ASTM D5199-01

(Test Method)Standard Test Method for Measuring the Nominal Thickness of Geosynthetics

Standard Test Method for Measuring the Nominal Thickness of Geosynthetics

SCOPE

1.1 This test method is limited to measuring the nominal thickness of geotextiles, smooth surfaced geomembranes, geonets, and geocomposite drainage products.

1.2 The values stated in SI units are to be regarded as the standard. The values are provided in inch-pound units for information only.

1.3 This test method does not provide thickness values for geosynthetics under variable normal compressive stresses. This test method determines nominal thickness, not necessarily minimum thickness.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 5199–01

Standard Test Method for

Measuring the Nominal Thickness of Geosynthetics

This standard is issued under the fixed designation D 5199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope technical engineering related material as an integral part of a

man-made project, structure, or system.

1.1 This test method is limited to measuring the nominal

3.1.3 geotextiles, n—any permeable textile used with soil,

thickness of geotextiles, smooth surfaced geomembranes, geo-

rock, earth or any other geotechnical material as an integral

nets, and geocomposite drainage products.

part of a man-made project, structure, or system.

1.2 The values stated in SI units are to be regarded as the

3.1.4 pressure, n—the force or load per unit area.

standard. The values are provided in inch-pound units for

3.1.5 thickness—(1) the distance between one planar sur-

information only.

face and its opposite parallel and planar surface; (2) in the

1.3 This test method does not provide thickness values for

textiles the distance between the upper and lower surfaces of

geosyntheticsundervariablenormalcompressivestresses.This

the material, measured under a specified pressure and time.

test method determines nominal thickness, not necessarily

3.1.6 For definition of other textile terms used in this

minimum thickness.

standard, refer to Terminology D 123.

1.4 This standard does not purport to address all of the

3.1.7 For definitions of other terms relating to geotextiles

safety concerns, if any, associated with its use. It is the

and geomembranes used in this standard, refer to Terminology

responsibility of the user of this standard to establish appro-

D 4439.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents 4.1 The nominal thicknesses of geosynthetics is determined

byobservingtheperpendiculardistancethatamovableplaneis

2.1 ASTM Standards:

displaced from a parallel surface by the geotextile or geomem-

D 123 Terminology Relating to Textiles

brane material while under a specified pressure (2 kPa for

D 1776 Practice for Conditioning Textiles for Testing

geotextiles and 20 kPa for geomembranes for 5 s).

D 1777 Method for Measuring Thickness of Textiles Mate-

rials

5. Significance and Use

D 4354 Practice for Sampling of Geosynthetics for Testing

3 5.1 Thickness is one of the basic physical properties used to

D 4439 Terminology for Geosynthetics

controlthequalityofmanygeosynthetics.Thicknessvaluesare

3. Terminology required in calculation of some geotextile and geomembrane

parameters such as permeability coefficients, tensile stress

3.1 Definitions:

(index), and the like thickness is not indicative of field

3.1.1 geomembrane, n—an essentially impermeable mem-

performance and therefore is not recommended for specifica-

brane used with foundation, soil, rock, earth or any other

tions.

geotechnical engineering related material as an integral part of

5.2 The thickness of geotextiles and geomembranes may

a man-made project, structure, or system.

vary considerably depending on the pressure applied to the

3.1.2 geotextiles, n—a planar product manufactured from

specimenduringmeasurement.Whereobservedchangesoccur,

polymeric material used with soil, rock, earth, or other geo-

thickness decreases when applied pressure is increased. To

minimize variation, specific sample size and applied pressure

This test method is under the jurisdiction of ASTM Committee D35 on

are indicated in this method to ensure all results are compa-

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme-

rable.

ability and Filtration.

Current edition approved Jan. 10, 2001. Published April 2001. Originally 5.3 To determine the effect of difference pressure loadings

published as D 5199 – 91. Last previous edition D 5199 – 99.

on the measure thickness of geotextiles and geomembranes,

Annual Book of ASTM Standards, Vol 07.01.

use this test method.

Annual Book of ASTM Standards, Vol 04.13.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5199–01

5.4 This test method may be used for acceptance testing of 7. Sampling

commercial shipments of geotextiles and geomembranes, but

7.1 Lot Sample—In the absence of other guidelines divide

caution is advised since information on between-laboratory

the product into lots and take lot samples as specified in

precision is incomplete. Comparative tests, as directed in 5.4.1

Practice D 4354.

may be advisable.

7.2 Laboratory Sample—Consider the units in the lot

5.4.1 In case of a dispute arising from differences in

sample as the units in the laboratory sample. For the laboratory

reported test results when using this test method for acceptance

sample, take a full width sample of sufficient length along the

testing of commercial shipments, the purchaser and the sup-

selvage or edge of the roll so that the requirements of 7.3-7.5.2

plier should conduct comparative tests to determine if there is

canbemet.Excludetheinnerandouterwrapsoftherollorany

a statistical bias between their laboratories. Competent statis-

material containing folds, crushed areas or other distortions not

tical assistance is recommended for the investigation of bias.

representative of the sampled lot.

As a minimum, the two parties should take a group of test

7.3 Remove test specimens from the laboratory sample in a

specimens that are as homogeneous as possible and that are

randomlydistributedpatternacrossthewidthwithnospecimen

formed from a lot of material of the type in question. The test

taken nearer than 100 mm (4 in.) from the selvage or roll edge,

specimens should be randomly assigned in equal numbers to

unless otherwise specified. For geomembranes include at least

each laboratory for testing. The average results from the two

one specimen taken no more than 152 mm (6 in.) from the

laboratories should be compared using Student’s t-test for

edge. Since seams are an important part of geomembrane

unpaireddataandanacceptableprobabilitylevelchosenbythe

applications, thickness readings within 152 mm (6 in.) of each

two parties before the testing is begun. If bias is found, either

edge is appropriate.

its cause must be found and corrected or the purchaser and

7.4 Test Specimens— From each unit in the laboratory

supplier must agree to interpret future tests in the light of the

sample, remove the specimens so that the edge of the specimen

known bias.

willextendbeyondtheedgeofthepressorfootby10mm(0.39

NOTE 1—The user should be aware that the compressibility of the

in.) in all directions (that is at least a circle of 75 mm ((3 in.)),

materials, their rebound characteristics, and the like will also affect the

diameter).

thickness of the geotextiles and geomembranes following the time when

7.5 Number of Specimens—Unless otherwise agreed upon,

they are rolled up on rolls shipped and stored.

as when provided in an applicable material specifications, take

6. Apparatus

a number of test specimens per laboratory sample such that the

usermayexpectatthe95 %probabilitylevelthatthetestresult

6.1 ThicknessTestingInstrument—Thethicknessgageshall

is not more than 6.0 % of the average above or below the true

have a base (or anvil) and a free moving presser foot plate

average of the sample. Determine the number of specimens per

whose planar faces are parallel to each other to <0.01 mm. A

sample as follows:

gage with a 56.4 mm (2.22 in.) diameter presser foot, the base

7.5.1 Reliable Estimate of v—When there is a reliable

shall extend at least 10 mm in all directions further than the

estimate of v based upon extensive part records for similar

edge of the 2500 mm circular pressor foot, shall be used for

materials tested in the user’s laboratory as directed in the

measurementsofgeotextiles,geocompositedrainagematerials,

method, calculate the required number of specimens for the

and geonets. A gage with a 6.35 mm (0.250 in.) diameter

machine and cross-machine directions as follows:

pressor foot shall be used for laboratory measurements of

geomembranes. A gage with 6.35 mm (0.250 in.) diameter 2

n 5 ~tv / A!

pressor foot and base may be used for field measurements of

geomembrane thickness. The instruments must be capable of where:

n = number of test specimens (rounded upward to a whole

measuring a maximum thickness of at least 10 mm to an

number),

accuracy of at least 60.02 mm. The gages shall be constructed

v = reliable estimate of the coefficient of variation of

to permit gradual application of pressure to a specific force of

individual observations on similar materials in the

2 6 0.02 kPa (0.29 6 0.003 psi) for geotextiles and 20 6 0.2

user’s laboratory under conditions of single-operation

kPa (2.9 6 0.03 psi) for geomembranes. Dead-weight loading

precision, %,

may be used.

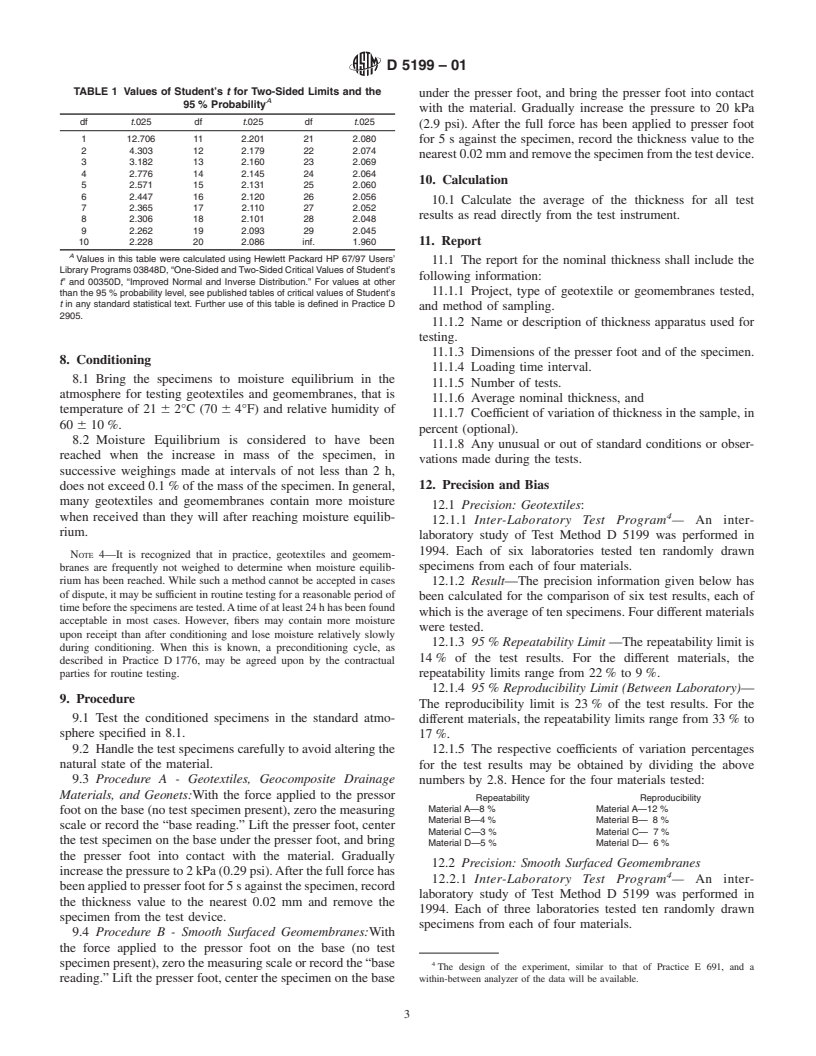

t = the value of Student’s t for two-sided limits (see Table

6.1.1 The specified force of 20 kPa may be inadequate for

1), a 95 % probability level, and the degrees of

some HDPE geomembranes. A pressure in the range of 50 to

freedom associated with the estimate of v, and

200 kPa is recommended for HDPE geomembranes if ficti-

A = 5.0 % of the average, the value of the allowable

tiously high readings are suspected using the 20 kPa pressure.

variation.

NOTE 2—(Appendix X1) lists some of the suppliers of apparatus for

7.5.2 No Reliable Estimate of v—When there is no reliable

thickness measurement.

estimate of v for the user’s laboratory, Eq 1 should not be used

6.2 Cutting Dies— Dies to cut specimens should have

directly. Instead, s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.