ASTM F1336-07

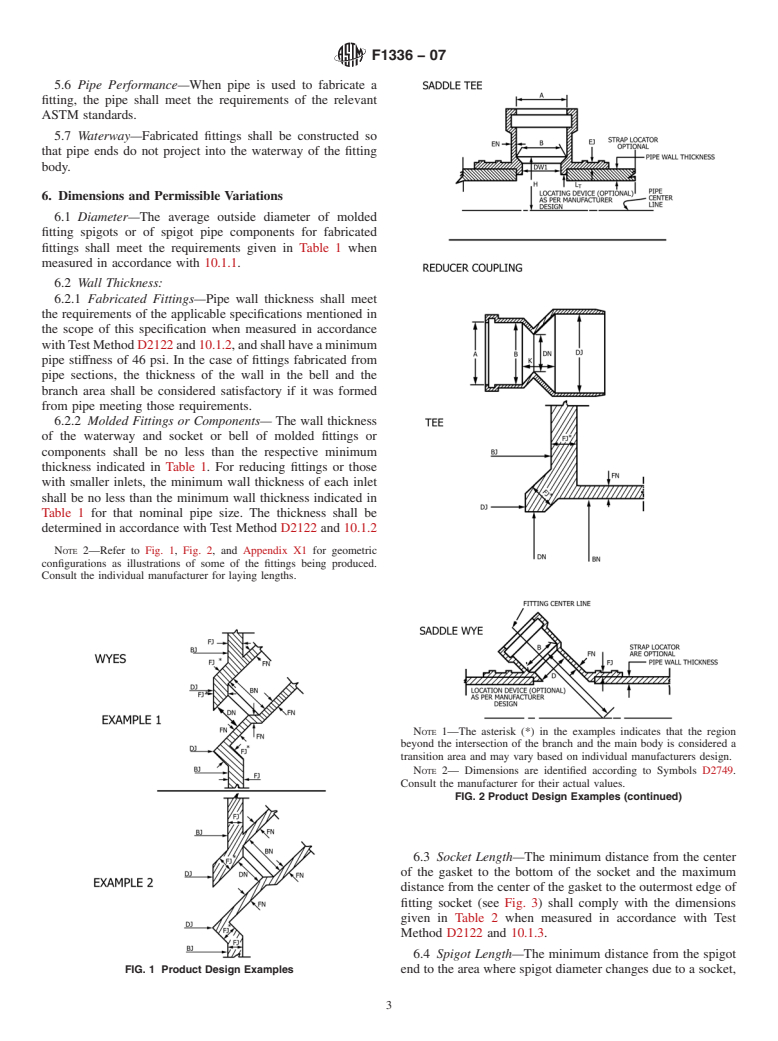

(Specification)Standard Specification for Poly(Vinyl Chloride) (PVC) Gasketed Sewer Fittings

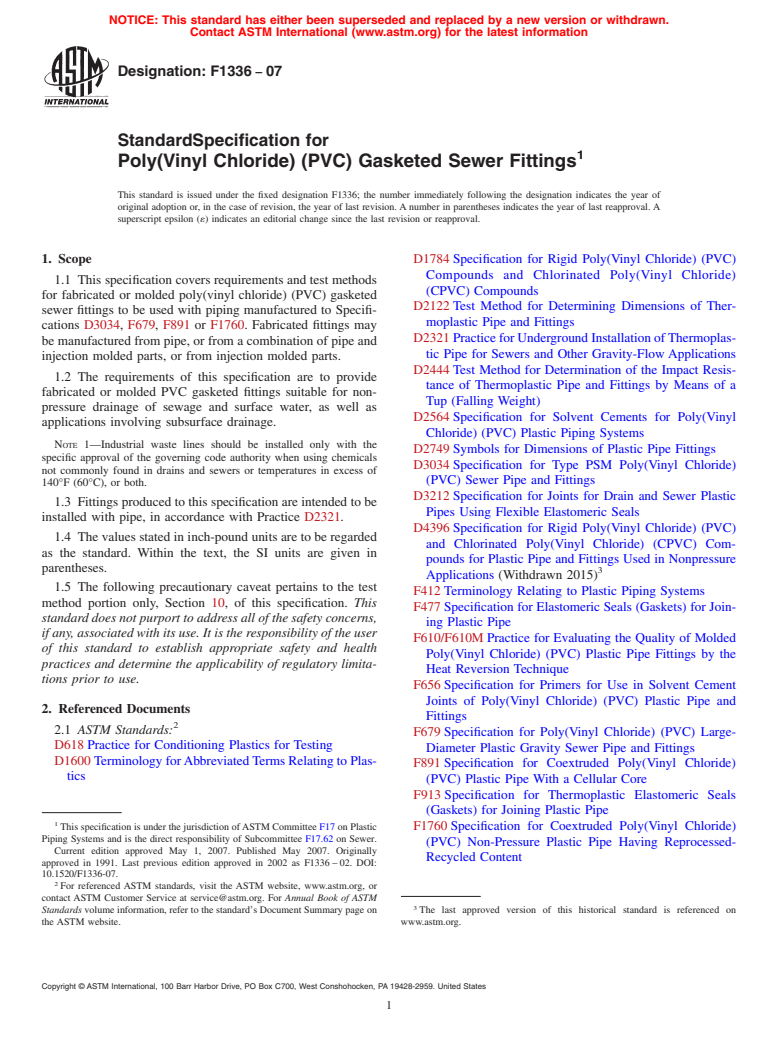

Standard Specification for Poly(Vinyl Chloride) (PVC) Gasketed Sewer Fittings

ABSTRACT

This specification covers the material, dimensional, and mechanical requirements, and associated test methods for fabricated or molded poly(vinyl chloride) (PVC) gasketed sewer fittings manufactured from pipe, or from a combination of pipe and injection molded parts, or from injection molded parts that are suitable for non-pressure drainage of sewage and surface water, as well as applications involving subsurface drainage. The fittings shall adhere to specified values for outside diameter, wall thickness, socket length, and spigot length. When evaluated according to the test procedures provided herein, the fittings shall meet specified requirements for impact strength, pipe stop load support, internal stress, and branch bending. The products shall also undergo referee testing and quality control tests.

SCOPE

1.1 This specification covers requirements and test methods for fabricated or molded poly(vinyl chloride) (PVC) gasketed sewer fittings to be used with piping manufactured to Specifications D 3034, F 679, F 891 or F 1760. Fabricated fittings may be manufactured from pipe, or from a combination of pipe and injection molded parts, or from injection molded parts.

1.2 The requirements of this specification are to provide fabricated or molded PVC gasketed fittings suitable for non-pressure drainage of sewage and surface water, as well as applications involving subsurface drainage.

Note 1—Industrial waste lines should be installed only with the specific approval of the governing code authority when using chemicals not commonly found in drains and sewers or temperatures in excess of 140°F (60°C), or both.

1.3 Fittings produced to this specification are intended to be installed with pipe, in accordance with Practice D 2321.

1.4 The values stated in inch-pound units are to be regarded as the standard. Within the text, the SI units are given in parentheses.

1.5 The following precautionary caveat pertains to the test method portion only, Section 10, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1336 −07

StandardSpecification for

1

Poly(Vinyl Chloride) (PVC) Gasketed Sewer Fittings

This standard is issued under the fixed designation F1336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

Compounds and Chlorinated Poly(Vinyl Chloride)

1.1 This specification covers requirements and test methods

(CPVC) Compounds

for fabricated or molded poly(vinyl chloride) (PVC) gasketed

D2122 Test Method for Determining Dimensions of Ther-

sewer fittings to be used with piping manufactured to Specifi-

moplastic Pipe and Fittings

cations D3034, F679, F891 or F1760. Fabricated fittings may

D2321 PracticeforUndergroundInstallationofThermoplas-

be manufactured from pipe, or from a combination of pipe and

tic Pipe for Sewers and Other Gravity-Flow Applications

injection molded parts, or from injection molded parts.

D2444 Test Method for Determination of the Impact Resis-

1.2 The requirements of this specification are to provide

tance of Thermoplastic Pipe and Fittings by Means of a

fabricated or molded PVC gasketed fittings suitable for non-

Tup (Falling Weight)

pressure drainage of sewage and surface water, as well as

D2564 Specification for Solvent Cements for Poly(Vinyl

applications involving subsurface drainage.

Chloride) (PVC) Plastic Piping Systems

NOTE 1—Industrial waste lines should be installed only with the

D2749 Symbols for Dimensions of Plastic Pipe Fittings

specific approval of the governing code authority when using chemicals

D3034 Specification for Type PSM Poly(Vinyl Chloride)

not commonly found in drains and sewers or temperatures in excess of

(PVC) Sewer Pipe and Fittings

140°F (60°C), or both.

D3212 Specification for Joints for Drain and Sewer Plastic

1.3 Fittings produced to this specification are intended to be

Pipes Using Flexible Elastomeric Seals

installed with pipe, in accordance with Practice D2321.

D4396 Specification for Rigid Poly(Vinyl Chloride) (PVC)

1.4 The values stated in inch-pound units are to be regarded

and Chlorinated Poly(Vinyl Chloride) (CPVC) Com-

as the standard. Within the text, the SI units are given in

pounds for Plastic Pipe and Fittings Used in Nonpressure

parentheses.

3

Applications (Withdrawn 2015)

1.5 The following precautionary caveat pertains to the test

F412 Terminology Relating to Plastic Piping Systems

method portion only, Section 10, of this specification. This

F477 Specification for Elastomeric Seals (Gaskets) for Join-

standarddoesnotpurporttoaddressallofthesafetyconcerns,

ing Plastic Pipe

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

F610/F610M Practice for Evaluating the Quality of Molded

of this standard to establish appropriate safety and health

Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings by the

practices and determine the applicability of regulatory limita-

Heat Reversion Technique

tions prior to use.

F656 Specification for Primers for Use in Solvent Cement

Joints of Poly(Vinyl Chloride) (PVC) Plastic Pipe and

2. Referenced Documents

Fittings

2

2.1 ASTM Standards:

F679 Specification for Poly(Vinyl Chloride) (PVC) Large-

D618 Practice for Conditioning Plastics for Testing

Diameter Plastic Gravity Sewer Pipe and Fittings

D1600 Terminology forAbbreviatedTerms Relating to Plas-

F891 Specification for Coextruded Poly(Vinyl Chloride)

tics

(PVC) Plastic Pipe With a Cellular Core

F913 Specification for Thermoplastic Elastomeric Seals

(Gaskets) for Joining Plastic Pipe

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

F1760 Specification for Coextruded Poly(Vinyl Chloride)

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

(PVC) Non-Pressure Plastic Pipe Having Reprocessed-

Current edition approved May 1, 2007. Published May 2007. Originally

Recycled Content

approved in 1991. Last previous edition approved in 2002 as F1336 – 02. DOI:

10.1520/F1336-07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1336−07

2.2 Federal Standard: 5.1.1 The assembled joint shall display no leakage when

4

Fed. Std. No. 123 Marking for Shipment (Civil Agencies) tested in accordance with the requir

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.