ASTM D3273-00(2005)

(Test Method)Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber

Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber

SIGNIFICANCE AND USE

An accelerated test for determining the resistance of interior coatings to mold growth is useful in estimating the performance of coatings designed for use in interior environments that promote mold growth and in evaluating compounds that may inhibit such growth and the aggregate levels for their use (see also Note 1).

This test method should preferably be used by persons who have had basic microbiological training.

FIG. 1 Environmental Cabinet Assembly

SCOPE

1.1 This test method describes a small environmental chamber and the conditions of operation to evaluate reproducibly in a 4-week period the relative resistance of paint films to surface mold fungi, mildew growth in a severe interior environment. The apparatus is designed so it can be easily built or obtained by any interested party and will duplicate results obtained in a large tropical chamber.

1.2 This test method can be used to evaluate the comparative resistance of interior coating to accelerated mildew growth. Performance at a certain rating (in accordance with Test Method D3274) does not imply any specific period of time for a fungal free coating. However, a better rated coating nearly always performs better in actual end use.

Note 1--This test method is intended for the accelerated evaluation of an interior coatings' resistance to fungal defacement. Use of this test method for evaluating exterior coatings' performance has not been validated, nor have the limitations for such use been determined. Should this test method be used for the testing of an exterior coating system, a precautionary statement regarding interpretation of results as being outside of the scope of this test method must be included. Any accelerated weathering (leaching, weathering machine exposure, etc.,) should be reported and should also bear reference to the fact that it is beyond the current scope of this test method.

1.3 Temperature and humidity must be effectively controlled within the relatively narrow limits specified in order for the chamber to function reproducibly during the short test period. Severity and rate of mold growth on a film is a function of the moisture content of both the film and the substrate. A relative humidity of 95 to 98 % at a temperature of 32.5+ 1oC (90+ 2oF ) is necessary for test panels to develop rapidly and maintain an adequate moisture level to support mold growth.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3273–00(Reapproved2005)

Standard Test Method for

Resistance to Growth of Mold on the Surface of Interior

Coatings in an Environmental Chamber

This standard is issued under the fixed designation D3273; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1.1 This test method describes a small environmental cham-

only.

ber and the conditions of operation to evaluate reproducibly in

1.5 This standard does not purport to address all of the

a 4-week period the relative resistance of paint films to surface

safety concerns, if any, associated with its use. It is the

mold fungi, mildew growth in a severe interior environment.

2 responsibility of the user of this standard to establish appro-

The apparatus is designed so it can be easily built or obtained

priate safety and health practices and determine the applica-

by any interested party and will duplicate results obtained in a

bility of regulatory limitations prior to use.

large tropical chamber.

1.2 This test method can be used to evaluate the compara-

2. Referenced Documents

tive resistance of interior coating to accelerated mildew

2.1 ASTM Standards:

growth. Performance at a certain rating (in accordance with

D3274 Test Method for Evaluating Degree of Surface

TestMethodD3274)doesnotimplyanyspecificperiodoftime

Disfigurement of Paint Films by Fungal or Algal Growth,

forafungalfreecoating.However,abetterratedcoatingnearly

or Soil and Dirt Accumulation

always performs better in actual end use.

3. Significance and Use

NOTE 1—This test method is intended for the accelerated evaluation of

an interior coatings’ resistance to fungal defacement. Use of this test

3.1 An accelerated test for determining the resistance of

method for evaluating exterior coatings’ performance has not been

interior coatings to mold growth is useful in estimating the

validated, nor have the limitations for such use been determined. Should

performance of coatings designed for use in interior environ-

this test method be used for the testing of an exterior coating system, a

ments that promote mold growth and in evaluating compounds

precautionary statement regarding interpretation of results as being

outside of the scope of this test method must be included.Any accelerated that may inhibit such growth and the aggregate levels for their

weathering (leaching, weathering machine exposure, etc.) should be

use (see also Note 1).

reported and should also bear reference to the fact that it is beyond the

3.2 This test method should preferably be used by persons

current scope of this test method.

who have had basic microbiological training.

1.3 Temperature and humidity must be effectively con-

4. Apparatus

trolled within the relatively narrow limits specified in order for

the chamber to function reproducibly during the short test

4.1 Environmental Chamber, capable of maintaining a rela-

period. Severity and rate of mold growth on a film is a function tive humidity of 95 to 98 % at a temperature of 32.5 6 1°C (90

of the moisture content of both the film and the substrate. A

6 2°F) while providing a continuous inoculation of the surface

relative humidity of 95 to 98 % at a temperature of 32.5 6 1°C of exposed panels with mold spores. The chamber should be

(90 6 2°F ) is necessary for test panels to develop rapidly and

kept in a room controlled to 21 to 24°C (70 to 75°F) so that

maintain an adequate moisture level to support mold growth. heat loss from the cabinet is insignificant and that 95 to 98 %

relative humidity is readily obtained at the test temperature.

Alternatively the cabinet must be insulated with suitable

This test method is under the jurisdiction of ASTM Committee D01 on Paint

materials to minimize heat loss.

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.28 on Biodeterioration.

Current edition approved Dec. 1, 2005. Published February 2006. Originally

approved in 1973. Last previous edition approved in 2000 as D3273 – 00. DOI:

10.1520/D3273-00R05. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Additional specifications for construction of a chamber that has been found contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

suitable for this method may be obtained from New Jersey Industrial Controls, P.O. Standards volume information, refer to the standard’s Document Summary page on

Box 601, Rockaway, NJ 07866. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3273–00 (2005)

place or inspect samples. It is so placed that it is immersed

when there are 50 to 75 mm (2 to 3 in.) of water in the bottom

of the chamber. The temperature in the chamber should be

monitoredandcontrolledbyplacingasuitablethermocoupleor

RTD in an area near the test panels. The temperature can be

displayed and controlled by a solid state proportional control-

ler.

4.2.3 Tray, stainless steel or plastic, approximately 25 mm

(1 in.) smaller than the inside dimensions of the chamber and

25 to 75 mm (1 to 3 in.) deep with a noncorrodible metal

mesh bottom should be supported 25 mm (1 in.) above the

water level and centered in the chamber. One layer of fine

plastic or fiberglass screen may be placed over the metal mesh,

if needed for holding soil.

NOTE 2—It has been found that eliminating the plastic screen helps

improvewatervaportransferintosoil,andmaintainactivefungalcultures.

4.2.4 Series of Wood, Glass, or Fiberglass Reinforced Plas-

ticBars, suspended across the width of the chamber at a height

and spacing that allows the use of test panels 75 by 100 mm (3

by 4 in.), hung vertically, with approximately 75-mm (3-in.)

clearance above the inoculated soil with a suitable method of

fastening. Screw eyes are used with the wooden panels while a

wire frame or a large clip is used with the gypsum board

panels. Other support systems may be utilized.

NOTE 3—Other angles of exposure may be used but may alter the rate

and severity of mold growth.

4.3 Psychrometer, for measuring relative humidity in the

test area.

5. Reagents and Materials

5.1 Soil—A good quality greenhouse-grade potting soil,

suitable for plant propagation, containing 25 % peat moss. pH

FIG. 1 Environmental Cabinet Assembly

of the soil should fall from 5.5 to 7.6. Do not allow soil to

become compacted.

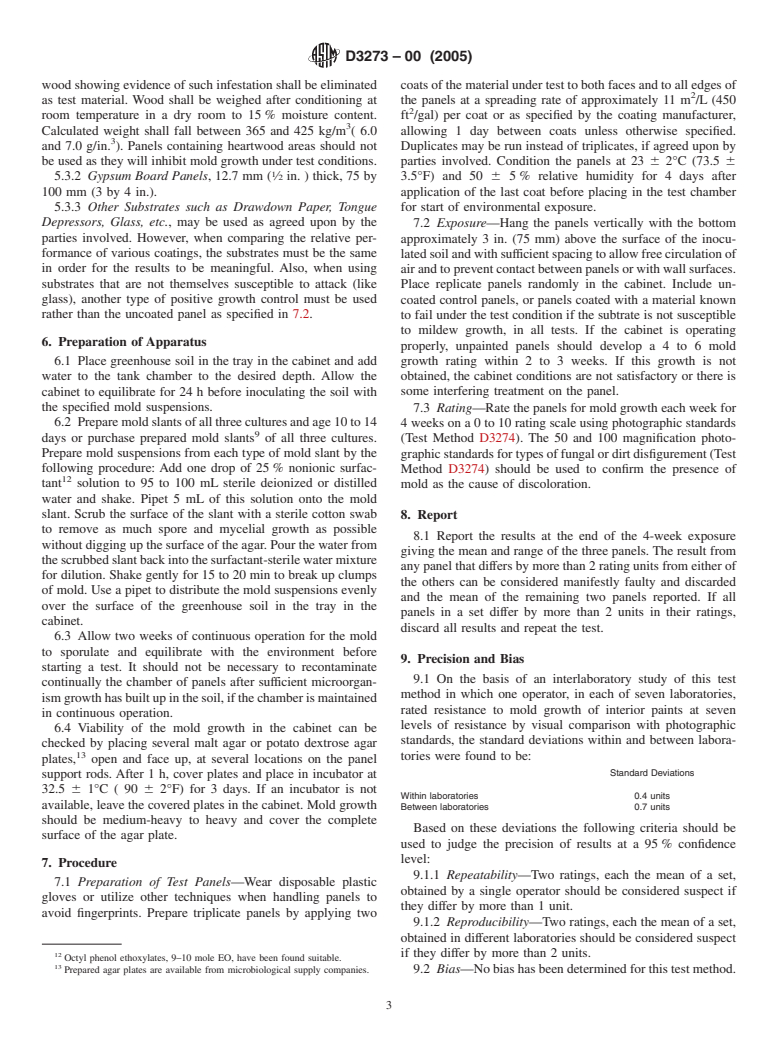

4.2 Cabinet, suitable to accommodate the desired number of 5.2 Cultures:

6,11

5.2.1 Aureobasidium pullulans, ATCC 9348

test panels [typically at least twenty-five 75 by 100-mm (3 by

,

6 11

4-in.) panels] under these test conditions can be constructed as 5.2.2 Aspergillus niger, ATCC 6275

6,11

5.2.3 Penicillium, Sp. 12667 or ATCC 9849

follows (Fig. 1):

4.2.1 Tank, polypropylene or polyethylene, with an offset 5.3 Test Panels:

shoulder at the top rim is used as the chamber. The minimum 5.3.1 Ponderosa Pine (Pinus ponderosa Laws) Sapwood

recommended tank size is 46 by 46 by 61 cm (18 by 18 by 24 Panels, 12.7 mm ( ⁄2 in.) thick, 75 by 100 mm (3 by 4 in.), free

in.).Apitched top with straight sides should be constructed out of excessive resins, knots, growth rings or other abnormalities,

of acrylic plastic so moisture condensation will run down the surfaced smooth on four sides. Wood shall be kiln dried after

sides and be recirculated instead of dripping onto the panels. sawing to avoid infestation of wood-rotting fungi, and any

5,6

4.2.2 Heating Coil, installed in the bottom of the cham-

ber by water tight connections through the end wall.The heater

should be sized to allow reasonable recovery time and uniform

For a 46 by 46 by 61-cm (18 by 18 by 24-in.) tank, a 250-watt heater is

heating of the water when the chamber is opened and closed to recommended. For a 61 by 61 by 91-mm (24 by 24 by 36-in.) tank, an 800-watt

heater is recommended.

1 3

A grounded 1.5 mm ( ⁄16) or 2.4 mm ( ⁄32-in.) “J” type stainless thermocouple

gives good response for this application.

4 9

Tanks of this type available in dimensions approximating 69 by 46 by 46 cm A Eurotherm Model 91 control

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.