ASTM D876-00

(Test Method)Standard Test Methods for Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical Insulation

Standard Test Methods for Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical Insulation

SCOPE

1.1 These test methods cover the testing of general-purpose (Grade A), low-temperature (Grade B), and high-temperature (Grade C) nonrigid vinyl chloride polymer tubing, or its copolymers with other materials, for use as electrical insulation. For the purpose of these test methods nonrigid tubing shall be tubing having an initial elongation in excess of 100% at break.

1.2 The values stated in inch-pound units are to be regarded as the standard, except temperature, which shall be stated in degrees Celsius. Values in parentheses are for information only.

1.3 The procedures appear in the following sections: ASTM Reference Procedure Section Standard Brittleness Temperature 43 to 45 D 746 Corrosion Tests 74 to 85 D 1000 Dielectric Breakdown Voltage at High Humidity 65 to 73 E 104 Dielectric Breakdown Voltage 58 to 64 D 149 Dimensional Tests 8 to 14 D 374 Effect of Elevated Temperatures 25 to 36 D 412 Flammability Test 15 to 21 Oil Resistance Test 35 to 42 D 471 Penetration Test 46 to 51 Sampling 6 Strain Relief Test 68 to 73 Tension Test 22 to 24 D 412 Test Conditions 7 Volume Resistivity 52 to 57 D 257

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D876–00

Standard Test Methods for

Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical

Insulation

This standard is issued under the fixed designation D 876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods cover the testing of general-purpose 2.1 ASTM Standards:

(Grade A), low-temperature (Grade B), and high-temperature D 149 Test Method for Dielectric Breakdown Voltage and

(Grade C) nonrigid vinyl chloride polymer tubing, or its Dielectric Strength of Solid Electrical Insulating Materials

copolymers with other materials, for use as electrical insula- at Commercial Power Frequencies

tion. For the purpose of these test methods nonrigid tubing D 257 Test Methods for D-C Resistance or Conductance of

shall be tubing having an initial elongation in excess of 100 % Insulating Materials

at break. D 374 Test Methods for Thickness of Solid Electrical Insu-

lation

NOTE 1—These test methods are similar but not identical to those in

D 412 Test Methods for Vulcanized Rubber and Thermo-

IEC 60684–2.

plastic Rubbers and Thermostatic Elastomers—Tension

1.2 The values stated in inch-pound units are to be regarded

D 471 Test Method for Rubber Property—Effect of Liq-

as the standard, except temperature, which shall be stated in

uids

degreesCelsius.Valuesinparenthesesareforinformationonly.

D 746 Test Method for Brittleness Temperature of Plastics

1.3 The procedures appear in the following sections:

and Elastomers by Impact

ASTM Reference

D 1000 Test Methods for Pressure-Sensitive Adhesive–

Procedure Section Standard

Coated Tapes Used for Electrical and Electronic Applica-

Brittleness Temperature 43-45 D 746

Corrosion Tests 74-85 D 1000

tions

Dielectric Breakdown Voltage at High Humidity 65-73 E 104 3

D 1711 Terminology Relating to Electrical Insulation

Dielectric Breakdown Voltage 58-64 D 149

D 5032 Practice for Maintaining Constant Relative Humid-

Dimensional Tests 8-14 D 374

Effect of Elevated Temperatures 25-36 D 412

ity by Means of Glycerin Solutions

Flammability Test 15-21 7

E 176 Terminology of Fire Standards

Oil Resistance Test 35-42 D 471

2.2 IEC Standards:

Penetration Test 46-51

Sampling 6

60684–2 Flexible insulating sleeving, Part 2, Methods of

Strain Relief Test 68-73

test

Tension Test 22-24 D 412

Test Conditions 7

3. Terminology

Volume Resistivity 52-57 D 257

3.1 Definitions:

1.4 This standard does not purport to address all of the

3.1.1 For definitions pertaining to electrical insulation, refer

safety concerns, if any, associated with its use. It is the

to Terminology D 1711.

responsibility of the user of this standard to establish appro-

3.1.2 For definitions pertaining to fire standards, refer to

priate safety and health practices and determine the applica-

Terminology E 176.

bility of regulatory limitations prior to use. For specific hazard

statements, see Section 3.

Annual Book of ASTM Standards, Vol 10.01.

1 4

These test methods are under the jurisdiction of ASTM Committee D09 on Annual Book of ASTM Standards, Vol 09.01.

Electrical and Electronic Insulating Materials and are the direct responsibility of Annual Book of ASTM Standards, Vol 08.01.

Subcommittee D09.07 on Flexible and Rigid Insulating Materials. Annual Book of ASTM Standards, Vol 10.02.

Current edition approved Apr. 10, 2000. Published July 2000. Originally Annual Book of ASTM Standards, Vol 04.07.

published as D 876 – 46 T. Last previous edition D 876 – 95a. Available from American National Standards Institute, 11 W. 42nd St., New

Test methods applicable to Grade B will be specified at a later date. York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D876

3.2 Definitions of Terms Specific to This Standard: 6. Sampling

3.2.1 brittleness temperature, n—that temperature at which

6.1 Select a sufficient number of pieces of tubing in such a

50 % of the specimens fail when the specified number are

manner as to be representative of the shipment.

tested, using the apparatus and conditions specified.

6.2 Cutthenumberofspecimensrequiredforthepurposeof

3.2.2 corrosive effect, n—under the prescribed conditions,

tests from the pieces selected in accordance with 6.1, taking

the percentage change in electrical resistance of a fine copper

care to select material that is free from obvious defects.

wire in contact with the tubing.

7. Test Conditions

3.2.3 resistance to penetration, n—that property of tubing

indicated by its resistance to high local pressures, as deter-

7.1 Unless otherwise specified in these test methods, con-

mined by the temperature at which a steel ball punctures the duct tests at atmospheric pressure and at a temperature of 23 6

tubing under the conditions of loading and temperature rise

2°C (73 6 4°F). Room temperature, as stated in these test

specified in these test methods. methods, shall be within this temperature range.

3.2.4 wall thickness, n—anaveragevaluedeterminedasone

DIMENSIONAL TESTS

half of the difference between the inside and outside diameters

of the tubing measured by the test method prescribed herein.

8. Significance and Use

8.1 The inside diameter and wall thickness are of impor-

4. Significance and Use

tance as a measure of dimensional uniformity. They also

4.1 Thesetestmethodsincludemostofthetestmethodsthat

provide important data for design purposes, and are used in the

are considered important to characterize nonrigid vinyl chlo-

calculation of certain physical and electrical properties of the

ride polymer tubing. While they were developed initially for

tubing.

this type of extruded tubing, their use is not limited to this type

of tubing.

9. Apparatus

4.2 Variations in these test methods or alternate contempo-

9.1 Tapered-Steel Gages—Use chromium-plated gages suit-

rary methods may be used to determine the values for the

able for covering the range of tubing sizes shown in Table 1.

properties in this standard provided such methods ensure

The gages shall have a uniform taper of 0.010 in./1 in. (0.010

qualitylevelsandmeasurementaccuracyequaltoorbetterthan

mm/mm) of length, and shall be graduated with circular

those prescribed herein. It is the responsibility of the organi-

zations using alternate test methods to be able to demonstrate

TABLE 1 Tubing Sizes

this condition. In cases of dispute, the test methods specified

A

herein shall be used. Inside Diameter, in.

Size

Max Min Nominal

NOTE 2—Provision for alternate methods is necessary because of (1)

2 in. 2.070 2.000 .

the desire to simplify procedures for specific applications without altering

1 ⁄4 in. 1.812 1.750 .

the result, and (2) the desire to eliminate redundant testing and use data

1 ⁄2 in. 1.550 1.500 .

generated during manufacturing process control, including that generated

1 ⁄4 in. 1.290 1.250 .

under Statistical Process Control (SPC) conditions, using equipment and

methods other than those specified herein. An example would be the use

1 in. 1.036 1.000 .

⁄8 in. 0.911 0.875 .

of laser micrometers or optical comparators to measure dimensions.

⁄4 in. 0.786 0.750 .

⁄8 in. 0.655 0.625 .

5. Hazards

⁄2 in. 0.524 0.500 .

5.1 Lethal voltages are a potential hazard during the

⁄16 in. 0.462 0.438 .

performance of this test. It is essential that the test apparatus,

⁄8 in. 0.399 0.375 .

and all associated equipment electrically connected to it, be ⁄16 in. 0.334 0.3125 .

properly designed and installed for safe operation. Solidly

No. 0 0.347 0.325 0.330

ground all electrically conductive parts which it is possible for

No. 1 0.311 0.289 0.294

No. 2 0.278 0.258 0.263

a person to contact during the test. Provide means for use at

No. 3 0.249 0.229 0.234

the completion of any test to ground any parts which were at

No. 4 0.224 0.204 0.208

high voltage during the test or have the potential for acquiring

an induced charge during the test or retaining a charge even No. 5 0.198 0.182 0.186

No. 6 0.178 0.162 0.166

after disconnection of the voltage source. Thoroughly instruct

No. 7 0.158 0.144 0.148

all operators as to the correct procedures for performing tests

No. 8 0.141 0.129 0.133

No. 9 0.124 0.114 0.118

safely. When making high voltage tests, particularly in com-

pressed gas or in oil, it is possible for the energy released at

No. 10 0.112 0.102 0.106

breakdowntobesuffıcienttoresultinfire,explosion,orrupture

No. 11 0.101 0.091 0.095

No. 12 0.089 0.081 0.085

of the test chamber. Design test equipment, test chambers, and

No. 14 0.072 0.064 0.066

test specimens so as to minimize the possibility of such

No. 16 0.061 0.051 0.053

occurrences, and to eliminate the possibility of personal injury.

No. 18 0.049 0.040 0.042

No. 20 0.039 0.032 0.034

If the potential for fire exists, have fire suppression equipment

A

available. NOTE—One inch equals 25.4 mm.

D876

lathe-cutringsevery0.5in.(13mm)oflength.Thegraduations 13.1.2 All readings on outside diameter of the specimen to

shall then represent a uniform increase in diameter of 0.005 the nearest 0.001 in.,

in./0.5 in. (0.010 mm/mm) of length. 13.1.3 Average outside diameter, and

9.2 Micrometers—Use machinist’s type micrometers suit- 13.1.4 Average wall thickness.

able for covering the range of tubing sizes shown in Table 1.

14. Precision and Bias

9.3 Steel Scale—A steel scale graduated in 0.01 in. (0.25

mm). 14.1 The precision of this test method has not been deter-

mined due to inadequate voluntary participation and funding

10. Test Specimens

needed to conduct the round-robin testing. A statement of bias

is unavailable in view of the lack of a standard reference

10.1 Cut a 1-in. (25-mm) specimen free of kinks from the

material for this property.

sample. Perform this operation perpendicular to the longitudi-

nal axis of the tubing specimen, giving a specimen 1 in. in

FLAMMABILITY TEST

length having cleanly cut square ends.

15. Scope

11. Procedure for Measuring Inside Diameter

15.1 This is a fire-test-response standard.The test procedure

11.1 Select a gage that will fit part way into the tubular

described measures the resistance of the tubing to ignition or

specimen.Slipthespecimen,withoutforcing(Note3),overthe

the spread of flame after ignition when tested under the

gage until there is no visible air space between the end of the

specified conditions.

specimen and the gage anywhere on the circumference. Con-

15.2 This standard should be used to measure and describe

siderthispointonthegagetheinsidediameterofthespecimen.

the response of materials, products, or assemblies to heat and

NOTE 3—When the tubing specimen tends to stick, the gage may be

flame under controlled conditions and should not be used to

dippedinwatertofacilitateslippingthespecimenoverthegage.However,

describe or appraise the fire-hazard or fire-risk of materials,

when water is used as a lubricant on the gage, great caution should be

products, or assemblies under actual fire conditions. However,

exercised to make certain that the specimen is not forced on the gage,

results of this test may be used as elements of a fire-hazard

thereby stretching the specimen.

assessment or a fire-risk assessment which takes into account

11.2 Determine the diameter at the point of contact between

all of the factors which are pertinent to an assessment of the

the specimen and gage by referring to the nearest visible

fire hazard or fire risk of a particular end use.

graduation. With the steel scale, measure any distance between

the edge of the specimen and the nearest graduation. Each 0.1 16. Significance and Use

in. (2.5 mm) on the length of the gage represents an increase of

16.1 This test may be employed to compare tubing made

0.001 in. (0.025 mm) in diameter. Since the diameter at the

from different compounds provided that specimens with the

nearest graduation is known, obtain the inside diameter of the

same dimensions are used, but it is not necessarily a measure

specimen by interpolation and report to the nearest 0.001 in.

of the flammability of the compound.

12. Procedure for Measuring Outside Diameter

17. Apparatus

12.1 With the specimen located on the tapered gage as

17.1 Sheet Metal Enclosure—A three-walled sheet metal

described in 11.1, make three outside diameter measurements

enclosure12in.(300mm)wideby14in.(360mm)deepby29

approximately 120° apart and adjacent to the edge of each

in. (740 mm) high, open at the top. It shall be equipped with

specimen. Make the measurements in accordance with Test

two parallel horizontal metal rods 16 in. (410 mm) apart, so

Methods D 374 using Apparatus B, and observing the follow-

situated that a wire stretched perpendicularly across each rod

ing additional details:

shall be at a 70° angle with the horizontal. The lower rod shall

12.1.1 Support the micrometer to allow both hands to be

be approximately 2 in. (50 mm) from the rear wall.

free for manipulation.

17.2 Bare Steel Wire—A length of bare steel wire, approxi-

12.1.2 Measure the outside diameter adjacent to, but not on

mately 0.029 in. (0.74 mm) in diameter, shall be used for

or over the cut edge, and

supporting the specimens during the test.

12.1.3 Rotate the tubular specimen, which is on the tapered

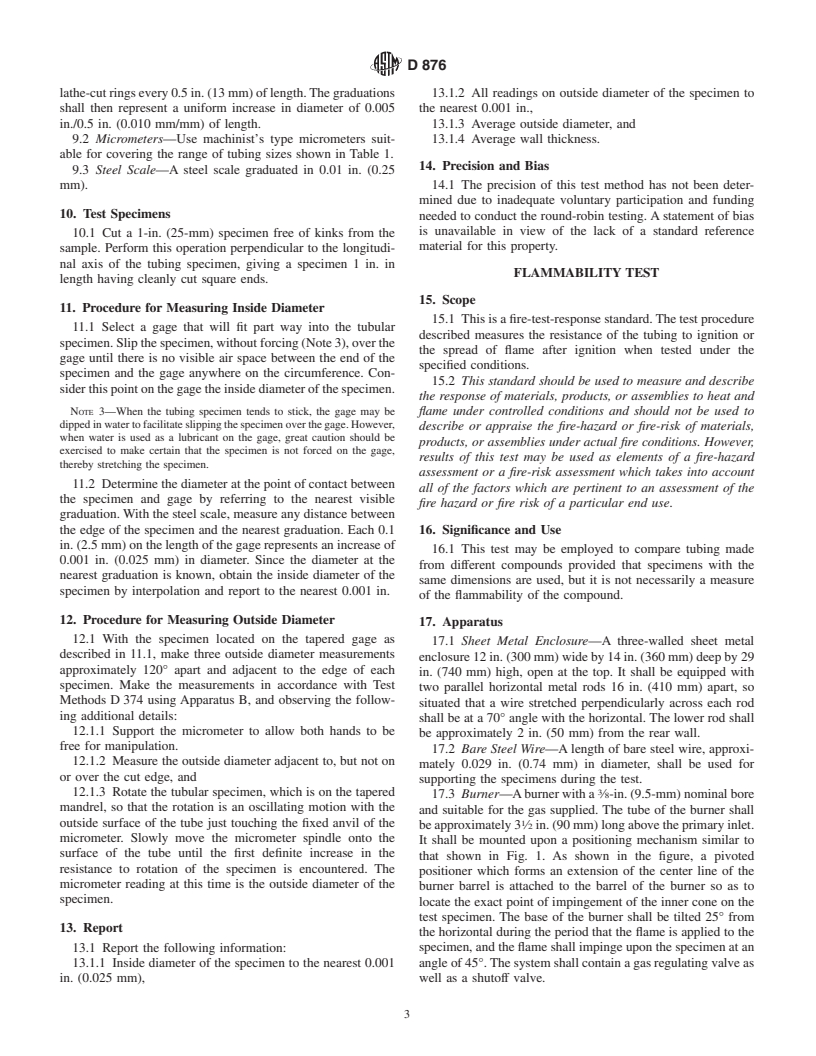

17.3 Burner—Aburnerwitha ⁄8-in.(9.5-mm)nominalbore

mandrel, so that the rotation is an oscillating motion with the

and suitable for the gas supplied. The tube of the burner shall

outside surface of the tube just touching the fixed anvil of the 1

beapproximately3 ⁄2in.(90mm)longabovetheprimaryinlet.

micrometer. Slowly move the micrometer spindle onto the

It shall be mounted upon a positioning mechanism similar to

surface of the tube until the first definite increase in the

that shown in Fig. 1. As shown in the figure, a pivoted

resistance to rotation of the specimen is encountered. The

positioner which forms an extension of the center line of the

micrometer reading at this time is the outside diameter of the

burner barrel is attached to the barrel of the burner so as to

specimen.

locate the exact point of impingement of the inner cone on the

test specimen. The base of the burner shall be tilted 25° from

13. Report

the horizontal during the period that the flame is applied to the

13.1 Report the following information: specimen, and the flame shall impinge upon the specimen at an

13.1.1 Inside diameter of the specimen to the nearest 0.001 angleof45°.Thesystemshallcontainagas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.