ASTM B769-11

(Test Method)Standard Test Method for Shear Testing of Aluminum Alloys

Standard Test Method for Shear Testing of Aluminum Alloys

SIGNIFICANCE AND USE

The intent of this method is to provide a means of measuring the ultimate shear strength of aluminum-alloy wrought and cast products. Data obtained by this method are used to calculate minimum properties that can be utilized in the design of structural members such as found in aircraft. It is recognized that loading conditions developed by this method, and by most others, are not ideal in that they do not strictly satisfy the definition of pure shear. However, rarely do pure shear conditions exist in structures.

Note 2—This method is not interchangeable with that described in Test Method B 565. Shear strengths obtained by Test Method B 565 are about 10 % lower than those developed by this test method.

The presence of a lubricant on the surface of the specimen and fixture may result in shear strengths up to 3 % lower than those determined in the absence of lubrication (see 8.1 and Test Method B 565).

SCOPE

1.1 This test method covers double-shear testing of wrought and cast aluminum products to determine shear ultimate strengths. Note 1

The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B769 − 11

StandardTest Method for

1

Shear Testing of Aluminum Alloys

This standard is issued under the fixed designation B769; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

1.1 This test method covers double-shear testing of wrought 4.1 This test method consists of subjecting a machined

and cast aluminum products to determine shear ultimate cylindrical test specimen to double-shear loading in a test

fixture using a tension (or compression) testing machine to

strengths.

determine the shear stress required to fracture the specimen,

NOTE1—Thevaluesstatedininch-poundunitsaretoberegardedasthe

that is, the shear strength.

standard. The values given in parentheses are provided for information

only.

5. Significance and Use

1.2 This standard does not purport to address all of the

5.1 The intent of this method is to provide a means of

safety concerns, if any, associated with its use. It is the

measuring the ultimate shear strength of aluminum-alloy

responsibility of the user of this standard to establish appro-

wrought and cast products. Data obtained by this method are

priate safety and health practices and determine the applica-

usedtocalculateminimumpropertiesthatcanbeutilizedinthe

bility of regulatory limitations prior to use.

design of structural members such as found in aircraft. It is

recognized that loading conditions developed by this method,

2. Referenced Documents

and by most others, are not ideal in that they do not strictly

2.1 The following documents of the issue in effect on the

satisfy the definition of pure shear. However, rarely do pure

dateofmaterialpurchase,unlessotherwisenotedformapartof

shear conditions exist in structures.

this specification to the extent referenced herein:

NOTE 2—This method is not interchangeable with that described inTest

2

2.2 ASTM Standards:

Method B565. Shear strengths obtained by Test Method B565 are about

B565 Test Method for Shear Testing of Aluminum and

10 % lower than those developed by this test method.

Aluminum-Alloy Rivets and Cold-Heading Wire and

5.2 The presence of a lubricant on the surface of the

Rods

specimen and fixture may result in shear strengths up to 3 %

E4 Practices for Force Verification of Testing Machines

lower than those determined in the absence of lubrication (see

E6 Terminology Relating to Methods of Mechanical Testing

8.1 and Test Method B565).

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

6. Apparatus

E691 Practice for Conducting an Interlaboratory Study to

6.1 Testing Machines—The testing machines shall conform

Determine the Precision of a Test Method

to the requirements of Practices E4. The loads used to

determine the shear strength shall be within the loading range

3. Terminology

of the testing machine as defined in Practices E4.

3.1 The definitions of terms relating to shear testing in

6.2 Loading Device:

Terminology E6 are applicable to the terms used in this test

6.2.1 The loading device shall be a double-shear test fixture

method.

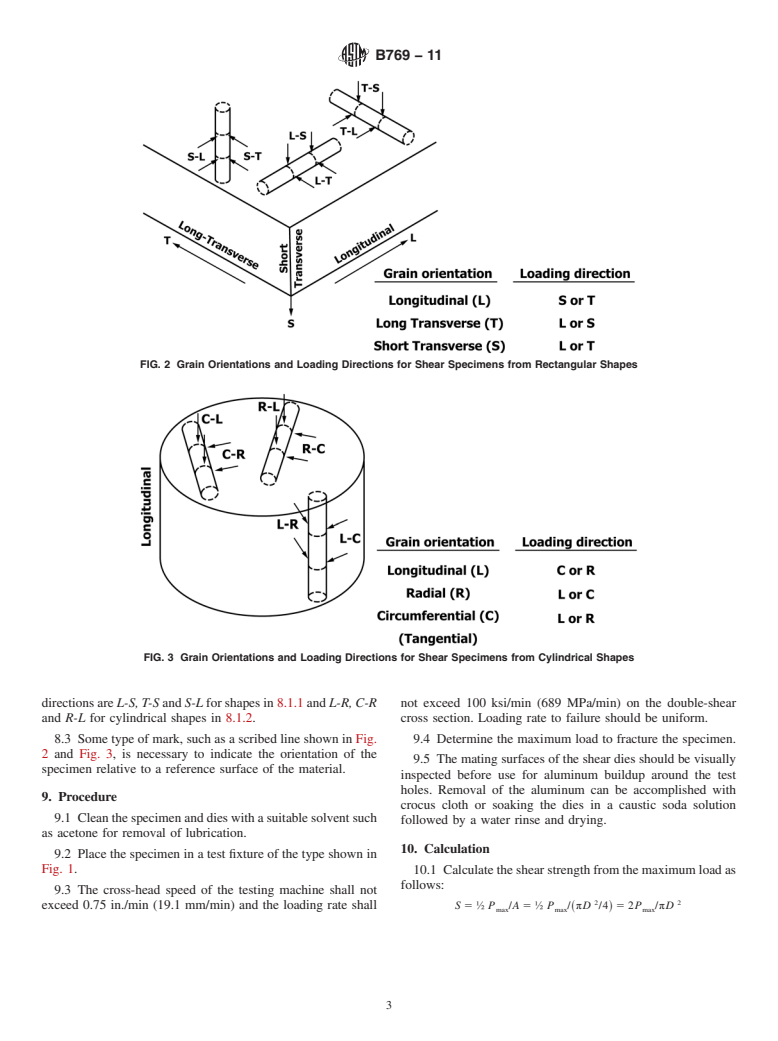

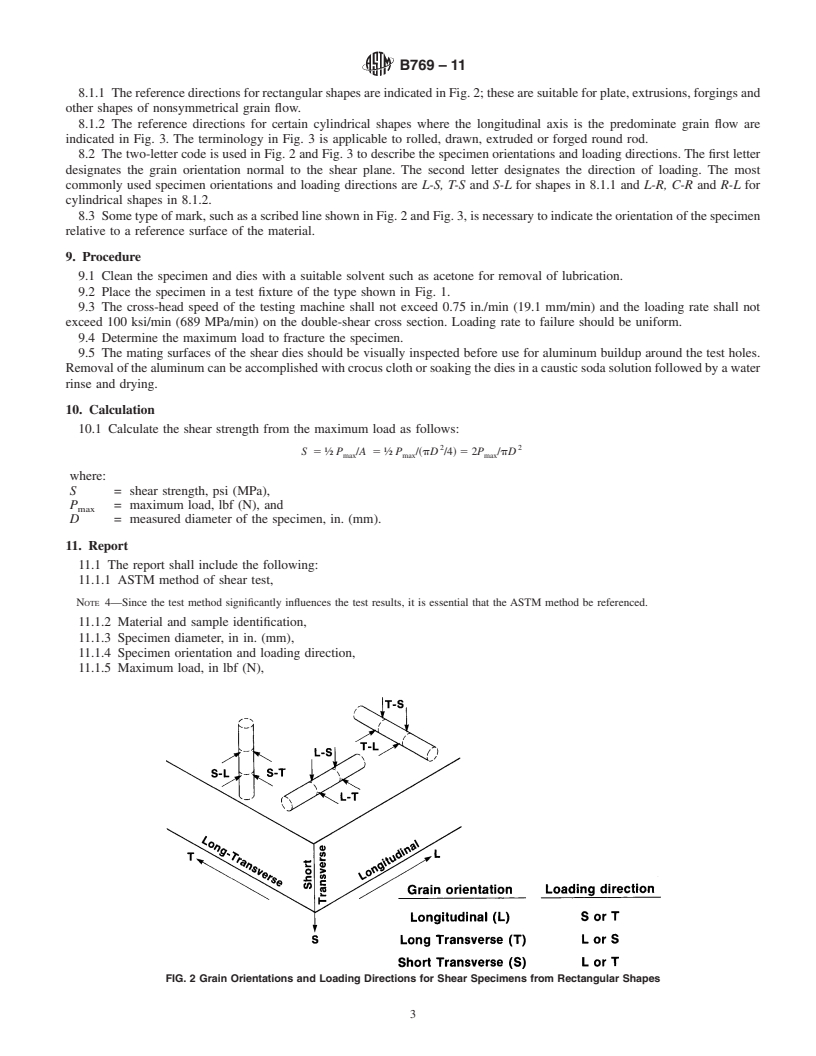

of the type shown in Fig. 1. The fixture shall be made of tool

steel having a Rockwell hardness from 60 to 62 HRC. A

suitable alternative is to use a lower-strength steel for the main

1

This test method is under the jurisdiction of ASTM Committee B07 on Light

frame of the fixture and have only the steel inserts hardened

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on

from 60 to 62 HRC.

Testing.

6.2.2 The shearing edges of the holes shall have a radius of

Current edition approved Nov. 1, 2011. Published December 2011. Originally

no more than 0.0005 in. (0.013 mm). The mating surfaces of

approved in 1987. Last previous edition approved in 2007 as B769–07. DOI:

10.1520/B0769-11.

the center and outside dies shall have a finish of 16 µin. (0.4

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

µm) R or less.There shall be sufficient clearances between the

a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

die interfaces to ensure that no binding occurs; clearance

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. should not exceed 0.002 in. (0.051 mm). Consequently, the

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B769 − 11

FIG. 1 Three Views of an Amsler Shear Tool

rigidity of the test fixture must be such that this clearan

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B769–07 Designation:B769–11

Standard Test Method for

1

Shear Testing of Aluminum Alloys

This standard is issued under the fixed designation B769; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers double-shear testing of wrought and cast aluminum products to determine shear ultimate strengths.

NOTE 1—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase, unless otherwise noted form a part of this

specification to the extent referenced herein:

2

2.2 ASTM Standards:

B565 Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Wire and Rods

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing Terminology Relating to Methods of Mechanical Testing

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 The definitions of terms relating to shear testing in Terminology E6 are applicable to the terms used in this test method.

4. Summary of Test Method

4.1 This test method consists of subjecting a machined cylindrical test specimen to double-shear loading in a test fixture using

a tension (or compression) testing machine to determine the shear stress required to fracture the specimen, that is, the shear

strength.

5. Significance and Use

5.1 The intent of this method is to provide a means of measuring the ultimate shear strength of aluminum-alloy wrought and

castproducts.Dataobtainedbythismethodareusedtocalculateminimumpropertiesthatcanbeutilizedinthedesignofstructural

members such as found in aircraft. It is recognized that loading conditions developed by this method, and by most others, are not

ideal in that they do not strictly satisfy the definition of pure shear. However, rarely do pure shear conditions exist in structures.

NOTE 2—This method is not interchangeable with that described inTest Method B565. Shear strengths obtained byTest Method B565 are about 10%

lower than those developed by this test method.

5.2 The presence of a lubricant on the surface of the specimen and fixture may result in shear strengths up to 3% lower than

those determined in the absence of lubrication (see 8.1 and Test Method B565).

6. Apparatus

6.1 Testing Machines—The testing machines shall conform to the requirements of Practices E4. The loads used to determine

the shear strength shall be within the loading range of the testing machine as defined in Practices E4.

6.2 Loading Device:

1

This test method is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on Testing.

Current edition approved JuneNov. 1, 2007.2011. Published July 2007.December 2011. Originally approved in 1987. Last previous edition approved in 20062007 as

B769–06.B769–07. DOI: 10.1520/B0769-07.10.1520/B0769-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B769–11

6.2.1 The loading device shall be a double-shear test fixture of the type shown in Fig. 1.The fixture shall be made of tool steel

having a Rockwell hardness from 60 to 62 HRC.Asuitable alternative is to use a lower-strength steel for the main frame of the

fixture and have only the steel inserts hardened from 60 to 62 HRC.

6.2.2 The shearing edges of the holes shall have a radius of no more than 0.0005 in. (0.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B769–07 Designation:B769–11

Standard Test Method for

1

Shear Testing of Aluminum Alloys

This standard is issued under the fixed designation B769; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers double-shear testing of wrought and cast aluminum products to determine shear ultimate strengths.

NOTE 1—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase, unless otherwise noted form a part of this

specification to the extent referenced herein:

2

2.2 ASTM Standards:

B565 Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Wire and Rods

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing Terminology Relating to Methods of Mechanical Testing

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 The definitions of terms relating to shear testing in Terminology E6 are applicable to the terms used in this test method.

4. Summary of Test Method

4.1 This test method consists of subjecting a machined cylindrical test specimen to double-shear loading in a test fixture using

a tension (or compression) testing machine to determine the shear stress required to fracture the specimen, that is, the shear

strength.

5. Significance and Use

5.1 The intent of this method is to provide a means of measuring the ultimate shear strength of aluminum-alloy wrought and

castproducts.Dataobtainedbythismethodareusedtocalculateminimumpropertiesthatcanbeutilizedinthedesignofstructural

members such as found in aircraft. It is recognized that loading conditions developed by this method, and by most others, are not

ideal in that they do not strictly satisfy the definition of pure shear. However, rarely do pure shear conditions exist in structures.

NOTE 2—This method is not interchangeable with that described inTest Method B565. Shear strengths obtained byTest Method B565 are about 10%

lower than those developed by this test method.

5.2 The presence of a lubricant on the surface of the specimen and fixture may result in shear strengths up to 3% lower than

those determined in the absence of lubrication (see 8.1 and Test Method B565).

6. Apparatus

6.1 Testing Machines—The testing machines shall conform to the requirements of Practices E4. The loads used to determine

the shear strength shall be within the loading range of the testing machine as defined in Practices E4.

6.2 Loading Device:

1

This test method is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on Testing.

Current edition approved JuneNov. 1, 2007.2011. Published July 2007.December 2011. Originally approved in 1987. Last previous edition approved in 20062007 as

B769–06.B769–07. DOI: 10.1520/B0769-07.10.1520/B0769-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B769–11

6.2.1 The loading device shall be a double-shear test fixture of the type shown in Fig. 1.The fixture shall be made of tool steel

having a Rockwell hardness from 60 to 62 HRC.Asuitable alternative is to use a lower-strength steel for the main frame of the

fixture and have only the steel inserts hardened from 60 to 62 HRC.

6.2.2 The shearing edges of the holes shall have a radius of no more than 0.0005 in. (0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.