ASTM E2261-03

(Practice)Standard Practice for Examination of Welds Using the Alternating Current Field Measurement Technique

Standard Practice for Examination of Welds Using the Alternating Current Field Measurement Technique

SIGNIFICANCE AND USE

The purpose of the alternating current field measurement method is to evaluate welds in the area of the toe for surface breaking discontinuities such as fatigue cracks. The examination results may then be used by qualified organizations to assess weld service life or other engineering characteristics (beyond the scope of this practice).

Comparison with Conventional Eddy Current Examination—conventional eddy current coils are typically configured to sense the field from the weld in the immediate vicinity of the emitting element, whereas alternating current field measurement probes are typically designed to sense the magnetic field from the weld distant from the exciter.

SCOPE

1.1 This practice describes procedures to be followed during alternating current field measurement examination of welds for baseline and service-induced surface breaking discontinuities.

1.2 This practice is intended for use on welds in any metallic material.

1.3 This practice does not establish weld acceptance criteria.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system might not be exact equivalents; therefore, each system shall be used independently of the other.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2261–03

Standard Practice for

Examination of Welds Using the Alternating Current Field

Measurement Technique

This standard is issued under the fixed designation E 2261; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions:

3.2.1 exciter—a device that generates a time varying elec-

1.1 Thispracticedescribesprocedurestobefollowedduring

tromagnetic field, usually a coil energized with alternating

alternating current field measurement examination of welds for

current (AC); also known as a transmitter.

baseline and service-induced surface breaking discontinuities.

3.2.2 detector—one or more coils or elements used to sense

1.2 This practice is intended for use on welds in any

or measure a magnetic field; also known as a receiver.

metallic material.

3.2.3 uniform field—as applied to nondestructive testing,

1.3 This practice does not establish weld acceptance crite-

the area of uniform magnetic field over the surface of the

ria.

material under examination produced by a parallel induced

1.4 The values stated in either inch-pound units or SI units

alternating current, which has been passed through the weld

are to be regarded separately as standard. The values stated in

and is observable beyond the direct coupling of the exciting

each system might not be exact equivalents; therefore, each

coil.The field is uniform on the surface but the strength decays

system shall be used independently of the other.

exponentially with depth.

1.5 This standard does not purport to address all of the

3.2.4 alternating current field measurement—a nondestruc-

safety concerns, if any, associated with its use. It is the

tiveexaminationtechniquethatmeasureschangesinanapplied

responsibility of the user of this standard to establish appro-

AC uniform magnetic field to detect and characterize discon-

priate safety and health practices and determine the applica-

tinuities.

bility of regulatory limitations prior to use.

3.3 Definitions of Terms Specific to This Standard:

2. Referenced Documents

3.3.1 alternating current field measurement system—the

electronic instrumentation, software, probes, and all associated

2.1 ASTM Standards:

components and cables required for performing weld exami-

E 543 Practice for Agencies Performing Nondestructive

nation using the alternating current field measurement tech-

Testing

nique.

E 1316 Terminology for Nondestructive Examinations

3.3.2 operational standardization block—a reference stan-

2.2 ASNT Standard:

dard with specified artificial slots, used to confirm the opera-

SNT-TC-1A Personnel Qualification in Nondestructive

tional parameters and to indicate discontinuity detection sen-

Testing

sitivity.

ANSI/ASNT-CP-189 Standard for Qualification and Certi-

3.3.3 Bx—the x component of the magnetic field, parallel to

fication of Nondestructive Testing Personnel

the weld toe, the magnitude of which is proportional to the

3. Terminology

current density set up by the electric field.

3.3.4 Bz—the z component of the magnetic field normal to

3.1 General definitions of terms used in this practice can be

the weld toe, the magnitude of which is proportional to the

found in Terminology E 1316, Section A, Common NDT

curvature of the current in the x-y plane.

terms, and Section C, Electromagnetic testing.

3.3.5 X-Y Plot—an X-Y graph with two orthogonal compo-

nents of magnetic field plotted against each other.

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

3.3.6 time base plots—these plot the relationship between

structive Testing and is the direct responsibility of Subcommittee E07.07 on

Bx or Bz values with time.

Electromagnetic Methods.

Current edition approved February 10, 2003. Published April 2003.

3.3.7 surface plot—for use with array probes. These plot

Annual Book of ASTM Standards,Vol 03.03.

one component of magnetic field over an area, typically as a

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

color contour plot or 3-D wire frame plot.

4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2261–03

3.3.8 data sample rate—the rate at which data is digitized sizepredictionmustcompensateforthecoatingthickness.This

for display and recording, in data points per second. can be accomplished using discontinuity-sizing tables in the

system software. Using the wrong coating thickness would

4. Summary of Practice

have a negative effect on depth sizing accuracy if the discrep-

ancy was 0.04 in. [1 mm] or more. As the current flow is

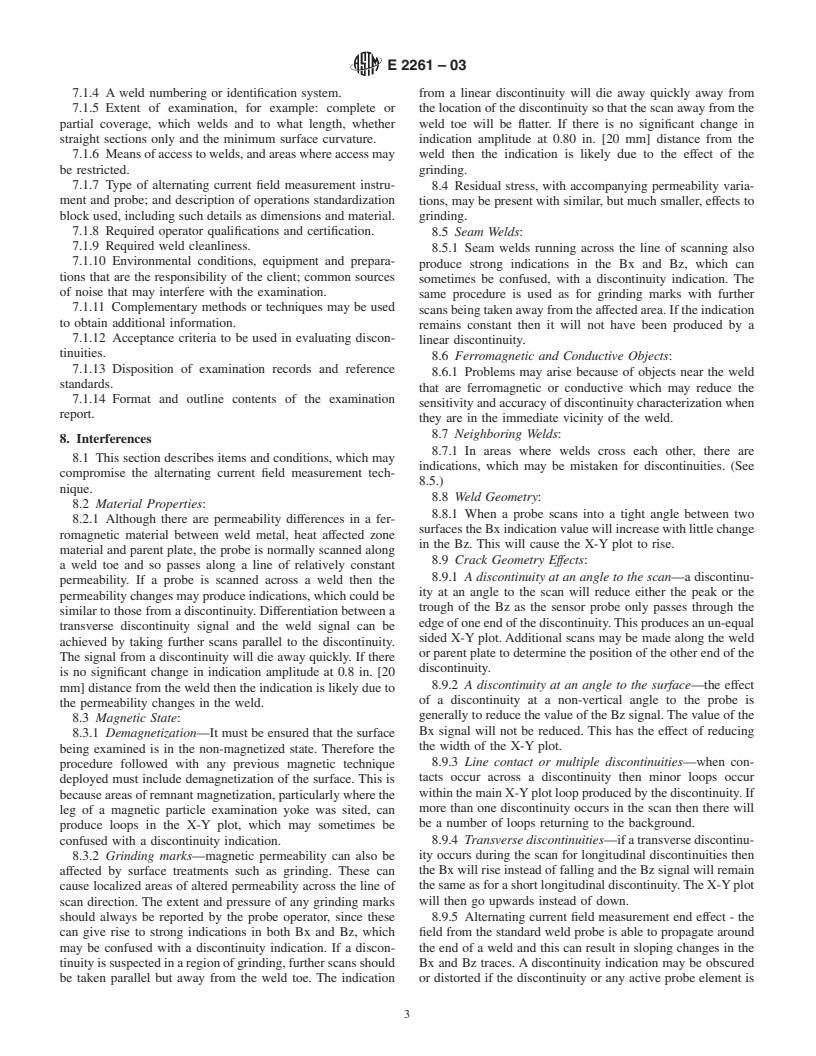

4.1 In a basic alternating current field measurement system,

arranged normal to the weld toe there is no perturbation in that

a small probe is moved along the toe of a weld. The probe

direction so that no indication occurs at the interface due to

contains an exciter coil, which induces anAC magnetic field in

changes in permeability. Data is recorded in a manner that

the material surface aligned to the direction of the weld. This,

allows archiving and subsequent recall for each weld location.

in turn, causes uniform alternating current to flow across the

Evaluationofexaminationresultsmaybeconductedatthetime

weld, orthogonal to the toe. The depth of penetration of this

of examination or at a later date. The examiner generates an

current varies with material type and frequency but is typically

examination report detailing complete results of the examina-

0.004in.[0.1mm]deepinmagneticmaterialsand0.08-0.3in.

tion.

[2-7mm]deepinnon-ferrousmaterials.Anysurfacebreaking

discontinuities within 0.4 in. [10 mm] of either side of the scan

5. Significance and Use

line at this location will interrupt or disturb the flow of the

5.1 The purpose of the alternating current field measure-

otherwise uniform electromagnetic field. Measurement of the

ment method is to evaluate welds in the area of the toe for

absolute quantities of the two major components of the surface

surface breaking discontinuities such as fatigue cracks. The

magnetic fields (Bx and Bz) determines the severity of the

examination results may then be used by qualified organiza-

disturbance (see Fig. 1) and thus the severity of the disconti-

tions to assess weld service life or other engineering charac-

nuity. Discontinuity sizes, such as crack length and depth, can

teristics (beyond the scope of this practice).

be predicted from key points selected from the Bx and Bz

5.2 Comparison with Conventional Eddy Current

traces along with the standardization data and instrument

Examination—conventional eddy current coils are typically

settings from each individual probe. This discontinuity sizing

configured to sense the field from the weld in the immediate

can be performed automatically using system software.

vicinity of the emitting element, whereas alternating current

4.2 Standardization data and instrument settings for each

field measurement probes are typically designed to sense the

individual probe are determined at the factory and stored in a

magnetic field from the weld distant from the exciter.

computer file, which is loaded at the start of the examination.

System sensitivity is verified using an operation standardiza-

6. Basis of Application

tion block. System sensitivity is checked and recorded prior to

6.1 Personnel Qualification:

andatregularintervalsduringtheexamination.Notethatwhen

6.1.1 If specified in the contractual agreement, personnel

a unidirectional input current is used, any decay in strength of

performing examinations to this practice shall be qualified in

the input field with probe lift-off or thin coating is relatively

accordance with a nationally recognized NDT personnel quali-

small so that variations of output signal (as may be associated

fication practice or standard such as ANSI/ASNT-CP-189 or

with a discontinuity) are reduced. If a thick coating, that is,

SNT-TC-1A or a similar document and certified by the em-

greater than 0.04 in. [1 mm] is present then the discontinuity

ployer or certifying agent, as applicable. The practice or

standard used and its applicable revision shall be identified in

the contractual agreement between the using parties.

6.2 Qualification of Nondestructive Evaluation

Agencies—if specified in the contractual agreement, NDT

agencies shall be qualified and evaluated as described in

Practice E 543, with reference to sections on electromagnetic

examination. The applicable edition of Practice E 543 shall be

specified in the contractual agreement.

7. Job Scope and Requirements

7.1 The following items may require agreement by the

examining party and their client and should be specified in the

purchase document or elsewhere:

7.1.1 Location and type of welded component to be exam-

ined, design specifications, degradation history, previous non-

destructive examination results, maintenance history, process

conditions, and specific types of discontinuities that are re-

quired to be detected, if known.

7.1.2 The maximum window of opportunity for work.

(Detection of small discontinuities may require a slower probe

scan speed, which will affect productivity.)

7.1.3 Size, material grade and type, and configuration of

FIG. 1 Typical Bx and Bz Traces as a Probe Passes Over a Crack welds to be examined.

E2261–03

7.1.4 A weld numbering or identification system. from a linear discontinuity will die away quickly away from

7.1.5 Extent of examination, for example: complete or the location of the discontinuity so that the scan away from the

partial coverage, which welds and to what length, whether weld toe will be flatter. If there is no significant change in

straight sections only and the minimum surface curvature. indication amplitude at 0.80 in. [20 mm] distance from the

7.1.6 Meansofaccesstowelds,andareaswhereaccessmay weld then the indication is likely due to the effect of the

be restricted. grinding.

7.1.7 Type of alternating current field measurement instru-

8.4 Residual stress, with accompanying permeability varia-

ment and probe; and description of operations standardization tions, may be present with similar, but much smaller, effects to

block used, including such details as dimensions and material.

grinding.

7.1.8 Required operator qualifications and certification.

8.5 Seam Welds:

7.1.9 Required weld cleanliness.

8.5.1 Seam welds running across the line of scanning also

7.1.10 Environmental conditions, equipment and prepara-

produce strong indications in the Bx and Bz, which can

tions that are the responsibility of the client; common sources

sometimes be confused, with a discontinuity indication. The

of noise that may interfere with the examination.

same procedure is used as for grinding marks with further

7.1.11 Complementary methods or techniques may be used

scans being taken away from the affected area. If the indication

to obtain additional information.

remains constant then it will not have been produced by a

7.1.12 Acceptance criteria to be used in evaluating discon-

linear discontinuity.

tinuities.

8.6 Ferromagnetic and Conductive Objects:

7.1.13 Disposition of examination records and reference

8.6.1 Problems may arise because of objects near the weld

standards.

that are ferromagnetic or conductive which may reduce the

7.1.14 Format and outline contents of the examination

sensitivity and accuracy of discontinuity characterization when

report.

they are in the immediate vicinity of the weld.

8.7 Neighboring Welds:

8. Interferences

8.7.1 In areas where welds cross each other, there are

8.1 This section describes items and conditions, which may

indications, which may be mistaken for discontinuities. (See

compromise the alternating current field measurement tech-

8.5.)

nique.

8.8 Weld Geometry:

8.2 Material Properties:

8.8.1 When a probe scans into a tight angle between two

8.2.1 Although there are permeability differences in a fer-

surfacestheBxindicationvaluewillincreasewithlittlechange

romagnetic material between weld metal, heat affected zone

in the Bz. This will cause the X-Y plot to rise.

material and parent plate, the probe is normally scanned along

8.9 Crack Geometry Effects:

a weld toe and so passes along a line of relatively constant

8.9.1 A discontinuity at an angle to the scan—a discontinu-

permeability. If a probe is scanned across a weld then the

ity at an angle to the scan will reduce either the peak or the

permeability changes may produce indications, which could be

trough of the Bz as the sensor probe only passes through the

similar to those from a discontinuity. Differentiation between a

edgeofoneendofthediscontinuity.Thisproducesanun-equal

transverse discontinuity signal and the weld signal can be

sided X-Y plot. Additional scans may be made along the weld

achieved by taking further scans parallel to the discontinuity.

or parent plate to determine the position of the other end of the

The signal from a discontinuity will die away quickly. If there

discontinuity.

is no significant change in indication amplitude at 0.8 in. [20

8.9.2 A discontinuity at an angle to the surface—the effect

mm] distance from the weld then the indication is likely due to

of a discontinuity at a non-vertical angle to the probe is

the permeability changes in the weld.

generally to reduce the value of the Bz signal. The value of the

8.3 Magnetic State:

Bx signal will not be reduced. This has the effect of reducing

8.3.1 Demagnetization—It must be ensured that the surface

the width of the X-Y plot.

being examined is in the non-magnetized state. Therefore the

8.9.3 Line contact or multiple discontinuities—when con-

procedure followed with any previous magnetic technique

tacts occur across a discontinuity then minor loops occur

deployed must include demagnetization of the surface. This is

withinthemainX-Yplotloopproducedbythediscontinuity.If

because areas of remnant magnetization, particularly where the

more than one discontinuity occurs in the scan then there will

leg of a magnetic particle examination yoke was sited, can

be a number of loops returning to the background.

produce loops in the X-Y plot, which may sometimes be

8.9.4 Transverse discontinuities—ifatransversediscontinu-

confused with a discontinuity indication.

8.3.2 Grinding marks—magnetic permeability can also be ity occurs during the scan for longitudinal discontinuities then

the Bx will rise instead of falling and the Bz signal will remain

affected by surface treatments such as grinding. These can

cause localized areas of altered permeability across the line of the same as for a short longitudinal discontinuity.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.