitudinal force sufficient for the calibration of

1

This practice is under the jurisdiction ofASTM Committee F09 on Tires and is

the operating range of the device, shall be used.The force shall

the direct responsibility of Subcommittee F09.10 on Structural Integrity.

be applied along the longitudinal centerline of the platform.

Current edition approved Dec. 1, 2003. Published January 2004. Originally

published as F377 – 74. Last previous edition F377 – 94. DOI: 10.1520/F0377-03.

6.1.3 Force Sensors—Sensors to measure applied forces in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the vertical and longitudinal directions that shall be used to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

calibrate braking/tractive measuring devices. These sensors

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. can be integrated force transducers located in the platform,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F377–03

scales or tension load cells. Sensors shall have sufficient have a tolerance of 0.01%. Apply the calibration forces in at

measurement range to cover the maximu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.