ASTM E2008-99

(Test Method)Standard Test Method for Volatility Rate by Thermogravimetry

Standard Test Method for Volatility Rate by Thermogravimetry

SCOPE

1.1 This test method covers procedures for assessing the volatility of solids and liquids at given temperatures using thermogravimetry under prescribed experimental conditions. Results of this test method are obtained as volatility rates expressed as mass per unit time. Rates > or = to 5 µg/min are achievable with this test method.

1.2 Temperatures typical for this test method are within the range from 25 °C to 500°C. This temperature range may differ depending upon the instrumentation used.

1.3 This test method is intended to provide a value for the volatility rate of a sample using a thermogravimetric analysis measurement on a single representative specimen. It is the responsibility of the user of this test method to determine the need for and the number of repetitive measurements on fresh specimens necessary to satisfy end use requirements.

1.4 Computer- or electronic-based instruments, techniques, or data treatment equivalent to this test method may also be used.

Note 1-Users of this test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user of this test method to determine the necessary equivalency prior to use.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2008 – 99

Standard Test Method for

Volatility Rate by Thermogravimetry

This standard is issued under the fixed designation E 2008; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers procedures for assessing the 3.1 Definitions:

volatility of solids and liquids at given temperatures using 3.1.1 The following terms are applicable to this test method

thermogravimetry under prescribed experimental conditions. and can be found in Terminologies E 473 and E 1142:

Results of this test method are obtained as volatility rates 3.1.1.1 thermogravimetric analysis (TGA),

expressed as mass per unit time. Rates $ 5 μg/min are 3.1.1.2 thermogravimetry (TG),

achievable with this test method. 3.1.1.3 volatility.

1.2 Temperatures typical for this test method are within the 3.2 Definitions of Terms Specific to This Standard:

range from 25°C to 500°C. This temperature range may differ 3.2.1 volatility rate—the rate of conversion of a solid or

depending upon the instrumentation used. liquid substance into the vapor state at a given temperature;

1.3 This test method is intended to provide a value for the mass per unit time.

volatility rate of a sample using a thermogravimetric analysis

4. Summary of Test Method

measurement on a single representative specimen. It is the

responsibility of the user of this test method to determine the 4.1 A solid or liquid specimen is confined in an appropriate

container with a pinhole opening between 0.33 and 0.38 mm.

need for and the number of repetitive measurements on fresh

specimens necessary to satisfy end use requirements. The confined specimen is heated within a thermogravimetric

analyzer either to a temperature and held constant at that

1.4 Computer- or electronic-based instruments, techniques,

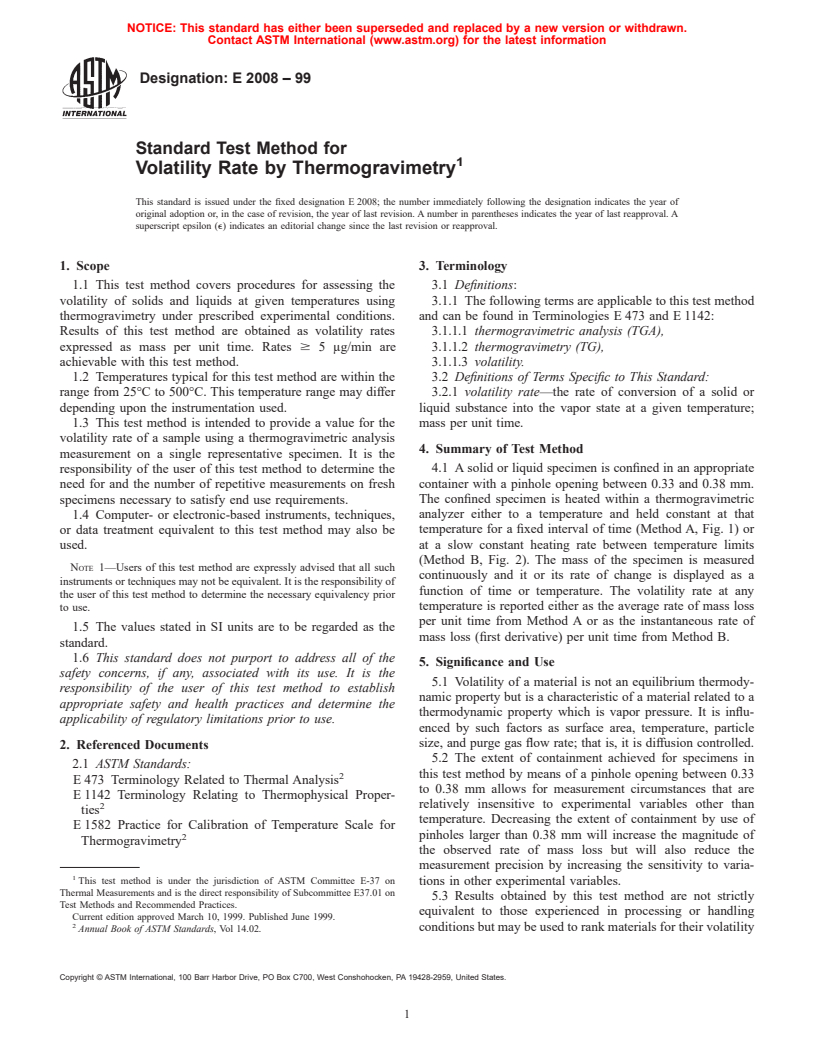

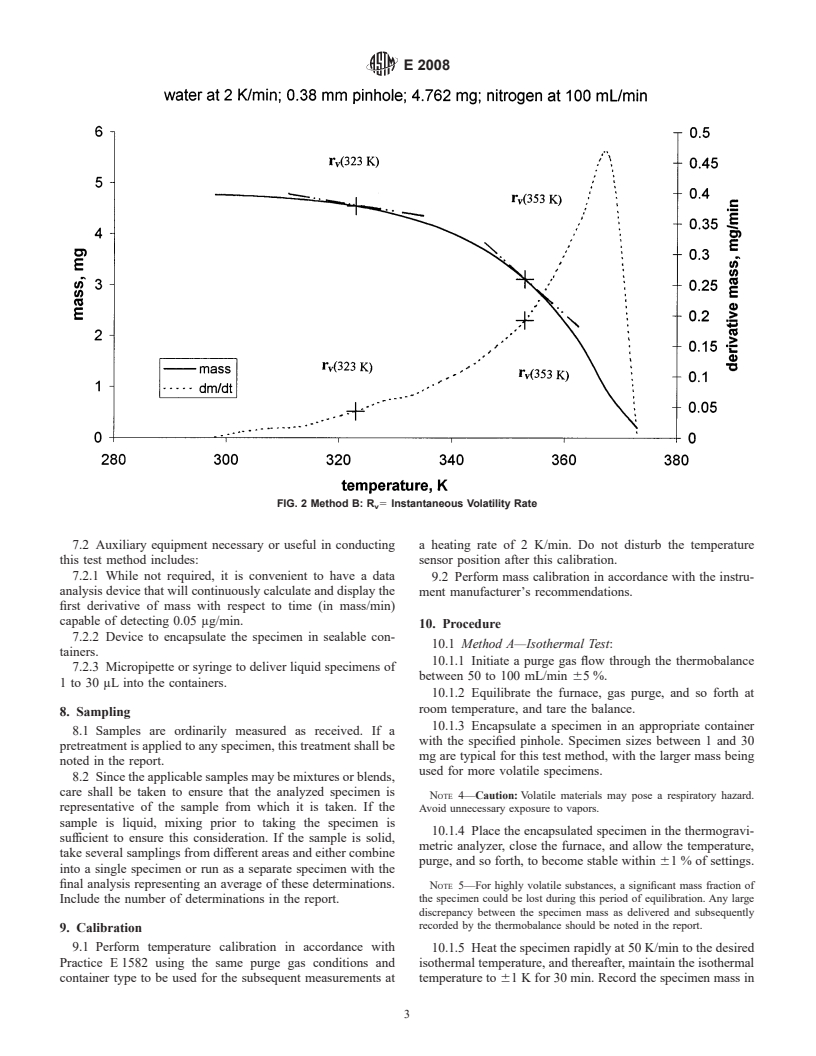

or data treatment equivalent to this test method may also be temperature for a fixed interval of time (Method A, Fig. 1) or

at a slow constant heating rate between temperature limits

used.

(Method B, Fig. 2). The mass of the specimen is measured

NOTE 1—Users of this test method are expressly advised that all such

continuously and it or its rate of change is displayed as a

instruments or techniques may not be equivalent. It is the responsibility of

function of time or temperature. The volatility rate at any

the user of this test method to determine the necessary equivalency prior

temperature is reported either as the average rate of mass loss

to use.

per unit time from Method A or as the instantaneous rate of

1.5 The values stated in SI units are to be regarded as the

mass loss (first derivative) per unit time from Method B.

standard.

1.6 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 Volatility of a material is not an equilibrium thermody-

responsibility of the user of this test method to establish

namic property but is a characteristic of a material related to a

appropriate safety and health practices and determine the

thermodynamic property which is vapor pressure. It is influ-

applicability of regulatory limitations prior to use.

enced by such factors as surface area, temperature, particle

size, and purge gas flow rate; that is, it is diffusion controlled.

2. Referenced Documents

5.2 The extent of containment achieved for specimens in

2.1 ASTM Standards:

2 this test method by means of a pinhole opening between 0.33

E 473 Terminology Related to Thermal Analysis

to 0.38 mm allows for measurement circumstances that are

E 1142 Terminology Relating to Thermophysical Proper-

2 relatively insensitive to experimental variables other than

ties

temperature. Decreasing the extent of containment by use of

E 1582 Practice for Calibration of Temperature Scale for

2 pinholes larger than 0.38 mm will increase the magnitude of

Thermogravimetry

the observed rate of mass loss but will also reduce the

measurement precision by increasing the sensitivity to varia-

This test method is under the jurisdiction of ASTM Committee E-37 on tions in other experimental variables.

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on

5.3 Results obtained by this test method are not strictly

Test Methods and Recommended Practices.

equivalent to those experienced in processing or handling

Current edition approved March 10, 1999. Published June 1999.

conditions but may be used to rank materials for their volatility

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 2008

FIG. 1 Method A: R 5 Average Volatility Rate

v

NOTE 2—Excessive purge rates should be avoided as this may intro-

in such circumstances. Therefore, the volatility rates deter-

duce interferences due to turbulence effects and temperature gradients.

mined by this test method should be considered as index values

only.

7.1.2 A temperature controller, capable of executing a

5.4 The volatility rate may be used to estimate such quan-

specific temperature program by operating the furnace between

tifiable values as drying interval or the extent of volatile release

selected temperature limits at a rate of temperature change of

from a process.

1 to 2 K/min constant to within 60.1 K/min or to rapidly heat

a specimen at a minimum of 50 K/min to an isothermal

6. Interferences

temperature that is maintained constant to 61 K for a mini-

6.1 Specimens that consist of a mixture of two or more

mum of 30 min.

volatile components or that undergo decomposition during this

7.1.3 A recording device, either analog or digital, capable of

test may exhibit curvature in the mass loss versus time plot of

recording and displaying any fraction of the specimen mass

Method A (see Fig. 3). In such cases the volatility rate is not

signal (TGA curve), including the signal noise versus time or

constant and shall not be reported as a singular value.

temperature.

7.1.4 Sealable containers (pans, crucibles, and so forth),

7. Apparatus

that are inert to the specimen, that will remain gravimetrically

7.1 The essential instrumentation required to provide the

stable within the temperature limits of this test method, and

minimum thermogravimetric analytical capability for this test

that contain a pinhole in the lid of diameter between 0.33 and

method includes:

0.38 mm.

7.1.1 A thermobalance, composed of:

NOTE 3—The most critical parameters for containers suitable for use

7.1.1.1 A furnace, to provide uniform controlled heating of

with this test method are the pinhole diameter and the lid thickness.

a specimen at a constant temperature or at a constant rate

Sealable containers of volumes (25 to 50 μL) and wall thicknesses (80 to

within the applicable temperature range of this test method;

150 μm) commercially available from Mettler-Toledo, Perkin-Elmer

7.1.1.2 A temperature sensor, to provide an indication of the

Corporation, and TA Instruments, Inc. have been found suitable for this

specimen/furnace temperature to 61K;

purpose.

7.1.1.3 A continuously recording balance, to measure the

specimen mass with a minimum capacity of 100 mg and a

sensitivity of 610 μg;

The sole source of supply of the 0.33 to 0.38-mm diameter pinhole lids known

7.1.1.4 A means of sustaining the specimen/container under

to the committee at this time is Kalbsey Corporation, 2725 W. CR1500 N., Carbon,

atmospheric control of inert gas (nitrogen, helium, and so

IN 47837. If you are aware of alternative suppliers, please provide this information

forth) of 99.9 % purity at a purge rate of 50 to 100 mL/min

to ASTM Headquarters. Your comments will receive careful consideration at a

65%. meet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.