ASTM D1089-59(1978)

(Test Method)Method of Test for Carbonyl Content of Butadiene (Withdrawn 1983)

Method of Test for Carbonyl Content of Butadiene (Withdrawn 1983)

General Information

Standards Content (Sample)

AMERICAN SOCIETY FOR TESTING MATERIALS

1916 RACE ST., PHILADELPHIA 3, PA.

Reprinted from Copyrigh.ted 1959 Supplement to

Book of ASTM Standards, Part 7

APPROVED AS

AMERICAN STANDARD

BY THB AMERICAN STANDARDS ASSOCl\11P.$fi

1960

ASA no . Zif.SI l95J UDC sis.162:620.1

OBS SSl.12. &6.1

Standard Method oj Test for

1

CARBONYL CONTENT OF BUTADIENE

~ \l.,

ASTM Designation: D 1089-59

1

ADOPTED, 1953; REVISED, 1959.

This Standard of the American Society for Testing Materials is issued under

the fixed designation D 1089; the final number indicates the year of original

adoption as standard or, in the case of revision, the year of last revision.

Scope Apparatus

3. (a) Bottles, narrow-mouthed, 500-

1. This method is intended for the de

ml. fitted with cork stoppers.

termination of the carbonyl content in

(b) Thermometer.-For observing tem

liquid Cc hydrocarbons containing less

peratures below -45 C, the Low Cloud

than 2500 ppm. Acid or alkaline ma

and Pour Thermometer, having a range

terials, if present, interfere and are de

of -80 to 20 C or -112 to 70 F and con

termined by a blank titration.

forming to the requirements for ther

mometer 6 C or 6 F as prescribed in the

Outline of Method

3

ASTM Specifications E 1 is satisfactory.

(c) Bomb Rack for supporting the

2. A measured quantity of liquid Cc

hydrocarbon is added to a cork stoppered sample bomb in an upright position.

narrow-mouthed bottle containing aque (d) Copper Cooling Coil.-Prepare a

ous hydroxylamine hydrochloride rea cooling coil by winding 4 in. of l-in.

seamless copper tubing on a short length

gent and Stoddard solvent. The carbonyl

content is determined from the increase of !-in. pipe, allowing sufficient length of

in the acidity of the resulting solution tubing at the end of the coil to connect

by titrating with a standard base, using it to the sample source. Attach a i-in.

a pH meter to determine the end point. valve on the outlet at a point that would

not extend more than 3 in. above the

surface of the bath liquid. To the valve

1

Under the standardization procedure of the

attach a 3-in. piece of tubing bent for

Society, this method is under the jurisdiction of

the ASTM Committee D-2 on Petroleum Prod

carrying the liquid into the required

ucts and Lubricants.

apparatus.

The method was derived from the one de

(e) pH Meter, having an accuracy of

veloped and cooperatively tested by the Buta

diene Producers' Committee on Specifications

plus or minus 0.05 pH units.

and Methods of Analysis of the Office of Rubber

(j) Burel, 10-ml. with 0.02-ml. divi

Reserve which appears in the Butadiene Lab

oratory Manual as method 2.1.5.1. sions.

2 Prior to its adoption as standard, this

(g) Buret, 50-m.I. with 0.1-ml. divi

method was published as tentative from 1950 to

sions.

1953.

In 1959, a new Note 2 was added and the sec

'Appears in this publication, see Contents in Numeric

tion on Precision was revised.

Sequence of ASTM Designations at front of book.

561

---------------------- Page: 1 ----------------------

562 TEST FOR CA.lil.BONYL CONTENT O!" BUTADIENE (D 1089)

·orously for 1 min. Transfer the contents ,

Reagents

of the bottle to a 500-ml. beaker and

4. (a) Stoddard Solvent, conforming to

wash the bottle with 75 ml. of distilled

4

A.S.T.M. Specifications D 484.

water catching the rinsings in the

(b) Hydroxylamine Hydrochloride Rea

' . .

beaker. Place the beaker on the t1tratmg

gent (2 per cent).-Dissolve ~O g. ~f c . .P·

stand of the pH meter and titrate the

hydroxylamine hydrochloride m dIS

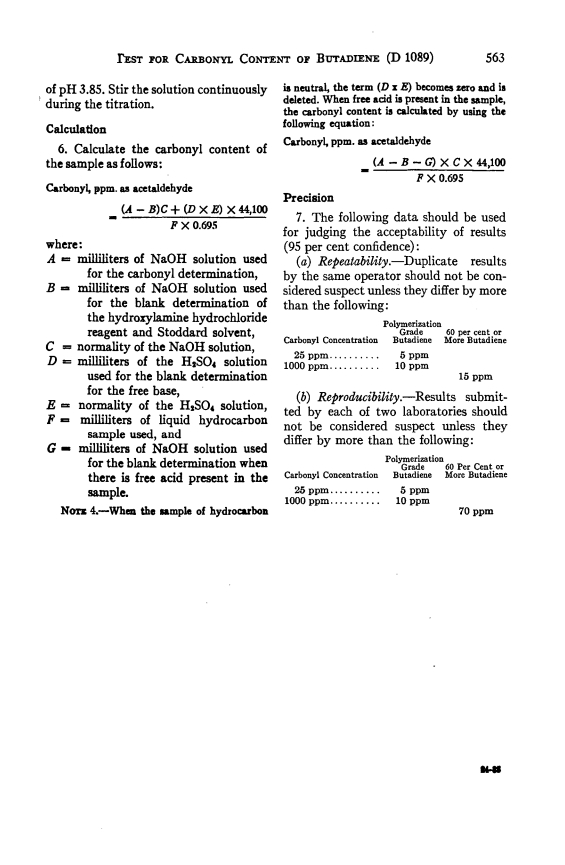

'olution with standard 0.05 N NaOH to

tilled water and dilute to 1 liter.

an end point of pH 3.85. Stir the solution

NOTE 1.-Hydroxylamine hydrochloride solu

continuously during the titration.

tions are known to cause dermatitis. Rubber

Non: 3.-Use a 100-ml. size &le when less

gloves should be worn whenever handling this

than 100 ppm. carbonyl content i11 present in the

substance and all contact of it with the skin

material being tested and a 50-ml. sample for

should be avoided.

higher concentrations.

(c) Sodium Hydroxide Solution (0.05

(b) Blank Determination for Hydroxyl

N).

amine Hydrochloride Reagent and Stod

(d) Sulfuric Acid Solution (0.05 N).

dard Solvent.-Add to a 500-ml. bottle

25 ml. of distilled water, 25 ml. of hy

Test Sample

droxylamine hydrochloride reagent, and

5. Set the sample bomb in an upright

150 ml. of Stoddard solvent. Stopper the

position in the bomb rack. Place the cop

bottle and shake it vigorously for 1 min.

per cooling coil in a dry ice-Stoddard

Transfer the contents of the bottle to a

solvent bath and connect the coil to the

500-ml. beaker and wash the bottle with

lower valve of the bomb. Purge the line

75 ml. of distilled water, catching the

with some of the sample before taking

rinsings in the beaker. Place the beaker

the sample to be tested. Cool a 100-ml.

on the titrating stand of the pH meter

graduated cylinder in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.