ASTM B910/B910M-07(2018)

(Specification)Standard Specification for Annealed Copper-Clad Steel Wire

Standard Specification for Annealed Copper-Clad Steel Wire

ABSTRACT

This specification covers annealed bare round copper-clad steel wire for the following applications: electrical, electronic, grounding, telecommunications, and other applications. Four types of copper-clad steel wires according to their electrical conductivities are included. The wire shall consist of a core of homogeneous open-hearth, electric-furnace, or basic-oxygen steel with a continuous outer cladding of copper thoroughly bonded to the core throughout. The copper-clad steel wire shall conform to the specified requirements for: tensile strength, elongation, dimension (diameter), adhesion and surface defects, joints, finish, copper thickness, density, and electrical resistivity. Methods for measurement, inspection, and testing such as torsion (twist) test are detailed.

SCOPE

1.1 This specification covers bare round copper-clad steel for the following applications: electrical, electronic, grounding, telecommunications, and other applications.

1.2 Four conductivities are covered as follows: 21, 30, 40, and 70 %.

1.3 Temper is designated as annealed.

1.4 The values stated in inch-pound or SI units are to be regarded separately as the standard. Each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. For conductor sizes designated by AWG, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.5 The following precautionary statement pertains to the test method portion only, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B910/B910M −07 (Reapproved 2018)

Standard Specification for

Annealed Copper-Clad Steel Wire

This standard is issued under the fixed designation B910/B910M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Standards:

B193Test Method for Resistivity of Electrical Conductor

1.1 This specification covers bare round copper-clad steel

Materials

forthefollowingapplications:electrical,electronic,grounding,

B258Specification for Standard Nominal Diameters and

telecommunications, and other applications.

Cross-Sectional Areas of AWG Sizes of Solid Round

1.2 Four conductivities are covered as follows: 21, 30, 40, Wires Used as Electrical Conductors

and 70%.

2.3 NIST Document:

NBS Handbook 100—Copper Wire Tables

1.3 Temper is designated as annealed.

3. Ordering Information

1.4 The values stated in inch-pound or SI units are to be

regarded separately as the standard. Each system shall be used

3.1 Ordersformaterialunderthisspecificationshallinclude

independently of the other. Combining values from the two

the following information:

systems may result in nonconformance with the specification.

3.1.1 Quantity of each size;

ForconductorsizesdesignatedbyAWG,therequirementsinSI

3.1.2 Wire size: diameter in inches (see 5.2);

units have been numerically converted from corresponding

3.1.3 Conductivity (see Table 1);

values stated or derived in inch-pound units. For conductor

3.1.4 Wire to be used for redraw or not;

sizesdesignatedbySIunitsonly,therequirementsarestatedor

3.1.5 Packaging and shipping (see 10); and

derived in SI units.

3.1.6 Place of inspection (see 6.1).

1.5 The following precautionary statement pertains to the

4. Material

test method portion only, Section 7, of this specification: This

standard does not purport to address all of the safety concerns, 4.1 The wire shall consist of a core of homogeneous

if any associated with its use. It is the responsibility of the user open-hearth, electric-furnace, or basic-oxygen steel with a

of this standard to establish appropriate safety, health, and continuous outer cladding of copper thoroughly bonded to the

environmental practices and determine the applicability of core throughout and shall be of such quality as to meet the

regulatory limitations prior to use. requirements of this specification.

1.6 This international standard was developed in accor-

5. General Requirements

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5.1 Tensile Strength and Elongation—The copper-clad steel

Development of International Standards, Guides and Recom- wireshallconformtothetensilestrengthrequirementsofTable

mendations issued by the World Trade Organization Technical 2. Because there are many carbon steel and copper thickness

combinations available, the desired tensile strength should be

Barriers to Trade (TBT) Committee.

agreed upon between the purchaser and manufacturer prior to

placing an order. The elongation shall be 15.0% minimum for

2. Referenced Documents

all diameters listed in 5.2.

2.1 The following documents of the issue in effect on the

5.2 Dimensions—The wire size range for this specification

dateofmaterialpurchaseformapartofthisspecificationtothe

shall be from 0.0253 (0.643 mm) to 0.2294 in. (5.827 mm)

extent referenced herein:

diameter (see Note 1).

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Bi-Metallic Conductors. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2018. Published October 2018. Originally the ASTM website.

approved in 2000. Last previous edition approved in 2013 as B910/B910M–07 Available from National Institute of Standards and Technology (NIST), 100

(2013). DOI: 10.1520/B0910_B0910M-07R18. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B910/B910M − 07 (2018)

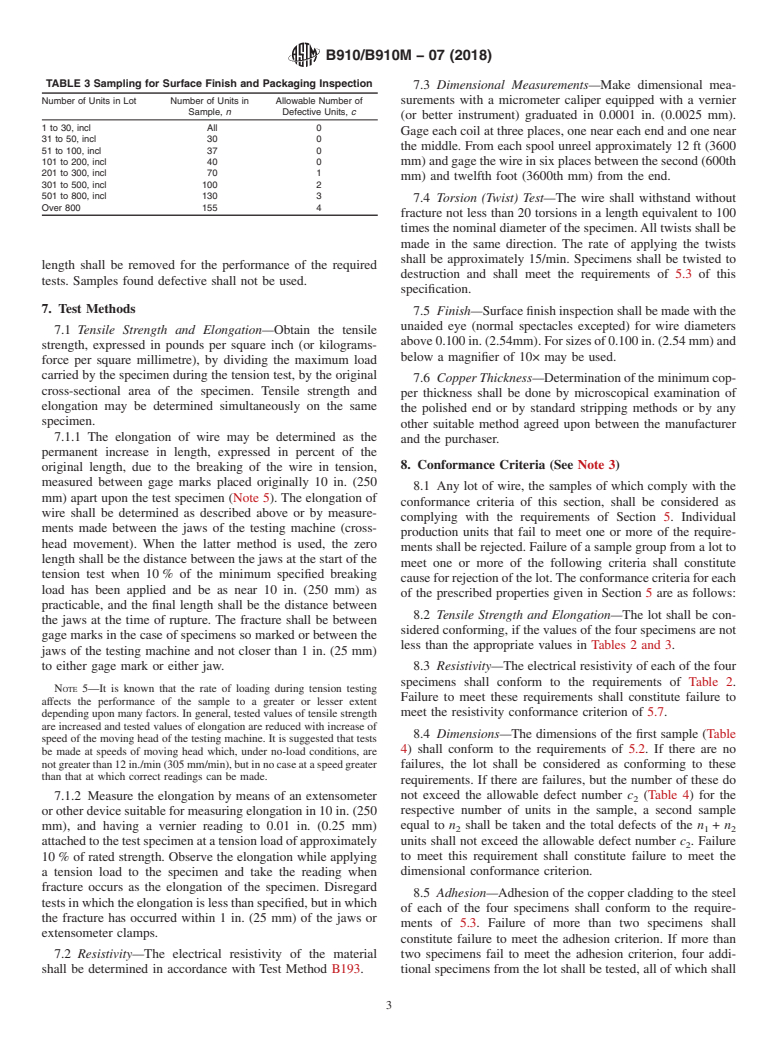

TABLE 1 Density (nom.) and Resistivity, (max.), at 20°C (Nominal Standard (IACS) adopted by IEC in 1913, which is ⁄58 ohm mm /m at

Conductivity, Minimum Conductivity, and Nominal Density for

20°C for 100% conductivity.The value of 0.017241 ohm mm /m and the

Reference Only) value of 0.15328 ohm g/m at 20°C are, respectively, the international

equivalent of volume and weight resistivity of annealed copper equal to

Maximum Resistivity

100% conductivity. The latter term means that a copper wire 1 in. in

Nominal Density at 20°C

Nominal Minimum

length and weighing 1 g would have a resistance of 0.15328 ohm. This is

Conductivity (ohm Conductivity

equivalent to a resistivity value of 875.20 ohm lb/mile , which signifies

3 3 2

(% IACS) lb/in. (g/cm ) Ohm cmil/ft mm /m) (% IACS)

the resistance of a copper wire 1 mile in length weighing 1 lb. It is also

21 0.2885 (7.99) 54.58 (0.0907) 19.00

equivalent,forexample,to1.7241ohm/cmoflengthofacopperbar1cm

30 0.2944 (8.15) 35.26 (0.0586) 29.41

in cross section. A complete discussion of this subject is contained in

40 0.2975 (8.24) 26.45 (0.0440) 39.21

NBSHandbook100. The use of five significant figures in expressing

70 0.3098 (8.58) 15.96 (0.0265) 65.00

resistivity does not imply the need for greater accuracy of measurement

thanthatspecifiedinTestMethodB193.Theuseoffivesignificantfigures

is required for complete reversible conversion from one set of resistivity

TABLE 2 Tensile and Minimum Copper Thickness (Conductivity

units to another.

and Nominal Copper Thickness for Reference Only)

Minimum Tensile Minimum Copper Nominal Copper 6. Inspection

Nominal

Strength Thickness Thickness

Conductivity

6.1 General—All tests and inspections shall be made at the

(% IACS) psi (N/mm ) (% of Diameter) (% of Diameter)

place of manufacture unless otherwise agreed upon between

21 50 000 (345) 1.5 3

themanufacturerandthepurchaseratthetimeofthepurchase.

30 45 000 (310) 3.0 7

40 40 000 (276) 5.0 9

The manufacturer shall afford the inspector representing the

70 35 000 (241) 15.0 20

purchaser all reasonable facilities to satisfy him that the

material is being furnished in accordance with this specifica-

tion (Note 3).

5.2.1 Permissible Variations—The wire sizes shall meet the

NOTE 3—Cumulative results secured on the product of a single

following tolerances:

manufacturer, indicating continued conformance to the criteria, are

5.2.1.1 For diameters 0.1000 in. (2.54 mm) and over, the

necessary to ensure an over-all product meeting the requirements of this

specification. The sample sizes and conformance criteria given for the

wireshallnotvaryfromthespecifieddiameterbymorethan 6

various characteristics are applicable only to lots produced under these

1 ⁄2%, expressed to the nearest 0.0001 in. (0.003 mm).

conditions.

5.2.1.2 Fordiametersunder0.1000in.(2.54mm)andabove

6.1.1 Unless otherwise agreed by the manufacturer and the

0.0253 in. (0.643 mm), the wire shall not vary from the

purchaser,conformanceofthewiretothevariousrequirements

specified diameter by more than 61%, expressed to the

listed in Section 5 shall be determined on samples taken from

nearest 0.0001 in. (0.003 mm).

each lot of wire presented for acceptance.

NOTE1—Thevaluesofthewirediametersin5.2aregiventothenearest

6.1.2 The manufacturer shall, if requested prior to

0.0001 in. (0.003 mm) and correspond to the standard sizes given in

inspection, certify that all wire in the lot was made under such

Specification B258. The use of gage numbers to specify wire sizes is not

conditions that the product as a whole conforms to the

recognizedinthisspecificationbecauseofthepossibilityofconfusion.An

excellent discussion of wire gages and related subjects is contained in requirements of this specification as determined by regularly

NBS Handbook 100.

made and recorded tests.

5.3 Adhesion and Surface Defects—The copper-clad steel

6.2 Definitions:

wire, when tested in accordance with 7.4, shall not reveal any

6.2.1 lot—any amount of wire of one class and size pre-

seams, pits, slivers, or other imperfection of sufficient magni-

sentedforacceptanceatonetime,suchamount,however,isnot

tudetoindicateinherentdefectsorimperfections.Examination

to exceed 40 000 lb (18 144 kg) (Note 4).

ofthewireatthebreakwiththeunaidedeye(normalspectacles

NOTE4—Alotshouldcomprisematerialtakenfromaproductregularly

excepted) shall show no separation of copper from the steel.

meeting the requirements of this specification. Inspection of individual

5.4 Joints—Necessary joints in the wire and rods prior to

lots of less than 500 lb (230 kg) of wire cannot be justified economically.

For small lots of 500 lb (230 kg) or less, the purchaser may agree to the

final drawing shall be made in accordance with good commer-

manufacturer’sregularinspectionoftheproductasawholeasevidenceof

cialpractice.Thefinishedwireshallcontainnojointsorsplices

acceptability of such small lots.

made at finished size.

6.2.2 sample—a quantity of production units (coils, reels,

5.5 Finish—The wire shall be free from copper discontinui-

andsoforth)selectedatrandomfromthelotforthepurposeof

ties and all imperfections not consistent with good commercial

determining conformance of the lot to the requirements of this

practice (see 7.5).

specification.

5.6 Copper Thickness—The minimum copper thickness due

6.2.3 specimen—a length of wire removed for test purposes

to eccentricity shall not be less than shown in Table 2.

from any individual production unit of the sample.

5.7 Resistivity—The electrical resistivity at a temperature of

6.3 Sample Size—The number of production units in a

20°C shall not exceed the values prescribed in Table 1. See

sample (see Note 3) shall be as follows:

Note 2 for calculating electrical resistance.

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B910/B910M − 07 (Reapproved 2018)

Standard Specification for

Annealed Copper-Clad Steel Wire

This standard is issued under the fixed designation B910/B910M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor

1.1 This specification covers bare round copper-clad steel

Materials

for the following applications: electrical, electronic, grounding,

B258 Specification for Standard Nominal Diameters and

telecommunications, and other applications.

Cross-Sectional Areas of AWG Sizes of Solid Round

1.2 Four conductivities are covered as follows: 21, 30, 40, Wires Used as Electrical Conductors

and 70 %.

2.3 NIST Document:

NBS Handbook 100 —Copper Wire Tables

1.3 Temper is designated as annealed.

3. Ordering Information

1.4 The values stated in inch-pound or SI units are to be

regarded separately as the standard. Each system shall be used

3.1 Orders for material under this specification shall include

independently of the other. Combining values from the two

the following information:

systems may result in nonconformance with the specification.

3.1.1 Quantity of each size;

For conductor sizes designated by AWG, the requirements in SI

3.1.2 Wire size: diameter in inches (see 5.2);

units have been numerically converted from corresponding

3.1.3 Conductivity (see Table 1);

values stated or derived in inch-pound units. For conductor

3.1.4 Wire to be used for redraw or not;

sizes designated by SI units only, the requirements are stated or

3.1.5 Packaging and shipping (see 10); and

derived in SI units.

3.1.6 Place of inspection (see 6.1).

1.5 The following precautionary statement pertains to the

4. Material

test method portion only, Section 7, of this specification: This

standard does not purport to address all of the safety concerns, 4.1 The wire shall consist of a core of homogeneous

if any associated with its use. It is the responsibility of the user open-hearth, electric-furnace, or basic-oxygen steel with a

of this standard to establish appropriate safety, health, and continuous outer cladding of copper thoroughly bonded to the

environmental practices and determine the applicability of core throughout and shall be of such quality as to meet the

regulatory limitations prior to use. requirements of this specification.

1.6 This international standard was developed in accor-

5. General Requirements

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5.1 Tensile Strength and Elongation—The copper-clad steel

Development of International Standards, Guides and Recom- wire shall conform to the tensile strength requirements of Table

2. Because there are many carbon steel and copper thickness

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. combinations available, the desired tensile strength should be

agreed upon between the purchaser and manufacturer prior to

placing an order. The elongation shall be 15.0 % minimum for

2. Referenced Documents

all diameters listed in 5.2.

2.1 The following documents of the issue in effect on the

5.2 Dimensions—The wire size range for this specification

date of material purchase form a part of this specification to the

shall be from 0.0253 (0.643 mm) to 0.2294 in. (5.827 mm)

extent referenced herein:

diameter (see Note 1).

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Bi-Metallic Conductors. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2018. Published October 2018. Originally the ASTM website.

approved in 2000. Last previous edition approved in 2013 as B910/B910M – 07 Available from National Institute of Standards and Technology (NIST), 100

(2013). DOI: 10.1520/B0910_B0910M-07R18. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B910/B910M − 07 (2018)

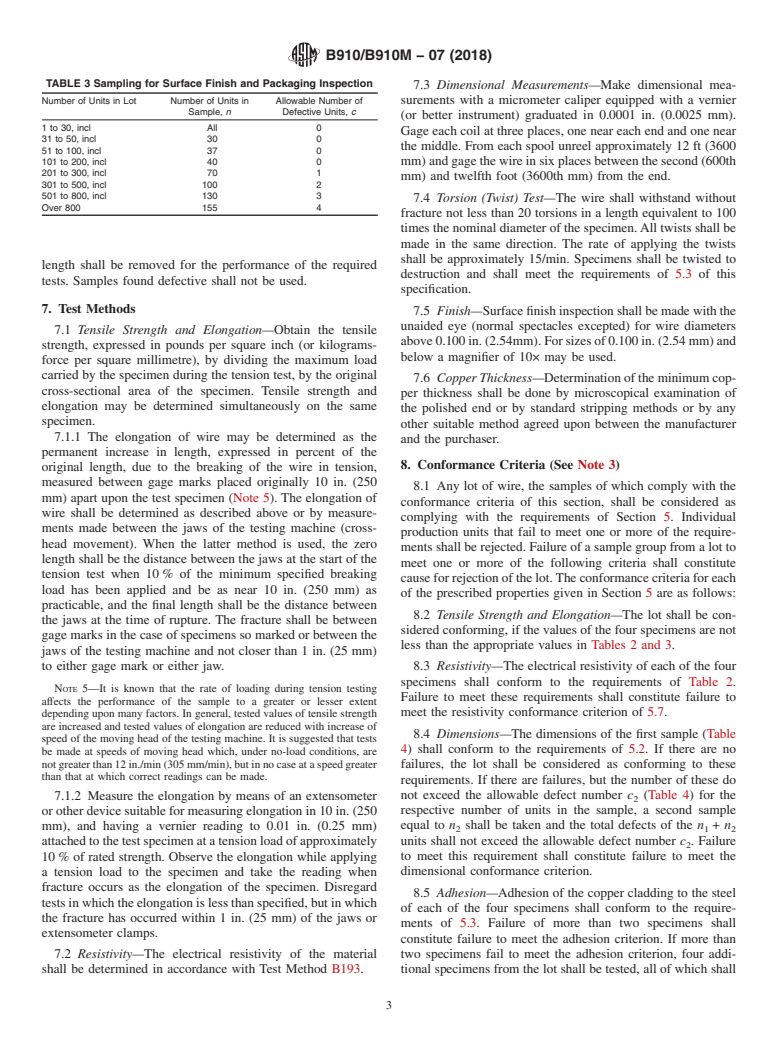

TABLE 1 Density (nom.) and Resistivity, (max.), at 20°C (Nominal

Standard (IACS) adopted by IEC in 1913, which is ⁄58 ohm mm /m at

Conductivity, Minimum Conductivity, and Nominal Density for 20°C for 100 % conductivity. The value of 0.017241 ohm mm /m and the

Reference Only)

value of 0.15328 ohm g/m at 20°C are, respectively, the international

equivalent of volume and weight resistivity of annealed copper equal to

Maximum Resistivity

100 % conductivity. The latter term means that a copper wire 1 in. in

Nominal Density at 20°C

Nominal Minimum

length and weighing 1 g would have a resistance of 0.15328 ohm. This is

Conductivity (ohm Conductivity

3 3 2 equivalent to a resistivity value of 875.20 ohm lb/mile , which signifies

(% IACS) lb/in. (g/cm ) Ohm cmil/ft mm /m) (% IACS)

the resistance of a copper wire 1 mile in length weighing 1 lb. It is also

21 0.2885 (7.99) 54.58 (0.0907) 19.00

equivalent, for example, to 1.7241 ohm/cm of length of a copper bar 1 cm

30 0.2944 (8.15) 35.26 (0.0586) 29.41

in cross section. A complete discussion of this subject is contained in

40 0.2975 (8.24) 26.45 (0.0440) 39.21

NBS Handbook 100. The use of five significant figures in expressing

70 0.3098 (8.58) 15.96 (0.0265) 65.00

resistivity does not imply the need for greater accuracy of measurement

than that specified in Test Method B193. The use of five significant figures

is required for complete reversible conversion from one set of resistivity

TABLE 2 Tensile and Minimum Copper Thickness (Conductivity

units to another.

and Nominal Copper Thickness for Reference Only)

Minimum Tensile Minimum Copper Nominal Copper

6. Inspection

Nominal

Strength Thickness Thickness

Conductivity

6.1 General—All tests and inspections shall be made at the

(% IACS) psi (N/mm ) (% of Diameter) (% of Diameter)

place of manufacture unless otherwise agreed upon between

21 50 000 (345) 1.5 3

the manufacturer and the purchaser at the time of the purchase.

30 45 000 (310) 3.0 7

40 40 000 (276) 5.0 9

The manufacturer shall afford the inspector representing the

70 35 000 (241) 15.0 20

purchaser all reasonable facilities to satisfy him that the

material is being furnished in accordance with this specifica-

tion (Note 3).

5.2.1 Permissible Variations—The wire sizes shall meet the

NOTE 3—Cumulative results secured on the product of a single

following tolerances:

manufacturer, indicating continued conformance to the criteria, are

5.2.1.1 For diameters 0.1000 in. (2.54 mm) and over, the necessary to ensure an over-all product meeting the requirements of this

specification. The sample sizes and conformance criteria given for the

wire shall not vary from the specified diameter by more than 6

various characteristics are applicable only to lots produced under these

1 ⁄2 %, expressed to the nearest 0.0001 in. (0.003 mm).

conditions.

5.2.1.2 For diameters under 0.1000 in. (2.54 mm) and above

6.1.1 Unless otherwise agreed by the manufacturer and the

0.0253 in. (0.643 mm), the wire shall not vary from the

purchaser, conformance of the wire to the various requirements

specified diameter by more than 61 %, expressed to the

listed in Section 5 shall be determined on samples taken from

nearest 0.0001 in. (0.003 mm).

each lot of wire presented for acceptance.

NOTE 1—The values of the wire diameters in 5.2 are given to the nearest

6.1.2 The manufacturer shall, if requested prior to

0.0001 in. (0.003 mm) and correspond to the standard sizes given in

inspection, certify that all wire in the lot was made under such

Specification B258. The use of gage numbers to specify wire sizes is not

conditions that the product as a whole conforms to the

recognized in this specification because of the possibility of confusion. An

excellent discussion of wire gages and related subjects is contained in

requirements of this specification as determined by regularly

NBS Handbook 100.

made and recorded tests.

5.3 Adhesion and Surface Defects—The copper-clad steel

6.2 Definitions:

wire, when tested in accordance with 7.4, shall not reveal any

6.2.1 lot—any amount of wire of one class and size pre-

seams, pits, slivers, or other imperfection of sufficient magni-

sented for acceptance at one time, such amount, however, is not

tude to indicate inherent defects or imperfections. Examination

to exceed 40 000 lb (18 144 kg) (Note 4).

of the wire at the break with the unaided eye (normal spectacles

NOTE 4—A lot should comprise material taken from a product regularly

excepted) shall show no separation of copper from the steel.

meeting the requirements of this specification. Inspection of individual

5.4 Joints—Necessary joints in the wire and rods prior to lots of less than 500 lb (230 kg) of wire cannot be justified economically.

For small lots of 500 lb (230 kg) or less, the purchaser may agree to the

final drawing shall be made in accordance with good commer-

manufacturer’s regular inspection of the product as a whole as evidence of

cial practice. The finished wire shall contain no joints or splices

acceptability of such small lots.

made at finished size.

6.2.2 sample—a quantity of production units (coils, reels,

5.5 Finish—The wire shall be free from copper discontinui-

and so forth) selected at random from the lot for the purpose of

ties and all imperfections not consistent with good commercial

determining conformance of the lot to the requirements of this

practice (see 7.5).

specification.

5.6 Copper Thickness—The minimum copper thickness due

6.2.3 specimen—a length of wire removed for test purposes

to eccentricity shall not be less than shown in Table 2.

from any individual production unit of the sample.

5.7 Resistivity—The electrical resistivity at a temperature of

6.3 Sample Size—The number of production units in a

20°C shall not exceed the values prescribed in Table 1. See

sample (see Note 3) shall be as follows:

Note 2 for calculating electrical resistance.

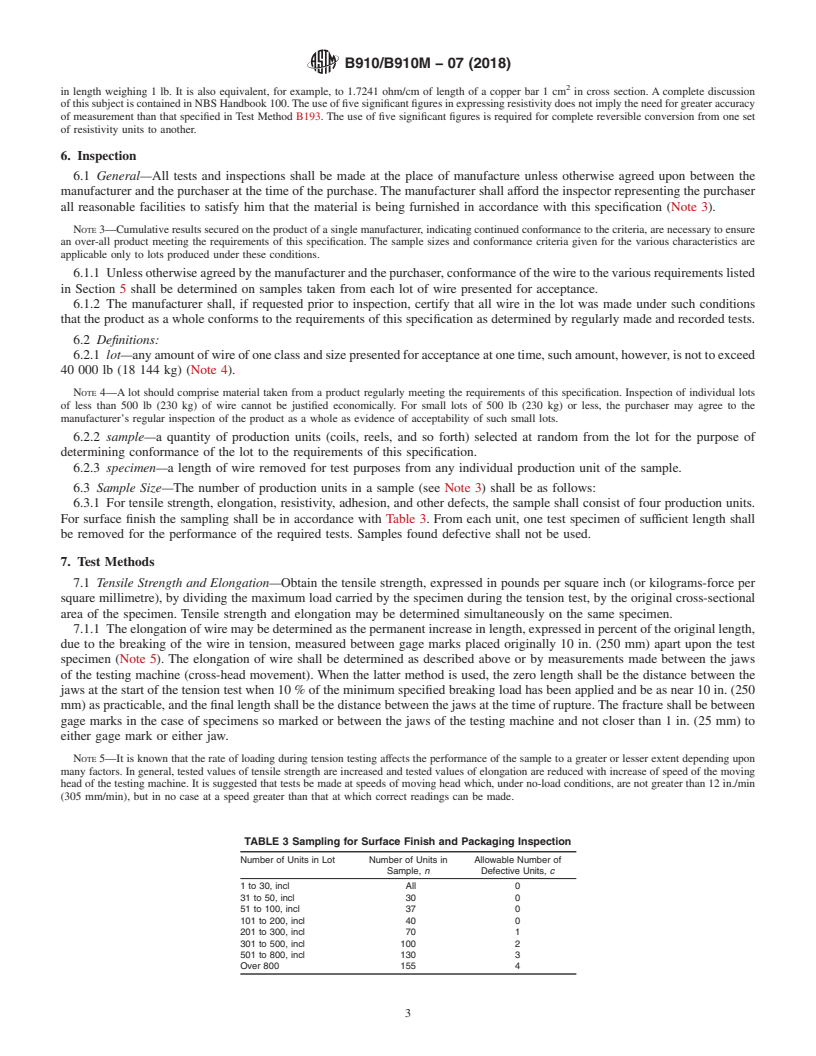

6.3.1 For tensile strength, elongation, re

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B910/B910M − 07 (Reapproved 2013) B910/B910M − 07 (Reapproved 2018)

Standard Specification for

Annealed Copper-Clad Steel Wire

This standard is issued under the fixed designation B910/B910M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers bare round copper-clad steel for the following applications: electrical, electronic, grounding,

telecommunications, and other applications.

1.2 Four conductivities are covered as follows: 21, 30, 40, and 70 %.

1.3 Temper is designated as annealed.

1.4 The values stated in inch-pound or SI units are to be regarded separately as the standard. Each system shall be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification. For

conductor sizes designated by AWG, the requirements in SI units have been numerically converted from corresponding values

stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in

SI units.

1.5 The following precautionary statement pertains to the test method portion only, Section 7, of this specification: This

standard does not purport to address all of the safety concerns, if any associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability

of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as

Electrical Conductors

2.3 NIST Document:

NBS Handbook 100 Copper—Copper Wire Tables

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size;

3.1.2 Wire size: diameter in inches (see 5.2);

3.1.3 Conductivity (see Table 1);

3.1.4 Wire to be used for redraw or not;

3.1.5 Packaging and shipping (see 10); and

3.1.6 Place of inspection (see 6.1).

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on Bi-Metallic

Conductors.

Current edition approved April 1, 2013Oct. 1, 2018. Published April 2013October 2018. Originally approved in 2000. Last previous edition approved in 20072013 as

B910/B910M – 07.B910/B910M – 07 (2013). DOI: 10.1520/B0910_B0910M-07R13.10.1520/B0910_B0910M-07R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B910/B910M − 07 (2018)

TABLE 1 Density (nom.) and Resistivity, (max.), at 20°C (Nominal

Conductivity, Minimum Conductivity, and Nominal Density for

Reference Only)

Maximum Resistivity

Nominal Density at 20°C

Nominal Minimum

Conductivity (ohm Conductivity

3 3 2

(% IACS) lb/in. (g/cm ) Ohm cmil/ft mm /m) (% IACS)

21 0.2885 (7.99) 54.58 (0.0907) 19.00

30 0.2944 (8.15) 35.26 (0.0586) 29.41

40 0.2975 (8.24) 26.45 (0.0440) 39.21

70 0.3098 (8.58) 15.96 (0.0265) 65.00

4. Material

4.1 The wire shall consist of a core of homogeneous open-hearth, electric-furnace, or basic-oxygen steel with a continuous outer

cladding of copper thoroughly bonded to the core throughout and shall be of such quality as to meet the requirements of this

specification.

5. General Requirements

5.1 Tensile Strength and Elongation—The copper-clad steel wire shall conform to the tensile strength requirements of Table 2.

Because there are many carbon steel and copper thickness combinations available, the desired tensile strength should be agreed

upon between the purchaser and manufacturer prior to placing an order. The elongation shall be 15.0 % minimum for all diameters

listed in 5.2.

5.2 Dimensions—The wire size range for this specification shall be from 0.0253 (0.643 mm) to 0.2294 in. (5.827 mm) diameter

(see Note 1).

5.2.1 Permissible Variations—The wire sizes shall meet the following tolerances:

5.2.1.1 For diameters 0.1000 in. (2.54 mm) and over, the wire shall not vary from the specified diameter by more than 6 1 ⁄2 %,

expressed to the nearest 0.0001 in. (0.003 mm).

5.2.1.2 For diameters under 0.1000 in. (2.54 mm) and above 0.0253 in. (0.643 mm), the wire shall not vary from the specified

diameter by more than 61 %, expressed to the nearest 0.0001 in. (0.003 mm).

NOTE 1—The values of the wire diameters in 5.2 are given to the nearest 0.0001 in. (0.003 mm) and correspond to the standard sizes given in

Specification B258. The use of gage numbers to specify wire sizes is not recognized in this specification because of the possibility of confusion. An

excellent discussion of wire gages and related subjects is contained in NBS Handbook 100.

5.3 Adhesion and Surface Defects—The copper-clad steel wire, when tested in accordance with 7.4, shall not reveal any seams,

pits, slivers, or other imperfection of sufficient magnitude to indicate inherent defects or imperfections. Examination of the wire

at the break with the unaided eye (normal spectacles excepted) shall show no separation of copper from the steel.

5.4 Joints—Necessary joints in the wire and rods prior to final drawing shall be made in accordance with good commercial

practice. The finished wire shall contain no joints or splices made at finished size.

5.5 Finish—The wire shall be free from copper discontinuities and all imperfections not consistent with good commercial

practice (see 7.5).

5.6 Copper Thickness—The minimum copper thickness due to eccentricity shall not be less than shown in Table 2.

5.7 Resistivity—The electrical resistivity at a temperature of 20°C shall not exceed the values prescribed in Table 1. See Note

2 for calculating electrical resistance.

NOTE 2—Relationships which may be useful in connection with the values of electrical resistivity prescribed in this specification are shown in Table

2. Resistivity units are based on the International Annealed Copper Standard (IACS) adopted by IEC in 1913, which is ⁄58 ohm mm /m at 20°C for 100 %

2 2

conductivity. The value of 0.017241 ohm mm /m and the value of 0.15328 ohm g/m at 20°C are, respectively, the international equivalent of volume

and weight resistivity of annealed copper equal to 100 % conductivity. The latter term means that a copper wire 1 in. in length and weighing 1 g would

have a resistance of 0.15328 ohm. This is equivalent to a resistivity value of 875.20 ohm lb/mile , which signifies the resistance of a copper wire 1 mile

TABLE 2 Tensile and Minimum Copper Thickness (Conductivity

and Nominal Copper Thickness for Reference Only)

Minimum Tensile Minimum Copper Nominal Copper

Nominal

Strength Thickness Thickness

Conductivity

(% IACS) psi (N/mm ) (% of Diameter) (% of Diameter)

21 50 000 (345) 1.5 3

30 45 000 (310) 3.0 7

40 40 000 (276) 5.0 9

70 35 000 (241) 15.0 20

B910/B910M − 07 (2018)

in length weighing 1 lb. It is also equivalent, for example, to 1.7241 ohm/cm of length of a copper bar 1 cm in cross section. A complete discussion

of this subject is contained in NBS Handbook 100. The use of five significant figures in expressing resistivity does not imply the need for greater accuracy

of measurement than that specified in Test Method B193. The use of five significant figures is required for complete reversible conversion from one set

of resistivity units to another.

6. Inspection

6.1 General—All tests and inspections shall be made at the place of manufacture unless otherwise agreed upon between the

manufacturer and the purchaser at the time of the purchase. The manufacturer shall afford the inspector representing the purchaser

all reasonable facilities to satisfy him that the material is being furnished in accordance with this specification (Note 3).

NOTE 3—Cumulative results secured on the product of a single manufacturer, indicating continued conformance to the criteria, are necessary to ensure

an over-all product meeting the requirements of this specification. The sample sizes and conformance criteria given for the various characteristics are

applicable only to lots produced under these conditions.

6.1.1 Unless otherwise agreed by the manufacturer and the purchaser, conformance of the wire to the various requirements listed

in Section 5 shall be determined on samples taken from each lot of wire presented for acceptance.

6.1.2 The manufacturer shall, if requested prior to inspection, certify that all wire in the lot was made under such conditions

that the product as a whole conforms to the requirements of this specification as determined by regularly made and recorded tests.

6.2 Definitions:

6.2.1 lot—any amount of wire of one class and size presented for acceptance at one time, such amount, however, is not to exceed

40 000 lb (18 144 kg) (Note 4).

NOTE 4—A lot should comprise material taken from a product regularly meeting the requirements of this specification. Inspection of individual lots

of less than 500 lb (230 kg) of wire cannot be justified economically. For small lots of 500 lb (230 kg) or less, the purchaser may agree to the

manufacturer’s regular inspection of the product as a whole as evidence of acceptability of such small lots.

6.2.2 sample—a quantity of producti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.