ASTM F528-99

(Test Method)Standard Test Method of Measurement of Common-Emitter D-C Current Gain of Junction Transistors

Standard Test Method of Measurement of Common-Emitter D-C Current Gain of Junction Transistors

SCOPE

1.1 This test method covers the measurement of common-emitter d-c current gain (forward, hFE, or inverted, hFEI) of bipolar transistors, for which the collector-emitter leakage current, ICEO, is less than 10% of the collector current, IC, at which the measurement is to be made, and for which the shunt leakage current in the base circuit is less than 10% of the base current required.

1.2 This test method is suitable for measurement of common-emitter d-c current gain at a single given value of test transistor collector current or over a given range of collector currents (for example, over the range of the transistor to be tested).

1.2.1 The nominal ranges of collector current over which the three test circuits are intended to be used are as follows:

1.2.1.1 Circuit 1, less than 100 [mu]A,

1.2.1.2 Circuit 2, from 100 [mu]A to 100 mA, and

1.2.1.3 Circuit 3, greater than 100 mA.

1.3 This test method incorporates tests to determine if the power dissipated in the transistor is low enough that the temperature of the junction is approximately the same as the ambient temperature.

1.4 The values stated in International System of Units (SI) are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address the safety problems, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 528–99

Standard Test Method of

Measurement of Common-Emitter D-C Current Gain of

Junction Transistors

This standard is issued under the fixed designation F 528; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of common-

emitter d-c current gain (forward, h , or inverted, h )of

FE FEI

bipolar transistors, for which the collector-emitter leakage

current, I , is less than 10 % of the collector current, I ,at

CEO C

which the measurement is to be made, and for which the shunt

leakage current in the base circuit is less than 10 % of the base

current required.

1.2 This test method is suitable for measurement of

common-emitter d-c current gain at a single given value of test

transistor collector current or over a given range of collector

currents (for example, over the range of the transistor to be

tested).

1.2.1 The nominal ranges of collector current over which

the three test circuits are intended to be used are as follows:

1.2.1.1 Circuit 1, less than 100 µA,

1.2.1.2 Circuit 2, from 100 µA to 100 mA, and

1.2.1.3 Circuit 3, greater than 100 mA.

1.3 This test method incorporates tests to determine if the

power dissipated in the transistor is low enough that the

temperature of the junction is approximately the same as the

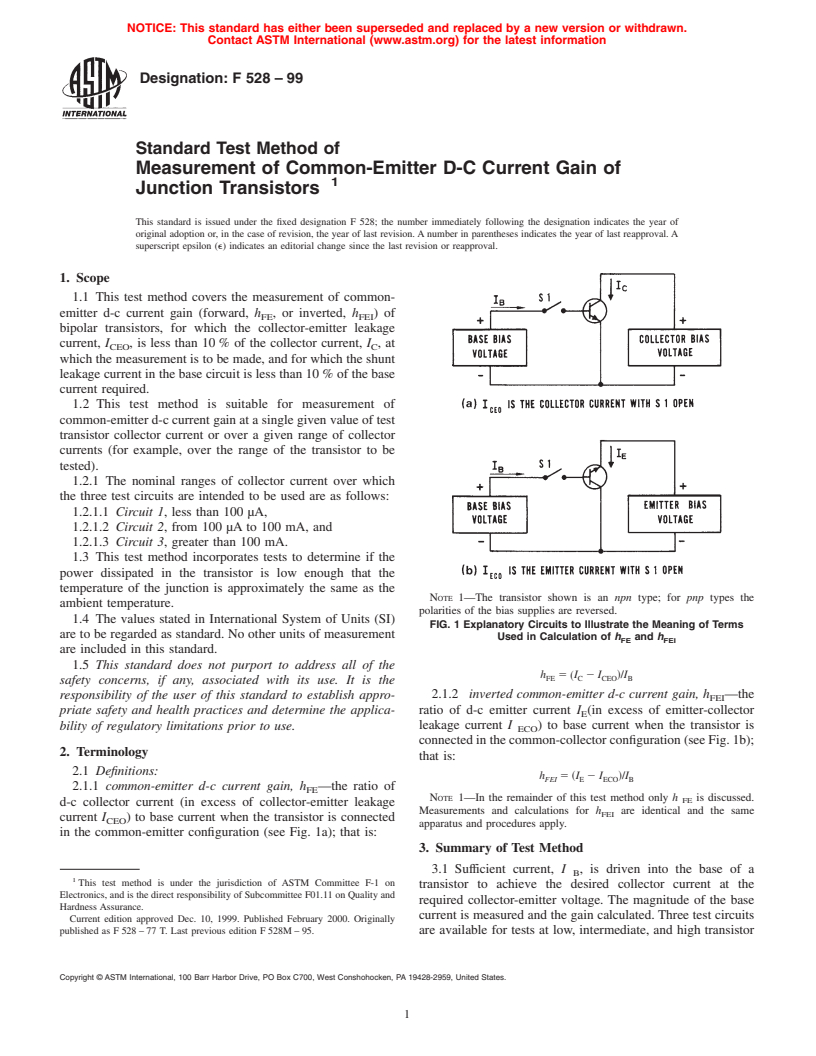

NOTE 1—The transistor shown is an npn type; for pnp types the

ambient temperature.

polarities of the bias supplies are reversed.

1.4 The values stated in International System of Units (SI)

FIG. 1 Explanatory Circuits to Illustrate the Meaning of Terms

are to be regarded as standard. No other units of measurement

Used in Calculation of h and h

FE FEI

are included in this standard.

1.5 This standard does not purport to address all of the

h 5 ~I 2 I !/I

FE C CEO B

safety concerns, if any, associated with its use. It is the

2.1.2 inverted common-emitter d-c current gain, h —the

responsibility of the user of this standard to establish appro-

FEI

priate safety and health practices and determine the applica- ratio of d-c emitter current I (in excess of emitter-collector

E

leakage current I ) to base current when the transistor is

bility of regulatory limitations prior to use.

ECO

connected in the common-collector configuration (see Fig. 1b);

2. Terminology

that is:

2.1 Definitions:

h 5 ~I 2 I !/I

FEI E ECO B

2.1.1 common-emitter d-c current gain, h —the ratio of

FE

NOTE 1—In the remainder of this test method only h is discussed.

FE

d-c collector current (in excess of collector-emitter leakage

Measurements and calculations for h are identical and the same

FEI

current I ) to base current when the transistor is connected

CEO

apparatus and procedures apply.

in the common-emitter configuration (see Fig. 1a); that is:

3. Summary of Test Method

3.1 Sufficient current, I , is driven into the base of a

B

This test method is under the jurisdiction of ASTM Committee F-1 on

transistor to achieve the desired collector current at the

Electronics, and is the direct responsibility of Subcommittee F01.11 on Quality and

required collector-emitter voltage. The magnitude of the base

Hardness Assurance.

current is measured and the gain calculated. Three test circuits

Current edition approved Dec. 10, 1999. Published February 2000. Originally

published as F 528 – 77 T. Last previous edition F 528M – 95. are available for tests at low, intermediate, and high transistor

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 528

collector currents, respectively. The measurements and calcu-

lations are repeated for all collector-current values of interest.

3.2 The following quantities are unspecified in the

method and are to be agreed upon by the parties to the test:

3.2.1 The collector currents, I , at which the measurements

C

are to be made,

3.2.2 The collector-emitter voltage, V , to be used when

CE

making the measurements, and

3.2.3 The temperature at which the measurements are to be

made.

4. Significance and Use

4.1 The current gain of a transistor is basic to its operation

and is its single most important parameter.

4.2 Ionizing radiation, that is, gamma radiation due to a

nuclear burst, will degrade the current gain due to lifetime

damage in the bulk material. Degradation of gain will be

greatest immediately following a burst of ionizing radiation

and the gain will rapidly recover to a quasi steady-state value.

Defect annealing may continue for weeks but usually the

current gain recovery is small or negligible.

4.3 This method provides a procedure that does not require

special-purpose test equipment.

NOTE 1—Capacitor C in Circuits 2 and 3 is a bypass capacitor that is

4.4 This method is suitable for use for specification accep-

used if required. (see Note 4).

tance, service evaluation, or manufacturing control.

NOTE 2—Oscilloscopes 1 and 2 may be digitizers.

FIG. 2 Schematics of Circuits for Measurement of h

FE

5. Interferences

5.1 Shunt Leakage—Whenthemagnitudeoftheimpedance

between the base and emitter connections on the test fixture is

6.1.1.3 Adjustable over a nominal range of 0 to 30 V, and

comparable to the base-emitter impedance of the transistor

being tested, the measurement results are invalid. 6.1.1.4 Capable of supplying currents up to 250 mA.

6.1.2 D-C Voltage Source 2—d-c power supply meeting the

NOTE 2—The shunt leakage current can be affected by high humidity.

following specifications:

Since the range over which valid current gain measurements can be made

6.1.2.1 Stability, noise and ripple, and current specifications

is reduced by shunt leakage, transistors that require measurement of very

the same as d-c voltage source 1 (see 6.1.1), and

low currents must be tested in an environment of less than 40 % relative

humidity. 6.1.2.2 Adjustable over the range from 0 to

V + I R (typically less than 0.1 V ).

CE C C CE

5.2 Temperature— For referee measurements, the tempera-

6.1.3 D-C Voltmeters 1 and 2—d-c digital voltmeters meet-

ture of the device must be controlled or a set of correction

ing the following specifications:

factors developed for adjusting the data to a common tempera-

6.1.3.1 At least 3 ⁄2-digit display,

ture since h may vary as much as 1 to 3 %/°C. Care must be

FE

6.1.3.2 Accuracy of at least 60.5 % of full-scale reading,

exercised in handling the device as well as in controlling the

6.1.3.3 Resolution of 61 least-significant digit,

ambient temperature. The operator may use one or any

6.1.3.4 Scales of at least 100 mV and 1, 10, and 100 V, and

combination of the following to reduce operator-induced tem-

6.1.3.5 Input impedance at least 100 times that of the

perature increases:

resistor (R or R ) across which the voltmeters are used to

5.2.1 Gloves. B C

measure voltages.

5.2.2 Tongs or some other suitable means for inserting the

6.1.4 Resistors, specified as follows:

device into the test fixture.

6.1.4.1 R —1 % resistor in the nominal resistance range 10

B

5.2.3 Procedure of waiting for the device to reach thermal

V to 100 kV, depending on the base current being used.

equilibrium (usually 20 to 30 s is sufficient).

6.1.4.2 R —1 % resistor in the nominal resistance range 10

C

V to 10 kV, depending on the collector current.

6. Apparatus

6.1.4.3 Voltage Divider Resistors R— and R —R shall

X Y X

6.1 Circuit 1— Measuring circuit for low currents with the

be at least equal to 10 R .

Y

following components (see Fig. 2a):

6.1.1 D-C Voltage Source 1—d-c power supply meeting the NOTE 3—These resistors form a voltage divider used to simplify the

adjustmentofbasecurrent.Nofurthertoleranceorvaluespecificationsare

following specifications:

applicable (see Fig. 2a).

6.1.1.1 Stable to within 60.1 % of the set voltage,

6.1.1.2 Noise and ripple less than 0.5 % of the output 6.2 Circuit 2—Measuring circuit for intermediate currents

voltage, with the following components (see Fig. 2b):

F 528

6.2.1 D-C Voltage Source, meeting the specifications of d-c 6.2.3.2 Digitizers with Bandwidth, Sampling Interval, and

voltage source 2 (see 6.1.2), and with the capability of Time-base Capabilities, adequate for handling the transient

supplying current pulses of the magnitude required for the signals with good resolution for all pulse widths utilized in the

transistor under test. test may be used. Hard copy printouts of the recorded signal

may be a part of the capability of this apparatus.

NOTE 4—For power transistors that need large current pulses, this

6.2.4 Resistors, specified as follows:

requirement can be met with a power supply inadequate in itself by

placing a large capacitor (1000 to 10 000 µF) across the output terminals 6.2.4.1 R —1 % resistor of the proper value to match the

O

of the power supply. To compensate for possible inductive components of

output impedance of the pulsed source,

the impedance of this large capacitor, it should be paralleled by a small

6.2.4.2 R —1 % resistor in the nominal resistance range 1

B

capacitor (0.001 to 0.1 µF).

V to 10 kV, depending on the base current being used, and

6.2.2 Pulsed Voltage Source, meeting the following specifi-

across which the voltage developed by the base current is

cations:

measured, and

6.2.2.1 Polarity selectable as positive or negative,

6.2.4.3 R —1 % resistor in the nominal resistance range 1

C

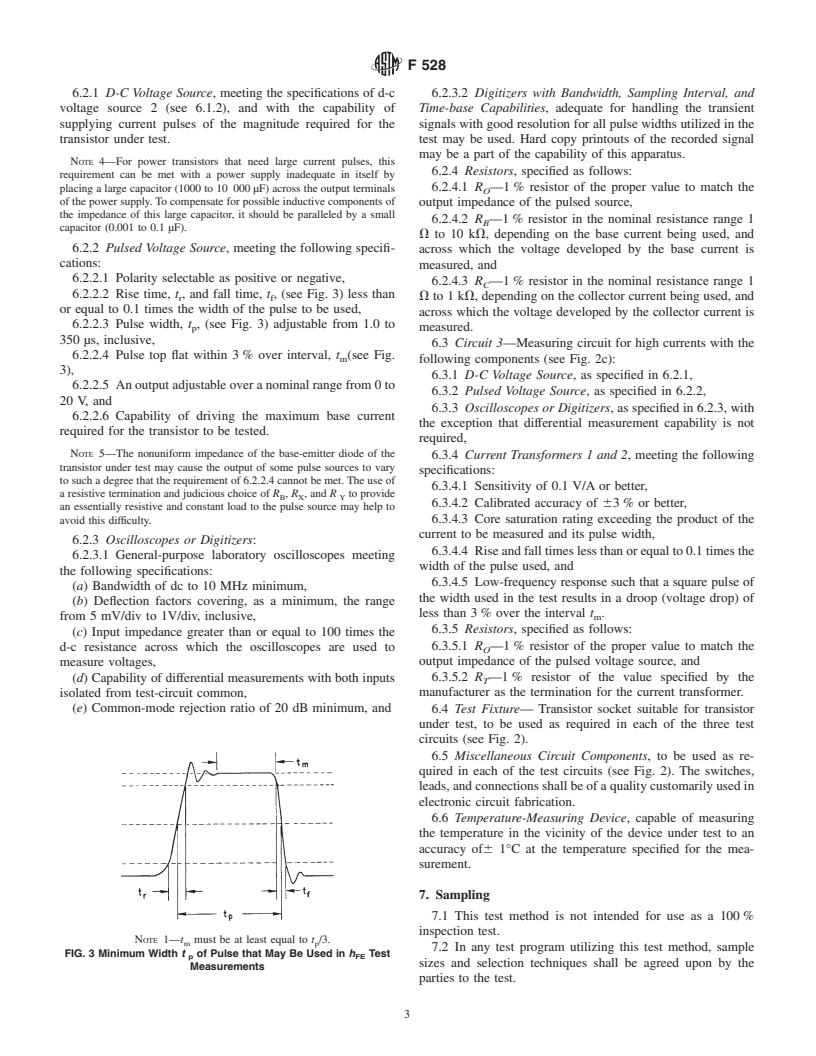

6.2.2.2 Rise time, t , and fall time, t , (see Fig. 3) less than

r f V to 1 kV, depending on the collector current being used, and

or equal to 0.1 times the width of the pulse to be used,

across which the voltage developed by the collector current is

6.2.2.3 Pulse width, t , (see Fig. 3) adjustable from 1.0 to

p measured.

350 µs, inclusive,

6.3 Circuit 3—Measuring circuit for high currents with the

6.2.2.4 Pulse top flat within 3 % over interval, t (see Fig.

m following components (see Fig. 2c):

3),

6.3.1 D-C Voltage Source, as specified in 6.2.1,

6.2.2.5 An output adjustable over a nominal range from 0 to

6.3.2 Pulsed Voltage Source, as specified in 6.2.2,

20 V, and

6.3.3 Oscilloscopes or Digitizers, as specified in 6.2.3, with

6.2.2.6 Capability of driving the maximum base current

the exception that differential measurement capability is not

required for the transistor to be tested.

required,

NOTE 5—The nonuniform impedance of the base-emitter diode of the

6.3.4 Current Transformers 1 and 2, meeting the following

transistor under test may cause the output of some pulse sources to vary

specifications:

to such a degree that the requirement of 6.2.2.4 cannot be met. The use of

6.3.4.1 Sensitivity of 0.1 V/A or better,

a resistive termination and judicious choice of R , R , and R to provide

B X Y

6.3.4.2 Calibrated accuracy of 63 % or better,

an essentially resistive and constant load to the pulse source may help to

avoid this difficulty. 6.3.4.3 Core saturation rating exceeding the product of the

current to be measured and its pulse width,

6.2.3 Oscilloscopes or Digitizers:

6.3.4.4 Rise and fall times less than or equal to 0.1 times the

6.2.3.1 General-purpose laboratory oscilloscopes meeting

width of the pulse used, and

the following specifications:

6.3.4.5 Low-frequency response such that a square pulse of

(a) Bandwidth of dc to 10 MHz minimum,

the width used in the test results in a droop (voltage drop) of

(b) Deflection factors covering, as a minimum, the range

less than 3 % over the interval t .

m

from 5 mV/div to 1V/div, inclusive,

6.3.5 Resistors, specified as follows:

(c) Input impedance greater than or equal to 100 times the

6.3.5.1 R —1 % resistor of the proper value to match the

d-c resistance across which the oscilloscopes are used to

O

output impedance of the pulsed voltage source, and

measure voltages,

6.3.5.2 R —1 % resistor of the value specified by the

(d) Capability of differential measurements with both inputs

T

isolated from test-circuit common, manufacturer as the termination for the current transformer.

(e) Common-mode rejection ratio of 20 dB minimum, and 6.4 Test Fixture— Transistor socket suitable for transistor

under test, to be used as required in each of the three test

circuits (see Fig. 2).

6.5 Miscellaneous Circuit Components, to be used as re-

quired in each of the test circuits (see Fig. 2). The switches,

leads, and connections shall be of a quality customarily used in

electronic circuit fabrication.

6.6 Temperature-Measuring Device, capable of measuring

the temperature in the vicinity of the device under test to an

accuracy of6 1°C at the temperature specified for the mea-

surement.

7. Sampling

7.1 This test method is not intended for use as a 100 %

inspection test.

NOTE 1—t must be at least equal to t /3.

m p

7.2 In any test program utilizing this test method, sample

FIG. 3 Minimum Width t of Pulse that May Be Used in h Test

p FE

sizes and selection techniques shall be agreed upon by the

Measurements

parties to the test.

F 528

8. Procedure 8.1.14.4 Repeat 8.1.14.2 and 8.1.14.3 until the desired I

C

and V values are obtained.

CE

8.1 Circuit 1—Low Current Levels (see Note 6):

8.1.15 Measure and record V , in volts.

RB

8.1.1 Assemble the test circuit incorporating a socket suit-

8.1.16 Calculate and record I , in amperes, using the

B

able for the transistor to be tested (see Fig. 2a).

following equation:

8.1.1.1 Use R 5 100 kV.

B

I 5 V /R (2)

8.1.2 With no transistor in the test fixture, S1 closed, and S3 B RB B

inposition1,adjustd-cvoltagesource1toitsmaximumvalue.

8.1.17 Calculate and record h , using the following equa-

FE

8.1.3 Using d-c voltmeter 1, measure the voltage across R .

tion:

B

Record this value as V , in volts.

RB

h 5 ~I 2 I !/I (3)

FE C CEO B

8.1.4 MoveS3toposition2.Usingd-cvoltmeter1,measure

8.1.18 Using the temperature-measuring device, measure

and record the voltage across R , V , in volts.

Y RY

the ambient temperature within 50 mm of the test fixture.

8.1.5 Calculate and record R , V (Note 2).

SHUNT

Record this value as T,in°C.

a

V

RY

8.1.19 Move S3 to Position 2. Using d-c voltmeter 1,

R 5 R 2 1 (1)

S D

SHUNT B

V

RB

measure and record the voltage across R with the test

Y

8.1.6 Replace the 100-kV resistor used for R in 8.1.1.1 transistorinthetestfixture.Recordthisvalueas V ,involts.

B

RYT

with a resistor chosen to have a sufficiently low value of

8.1.20 Calculate and record the base to emitter resistance

resistance so that the required base current can be supplied R , in ohms, using the following equation:

BE

without exceeding the voltage rating of d-c voltage source 1,

V 2 V

RYT RB

R 5 (4)

but have a sufficiently high value of resistance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.