ASTM D4848-98(2004)e1

(Terminology)Standard Terminology Related to Force, Deformation and Related Properties of Textiles

Standard Terminology Related to Force, Deformation and Related Properties of Textiles

SCOPE

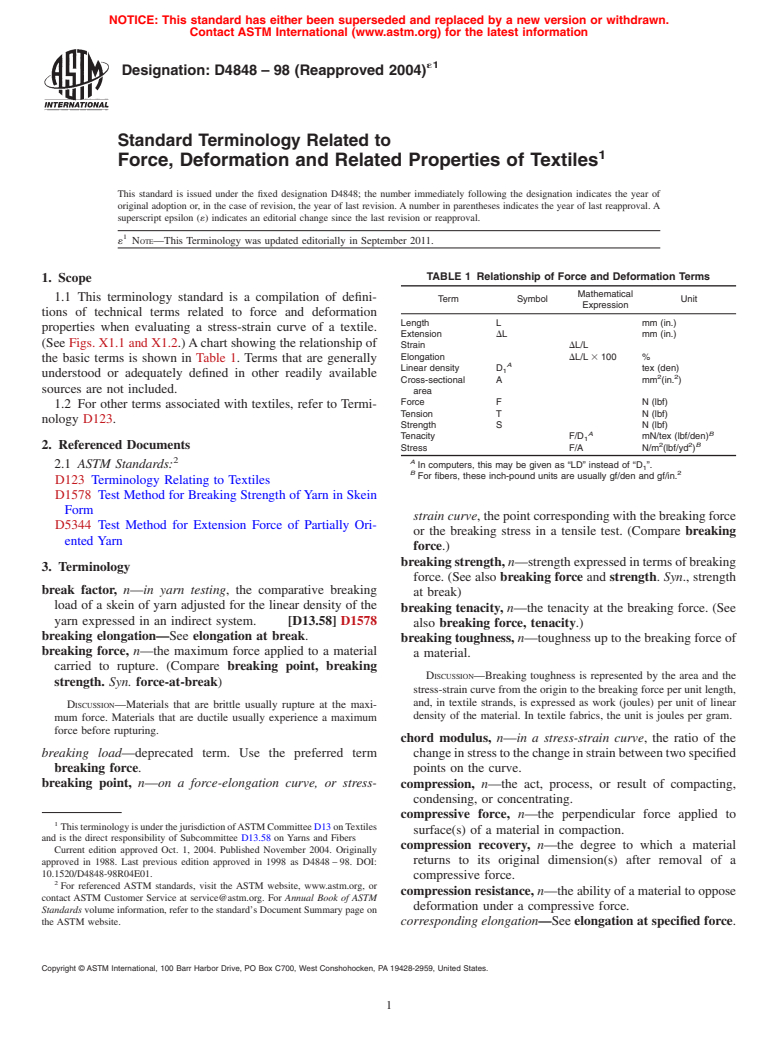

1.1 This terminology standard is a compilation of definitions of technical terms related to force and deformation properties when evaluating a stress-strain curve of a textile. (See Figs. X1.1 and X1.2.) A chart showing the relationship of the basic terms is shown in Table 1. Terms that are generally understood or adequately defined in other readily available sources are not included.

1.2 For other terms associated with textiles, refer to Terminology D123.

TABLE 1 Relationship of Force and Deformation Terms TermSymbolMathematical

ExpressionUnit LengthLmm (in.) ExtensionΔLmm (in.) StrainΔL/L ElongationΔL/L × 100% Linear densityD1Atex (den) Cross-sectional

areaAmm2 (in.2) ForceFN (lbf) TensionTN (lbf) StrengthSN (lbf) TenacityF/D1AmN/tex (lbf/den)B StressF/AN/m2 (lbf/yd2)B

A In computers, this may be given as “LD” instead of “D1”.

B For fibers, these inch-pound units are usually gf/den and gf/in.2

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D4848–98 (Reapproved 2004)

Standard Terminology Related to

Force, Deformation and Related Properties of Textiles

This standard is issued under the fixed designation D4848; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—This Terminology was updated editorially in September 2011.

TABLE 1 Relationship of Force and Deformation Terms

1. Scope

Mathematical

1.1 This terminology standard is a compilation of defini-

Term Symbol Unit

Expression

tions of technical terms related to force and deformation

Length L mm (in.)

properties when evaluating a stress-strain curve of a textile.

Extension DL mm (in.)

(See Figs. X1.1 and X1.2.)Achart showing the relationship of

Strain DL/L

Elongation DL/L 3 100 %

the basic terms is shown in Table 1. Terms that are generally

A

Linear density D tex (den)

understood or adequately defined in other readily available

2 2

Cross-sectionalAmm (in. )

sources are not included.

area

Force F N (lbf)

1.2 For other terms associated with textiles, refer to Termi-

Tension T N (lbf)

nology D123.

Strength S N (lbf)

A B

Tenacity F/D mN/tex (lbf/den)

2 2 B

2. Referenced Documents

Stress F/A N/m (lbf/yd )

A

2.1 ASTM Standards: In computers, this may be given as “LD” instead of “D ”.

B 2

For fibers, these inch-pound units are usually gf/den and gf/in.

D123 Terminology Relating to Textiles

D1578 Test Method for Breaking Strength of Yarn in Skein

Form

strain curve,thepointcorrespondingwiththebreakingforce

D5344 Test Method for Extension Force of Partially Ori-

or the breaking stress in a tensile test. (Compare breaking

ented Yarn

force.)

breaking strength, n—strengthexpressedintermsofbreaking

3. Terminology

force. (See also breaking force and strength. Syn., strength

break factor, n—in yarn testing, the comparative breaking

at break)

load of a skein of yarn adjusted for the linear density of the

breaking tenacity, n—the tenacity at the breaking force. (See

yarn expressed in an indirect system. [D13.58] D1578

also breaking force, tenacity.)

breaking elongation—See elongation at break.

breaking toughness, n—toughness up to the breaking force of

breaking force, n—the maximum force applied to a material

a material.

carried to rupture. (Compare breaking point, breaking

DISCUSSION—Breaking toughness is represented by the area and the

strength. Syn. force-at-break)

stress-strain curve from the origin to the breaking force per unit length,

and, in textile strands, is expressed as work (joules) per unit of linear

DISCUSSION—Materials that are brittle usually rupture at the maxi-

density of the material. In textile fabrics, the unit is joules per gram.

mum force. Materials that are ductile usually experience a maximum

force before rupturing.

chord modulus, n—in a stress-strain curve, the ratio of the

breaking load—deprecated term. Use the preferred term changeinstresstothechangeinstrainbetweentwospecified

breaking force. points on the curve.

breaking point, n—on a force-elongation curve, or stress- compression, n—the act, process, or result of compacting,

condensing, or concentrating.

compressive force, n—the perpendicular force applied to

ThisterminologyisunderthejurisdictionofASTMCommitteeD13onTextiles

surface(s) of a material in compaction.

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers

compression recovery, n—the degree to which a material

Current edition approved Oct. 1, 2004. Published November 2004. Originally

returns to its original dimension(s) after removal of a

approved in 1988. Last previous edition approved in 1998 as D4848 – 98. DOI:

10.1520/D4848-98R04E01.

compressive force.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

compression resistance, n—the ability of a material to oppose

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

deformation under a compressive force.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. corresponding elongation—See elongation at specified force.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D4848–98 (2004)

corresponding force—See force-at-specified-elongation. failure, n—an arbitrary point beyond which a material ceases

deformation, n—a change in shape of a material caused by to be functionally capable of its intended use. (Compare

forces of compression, shear, tension, or torsion. rupture.)

DISCUSSION—Deformation may be immediate or delayed. Delayed DISCUSSION—A material may be considered to have failed without

deformation may be either recoverable or nonrecoverable. having ruptured.

deformation, permanent, n—the net long-term change in a force, n—a physical influence exerted by one body on another

dimension of a specimen after deformation and relaxation which produces acceleration of bodies that are free to move

under specified conditions. (Syn. permanent set, nonrecov- and deformation of bodies that are not free to move.

erable deformation, and nonrecoverable stretch. (Compare strength.)

DISCUSSION—Permanent deformation is usually expressed as a per- DISCUSSION—Forceisproperlyexpressedinnewtons(N)ormultiples

centage of the original dimension. and submultiples of newtons, for example kilonewtons (kN) and

millinewtons (mN). Force is also expressed as grams-force (gf),

delayed deformation, n—deformation which is time-

kilograms-force (kgf), or pounds-force (lbf), but the use of these terms

dependent and exhibited by material subject to a continuing

is deprecated.

force. [D13.58] D4848

force at break, n—See breaking force.

elastic limit, n—in mechanics, the maximum stress which can

force at rupture, n—the force applied to a material immedi-

be obtained in a material without causing permanent defor-

ately preceding rupture. (Compare breaking force. See also

mation of the material. (Compare yield point.)

rupture.)

DISCUSSION—Elastic limit is a property of a material whereas yield

DISCUSSION—Materials that are brittle usually rupture at the maxi-

point is a specific point on a stress-strain curve.

mum force. Materials that are ductile usually experience a maximum

elasticity, n—that property of a material by virtue of which it force before rupturing.

tends to recover its original size and shape immediately after

force at specified elongation (FASE), n—the force associated

removal of the force causing deformation.

with a specific elongation on the force-extension or force-

elongation, n—the ratio of the extension of a material to the

elongation curve. (Syn. corresponding force.)

length of the material prior to stretching, expressed as a

force-deformation curve, n—agraphicalrepresentationofthe

percent.

force and deformation relationship of a material under

DISCUSSION—Elongationmaybemeasuredatanyspecifiedforceorat

conditions of compression, shear, tension or torsion. (Com-

rupture.

pare force-elongation curve, force-extension curve and

stress-strain curve.)

elongation at break, n—the elongation corresponding to the

breaking force. (Compare elongation at rupture. See also

DISCUSSION—Force-deformation related curves include force-

elongation.) Syn. breaking elongation. extension, force-compression, force-shear (displacement), force-torque

and stress-strain curves. The shape of the force-extension curve of a

elongation at the breaking load, n—deprecated term. Use the

material and the shape of the corresponding stress-strain curve are the

preferred term elongation at break.

same, only the units are different. Force is expressed in such units as

elongation at specified force, (EASF), n—the elongation

newton, kilogram-force, pound force. In tension, shear or compression

associated with a specified force on the force-extension

tests, deformation is expressed in such units of length as metre,

curve. (Syn. corresponding elongation).

millimetre or inches. In torsion tests, deformation is expressed in such

elongation at rupture, n—the elongation corresponding to the

units for plane angles as radians or degrees.

force-at-rupture. (Compare elongation at break.)

force-elongation curve, n—a graphical representation of the

DISCUSSION—Theelongationatruptureforabrittlematerialisusually

forceandelongationrelationshipofamaterialundertension.

equaltotheelongationatbreak;butforductilematerialsthiselongation

(Compare force-deformation curve, force-extension curve

may be greater.

and stress-strain curve.)

force-extension curve, n—a graphical representation of the

extensibility, n—that property by virtue of which a material

force and extension relationship of a material under tension.

can undergo extension or elongation following the applica-

(Compare force-deformation curve, force-elongation

tion of sufficient force.

curve and stress-strain curve.)

extension, n—the change in length of a material due to

immediate elastic recovery, n—recoverable deformation

stretching. (Compare elongation.)

whichisessentiallyindependentoftime,thatis,occurringin

DISCUSSION—Extension may be measured at any specified force or at

(a time approaching) zero time and recoverable in (a time

ruptureandisexpressedinunitsoflength,forexample,millimetresand

approaching) zero time after removal of the applied force.

inches.

(Compare delayed deformation and delayed elastic recov-

extension force, n—the force required to stretch a material to

ery.)

a given length. [D13.58] D5344

initial modulus, n—in a stress-strain curve, the slope of the

extension-recovery cycle, n—in tension testing, the continu-

initial straight-line portion of the curve.

ous extension of a specimen, with a momentary hold at a

knot breaking force, n—in tensile testing, the breaking force

specifiedextension,followedbyacontrolledrateofreturnto

of a strand having a specified knot configuration tied in the

zero extension.

´1

D4848–98 (2004)

portion of the strand mounted between the clamps of a expressed in an indirect system; the product of the breaking

tensile testing machine. (Compare knot breaking strength. strength of the skein and the yarn number expressed in an

See also breaking force.) indirect system.

knot breaking load, n—deprecated term. Use the preferred

DISCUSSION—A statement of the break factor of the skein must

term, knot breaking force.

indicate the number of wraps in the skein if this is not otherwise

knot breaking strength, n—strength expressed in terms of

apparent; without information on the number of wraps, a statement of

knot breaking force. (See also knot breaking force.)

the break factor is meaningless. Break factor is frequently given other

designationssuchasleacountconstant,leaproduct,andbreakingratio.

linear density, n—mass per unit length.

load—deprecated term. Use the preferred term, force.

skein breaking tenacity, n—the skein breaking strength di-

load, vt—to apply a force.

vided by the product of the yarn number in direct numbering

DISCUSSION—Although the terms load and force are frequently used system and the number of strands placed under tension.

interchangeablytodenotethesamephenomena,ASTMhasadopteduse

DISCUSSION—Observed breaking strength can be converted to break-

of the technically correct term force.

ingtenacitybydividingthebreakingstrengthbytheproductoftheyarn

measured in a direct numbering system and the number of strands

load at specified elongation (LASE)—deprecated term. Use the

placed under tension (twice the number of wraps in the skein).

preferred term, force at specified elongation (FASE).

load-deformation curve, n—deprecatedterm.Usethepreferred

strain, n—deformation of a material caused by the application

term, force-deformation curve.

of an external force.

load-elongation curve, n—deprecated term. Use the preferred

DISCUSSION—Strain is usually expressed as a ratio involving exten-

term, force-elongation curve.

sion.

loop breaking force, n—in tensile testing, the breaking force

of a specimen consisting of two lengths of strand from the

strength, n—thepropertyofamaterialthatresistsdeformation

same supply looped together in a specified configuration and induced by external forces. (Compare force.)

mounted between the clamps of a tensile testing machine.

DISCUSSION—Strength may be expressed in units of force for a

(Compare loop breaking strength. See also breaking

specific material or units of stress. Traditionally, some have considered

force.)

strength to be an average of individual values rather than the individual

loop breaking load, n—deprecated term. Use the preferred

values.

term, loop breaking force.

strength at break, n—See breaking strength.

loop breaking strength, n—strength expressed in terms of

strength at rupture, n—strength expressed in terms of the

loop breaking force. (See also loop breaking force,

force at rupture. (Compare breaking strength.)

strength.)

stress, n—the resistance to deformation developed within a

modulus, n—the property of a material representative of its

material subjected to an external force.

resistance to deformation. (See also chord modulus, initial

modulus, tangent modulus, Young’s modulus). DISCUSSION—Stress is the result of strain and vice versa. In textiles,

stressisexpressedinunitsofforceperunitcross-sectionalarea.Typical

pretension, n—the specified tension applied to a specimen

examples are tensile stress, shear stress, or compressive stress.

preparatory to making a test.

stress decay, n—in mechanics, the reduction in force to hold a

DISCUSSION—Pretension may be used to establish a uniform baseline

material at a fixed deformation over a period of time.

for a test. In tensile testing, the pretension is usually a low force

designed to remove kinks, crimp or wrinkles and essentially straighten

DISCUSSION—This is a generic definition. Stress is already defined.

and align the specimen as it is being mounted in the testing machine.

The stress decay is due to adsorption of energy.

recovery, delayed elastic—See delayed elastic recovery.

stress-strain curve, n—a graphical representation of the stress

recovery immediate elastic—See immediate elastic recovery.

and strain relationship of a material under conditions of

recovery tensile strain—See tensile strain recovery.

compression, shear, tension, or torsion. (Compare force-

rupture, n—the breaking or tearing apart of a material.

deformation curve, force-elongation curve, and force-

(Compare failure.)

extension curve.)

DISCUSSION—As applied to tensile testing, rupture refers to the total

DISCUSSION—In tension tests of textile materials, the stress may be

separation of a material into two parts either all at once o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.