ASTM F606-98

(Test Method)Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and Rivets

Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and Rivets

SCOPE

1.1 These test methods establish procedures for conducting tests to determine the mechanical properties of externally and internally threaded fasteners, washers, and rivets.

1.2 Property requirements and the applicable tests for their determination are specified in individual product standards. In those instances where the testing requirements are unique or at variance with these standard procedures, the product standard shall specify the controlling testing requirements.

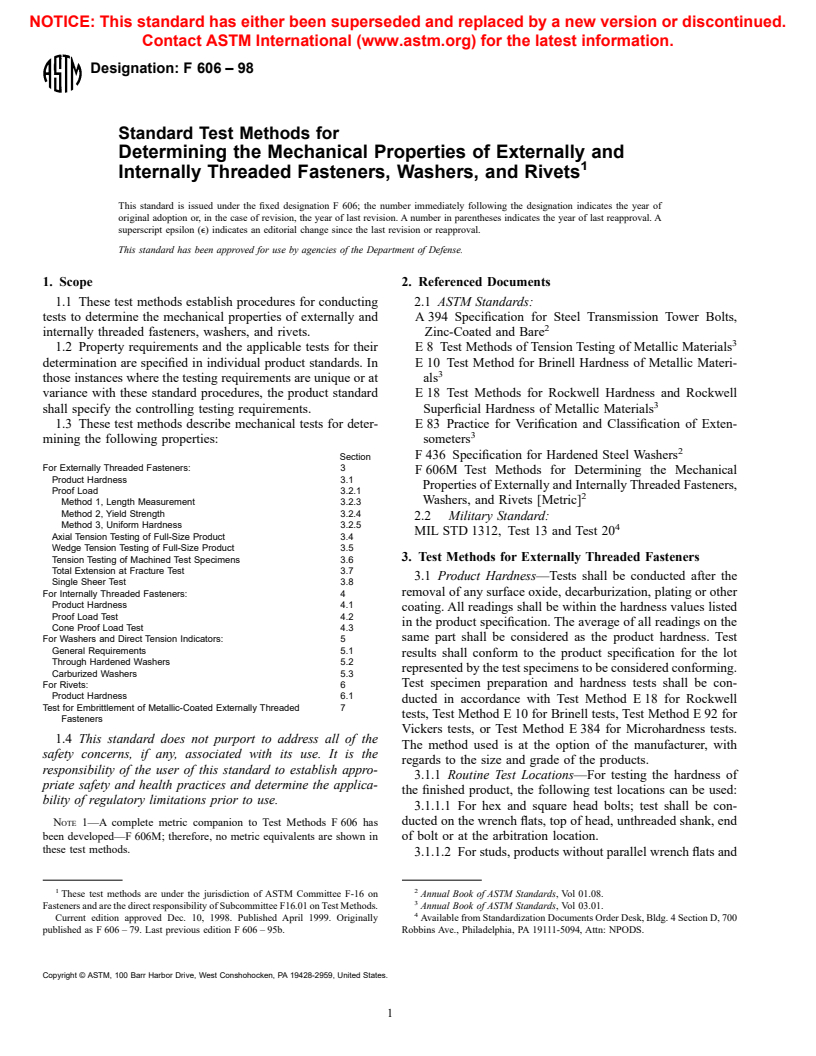

1.3 These test methods describe mechanical tests for determining the following properties: Section For Externally Threaded Fasteners: 3 Product Hardness 3.1 Proof Load 3.2.1Method 1, Length Measurement 3.2.3Method 2, Yield Strength 3.2.4Method 3, Uniform Hardness 3.2.5Axial Tension Testing of Full-Size Product 3.4Wedge Tension Testing of Full-Size Product 3.5Tension Testing of Machined Test Specimens 3.6Total Extension at Fracture TestSingle Sheer Test 3.7 3.8For Internally Threaded Fasteners: 4 Product Hardness 4.1Proof Load Test 4.2 Cone Proof Load Test 4.3 For Washers and Direct Tension Indicators: 5General Requirements 5.1Through Hardened Washers 5.2Carburized Washers 5.3For Rivets: 6 Product Hardness 6.1 Test for Embrittlement of Metallic-Coated Externally Threaded Fasteners 7

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1--A complete metric companion to Test Methods F606 has been developed--F606M; therefore, no metric equivalents are shown in these test methods.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 606 – 98

Standard Test Methods for

Determining the Mechanical Properties of Externally and

1

Internally Threaded Fasteners, Washers, and Rivets

This standard is issued under the fixed designation F 606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods establish procedures for conducting 2.1 ASTM Standards:

tests to determine the mechanical properties of externally and A 394 Specification for Steel Transmission Tower Bolts,

2

internally threaded fasteners, washers, and rivets. Zinc-Coated and Bare

3

1.2 Property requirements and the applicable tests for their E 8 Test Methods of Tension Testing of Metallic Materials

determination are specified in individual product standards. In E 10 Test Method for Brinell Hardness of Metallic Materi-

3

those instances where the testing requirements are unique or at als

variance with these standard procedures, the product standard E 18 Test Methods for Rockwell Hardness and Rockwell

3

shall specify the controlling testing requirements. Superficial Hardness of Metallic Materials

1.3 These test methods describe mechanical tests for deter- E 83 Practice for Verification and Classification of Exten-

3

mining the following properties: someters

2

F 436 Specification for Hardened Steel Washers

Section

For Externally Threaded Fasteners: 3

F 606M Test Methods for Determining the Mechanical

Product Hardness 3.1

Properties of Externally and Internally Threaded Fasteners,

Proof Load 3.2.1

2

Washers, and Rivets [Metric]

Method 1, Length Measurement 3.2.3

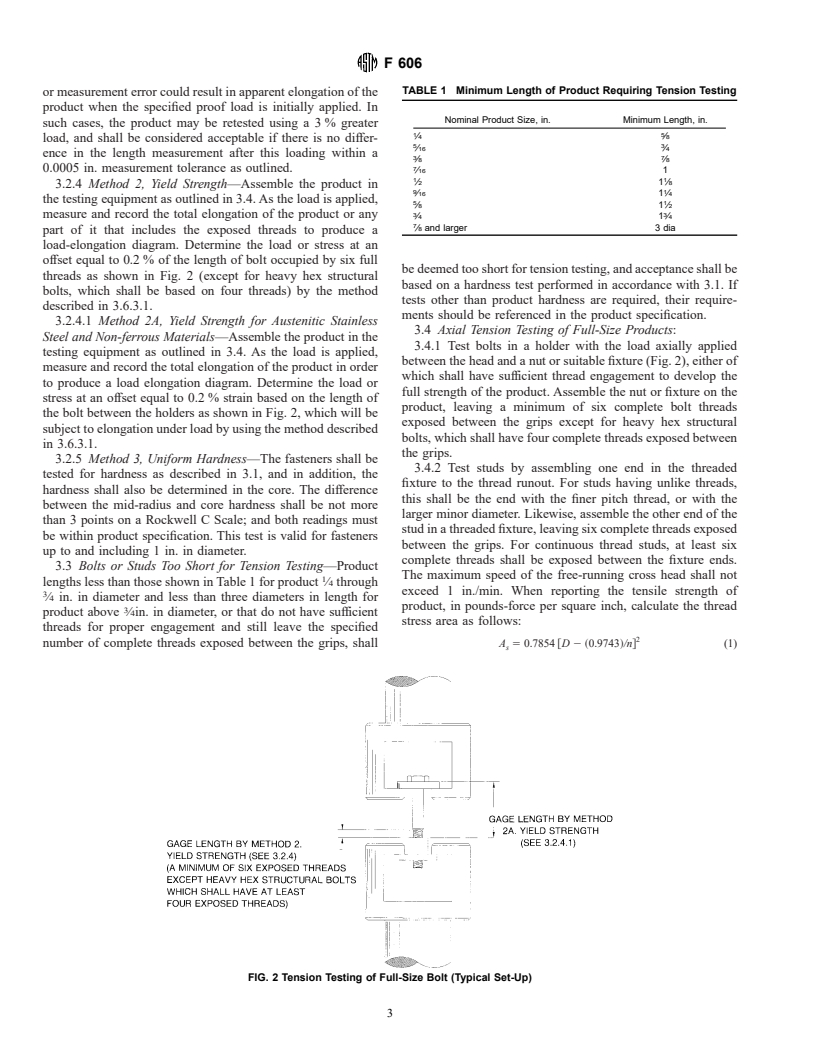

Method 2, Yield Strength 3.2.4

2.2 Military Standard:

Method 3, Uniform Hardness 3.2.5

4

MIL STD 1312, Test 13 and Test 20

Axial Tension Testing of Full-Size Product 3.4

Wedge Tension Testing of Full-Size Product 3.5

3. Test Methods for Externally Threaded Fasteners

Tension Testing of Machined Test Specimens 3.6

Total Extension at Fracture Test 3.7

3.1 Product Hardness—Tests shall be conducted after the

Single Sheer Test 3.8

removal of any surface oxide, decarburization, plating or other

For Internally Threaded Fasteners: 4

Product Hardness 4.1

coating. All readings shall be within the hardness values listed

Proof Load Test 4.2

in the product specification. The average of all readings on the

Cone Proof Load Test 4.3

For Washers and Direct Tension Indicators: 5 same part shall be considered as the product hardness. Test

General Requirements 5.1

results shall conform to the product specification for the lot

Through Hardened Washers 5.2

represented by the test specimens to be considered conforming.

Carburized Washers 5.3

Test specimen preparation and hardness tests shall be con-

For Rivets: 6

Product Hardness 6.1

ducted in accordance with Test Method E 18 for Rockwell

Test for Embrittlement of Metallic-Coated Externally Threaded 7

tests, Test Method E 10 for Brinell tests, Test Method E 92 for

Fasteners

Vickers tests, or Test Method E 384 for Microhardness tests.

1.4 This standard does not purport to address all of the

The method used is at the option of the manufacturer, with

safety concerns, if any, associated with its use. It is the

regards to the size and grade of the products.

responsibility of the user of this standard to establish appro-

3.1.1 Routine Test Locations—For testing the hardness of

priate safety and health practices and determine the applica-

the finished product, the following test locations can be used:

bility of regulatory limitations prior to use.

3.1.1.1 For hex and square head bolts; test shall be con-

ducted on the wrench flats, top of head, unthreaded shank, end

NOTE 1—A complete metric companion to Test Methods F 606 has

been developed—F 606M; therefore, no metric equivalents are shown in

of bolt or at the arbitration location.

these test methods.

3.1.1.2 For studs, products without parallel wrench flats and

1 2

These test methods are under the jurisdiction of ASTM Committee F-16 on Annual Book of ASTM Standards, Vol 01.08.

3

Fasteners and are the direct responsibility of Subcommittee F16.01 on Test Methods. Annual Book of ASTM Standards, Vol 03.01.

4

Current edition approved Dec. 10, 1998. Published April 1999. Originally Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as F 606 – 79. Last previous edition F 606 – 95b. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.