ASTM D5363-03(2008)

(Specification)Standard Specification for Anaerobic Single-Component Adhesives (AN)

Standard Specification for Anaerobic Single-Component Adhesives (AN)

ABSTRACT

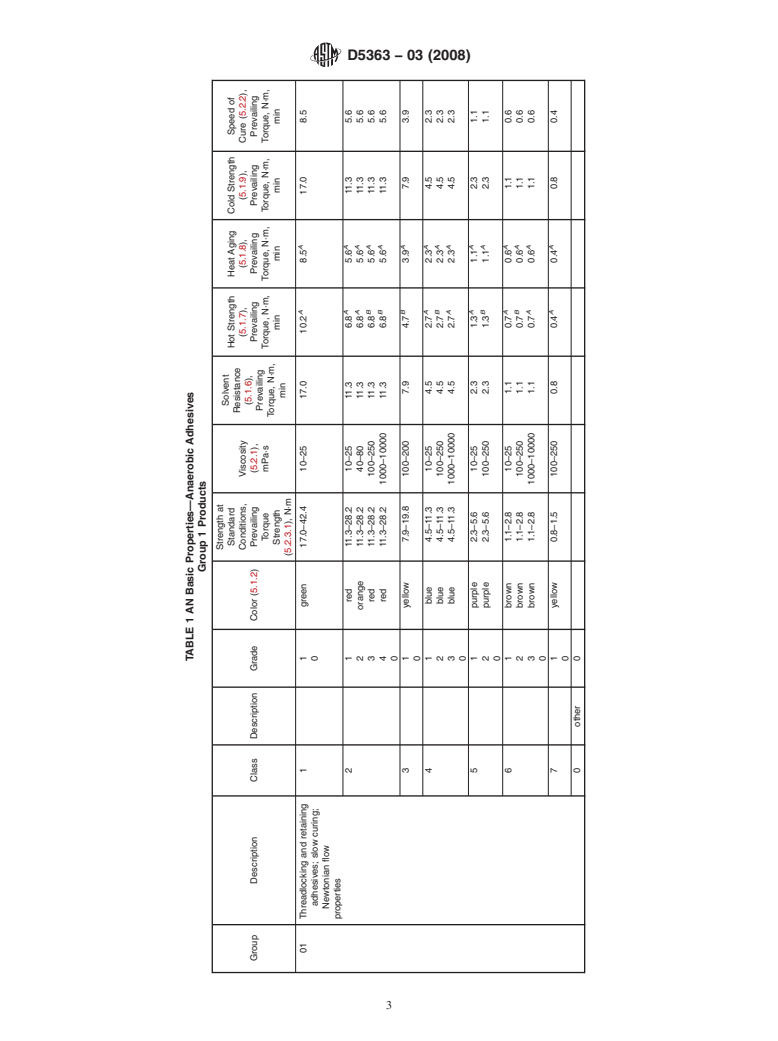

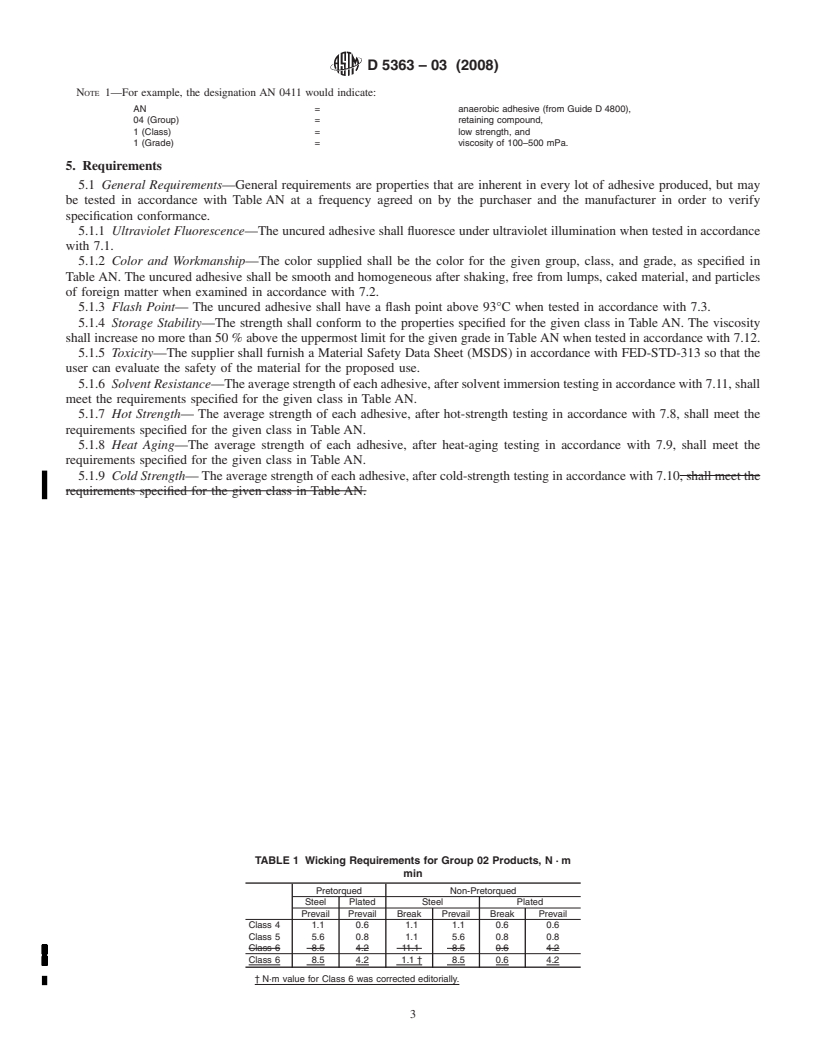

This specification establishes the requirements for single-component anaerobic adhesives suitable for locking, sealing, and retaining threaded or cylindrical assemblies. It is intended to be a means of classifying the adhesives, and does not address engineering design purposes. The adhesives are cured to a solid state when confined between closely fitting active metal surfaces. Materials shall undergo test procedures and conform accordingly to the following requirements: ultraviolet fluorescence; color and workmanship; flash point; storage stability; toxicity; solvent resistance; hot strength; heat aging; cold strength; lubricity; fluid tightness; wicking; viscosity; speed of cure; prevailing torque strength (strength at standard conditions); and qualification of primers.

SCOPE

1.1 This specification covers single-component anaerobic adhesives suitable for locking, sealing, and retaining threaded or cylindrical assemblies. The adhesives are cured to a solid state when confined between closely fitting active metal surfaces.

1.2 This specification is intended to be a means of classifying anaerobic adhesives. It is not intended for engineering design purposes.

1.3 This specification is intended to replace Military Specifications MIL-S-22473, MIL-S-46163, and MIL-R-46082.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5363 −03(Reapproved 2008)

Standard Specification for

1

Anaerobic Single-Component Adhesives (AN)

This standard is issued under the fixed designation D5363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D56Test Method for Flash Point by Tag Closed Cup Tester

D439Specification for Automotive Gasoline (Withdrawn

1.1 This specification covers single-component anaerobic

3

1990)

adhesives suitable for locking, sealing, and retaining threaded

D445Test Method for Kinematic Viscosity of Transparent

or cylindrical assemblies. The adhesives are cured to a solid

and Opaque Liquids (and Calculation of DynamicViscos-

state when confined between closely fitting active metal

ity)

surfaces.

D770Specification for Isopropyl Alcohol

1.2 This specification is intended to be a means of classify-

D907Terminology of Adhesives

ing anaerobic adhesives. It is not intended for engineering

D1084Test Methods for Viscosity of Adhesives

design purposes.

D1193Specification for Reagent Water

1.3 This specification is intended to replace Military Speci-

D2693Specification for Ethylene Glycol

fications MIL-S-22473, MIL-S-46163, and MIL-R-46082.

D3951Practice for Commercial Packaging

D4562Test Method for Shear Strength of Adhesives Using

1.4 The values stated in SI units are to be regarded as the

Pin-and-Collar Specimen

standard.

D4800Guide for Classifying and Specifying Adhesives

1.5 The following safety hazards caveat pertains only to the

D5648Test Method for Torque-Tension Relationship of

test methods portion, Section 7, of this specification.This

Adhesives Used on Threaded Fasteners (Lubricity)

standard does not purport to address all of the safety concerns,

D5649Test Method for Torque Strength ofAdhesives Used

if any, associated with its use. It is the responsibility of the user

on Threaded Fasteners

of this standard to establish appropriate safety and health

D5657TestMethodforFluidTightnessAbilityofAdhesives

practices and determine the applicability of regulatory limita-

Used on Threaded Fasteners

tions prior to use.

E122PracticeforCalculatingSampleSizetoEstimate,With

2. Referenced Documents Specified Precision, the Average for a Characteristic of a

2

Lot or Process

2.1 ASTM Standards:

A109/A109MSpecification for Steel, Strip, Carbon (0.25

2.2 Military Standards:

Maximum Percent), Cold-Rolled MIL-STD-105Sampling Procedures and Tables for Inspec-

4

B36/B36MSpecification for Brass Plate, Sheet, Strip, And

tion by Attributes

4

Rolled Bar

MIL-STD-129Marking for Shipment and Storage

B209Specification for Aluminum and Aluminum-Alloy

MIL-STD-810Environmental Test Methods and Engineer-

4

Sheet and Plate

ing Guides

B633SpecificationforElectrodepositedCoatingsofZincon

MIL-STD-118 Commercial Packaging of Supplies and

4

Iron and Steel

Equipment

2.3 Federal Standards:

FED-STD-313Material Safety Data Sheets, Preparation and

1

This specification is under the jurisdiction of ASTM Committee D14 on

4

Submission of

Adhesives and is the direct responsibility of Subcommittee D14.60 on Adhesive

Material Classification System.

Current edition approved Oct. 1, 2008. Published October 2008. Originally

ε1

approved in 1993. Last previous edition approved in 2003 as D5363–03 . DOI:

3

10.1520/D5363-03R08. The last approved version of this historical standard is referenced on

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.astm.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5363−03 (2008)

2.4 Federal Specifications: 3.2.2 prevailing torque, n—the torque measured at 180°

FF-N-836 Nut: Square, Hexagon, Cap, Slotted, Castle, rotation of the nut.

4

Knurled, Welding and Single Ball Seat

3.2.2.1 Discussion—Prevailing torque was originally de-

4

PPP-B-636Box, Shipping, Fiberboard

fined in MIL-S-46163 and MIL-S-22473 as the average of the

4

QQ-P-416Plating, Cadmium, Electrodeposited

fourtorquesmeasuredat90,180,270,and360°rotationofthe

2.5 Military Specifications:

nut. Studies have shown that the torque measured at 180°

MIL-R-46082Retaining Compounds, Single-Component,

rotation of the nut is stat

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5363–97 Designation: D 5363 – 03 (Reapproved 2008)

Standard Specification for

1

Anaerobic Single-Component Adhesives (AN)

This standard is issued under the fixed designation D5363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers single-component anaerobic adhesives suitable for locking, sealing, and retaining threaded or

cylindrical assemblies. The adhesives are cured to a solid state when confined between closely fitting active metal surfaces.

1.2 This specification is intended to be a means of classifying anaerobic adhesives. It is not intended for engineering design

purposes.

1.3 This specification is intended to replace Military Specifications MIL-S-22473, MIL-S-46163, and MIL-R-46082.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section7,ofthisspecification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A109Specification for Steel, Strip, Carbon, Cold-Rolled 109/A109M Specification for Steel, Strip, Carbon (0.25 Maximum

Percent), Cold-Rolled

B36/B36M Specification for Brass Plate, Sheet, Strip, andAnd Rolled Bar

B209 Specification for Aluminum and Aluminum-Alloy Sheet and Plate

B633 Specification for Electrodeposited Coatings of Zinc on Iron and Steel

D56 Test Method for Flash Point by Tag Closed Cup Tester

3

D439Specification for Automotive Gasoline Specification for Automotive Gasoline

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and the Calculation of Dynamic Viscosity)

D770 Specification for Isopropyl Alcohol

D907 Terminology of Adhesives

D1084 Test Methods for Viscosity of Adhesives

D1193 Specification for Reagent Water

D2693 Specification for Ethylene Glycol

D3951 Practice for Commercial Packaging

D4562 Test Method for Shear Strength of Adhesives Using Pin-and-Collar Specimen

D4800 Guide for Classifying and Specifying Adhesives

D5648 Test Method for Torque-Tension Relationship of Adhesives Used on Threaded Fasteners (Lubricity)

D5649 Test Method for Torque Strength of Adhesives Used on Threaded Fasteners

D5657 Test Method for Fluid Tightness Ability of Adhesives Used on Threaded Fasteners

E122PracticeforChoiceofSampleSizetoEstimateaMeasureofQualityforaLotorProcess PracticeforCalculatingSample

Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or Process

2.2 Military Standards:

1

This specification is under the jurisdiction of ASTM Committee D-14 on Adhesives and is the direct responsibility of Subcommittee D14.60 on Adhesive Material

Classification System.

Current edition approved Nov. 10, 1997. Published March 1998. Originally published as D 5363–93. Last previous edition D 5363–93.

1

This specification is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.60 on Adhesive Material

Classification System.

´1

Current edition approved Oct. 1, 2008. Published October 2008. Originally approved in 1993. Last previous edition approved in 2003 as D5363–03 .

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5363 – 03 (2008)

4

MIL-STD-105 Sampling Procedures and Tables for Inspection by Attributes

4

MIL-STD-129 Marking for Shipment and Storage

4

MIL-STD-810 Environmental Test Methods and Engineering Guides

4

MIL-STD-118 Commercial Packaging of Supplies and Equipment

2.3 Federal Standards:

4

FED-STD-313 Material Safety Data Sheets, Preparation and Submission of

2.4 Federal Specifications:

4

FF-N-836 Nut: Square, Hexagon, Cap, Slotted, Castle, Knurled,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.