ASTM B871-01

(Test Method)Standard Test Method for Tear Testing of Aluminum Alloy Products

Standard Test Method for Tear Testing of Aluminum Alloy Products

SCOPE

1.1 This test method covers the static tear test of aluminum alloy products using specimens that are 0.040 in. (1 mm) to 0.250 in. (6.35 mm) thick.

1.2 This test method is applicable to aluminum alloy products having a minimum thickness of 0.040 in. (1 mm).

1.3 This test method provides a measure of both notch toughness and resistance to crack propagation with the primary use as a screening or merit rank test.

1.4 The reliability of the tear test has been established in various research programs by reasonably good correlations between data from the tear tests and fracture toughness tests.

Note 1—Direct measurement of fracture toughness may be made in accordance with Practices B 645, B 646 and Test Method E 399.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B871–01

Standard Test Method for

1

Tear Testing of Aluminum Alloy Products

This standard is issued under the fixed designation B871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

5

1. Scope E4 Practices for Force Verification of Testing Machines

E83 Practice for Verification and Classification of Exten-

1.1 This test method covers the static tear test of aluminum

5

someters

alloy products using specimens that are 0.040 in. (1 mm) to

E338 Test Method for Sharp-Notch Testing of High-

0.250 in. (6.35 mm) thick.

5

Strength Sheet Materials

1.2 This test method is applicable to aluminum alloy prod-

E399 Test Method for Plane-Strain Fracture Toughness of

ucts having a minimum thickness of 0.040 in. (1 mm).

5

Metallic Materials

1.3 This test method provides a measure of both notch

toughnessandresistancetocrackpropagationwiththeprimary

3. Terminology

use as a screening or merit rank test.

3.1 Definitions of Terms Specific to This Standard:

1.4 The reliability of the tear test has been established in

3.1.1 initiation energy, IE (FL)—the amount of energy

various research programs by reasonably good correlations

,

23 requiredtoinitiateacrackinatearspecimen.Initiationenergy

betweendatafromtheteartestsandfracturetoughnesstests.

is determined by integrating the area under the force-

NOTE 1—Direct measurement of fracture toughness may be made in

displacement curve from the beginning of the test to the point

accordance with Practices B645, B646 and Test Method E399.

of maximum force.

1.5 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.2 propagation energy, PE (FL)—the amount of energy

as the standard. The values given in parentheses are for

required to propagate a crack in a tear specimen. Propagation

information only.

energy is determined by integrating the area under the force-

1.6 This standard does not purport to address all of the

displacement curve from the point of maximum force to the

safety concerns, if any, associated with its use. It is the

point of complete fracture.

responsibility of the user of this standard to establish appro-

3.1.3 tear resistance—a general term describing the resis-

priate safety and health practices and determine the applica-

tance of a material to crack propagation under static loading,

bility of regulatory limitations prior to use.

either in an elastic or plastic stress field.

−2

3.1.4 tear strength, TS (FL )—the maximum nominal di-

2. Referenced Documents

rect and bending stress that the tear specimen is capable of

2.1 ASTM Standards:

sustaining.

B557 Test Methods for Tension Testing Wrought and Cast

3.1.5 tear strength to tensile yield strength ratio (TYR)—the

4

Aluminum- and Magnesium-Alloy Products

ratioofthetearstrengthtotensileyieldstrengthofthematerial

B645 Practice for Plane Strain Fracture Toughness Testing

determined in accordance with Test Methods B557.

4

−1

of Aluminum Alloys

3.1.6 unit propagation energy, UPE (FL )—the amount of

B646 Practice for Fracture Toughness Testing of Alumi-

energy required to propagate a crack across a tear specimen

4

num Alloys

divided by the original net area of the specimen.

4. Summary of Test Method

1

This test method is under the jurisdiction of ASTM Committee B07 on Light

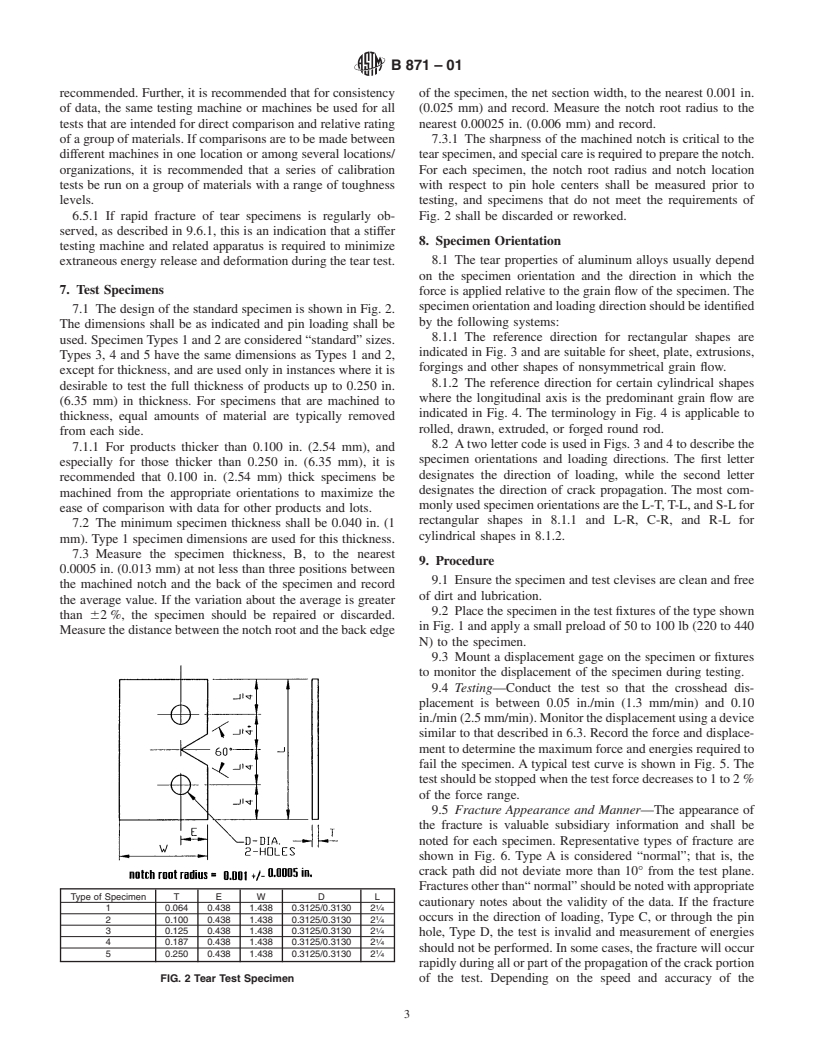

4.1 The tear test involves a single edge notched specimen

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on

that is statically loaded through pin loading holes. The force

Testing.

Current edition approved Oct. 10, 2001. Published January 2002. Originally and displacement required to fracture the specimen are re-

published as B 871–96. Last previous edition B 871–96.

corded for analysis.

2

Kaufman, J. G., and Holt, Marshall, “Fracture Characteristics of Aluminum

Alloys,” Alcoa Research Laboratories Technical Paper No. 18.

3

Kaufman,J.G.,andKnoll,A.H.,“Kahn-TypeTearTestsandCrackToughness

of Aluminum Sheet,” Metals Research and Standards, April 1964, pp. 151–155.

4 5

Annual Book of ASTM Standards, Vol 02.02. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B871–01

4.2 Tear test specimens should be fractured using any products, as determined in accordance with Practices B645,

mechanical test machine capable of quasi-static loading at a B646 and Test Method E399. Limited data suggest that the

crosshead speed of 0.05 in./min (1.3 mm/min) or less. test may be sensitive to crosshead rates above 0.5 in./min.

6. Apparatus

5. Significance and Use

6.1 The test shall be conducte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.