ASTM B147-72

(Specification)Specification for High-Strength Yellow Brass (Manganese Bronze) and Leaded High-Strength Yellow Brass (Leaded Manganese Bronze) Sand Castings (Withdrawn 1972)

Specification for High-Strength Yellow Brass (Manganese Bronze) and Leaded High-Strength Yellow Brass (Leaded Manganese Bronze) Sand Castings (Withdrawn 1972)

General Information

Standards Content (Sample)

f ,., . , ,,.,.

4IJ~ Dasigna1ion: B 147 - 72

A11101lc.su (01,IIIJl\ln.on'• SO(jltly

Standard Specification for

HIGH-STRENGTH YELLOW BRASS (MANGANESE

BRONZE) AND LEADED HIGH-STRENGTH YELLOW

BRASS (LEADED MANGANESE BRONZE)

SAND CASTINGS'

Thi~ St;a11ct,,.t i, 1,~vc.d under lhe fixed deJ.lari,uinn 8 1,1; dte: numhe, ,m111tdta1cly fc1H1t . mg lhe (ksip.f\11•ii.>n indic.111es the

)Ur or ot'.Binal ado,1ti@1t ur, 1n. 11tc: ~;i1e or reYision. lht )tat or 11111 u:viuon. A muubtt in ~,cf\thcJC!l 11tJic.sfc1, the yc.n at

I.U( ~!\l)j'.HO~ .

4, Chemical Rcqalrcments

I, Se<>p•

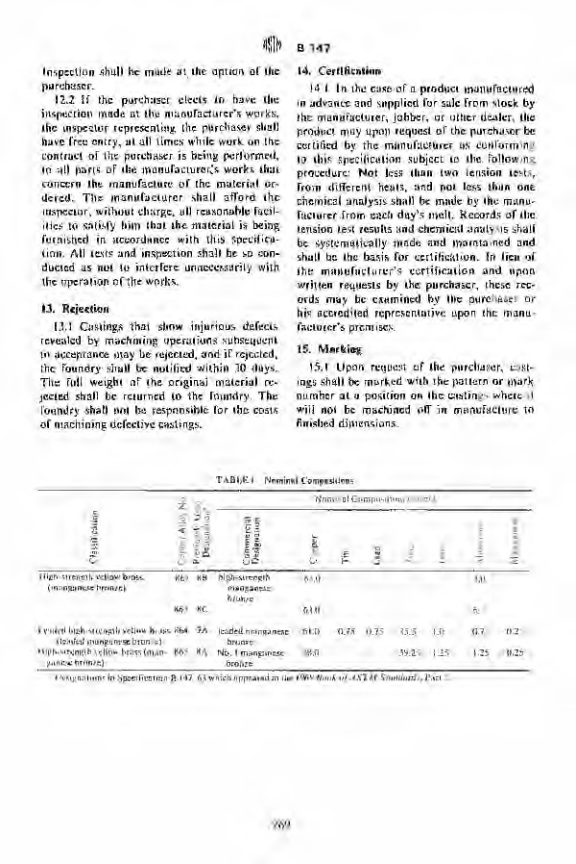

l.t This. ~pcciricution ~·overs four copper 4.1 The C41sling,; shall conform to lhc re

alloys hnving the /\STM clas~ifications.'" quirements n~ to Ch\:rnical compo!;ition p~

scribcd in Tublc 2.

<:oppcr o.lloy nu1nbet$ and (:Ommcn:ial dcsig•

nation~. and nominal composHion~. shown

S. M0

in Table I.

Non: t- This spcc.aficatinn coti1cr~ the recllnic,t{ S. I The mottrial shall

,cquircmems for ooppcr-basc alluy castings a111J is.

quirements as to tensile properties prescrihcd

not int<:nded fot u'Se fo, the oorrc sponding alloys in

in T•hle ).

i ngot form which .ln: spcciticd in AS T M Specifil.\

tion B 30, for Cuppcr-BHc Alloys in Ingot Fu,m for

8.1.nd Casting$."

6, l't.,re and Fracture Tts1•

Non: 2-The vu!ue~ s111.t«I in U.S. i.:uslum11ry

unilS are to be regarded as lh<: $\andard. The metric 6. I The castings shall conform lu such

equi"¥alcnts of U.S. c1,1stom~1r)' units may be upprus:

requirement~ a~ lo pressure and fracture te!;ls

im3tc.

as may be agreed u~on by the manufacturer

2. Or4rring lmonaalian and the rurchaser and as specified in the a, .

der.

2. I Orders for material under this specifi

cation shall include tho fallowing information:

2.1. I Copf)(;ralloy number (Section I). 7. Won.man,hip IUld Fiaish

2.1.2 Tests ot cerlification required (see 8.1

7.1 The ca

and 14.1 ), and

hulcs, porosity, hard spots. shrinkage defects

2.1.) Marking. if rcquir,;d (Section IS).

or cracks. or other injuriau~ defect~ and shatll

be smooth and well cleaned, before inspection,

3. Materials and Manofadur<

by . nd blasting, tumhling, ,·hipping. or other

3.1 The alloy m•y be made hy any ap

proce,s approved by lhc inspector.

proved method. If alloy• in ingot form arc

1.2 Tho casting.s shall not be n:paired,

usc:o. the alloy ingot sele<:tcd shall have the

plllS&C(I, welded, ur "burned in," unless per-

same ASTM clossification and alloy number

as prescribed in this ,pecification and shall

conform to the r<:quirt:mc:nts. for that alloy as

* 'fhif. i riecifl¢o,1i(in i> under the j1.1tfs;.ti"ian al ASY'M

C:ommillct 9 .5 011 Co(11'1Ct titld Cflppc, Altoy,.

prescribed in Specification 8 30.

<:iim nl cdi,ion appro~cd Ott. 29, 1972. Publishtd

3.2 The <:aslings shall be made in accord

fo'eb1u11rr 1'173. Otiiin.ally publish

anct:: wilh ~uch J'r.actice as to obtain th~ physi~ pr~v((l1,1X ~dition tJ 147 ll.

v ASTM Ch1ssiti"tkin 8 II~. Ct ~l (.'oppe1-80.se Alloy,;.

(al properties prcs.,ribcd in this s.pecitie.:ttion.

wh i~i'I o.ppur~ in the Amtc.ol Book u/ ASTM StG11do11/J.

3.) The ca

Put 5.

ily. ·' Am111nl Book of ASTM Sto4dan1$, Port 5.

267

---------------------- Page: 1 ----------------------

8147

nuss1on rrom th~ inspector has hl!cn pri:

9. T<>l Spe

viuusly secured. l'ht~ pt:tmis.s.iun will be given

9.1 Unless special ;iuthurity to u!-c couf'nns

only when th~ d~fcct$ urc such thut afttr (h~

of other fmm :,: Hnd dimc:nsiom: is obtaiocd

npprovcd repair the usefolness nnd !itrength of

rrnm 1f1t purchaser, it is recommttHfed I hat

the castint hu~ not he~n impaired. Each such

the lest coupons and sp1:c:imc:ns for tension

ccpuic shull be encircltd by u rin, of white

tc:!>t~ b(: prepared 10 accordance with ,\STM

puint at the time of shipnumt,

Recommended Pra.::ti\.:e 8 20S. for Tent.ion

7.3 All casting.-. .~hall hr,,: true tn p;,tlcm.

Tosi Specimens for Copper-Ila« Alloys for

frc:e from ~wells. etc. Wall thic1mes~cs !\hall be

Snnd Ca!ttiogs.3 c:x.ccpt that F;gs. 2. 3 and 4 C>f

unirorm throughoul the lot uf castings and all

K«ommonded Practice B 208 are not appli

..:orts shull be accuratcl)• ~t.

i:ahle 10 these alloys.

7 .4 Whee~ thick und thtn ~ection!. join.

the: mitnufoc:turcc :e;hall be pcrmith::d tu udd

10 . Method• of Tt>I

(where not rr~vioosly provid~d) fillets of

10.1 Analy, . when made, shall be per,

prupec siz,; to avoid c,acking upon cuuH ng.

formed in accoruance wi\h ASTM Methods E

.c.uhj~cl to lht approvul of the inspector.

54, Chemical Analysis of Sl'(cial Brasses and

7.S Thi: manuf:lc«ur~c . hall not he re-spon

Bron.::es, •

~iblc for the d i01ensio11al ,u;c."\lrBc:y of pnth:rns

10.2 The samplo for chemical analysis shall

furnished l>y !ht purchu,cr.

be taktl'I by driHing or cuttfog th~ test e:oupon

8. Nuraber o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.