ASTM D5572-95(2005)

(Specification)Standard Specification for Adhesives Used for Finger Joints in Nonstructural Lumber Products

Standard Specification for Adhesives Used for Finger Joints in Nonstructural Lumber Products

ABSTRACT

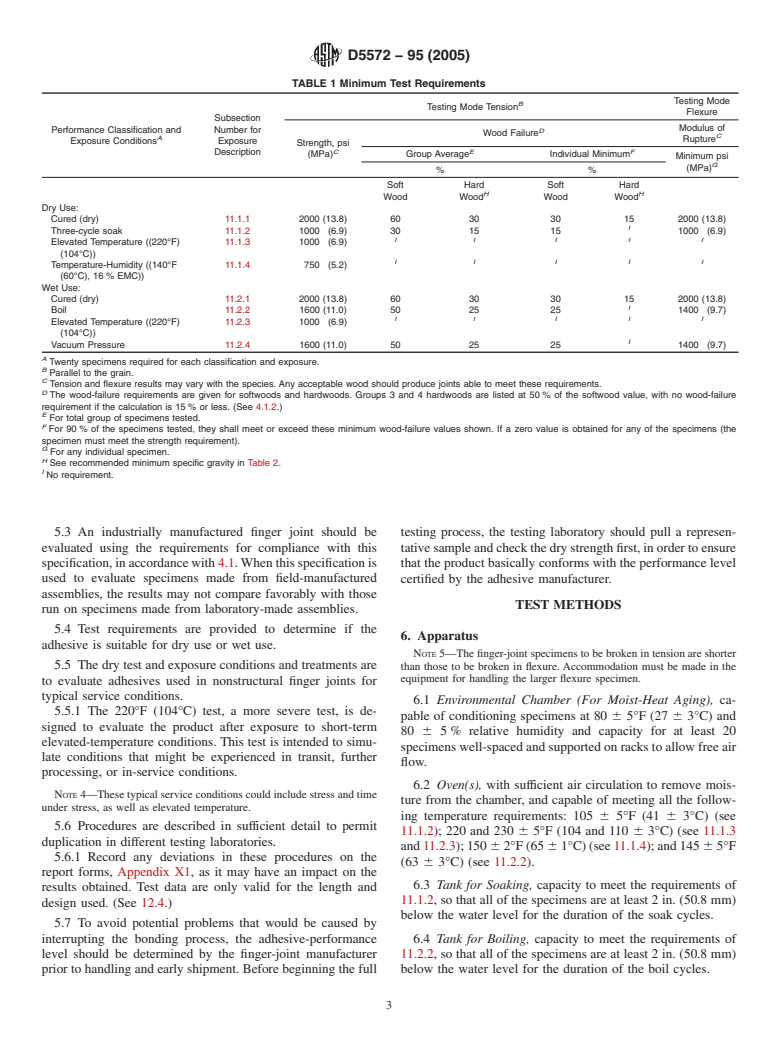

This specification establishes the performance levels for adhesives to be used in finger joints in nonstructural bonded-lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded-lumber panels. The apparatus shall consist of environmental chamber for moist-heat aging, oven with sufficient air circulation to remove moisture from the chamber, tanks for soaking and boiling, testing machines for the flexure and tension specimens, and vacuum-pressure vessel. Tests shall be conducted such as dry, soak, elevated-temperature, and temperature-humidity tests for dry-use classification and dry, boil, elevated-temperature, and vacuum-pressure tests for the wet-use classification. The adhesives shall be tested for performance which shall meet the following requirements: moisture content; specific gravities of wood species; tensile strength; wood failure for soft and hard woods; and rupture modulus.

SCOPE

1.1 This specification establishes performance levels for adhesives to be used in finger joints in nonstructural bonded-lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded-lumber panels. Adhesives that meet the requirements of the various performance classes are considered capable of providing an adequate bond for use under the conditions described for the class. This specification is to be used to evaluate adhesives as well as the adhesive bonds in the finger joints. See Section , Significance and Use, for limitations when using this specification to evaluate industrially manufactured finger joints. Note 1This specification supersedes the finger-joint portion of the 1990 edition of Specification D 3110.

1.2 The following index is provided as a guide to the test methods in this specification: SectionApparatusEquipment, Material, and Preparation of Assemblies and SpecimensConditioning for Factory-Manufactured Assemblies, Laboratory-Made Assemblies, and Test SpecimensTesting in FlexureTesting in TensionExposure Conditions and Treatments1.Dry Use Tests: Dry, 3-cycle Soak, Elevated Temperature, and Temperature-Humidity2.Wet Use Tests: Dry, Boil, Elevated Temperature, and Vacuum-PressureNote 2

The conditioning needed for various stages in the preparation of both types of specimens and for the exposure tests are given. Note 3

Specific guidelines for specimen size, exposure conditions, testing, calculation, and reporting are given for flexure specimens in Sections and , and for tension specimens in Sections and .

1.3 For the definitions of dry useand wet use, see and .

1.4 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information only.

The following precautionary caveat pertains only to the apparatus and test methods portions, Sections of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5572 −95(Reapproved2005)

Standard Specification for

Adhesives Used for Finger Joints in Nonstructural Lumber

1

Products

This standard is issued under the fixed designation D5572; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 The following precautionary caveat pertains only to the

apparatus and test methods portions, Sections 6-11 of this

1.1 This specification establishes performance levels for

specification: This standard does not purport to address all of

adhesives to be used in finger joints in nonstructural bonded-

the safety concerns, if any, associated with its use. It is the

lumber products. Such products include, but are not limited to,

responsibility of the user of this standard to establish appro-

interior and exterior mouldings, window and door components

priate safety and health practices and determine the applica-

or parts, and bonded-lumber panels. Adhesives that meet the

bility of regulatory limitations prior to use.

requirementsofthevariousperformanceclassesareconsidered

capable of providing an adequate bond for use under the

2. Referenced Documents

conditions described for the class. This specification is to be

2

2.1 ASTM Standards:

usedtoevaluateadhesivesaswellastheadhesivebondsinthe

D143Test Methods for Small Clear Specimens of Timber

finger joints. See Section 5, Significance and Use, for limita-

D907Terminology of Adhesives

tions when using this specification to evaluate industrially

D2016Methods of Test for Moisture Content of Wood

manufactured finger joints.

3

(Withdrawn 1987)

NOTE 1—This specification supersedes the finger-joint portion of the

D3110Specification forAdhesives Used in Laminate Joints

1990 edition of Specification D3110.

for Nonstructural Glued Lumber Products (Withdrawn

1.2 The following index is provided as a guide to the test

3

1996)

methods in this specification:

D4688Test Method for Evaluating StructuralAdhesives for

Section

Finger Jointing Lumber

Apparatus 6

D5266Practice for Estimating the Percentage of Wood

Equipment, Material, and Preparation of Assemblies and Specimens 7

Conditioning for Factory-Manufactured Assemblies, Laboratory-Made 8 Failure in Adhesive Bonded Joints

Assemblies, and Test Specimens

E4Practices for Force Verification of Testing Machines

Testing in Flexure 9

E6Terminology Relating to Methods of MechanicalTesting

Testing in Tension 10

Exposure Conditions and Treatments 11 E41Terminology Relating To Conditioning

1. Dry Use Tests: Dry, 3-cycle Soak, Elevated Temperature, 11.1

E177Practice for Use of the Terms Precision and Bias in

and Temperature-Humidity

ASTM Test Methods

2. Wet Use Tests: Dry, Boil, Elevated Temperature, and 11.2

Vacuum-Pressure

E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

NOTE 2—The conditioning needed for various stages in the preparation

of both types of specimens and for the exposure tests are given.

NOTE 3—Specific guidelines for specimen size, exposure conditions, 3. Terminology

testing, calculation, and reporting are given for flexure specimens in

3.1 Definitions:

Sections 9 and 11, and for tension specimens in Sections 10 and 11.

3.1.1 Many terms in this specification are defined in Termi-

1.3 For the definitions of dry use and wet use, see 3.2.1.1

nology D907 and Terminology E41.

and 3.2.1.2.

3.1.2 bond, n—the union of materials by adhesives.

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.3 finger joint, n—a joint formed by bonding two precut

as standard. The SI units given in parentheses are for informa-

members shaped like fingers. (See Figs. 1 and 2.)

tion only.

1 2

This specification is under the jurisdiction of ASTM Committee D14 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Adhesives. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2005. Published May 2005. Originally the ASTM website.

3

approved in 1994. Last previous edition approved in 1999 as D5572–95(1999). The last approved version of this historical standard is referenced on

DOI: 10.1520/D5572-95R05. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5572−95(2005)

wood-failure requirements for hardwood are 50% of the

requirements for softwoods.

4.2 Industrially Manufactured Finger Joint—An industri-

ally manuf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.