ASTM D1981-02

(Test Method)Standard Test Method for Measuring Color After Heating of Tall Oil Fatty Acids

Standard Test Method for Measuring Color After Heating of Tall Oil Fatty Acids

SCOPE

1.1 This test method covers the measurement of the Gardner color of tall oil fatty acids after heating in an atmosphere of nitrogen at 205°C for one or two h, depending on whether its iodine value is over or under 15, respectively. The specimen may be heated using either an aluminum heating block or an oil bath. This method is applicable to all tall oil fatty acids. Applicability of this method to other types of fatty acids has not been determined.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1981–02

Standard Test Method for

1

Measuring Color After Heating of Tall Oil Fatty Acids

This standard is issued under the fixed designation D 1981; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

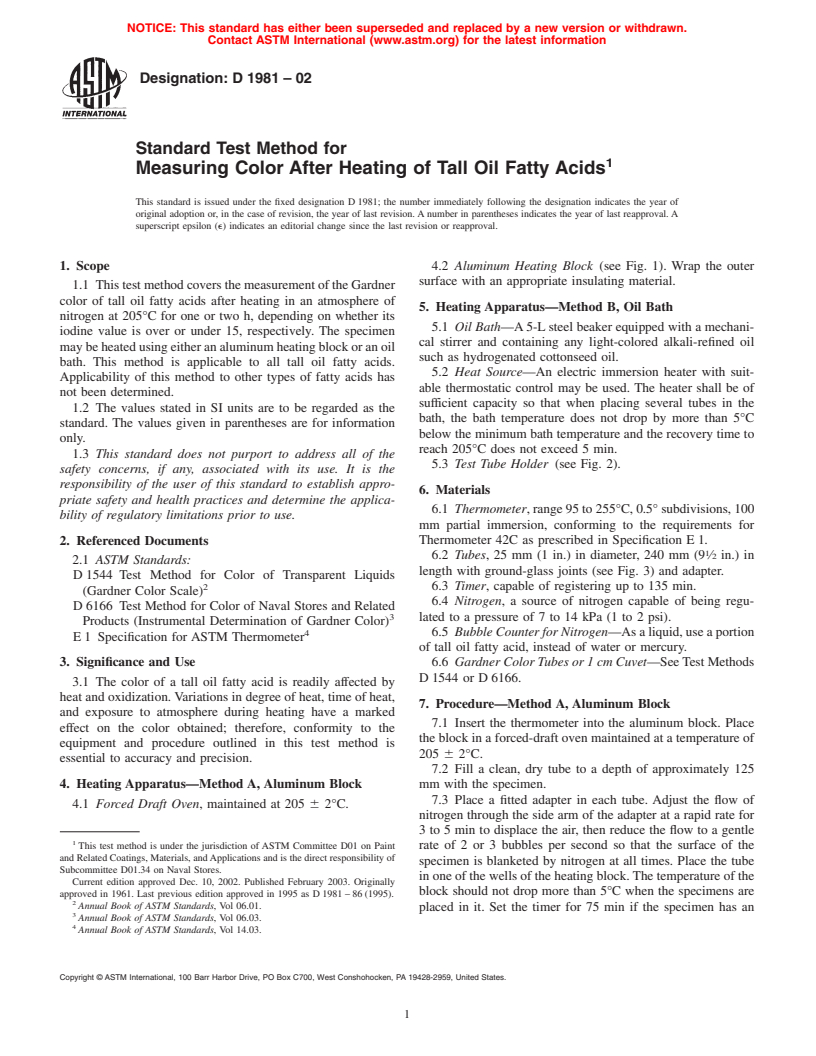

1. Scope 4.2 Aluminum Heating Block (see Fig. 1). Wrap the outer

surface with an appropriate insulating material.

1.1 ThistestmethodcoversthemeasurementoftheGardner

color of tall oil fatty acids after heating in an atmosphere of

5. Heating Apparatus—Method B, Oil Bath

nitrogen at 205°C for one or two h, depending on whether its

5.1 Oil Bath—A5-L steel beaker equipped with a mechani-

iodine value is over or under 15, respectively. The specimen

cal stirrer and containing any light-colored alkali-refined oil

maybeheatedusingeitheranaluminumheatingblockoranoil

such as hydrogenated cottonseed oil.

bath. This method is applicable to all tall oil fatty acids.

5.2 Heat Source—An electric immersion heater with suit-

Applicability of this method to other types of fatty acids has

able thermostatic control may be used. The heater shall be of

not been determined.

sufficient capacity so that when placing several tubes in the

1.2 The values stated in SI units are to be regarded as the

bath, the bath temperature does not drop by more than 5°C

standard. The values given in parentheses are for information

below the minimum bath temperature and the recovery time to

only.

reach 205°C does not exceed 5 min.

1.3 This standard does not purport to address all of the

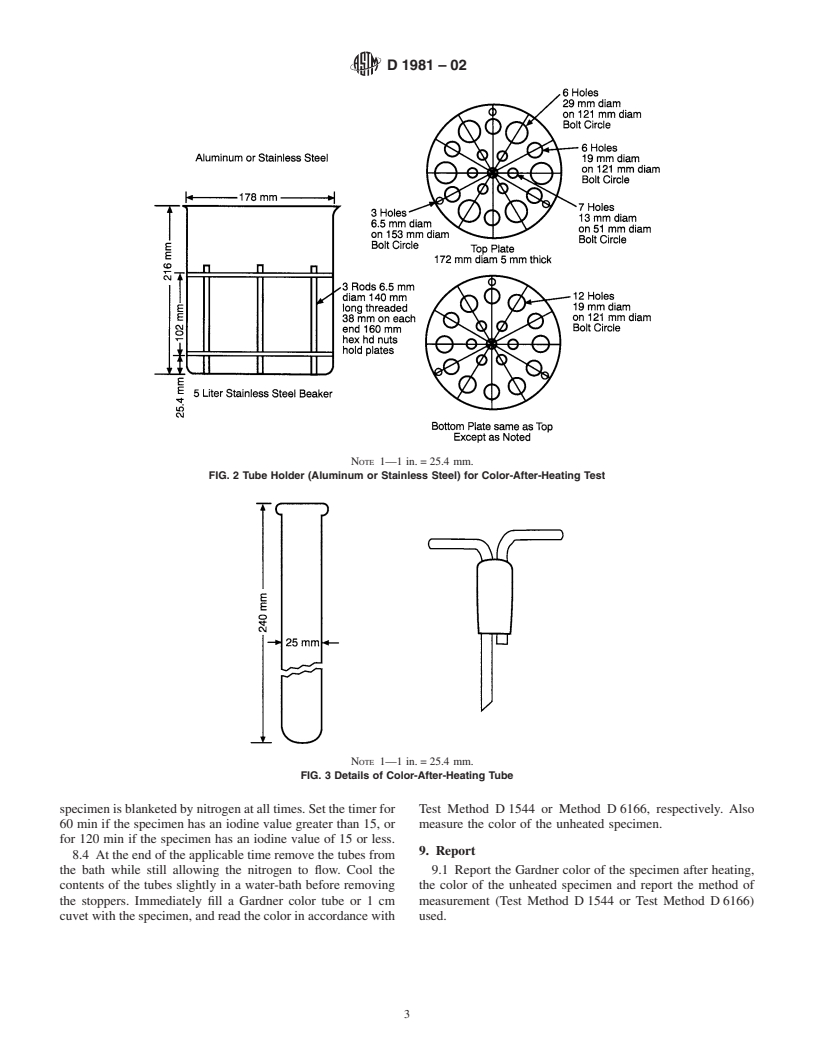

5.3 Test Tube Holder (see Fig. 2).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

6. Materials

priate safety and health practices and determine the applica-

6.1 Thermometer, range 95 to 255°C, 0.5° subdivisions, 100

bility of regulatory limitations prior to use.

mm partial immersion, conforming to the requirements for

2. Referenced Documents Thermometer 42C as prescribed in Specification E 1.

1

6.2 Tubes, 25 mm (1 in.) in diameter, 240 mm (9 ⁄2 in.) in

2.1 ASTM Standards:

length with ground-glass joints (see Fig. 3) and adapter.

D 1544 Test Method for Color of Transparent Liquids

2 6.3 Timer, capable of registering up to 135 min.

(Gardner Color Scale)

6.4 Nitrogen, a source of nitrogen capable of being regu-

D 6166 Test Method for Color of Naval Stores and Related

3 lated to a pressure of 7 to 14 kPa (1 to 2 psi).

Products (Instrumental Determination of Gardner Color)

4 6.5 BubbleCounterforNitrogen—As a liquid, use a portion

E 1 Specification for ASTM Thermometer

of tall oil fatty acid, instead of water or mercury.

3. Significance and Use 6.6 GardnerColorTubesor1cmCuvet—SeeTest Methods

D 1544 or D 6166.

3.1 The color of a tall oil fatty acid is readily affected by

heat and oxidization. Variations in degree of heat, time of heat,

7. Procedure—Method A, Aluminum Block

and exposure to atmosphere during heating have a marked

7.1 Insert the thermometer into the aluminum block. Place

effect on the color obtained; therefore, conformity to the

the block in a forced-draft oven maintained at a temperature of

equipment and procedure outlined in this test method is

205 6 2°C.

essential to accuracy and precision.

7.2 Fill a clean, dry tube to a depth of approximately 125

4. Heating Apparatus—Method A, Aluminum Block mm with the specimen.

7.3 Place a fitted adapter in each tube. Adjust the flow of

4.1 Forced Draft Oven, maintained at 205 6 2°C.

nitrogen through the side arm of the adapter at a rapid rate for

3 to 5 min to displace the air, then reduce the flow to a gentle

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

rate of 2 or 3 bubbles per second so that the surface of the

and Related Coatings, Materials, andApplications and is the direct responsibility of

specimen is blanketed by nitrogen at all times. Place the tube

Subcommittee D01.34 on Naval Stores.

in one of the wells of the heating block.The temperature of the

Current edition approved Dec. 10, 2002. Published February 2003. Originally

block should not drop more than 5°C when the specimens are

approved in 1961. Last previous edition approved in 1995 as D 1981 – 86 (1995).

2

Annual Book of ASTM Standards, Vol 06.01.

placed in it. Set the timer for 75 min if the specimen has an

3

Annual Book of ASTM Standards, Vol 06.03.

4

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1981–02

FIG. 1 Eight Hole Aluminum Heating Block

iodine value greater than

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.