ASTM C39/C39M-99

(Test Method)Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

SCOPE

1.1 This test method covers determination of compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores. It is limited to concrete having a unit weight in excess of 50 lb/ft3 [800 kg/m3].

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standard. The SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The text of this standard references notes which provide explanatory material. These notes shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 39/C 39M – 99

Standard Test Method for

Compressive Strength of Cylindrical Concrete Specimens

This standard is issued under the fixed designation C 39/C 39M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope tion of Compressive Strength of Hardened Concrete Cyl-

inders

1.1 This test method covers determination of compressive

E 4 Practices for Force Verification of Testing Machines

strength of cylindrical concrete specimens such as molded

E 74 Practice for Calibration of Force-Measuring Instru-

cylinders and drilled cores. It is limited to concrete having a

3 3

ments for Verifying the Load Indication of Testing Ma-

unit weight in excess of 50 lb/ft [800 kg/m ].

chines

1.2 The values stated in either inch-pound or SI units are to

Manual of Aggregate and Concrete Testing

be regarded separately as standard. The SI units are shown in

2.2 American Concrete Institute:

brackets. The values stated in each system may not be exact

CP-16 Concrete Laboratory Testing Technician, Grade I

equivalents; therefore, each system shall be used independently

of the other. Combining values from the two systems may

3. Summary of Test Method

result in nonconformance with the standard.

3.1 This test method consists of applying a compressive

1.3 This standard does not purport to address all of the

axial load to molded cylinders or cores at a rate which is within

safety concerns, if any, associated with its use. It is the

a prescribed range until failure occurs. The compressive

responsibility of the user of this standard to establish appro-

strength of the specimen is calculated by dividing the maxi-

priate safety and health practices and determine the applica-

mum load attained during the test by the cross-sectional area of

bility of regulatory limitations prior to use.

the specimen.

1.4 The text of this standard references notes which provide

explanatory material. These notes shall not be considered as

4. Significance and Use

requirements of the standard.

4.1 Care must be exercised in the interpretation of the

2. Referenced Documents significance of compressive strength determinations by this test

method since strength is not a fundamental or intrinsic property

2.1 ASTM Standards:

of concrete made from given materials. Values obtained will

C 31 Practice for Making and Curing Concrete Test Speci-

2 depend on the size and shape of the specimen, batching, mixing

mens in the Field

procedures, the methods of sampling, molding, and fabrication

C 42 Test Method for Obtaining and Testing Drilled Cores

2 and the age, temperature, and moisture conditions during

and Sawed Beams of Concrete

curing.

C 192 Practice for Making and Curing Concrete Test Speci-

2 4.2 This test method is used to determine compressive

mens in the Laboratory

strength of cylindrical specimens prepared and cured in accor-

C 617 Practice for Capping Cylindrical Concrete Speci-

2 dance with Practices C 31, C 192, C 617 and C 1231 and Test

mens

Methods C 42 and C 873.

C 670 Practice for Preparing Precision and Bias Statements

2 4.3 The results of this test method are used as a basis for

for Test Methods for Construction Materials

quality control of concrete proportioning, mixing, and placing

C 873 Test Method for Compressive Strength of Concrete

2 operations; determination of compliance with specifications;

Cylinders Cast in Place in Cylindrical Molds

control for evaluating effectiveness of admixtures and similar

C 1077 Practice for Laboratories Testing Concrete and Con-

uses.

crete Aggregates for Use in Construction and Criteria for

2 4.4 The individual who tests concrete cylinders for accep-

Laboratory Evaluation

tance testing shall have demonstrated a knowledge and ability

C 1231 Practice for Use of Unbonded Caps in Determina-

to perform the test procedure equivalent to the minimum

guidelines for certification of Concrete Laboratory Technician,

This test method is under the jurisdiction of ASTM Committee C-9 on Concrete

Level I, in accordance with ACI CP-16.

and Concrete Aggregates and is the direct responsibility of Subcommittee C09.61 on

Testing Concrete for Strength.

Current edition approved July 10, 1999. Published September 1999. Originally Annual Book of ASTM Standards, Vol 03.01.

published as C 39 – 21 T. Last previous edition C 39 – 96. Available from American Concrete Institute, P.O. Box 9094, Farmington Hills,

Annual Book of ASTM Standards, Vol 04.02. MI 48333-9094.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 39/C 39M

NOTE 1—The testing laboratory performing this test method should be

E 5 100~A 2 B!/B

p

evaluated in accordance with Practice C 1077.

where:

5. Apparatus

A 5 load, lbf [kN] indicated by the machine being verified,

and

5.1 Testing Machine—The testing machine shall be of a

B 5 applied load, lbf [kN] as determined by the calibrating

type having sufficient capacity and capable of providing the

device.

rates of loading prescribed in 7.5.

5.1.3.4 The report on the verification of a testing machine

5.1.1 Verification of calibration of the testing machines in

shall state within what loading range it was found to conform

accordance with Practices E 4 is required under the following

to specification requirements rather than reporting a blanket

conditions:

acceptance or rejection. In no case shall the loading range be

5.1.1.1 After an elapsed interval since the previous verifi-

stated as including loads below the value which is 100 times

cation of 18 months maximum, but preferably after an interval

the smallest change of load estimable on the load-indicating

of 12 months,

mechanism of the testing machine or loads within that portion

5.1.1.2 On original installation or relocation of the machine,

of the range below 10 % of the maximum range capacity.

5.1.1.3 Immediately after making repairs or adjustments

5.1.3.5 In no case shall the loading range be stated as

that affect the operation of the force applying system of the

including loads outside the range of loads applied during the

machine or the values displayed on the load indicating system,

verification test.

except for zero adjustments that compensate for the mass of

5.1.3.6 The indicated load of a testing machine shall not be

bearing blocks, or specimen, or both, or

corrected either by calculation or by the use of a calibration

5.1.1.4 Whenever there is reason to doubt the accuracy of

diagram to obtain values within the required permissible

the results, without regard to the time interval since the last

variation.

verification.

5.2 The testing machine shall be equipped with two steel

5.1.2 Design—The design of the machine must include the

bearing blocks with hardened faces (Note 4), one of which is a

following features:

spherically seated block that will bear on the upper surface of

5.1.2.1 The machine must be power operated and must

the specimen, and the other a solid block on which the

apply the load continuously rather than intermittently, and

specimen shall rest. Bearing faces of the blocks shall have a

without shock. If it has only one loading rate (meeting the

minimum dimension at least 3 % greater than the diameter of

requirements of 7.5), it must be provided with a supplemental

the specimen to be tested. Except for the concentric circles

means for loading at a rate suitable for verification. This

described below, the bearing faces shall not depart from a plane

supplemental means of loading may be power or hand oper-

by more than 0.001 in. [0.02 mm] in any 6 in. [150 mm] of

ated.

blocks 6 in. [150 mm] in diameter or larger, or by more than

NOTE 2—High-strength concrete cylinders rupture more intensely than

0.001 in. [0.02 mm] in the diameter of any smaller block; and

normal strength cylinders. As a safety precaution, it is recommended that

new blocks shall be manufactured within one half of this

the testing machines should be equipped with protective fragment guards.

tolerance. When the diameter of the bearing face of the

5.1.2.2 The space provided for test specimens shall be large

spherically seated block exceeds the diameter of the specimen

enough to accommodate, in a readable position, an elastic

by more than 0.5 in. [13 mm], concentric circles not more than

calibration device which is of sufficient capacity to cover the

0.03 in. [0.8 mm] deep and not more than 0.04 in. [1 mm] wide

potential loading range of the testing machine and which

shall be inscribed to facilitate proper centering.

complies with the requirements of Practice E 74.

NOTE 4—It is desirable that the bearing faces of blocks used for

NOTE 3—The types of elastic calibration devices most generally avail-

compression testing of concrete have a Rockwell hardness of not less than

able and most commonly used for this purpose are the circular proving

55 HRC.

ring or load cell.

5.2.1 Bottom bearing blocks shall conform to the following

5.1.3 Accuracy—The accuracy of the testing machine shall

requirements:

be in accordance with the following provisions:

5.2.1.1 The bottom bearing block is specified for the pur-

5.1.3.1 The percentage of error for the loads within the

pose of providing a readily machinable surface for mainte-

proposed range of use of the testing machine shall not exceed

nance of the specified surface conditions (Note 5). The top and

61.0 % of the indicated load.

bottom surfaces shall be parallel to each other. If the testing

5.1.3.2 The accuracy of the testing machine shall be verified

machine is so designed that the platen itself is readily main-

by applying five test loads in four approximately equal

tained in the specified surface condition, a bottom block is not

increments in ascending order. The difference between any two

required. Its least horizontal dimension shall be at least 3 %

successive test loads shall not exceed one third of the differ-

greater than the diameter of the specimen to be tested.

ence between the maximum and minimum test loads.

Concentric circles as described in 5.2 are optional on the

5.1.3.3 The test load as indicated by the testing machine and

bottom block.

the applied load computed from the readings of the verification

NOTE 5—The block may be fastened to the platen of the testing

device shall be recorded at each test point. Calculate the error,

machine.

E, and the percentage of error, E , for each point from these

p

data as follows:

5.2.1.2 Final centering must be made with reference to the

E 5 A 2 B (1) upper spherical block. When the lower bearing block is used to

C 39/C 39M

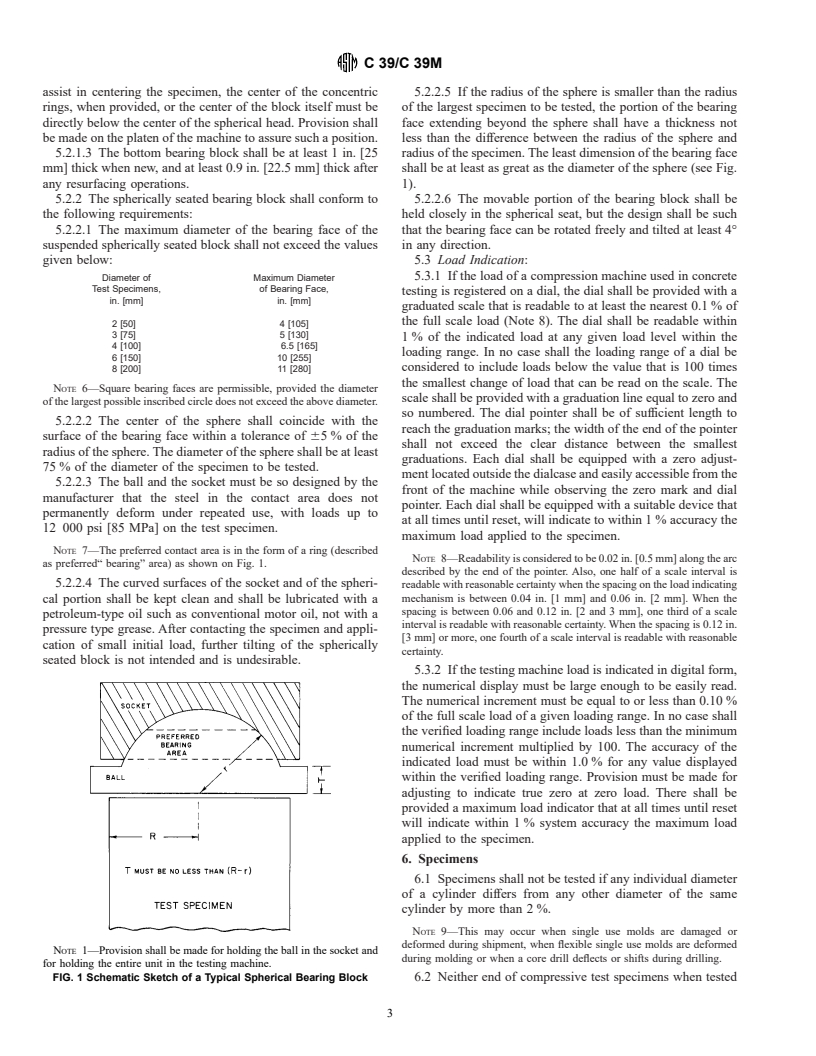

assist in centering the specimen, the center of the concentric 5.2.2.5 If the radius of the sphere is smaller than the radius

rings, when provided, or the center of the block itself must be of the largest specimen to be tested, the portion of the bearing

directly below the center of the spherical head. Provision shall face extending beyond the sphere shall have a thickness not

be made on the platen of the machine to assure such a position. less than the difference between the radius of the sphere and

5.2.1.3 The bottom bearing block shall be at least 1 in. [25 radius of the specimen. The least dimension of the bearing face

mm] thick when new, and at least 0.9 in. [22.5 mm] thick after shall be at least as great as the diameter of the sphere (see Fig.

any resurfacing operations. 1).

5.2.2 The spherically seated bearing block shall conform to 5.2.2.6 The movable portion of the bearing block shall be

the following requirements: held closely in the spherical seat, but the design shall be such

5.2.2.1 The maximum diameter of the bearing face of the that the bearing face can be rotated freely and tilted at least 4°

suspended spherically seated block shall not exceed the values in any direction.

given below: 5.3 Load Indication:

5.3.1 If the load of a compression machine used in concrete

Diameter of Maximum Diameter

Test Specimens, of Bearing Face,

testing is registered on a dial, the dial shall be provided with a

in. [mm] in. [mm]

graduated scale that is readable to at least the nearest 0.1 % of

2 [50] 4 [105] the full scale load (Note 8). The dial shall be readable within

3 [75] 5 [130]

1 % of the indicated load at any given load level within the

4 [100] 6.5 [165]

loading range. In no case shall the loading range of a dial be

6 [150] 10 [255]

considered to include loads below the value that is 100 times

8 [200] 11 [280]

the smallest change of load that can be read on the scale. The

NOTE 6—Square bearing faces are permissible, provided the diameter

scale shall be provided with a graduation line equal to zero and

of the largest possible inscribed circle does not exceed the above diameter.

so numbered. The dial pointer shall be of sufficient length to

5.2.2.2 The center of the sphere shall coincide with the

reach the graduation marks; the width of the end of the pointer

surface of the bearing face within a tolerance of 65 % of the

shall not exceed the clear distance between the smallest

radius of the sphere. The diameter of the sphere shall be at least

graduations. Each dial shall be equipped with a zero adjust-

75 % of the diameter of the specimen to be tested.

ment located outside the dialcase and easily accessible from the

5.2.2.3 The ball and the socket must be so designed by the

front of the machine while observing the zero mark and dial

manufacturer that the steel in the contact area does not

pointer. Each dial shall be equipped with a suitable device that

permanently deform under repeated use, with loads up to

at all times until reset, will indicate to within 1 % accuracy the

12 000 psi [85 MPa] on the test specimen.

maximum load applied to the specimen.

NOTE 7—The preferred contact area is in the form of a ring (described

NOTE 8—Readability is considered to be 0.02 in. [0.5 mm] along the arc

as preferred“ bearing” area) as shown on Fig. 1.

described by the end of the pointer. Also, one half of a scale interval is

5.2.2.4 The curved surfaces of the socket and of the spheri-

readable with reasonable certainty when the spacing on the load indicating

mechanism is between 0.04 in. [1 mm] and 0.06 in. [2 mm]. When the

cal portion shall be kept clean and shall be lubricated with a

spacing is between 0.06 and 0.12 in. [2 and 3 mm], one third of a scale

petroleum-type oil such as conventional motor oil, not with a

interval is readable with reasonable certainty. When the spacing is 0.12 in.

pressure type grease. After contacting the specimen and appli-

[3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.