ASTM F1711-96(2016)

(Practice)Standard Practice for Measuring Sheet Resistance of Thin Film Conductors for Flat Panel Display Manufacturing Using a Four-Point Probe Method (Withdrawn 2023)

Standard Practice for Measuring Sheet Resistance of Thin Film Conductors for Flat Panel Display Manufacturing Using a Four-Point Probe Method (Withdrawn 2023)

SIGNIFICANCE AND USE

5.1 Applying Test Method F390 to large flat panel substrates presents a number of serious difficulties not anticipated in the development of that standard. The following problems are encountered.

5.1.1 The four-point probe method may be destructive to the thin film being measured. Sampling should therefore be taken close to an edge or corner of the plate, where the film is expendable. Special geometrical correction factors are then required to derive the true sheet resistance.

5.1.2 Test Method F390 is limited to a conventional collinear probe arrangement, but a staggered collinear and square arrays are useful in particular circumstances. Correction factors are needed to account for nonconventional probe arrangements.

5.1.3 Test Method F390 anticipates a precision testing arrangement in which the probe mount and sample are rigidly positioned. There is no corresponding apparatus available for testing large glass or plastic substrates. Indeed, it is common in flat panel display making that the probe is hand held by the operator.

5.1.4 It is difficult, given the conditions cited in 5.1.3, to ensure that uniform probe spacing is not degraded by rough handling of the equipment. The phased square array, described, averages out probe placement errors.

5.1.5 This practice is estimated to be precise to the following levels. Otherwise acceptable precision may be degraded by probe wobble, however (see 8.6.4).

5.1.5.1 As a referee method, in which the probe and measuring apparatus are checked and qualified before use by the procedures of Test Method F390 paragraph 7 and this practice, paragraph 8: standard deviation, s, from measured sheet resistance, RS, is ≤ 0.01 RS.

5.1.5.2 As a routine method, with periodic qualifications of probe and measuring apparatus by the procedures of Test Method F390 paragraph 7 and this practice, paragraph 8: standard deviation, s, from measured sheet resistance, RS, is ≤ 0.02 RS.

SCOPE

1.1 This practice describes methods for measuring the sheet electrical resistance of sputtered thin conductive films deposited on large insulating substrates, used in making flat panel information displays. It is assumed that the thickness of the conductive thin film is much thinner than the spacing of the contact probes used to measure the sheet resistance.

1.2 This standard is intended to be used with Test Method F390.

1.3 Sheet resistivity in the range 0.5 to 5000 ohms per square may be measured by this practice. The sheet resistance is assumed uniform in the area being probed.

1.4 This practice is applicable to flat surfaces only.

1.5 Probe pin spacings of 1.5 mm to 5.0 mm, inclusive (0.059 to 0.197 in inclusive) are covered by this practice.

1.6 The method in this practice is potentially destructive to the thin film in the immediate area in which the measurement is made. Areas tested should thus be characteristic of the functional part of the substrate, but should be remote from critical active regions. The method is suitable for characterizing dummy test substrates processed at the same time as substrates of interest.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice describes methods for measuring the sheet electrical resistance of sputtered thin conductive films deposited on large insulating substrates, used in making flat panel information displays. It is assumed that the thickness of the conductive thin film is much thinner than the spacing of the contact probes used to measure the sheet resistance.

Formerly under the jurisdiction of Committe...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1711 −96 (Reapproved 2016)

Standard Practice for

Measuring Sheet Resistance of Thin Film Conductors for

Flat Panel Display Manufacturing Using a Four-Point Probe

Method

This standard is issued under the fixed designation F1711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice describes methods for measuring the sheet

F390Test Method for Sheet Resistance of Thin Metallic

electrical resistance of sputtered thin conductive films depos-

Films With a Collinear Four-Probe Array

ited on large insulating substrates, used in making flat panel

information displays. It is assumed that the thickness of the

3. Terminology

conductive thin film is much thinner than the spacing of the

contact probes used to measure the sheet resistance.

3.1 Definitions:

3.1.1 For definitions of terms used in this practice see Test

1.2 This standard is intended to be used with Test Method

Method F390.

F390.

1.3 Sheet resistivity in the range 0.5 to 5000 ohms per

4. Summary of Practice

square may be measured by this practice. The sheet resistance

4.1 This practice describes the preferred means of applying

is assumed uniform in the area being probed.

Test Method F390 to measure the electrical sheet resistance of

1.4 This practice is applicable to flat surfaces only. thinfilmsonverylargeflatsubstrates.Anarrayoffourpointed

probesisplacedincontactwiththefilmofinterest.Ameasured

1.5 Probe pin spacings of 1.5 mm to 5.0 mm, inclusive

electrical current is passed between two of the probes, and the

(0.059 to 0.197 in inclusive) are covered by this practice.

electrical potential difference between the remaining two

probes is determined. The sheet resistance is calculated from

1.6 The method in this practice is potentially destructive to

the measured current and potential values using correction

the thin film in the immediate area in which the measurement

factors associated with the probe geometry and the probe’s

is made. Areas tested should thus be characteristic of the

distance from the test specimen’s boundaries.

functional part of the substrate, but should be remote from

critical active regions. The method is suitable for characteriz-

4.2 The method of F390 is extended to cover staggered

ing dummy test substrates processed at the same time as

in-lineandsquareprobearrays.Inallthedesigns,however,the

substrates of interest.

probe spacings are nominally equal.

4.3 This practice includes a special electrical test for veri-

1.7 The values stated in SI units are to be regarded as the

fying the proper functioning of the potential measuring instru-

standard. The values given in parentheses are for information

ment (voltmeter), directions for making and using sheet resis-

only.

tance reference films, an estimation of measurement error

1.8 This standard does not purport to address all of the

caused by probe wobble in the probe supporting fixture, and a

safety concerns, if any, associated with its use. It is the

protocol for reporting film uniformity.

responsibility of the user of this standard to establish appro-

4.4 Two appendices indicate the computation methods em-

priate safety and health practices and determine the applica-

ployed in deriving numerical relationships and correction

bility of regulatory limitations prior to use.

factors employed in this practice, and in Test Method F390.

This practice is under the jurisdiction ofASTM Committee F01 on Electronics

and is the direct responsibility of Subcommittee F01.17 on Sputter Metallization. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2016. Published May 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2008 as F1711–96(2008). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1711-96R16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1711−96 (2016)

5. Significance and Use 5.1.4 It is difficult, given the conditions cited in 5.1.3,to

ensure that uniform probe spacing is not degraded by rough

5.1 ApplyingTestMethodF390tolargeflatpanelsubstrates

handlingoftheequipment.Thephasedsquarearray,described,

presents a number of serious difficulties not anticipated in the

averages out probe placement errors.

development of that standard. The following problems are

5.1.5 This practice is estimated to be precise to the follow-

encountered.

inglevels.Otherwiseacceptableprecisionmaybedegradedby

5.1.1 Thefour-pointprobemethodmaybedestructivetothe

probe wobble, however (see 8.6.4).

thin film being measured. Sampling should therefore be taken

5.1.5.1 As a referee method, in which the probe and

close to an edge or corner of the plate, where the film is

measuring apparatus are checked and qualified before use by

expendable. Special geometrical correction factors are then

the procedures of Test Method F390 paragraph 7 and this

required to derive the true sheet resistance.

practice, paragraph 8: standard deviation, s, from measured

5.1.2 Test Method F390 is limited to a conventional col-

sheet resistance, R,is ≤ 0.01 R .

S S

linear probe arrangement, but a staggered collinear and square

5.1.5.2 As a routine method, with periodic qualifications of

arraysareusefulinparticularcircumstances.Correctionfactors

probe and measuring apparatus by the procedures of Test

are needed to account for nonconventional probe arrange-

Method F390 paragraph 7 and this practice, paragraph 8:

ments.

standard deviation, s, from measured sheet resistance, R,is ≤

5.1.3 Test Method F390 anticipates a precision testing S

0.02 R .

S

arrangement in which the probe mount and sample are rigidly

positioned. There is no corresponding apparatus available for

6. Apparatus

testinglargeglassorplasticsubstrates.Indeed,itiscommonin

flat panel display making that the probe is hand held by the

6.1 Probe Assembly:

operator.

6.1.1 The probe assembly must meet the apparatus require-

ments of F390, 5.1.1 – 5.1.3.

6.1.2 Four arrangements of probe tips are covered in this

practice:

6.1.2.1 In-Line, Collinear, Probe Tips, with current flowing

between the outer two probes (see Fig. 1A). This is the

conventional arrangement specified in Test Method F390.

6.1.2.2 Staggered Collinear Probe Tips, with current flow-

ing between one outer and one interior probe (see Fig. 1B).

This arrangement is sometimes used as a check to verify the

results of a conventional collinear measurement (see 6.1.2.1).

6.1.2.3 Square Array, with current conducted between two

adjacent probe tips (see Fig. 1C).

6.1.2.4 Phased Square Array, with current applied alter-

nately between opposite pairs of tips (see Fig. 1D). This

arrangement has the advantage of averaging out errors caused

by unequal probe spacing.

6.1.3 Probe Support— The probe support shall be designed

in such a manner that the operator can accurately lower the

probes perpendicularly onto the surface and provide a repro-

ducible probe force for each measurement. Spring loading or

gravity probe pin loading are acceptable.

6.2 Electrical Measuring Apparatus— The electrical appa-

ratus must meet the apparatus requirements of Test Method

F390, 5.2.1 through 5.2.4.

6.3 Specimen Support— The substrate to be tested must be

supported firmly.

6.4 Additional Apparatus:

6.4.1 If measurements will be made within a distance of 20

times the probe spacing from an insulating or highly conduc-

tive edge or corner (20× S, where i =1, 2, 3, or 4, with

i

reference to Fig. 1), an instrument capable of measuring the

distance from the probe array position to the insulating or

highly conductive boundary within 60.25 mm (60.010 in) is

required. In most instances a vernier depth gage is suitable.

6.4.2 Toolmaker’s Microscope, capable or measuring incre-

FIG. 1 Four-Point Probe Configurations ments of 2.5 µm.

F1711−96 (2016)

7. Test Specimen films on soda lime glass substrates. The surface of this glass

can be somewhat electrically conductive (on the order of

7.1 Thetestarticleshallbeeitheradisplaysubstratethathas

6 2

1×10 Ω ) when the ambient relative humidity is about 90%

been sputter coated with the thin film of interest, or,

or higher.

alternatively, a dummy plate coated in the same operation as

the substrate of interest. 7.5.1 The glass conductivity degradation may interfere with

the sheet resistance measurement when specimen sheet resis-

7.2 The conductive film must be thick enough that it is

tivity is 1000 Ω/square or higher.

continuous. Generally this requires that the film be at least 15

7.5.2 Ensure that films >1000 Ω/square sheet resistance

nm (150Å) thick.

deposited on soda lime glass are conditioned at less than 50%

7.3 The area to be tested shall be free of contamination and

humidity for at least 48 h prior to measurement, and that the

mechanical damage, but shall not be cleaned or otherwise

measurementisperformedatanambientrelativehumidityless

prepared.

than 50%.

7.4 Note that a sputtered film may also coat the edge of the

7.5.3 Note that at relative humidity less than 50% the

glassandcancoatthebacksideofthesubstrate(“overspray”).

surface resistance of soda lime glass in on the order of

Thus the edge of the glass cannot be automatically assumed to

1×10 Ω/ square.

be insulating. If sheet resistance determinations will be made

within a distance of 20 times the probe spacing to an edge of

8. Suitability of Test Equipment

thesubstrateitisnecessarytoensurethatthefilmterminatesat

the edge.

8.1 Equipment Qualification—The probe assembly and the

7.4.1 To eliminate over spray error in compensating for

electrical equipment must be qualified for use as specified in

edgeeffectsataninsulatingboundary(see10.2.2),eithermake

Test Method F390, paragraphs 7.1 through 7.2.3.3 on suitabil-

a fresh cut of the substrate, grind the edge to remove any

ity.

residual film, or etch the film from the edge.

7.4.2 Scribing the substrate near the edge using a glass

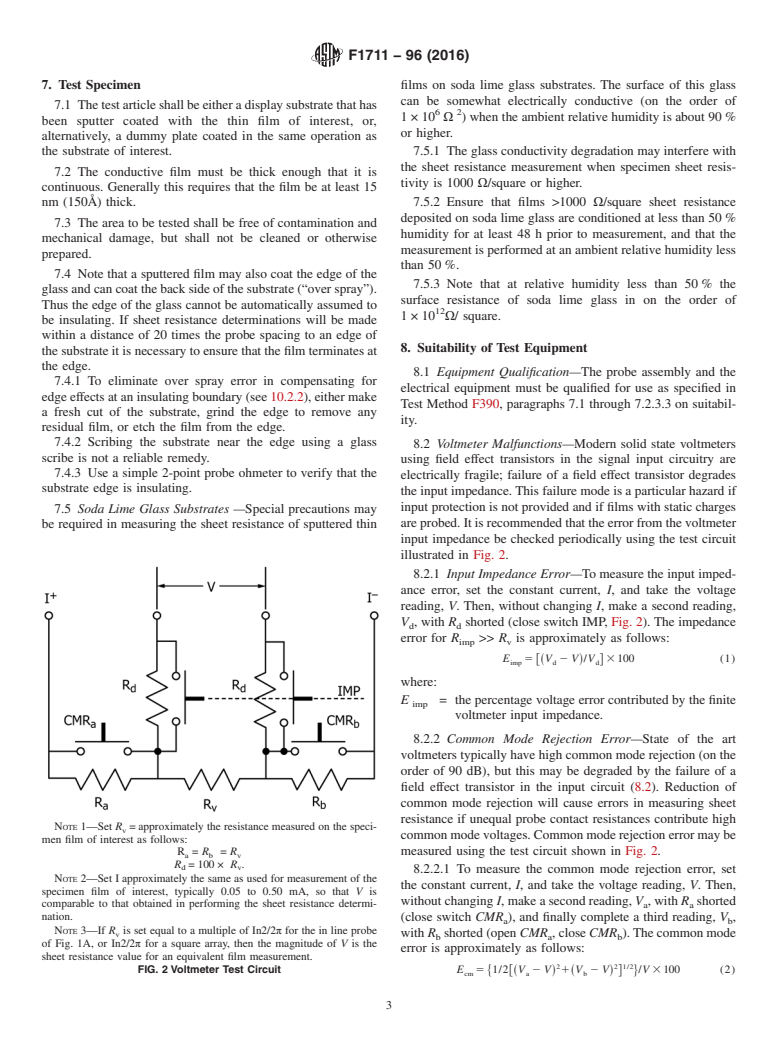

8.2 Voltmeter Malfunctions—Modern solid state voltmeters

scribe is not a reliable remedy.

using field effect transistors in the signal input circuitry are

7.4.3 Use a simple 2-point probe ohmeter to verify that the

electrically fragile; failure of a field effect transistor degrades

substrate edge is insulating.

theinputimpedance.Thisfailuremodeisaparticularhazardif

inputprotectionisnotprovidedandiffilmswithstaticcharges

7.5 Soda Lime Glass Substrates —Special precautions may

areprobed.Itisrecommendedthattheerrorfromthevoltmeter

be required in measuring the sheet resistance of sputtered thin

input impedance be checked periodically using the test circuit

illustrated in Fig. 2.

8.2.1 Input Impedance Error—To measure the input imped-

ance error, set the constant current, I, and take the voltage

reading, V. Then, without changing I, make a second reading,

V , with R shorted (close switch IMP, Fig. 2). The impedance

d d

error for R >> R is approximately as follows:

imp v

E 5 @~V 2 V!/V # 3100 (1)

imp d d

where:

E = the percentage voltage error contributed by the finite

imp

voltmeter input impedance.

8.2.2 Common Mode Rejection Error—State of the art

voltmeterstypicallyhavehighcommonmoderejection(onthe

order of 90 dB), but this may be degraded by the failure of a

field effect transistor in the input circuit (8.2). Reduction of

common mode rejection will cause errors in measuring sheet

resistance if unequal probe contact resistances contribute high

NOTE 1—Set R =approximately the resistance measured on the speci-

v

commonmodevoltages.Commonmoderejectionerrormaybe

men film of interest as follows:

measured using the test circuit shown in Fig. 2.

R =R =R

a b v

R =100× R .

d v

8.2.2.1 To measure the common mode rejection error, set

NOTE 2—Set I approximately the same as used for measurement of the

the constant current, I, and take the voltage reading, V. Then,

specimen film of interest, typically 0.05 to 0.50 mA, so that V is

withoutchanging I,makeasecondreading, V ,with R shorted

comparable to that obtained in performing the sheet resistance determi- a a

nation.

(close switch CMR ), and finally complete a third reading, V ,

a b

NOTE 3—If R is set equal to a multiple of In2/2π for the in line probe

v with R shorted(open CMR ,close CMR ).Thecommonmode

b a b

of Fig. 1A, or In2/2π for a square array, then the magnitude of V is the

error is approximately as follows:

sheet resistance value for an equivalent film measurement.

2 2 1/2

FIG. 2Voltmeter Test Circuit E 5 1/2 V 2 V 1 V 2 V /V 3100 (2)

$ @~ ! ~ ! # %

cm a b

F1711−96 (2016)

where:

E = the percentage voltage error contributed by common

cm

mode voltages. The voltmeter must be repaired or

replaced if E exceeds 0.5%.

cm

8.3 Voltage Limited Constant Current Supply—In cases of

high sheet resistance or high contact resistance, the voltage at

theconstantcurrentsourcemaynotbehighenoughtodrivethe

setcurrent.Thisconditioncausesverylargeerrorsincomputed

sheet resistance.

8.3.1 Ensure that the measuring circuit contains a direct

readingammeter(seeTestMethodF390,5.2.4),permittingthe

operator to verify the true current flow.

8.3.2 Alternatively, provide electronic means to divide the

measured voltage by the measured current. This ratio may be

provideddigitallyorbyadual-slopeintegratingvoltmeterwith

reference voltage inputs.

8.4 Avoid Arcing On the Film—Astheprobesaremakingor

breakingcontactwiththefilm,thevoltagedrivingtheconstant

current source can cause arcing damage to the film and the

FIG. 3 Sheet Resistance Reference Specimen

probes. To avoid arcing, keep the constant current supply

voltage low or provide switching preventing application of

current supply voltage until after contact is made with the film

electrode for reference films of 20 Ω per square or greater.

under test.

Referencefilmslessthan20Ωpersquareshouldhaveacopper

wire soldered to the lengths of the bus electrodes, or should

NOTE 1—Ten-volt potential typically does not cause visible arcing

damage, but 100 volt potential often does.

have the thickness of the copper film electrodes increased

proportionately.

8.5 Fabrication and Use of Sheet-Resistance Reference

8.5.4.2 The sheet resistance of the reference film may be

Specimens—It is useful to maintain sheet-resistance reference

cali

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1711 − 96 (Reapproved 2016)

Standard Practice for

Measuring Sheet Resistance of Thin Film Conductors for

Flat Panel Display Manufacturing Using a Four-Point Probe

Method

This standard is issued under the fixed designation F1711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice describes methods for measuring the sheet

F390 Test Method for Sheet Resistance of Thin Metallic

electrical resistance of sputtered thin conductive films depos-

Films With a Collinear Four-Probe Array

ited on large insulating substrates, used in making flat panel

information displays. It is assumed that the thickness of the

3. Terminology

conductive thin film is much thinner than the spacing of the

contact probes used to measure the sheet resistance.

3.1 Definitions:

3.1.1 For definitions of terms used in this practice see Test

1.2 This standard is intended to be used with Test Method

Method F390.

F390.

1.3 Sheet resistivity in the range 0.5 to 5000 ohms per

4. Summary of Practice

square may be measured by this practice. The sheet resistance

4.1 This practice describes the preferred means of applying

is assumed uniform in the area being probed.

Test Method F390 to measure the electrical sheet resistance of

thin films on very large flat substrates. An array of four pointed

1.4 This practice is applicable to flat surfaces only.

probes is placed in contact with the film of interest. A measured

1.5 Probe pin spacings of 1.5 mm to 5.0 mm, inclusive

electrical current is passed between two of the probes, and the

(0.059 to 0.197 in inclusive) are covered by this practice.

electrical potential difference between the remaining two

probes is determined. The sheet resistance is calculated from

1.6 The method in this practice is potentially destructive to

the measured current and potential values using correction

the thin film in the immediate area in which the measurement

factors associated with the probe geometry and the probe’s

is made. Areas tested should thus be characteristic of the

distance from the test specimen’s boundaries.

functional part of the substrate, but should be remote from

critical active regions. The method is suitable for characteriz-

4.2 The method of F390 is extended to cover staggered

ing dummy test substrates processed at the same time as

in-line and square probe arrays. In all the designs, however, the

substrates of interest. probe spacings are nominally equal.

1.7 The values stated in SI units are to be regarded as the 4.3 This practice includes a special electrical test for veri-

fying the proper functioning of the potential measuring instru-

standard. The values given in parentheses are for information

ment (voltmeter), directions for making and using sheet resis-

only.

tance reference films, an estimation of measurement error

1.8 This standard does not purport to address all of the

caused by probe wobble in the probe supporting fixture, and a

safety concerns, if any, associated with its use. It is the

protocol for reporting film uniformity.

responsibility of the user of this standard to establish appro-

4.4 Two appendices indicate the computation methods em-

priate safety and health practices and determine the applica-

ployed in deriving numerical relationships and correction

bility of regulatory limitations prior to use.

factors employed in this practice, and in Test Method F390.

This practice is under the jurisdiction of ASTM Committee F01 on Electronics

and is the direct responsibility of Subcommittee F01.17 on Sputter Metallization. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2016. Published May 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2008 as F1711 – 96(2008). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1711-96R16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1711 − 96 (2016)

5. Significance and Use 5.1.4 It is difficult, given the conditions cited in 5.1.3, to

ensure that uniform probe spacing is not degraded by rough

5.1 Applying Test Method F390 to large flat panel substrates

handling of the equipment. The phased square array, described,

presents a number of serious difficulties not anticipated in the

averages out probe placement errors.

development of that standard. The following problems are

5.1.5 This practice is estimated to be precise to the follow-

encountered.

ing levels. Otherwise acceptable precision may be degraded by

5.1.1 The four-point probe method may be destructive to the

probe wobble, however (see 8.6.4).

thin film being measured. Sampling should therefore be taken

5.1.5.1 As a referee method, in which the probe and

close to an edge or corner of the plate, where the film is

measuring apparatus are checked and qualified before use by

expendable. Special geometrical correction factors are then

the procedures of Test Method F390 paragraph 7 and this

required to derive the true sheet resistance.

practice, paragraph 8: standard deviation, s, from measured

5.1.2 Test Method F390 is limited to a conventional col-

sheet resistance, R , is ≤ 0.01 R .

S S

linear probe arrangement, but a staggered collinear and square

5.1.5.2 As a routine method, with periodic qualifications of

arrays are useful in particular circumstances. Correction factors

probe and measuring apparatus by the procedures of Test

are needed to account for nonconventional probe arrange-

Method F390 paragraph 7 and this practice, paragraph 8:

ments.

standard deviation, s, from measured sheet resistance, R , is ≤

S

5.1.3 Test Method F390 anticipates a precision testing

0.02 R .

arrangement in which the probe mount and sample are rigidly S

positioned. There is no corresponding apparatus available for

6. Apparatus

testing large glass or plastic substrates. Indeed, it is common in

flat panel display making that the probe is hand held by the

6.1 Probe Assembly:

operator.

6.1.1 The probe assembly must meet the apparatus require-

ments of F390, 5.1.1 – 5.1.3.

6.1.2 Four arrangements of probe tips are covered in this

practice:

6.1.2.1 In-Line, Collinear, Probe Tips, with current flowing

between the outer two probes (see Fig. 1A). This is the

conventional arrangement specified in Test Method F390.

6.1.2.2 Staggered Collinear Probe Tips, with current flow-

ing between one outer and one interior probe (see Fig. 1B).

This arrangement is sometimes used as a check to verify the

results of a conventional collinear measurement (see 6.1.2.1).

6.1.2.3 Square Array, with current conducted between two

adjacent probe tips (see Fig. 1C).

6.1.2.4 Phased Square Array, with current applied alter-

nately between opposite pairs of tips (see Fig. 1D). This

arrangement has the advantage of averaging out errors caused

by unequal probe spacing.

6.1.3 Probe Support— The probe support shall be designed

in such a manner that the operator can accurately lower the

probes perpendicularly onto the surface and provide a repro-

ducible probe force for each measurement. Spring loading or

gravity probe pin loading are acceptable.

6.2 Electrical Measuring Apparatus— The electrical appa-

ratus must meet the apparatus requirements of Test Method

F390, 5.2.1 through 5.2.4.

6.3 Specimen Support— The substrate to be tested must be

supported firmly.

6.4 Additional Apparatus:

6.4.1 If measurements will be made within a distance of 20

times the probe spacing from an insulating or highly conduc-

tive edge or corner (20 × S , where i = 1, 2, 3, or 4, with

i

reference to Fig. 1), an instrument capable of measuring the

distance from the probe array position to the insulating or

highly conductive boundary within 60.25 mm (60.010 in) is

required. In most instances a vernier depth gage is suitable.

6.4.2 Toolmaker’s Microscope, capable or measuring incre-

FIG. 1 Four-Point Probe Configurations ments of 2.5 µm.

F1711 − 96 (2016)

7. Test Specimen films on soda lime glass substrates. The surface of this glass

can be somewhat electrically conductive (on the order of

7.1 The test article shall be either a display substrate that has

6 2

1 × 10 Ω ) when the ambient relative humidity is about 90 %

been sputter coated with the thin film of interest, or,

or higher.

alternatively, a dummy plate coated in the same operation as

the substrate of interest. 7.5.1 The glass conductivity degradation may interfere with

the sheet resistance measurement when specimen sheet resis-

7.2 The conductive film must be thick enough that it is

tivity is 1000 Ω/square or higher.

continuous. Generally this requires that the film be at least 15

nm (150Å) thick. 7.5.2 Ensure that films >1000 Ω/square sheet resistance

deposited on soda lime glass are conditioned at less than 50 %

7.3 The area to be tested shall be free of contamination and

humidity for at least 48 h prior to measurement, and that the

mechanical damage, but shall not be cleaned or otherwise

measurement is performed at an ambient relative humidity less

prepared.

than 50 %.

7.4 Note that a sputtered film may also coat the edge of the

7.5.3 Note that at relative humidity less than 50 % the

glass and can coat the back side of the substrate (“over spray”).

surface resistance of soda lime glass in on the order of

Thus the edge of the glass cannot be automatically assumed to

1 × 10 Ω/ square.

be insulating. If sheet resistance determinations will be made

within a distance of 20 times the probe spacing to an edge of

8. Suitability of Test Equipment

the substrate it is necessary to ensure that the film terminates at

the edge.

8.1 Equipment Qualification—The probe assembly and the

7.4.1 To eliminate over spray error in compensating for

electrical equipment must be qualified for use as specified in

edge effects at an insulating boundary (see 10.2.2), either make

Test Method F390, paragraphs 7.1 through 7.2.3.3 on suitabil-

a fresh cut of the substrate, grind the edge to remove any

ity.

residual film, or etch the film from the edge.

7.4.2 Scribing the substrate near the edge using a glass

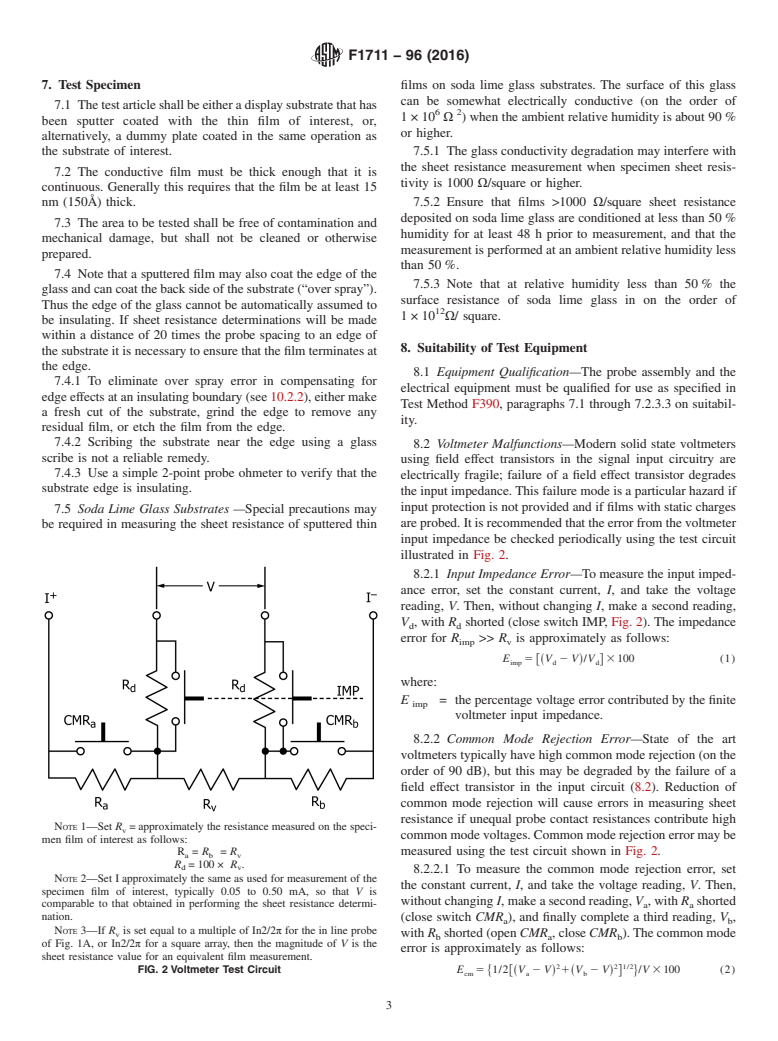

8.2 Voltmeter Malfunctions—Modern solid state voltmeters

scribe is not a reliable remedy.

using field effect transistors in the signal input circuitry are

7.4.3 Use a simple 2-point probe ohmeter to verify that the

electrically fragile; failure of a field effect transistor degrades

substrate edge is insulating.

the input impedance. This failure mode is a particular hazard if

input protection is not provided and if films with static charges

7.5 Soda Lime Glass Substrates —Special precautions may

are probed. It is recommended that the error from the voltmeter

be required in measuring the sheet resistance of sputtered thin

input impedance be checked periodically using the test circuit

illustrated in Fig. 2.

8.2.1 Input Impedance Error—To measure the input imped-

ance error, set the constant current, I, and take the voltage

reading, V. Then, without changing I, make a second reading,

V , with R shorted (close switch IMP, Fig. 2). The impedance

d d

error for R >> R is approximately as follows:

imp v

E 5 V 2 V /V 3 100 (1)

@~ ! #

imp d d

where:

E = the percentage voltage error contributed by the finite

imp

voltmeter input impedance.

8.2.2 Common Mode Rejection Error—State of the art

voltmeters typically have high common mode rejection (on the

order of 90 dB), but this may be degraded by the failure of a

field effect transistor in the input circuit (8.2). Reduction of

common mode rejection will cause errors in measuring sheet

resistance if unequal probe contact resistances contribute high

NOTE 1—Set R = approximately the resistance measured on the speci-

v

common mode voltages. Common mode rejection error may be

men film of interest as follows:

R = R = R measured using the test circuit shown in Fig. 2.

a b v

R = 100 × R .

d v

8.2.2.1 To measure the common mode rejection error, set

NOTE 2—Set I approximately the same as used for measurement of the

the constant current, I, and take the voltage reading, V. Then,

specimen film of interest, typically 0.05 to 0.50 mA, so that V is

without changing I, make a second reading, V , with R shorted

comparable to that obtained in performing the sheet resistance determi-

a a

nation. (close switch CMR ), and finally complete a third reading, V ,

a b

NOTE 3—If R is set equal to a multiple of In2/2π for the in line probe

v with R shorted (open CMR , close CMR ). The common mode

b a b

of Fig. 1A, or In2/2π for a square array, then the magnitude of V is the

error is approximately as follows:

sheet resistance value for an equivalent film measurement.

2 2 1/2

FIG. 2 Voltmeter Test Circuit E 5 $1/2@~V 2 V! 1~V 2 V! # %/V 3 100 (2)

cm a b

F1711 − 96 (2016)

where:

E = the percentage voltage error contributed by common

cm

mode voltages. The voltmeter must be repaired or

replaced if E exceeds 0.5 %.

cm

8.3 Voltage Limited Constant Current Supply—In cases of

high sheet resistance or high contact resistance, the voltage at

the constant current source may not be high enough to drive the

set current. This condition causes very large errors in computed

sheet resistance.

8.3.1 Ensure that the measuring circuit contains a direct

reading ammeter (see Test Method F390, 5.2.4), permitting the

operator to verify the true current flow.

8.3.2 Alternatively, provide electronic means to divide the

measured voltage by the measured current. This ratio may be

provided digitally or by a dual-slope integrating voltmeter with

reference voltage inputs.

8.4 Avoid Arcing On the Film—As the probes are making or

breaking contact with the film, the voltage driving the constant

current source can cause arcing damage to the film and the

FIG. 3 Sheet Resistance Reference Specimen

probes. To avoid arcing, keep the constant current supply

voltage low or provide switching preventing application of

current supply voltage until after contact is made with the film

electrode for reference films of 20 Ω per square or greater.

under test.

Reference films less than 20 Ω per square should have a copper

wire soldered to the lengths of the bus electrodes, or should

NOTE 1—Ten-volt potential typically does not cause visible arcing

damage, but 100 volt potential often does.

have the thickness of the copper film electrodes increased

proportionatel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.