ASTM D6759-02

(Practice)Standard Practice for Sampling Liquids Using Grab and Discrete Depth Samplers

Standard Practice for Sampling Liquids Using Grab and Discrete Depth Samplers

SCOPE

1.1 This practice describes sampling devices and procedures for collecting samples of liquids or sludges, or both, whose upper surface can be accessed by the suitable device. These devices may be used to sample tanks that have an appropriately sized and located sampling port.

1.2 This practice describes and discusses the advantages and limitations of the following commonly used equipment, some of which can be used for both grab and discrete depth sampling: dipper, liquid grab sampler, swing jar sampler, Bacon Bomb, Kemmerer sampler, Discrete Level sampler, liquid profiler, lidded sludge/water sampler, peristaltic pump, and the Syringe sampler.

1.3 This practice provides instructions on the use of these samplers.

1.4 This practice does not address sampling devices for collecting ground water.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6759 – 02

Standard Practice for

Sampling Liquids Using Grab and Discrete Depth Samplers

This standard is issued under the fixed designation D 6759; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5743 Practice for Sampling Single or Multilayered Liq-

uidswithorwithoutSolidsinDrumsorSimilarContainers

1.1 Thispracticedescribessamplingdevicesandprocedures

D 5753 Guide for Planning and Conducting Borehole Geo-

for collecting samples of liquids or sludges, or both, whose

physical Logging

upper surface can be accessed by the suitable device. These

D 5792 Practice for Generation of Environmental Data

devicesmaybeusedtosampletanksthathaveanappropriately

Related to Waste ManagementActivities: Development of

sized and located sampling port.

Data Quality Objectives

1.2 Thispracticedescribesanddiscussestheadvantagesand

D 5956 Guide for Sampling Strategies for Heterogeneous

limitations of the following commonly used equipment, some

Wastes

of which can be used for both grab and discrete depth

D 6044 Guide for Representative Sampling for Manage-

sampling: dipper, liquid grab sampler, swing jar sampler,

ment of Waste and Contaminated Media

Bacon Bomb, Kemmerer sampler, Discrete Level sampler,

D 6051 Guide for Composite Sampling and Field Subsam-

liquid profiler, lidded sludge/water sampler, peristaltic pump,

pling for Environmental Waste Management Activities

and the Syringe sampler.

D 6232 Guide for Selection of Sampling Equipment for

1.3 This practice provides instructions on the use of these

Waste and Contaminated Media Data CollectionActivities

samplers.

D 6323 Guide for Laboratory Subsampling of Media Re-

1.4 This practice does not address sampling devices for

lated to Waste Management Activities

collecting ground water.

D 6538 Guide for Sampling Wastewater With Automatic

1.5 This standard does not purport to address all of the

Samplers

safety concerns, if any, associated with its use. It is the

D 6699 Practice for Sampling Liquids Using Bailers

responsibility of the user of this standard to establish appro-

E 856 Definitions of Terms and Abbreviations Relating to

priate safety and health practices and determine the applica-

Physical and Chemical Characteristics of Refuse Derived

bility of regulatory limitations prior to use.

Fuel

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 discrete depth sample, n—sample obtained from a

D 4687 Guide for General Planning of Waste Sampling

defined level within the liquid being sampled.

D 4840 Guide for Sample Chain of Custody Procedures

3.2 grab sample, n—individual sample collected over a

D 5088 Practice for Decontamination of Field Equipment

period of time usually not exceeding 15 min and in such a

Used at Non-Radioactive Waste Sites

manner as to be representative of conditions at the time of

D 5283 Practice for Generation of Environmental Data

sampling. Grab samples are sometimes called individual or

Related to Waste Management Activities: Quality Assur-

discrete samples.

ance and Quality Control Planning and Implementation

3.3 representative sample, n—sample collected such that it

D 5358 Practice for Sampling with a Dipper or Pond

reflects one or more characteristics of interest (as defined by

Sampler

the project objectives) of a population from which it was

collected. D 5956

This practice is under the jurisdiction of ASTM Committee D34 on Waste

3.4 sample, n—portion of material taken from a larger

Management and is the direct responsibility of Subcommittee D34.01.03 on

quantity for the purpose of estimating properties or composi-

Sampling Equipment.

tion of the larger quantity. E 856

Current edition approved Feb.10, 2002. Published May 2002.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.5 sludge, n—any mixture of solids that settles out of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

solution. Sludges contain liquids that are not apparent as free

Standards volume information, refer to the standard’s Document Summary page on

liquids (see Practice D 5743). D 6323

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6759–02

4. Significance and Use

4.1 Sampling at specified depth(s) within a liquid may be

needed to confirm or rule out variations within a target

population. This practice describes the design and operation of

commercially available grab and discrete depth samplers for

persons responsible for designing or implementing sampling

programs, or both.

4.2 These sampling devices are used for sampling liquids in

tanks, ponds, impoundments, and other open bodies of water.

Some may be used from the edge or bank of the sampling site,

whereassomecanonlybeusedfromaplatform,boat,orbridge

over the sampling site. Some of the devices described are

suitable for sampling slurries and sludges as well as aqueous

and other liquids with few or no suspended solids.

4.3 Practice D 5743 provides guidance for sampling drums,

tanks, or similar containers.

4.4 This practice does not address general guidelines for

planning waste sampling activities (Guide D 4687), develop- FIG. 1 Dipper

mentofdataqualityobjectives(PracticeD 5792),thedesignof

monitoring systems and determination of the number of

samples to collect (Practice D 6311), in situ measurement of

6. Sampling Equipment and Procedures

parameters of interest, data assessment and statistical interpre-

6.1 Dipper:

tation of resultant data (Guide D 6233), sample preservation,

6.1.1 Description—A dipper can consist of a variety of

sampling and field quality assurance (Guide D 5612), or the

pieces of equipment assembled in a manner to obtain a sample.

selection of sampling locations or obtaining a representative

6.1.1.1 Onetypehasanadjustableclampattachedtotheend

sample (Guide D 6044).

of a metal rod or tube, which may be extendable (see Fig. 1).

The rod or tube forms the handle and the clamp is used to

5. Pre-Sampling

secure it to a beaker or other sample container.

5.1 Samples should be collected in accordance with an

6.1.1.2 Another type of device is made using a stainless

appropriate work plan (Practice D 5283 and Guide D 4687)

steel tube clamped to a moveable bracket that is attached to a

and in accordance with the Data Quality Objectives (Practice

rigid handle. The angle of the cup to the handle is adjustable

D 5792). The plan should include a worker health and safety

(Practice D 5358).

section because of the potential hazards associated with sam-

6.1.2 Procedure:

pling wastes.

6.1.2.1 With the beaker facing downward, lower the dipper

5.2 All equipment shall be clean, dry, and compatible with

beaker into the liquid slowly until it is submerged.Try to cause

the anticipated composition of the material being sampled

a minimum of surface disturbance.

(Practice D 5088). When sampling a hazardous material, if the

6.1.2.2 Rotate the beaker through 180°. If there is a current,

exteriorofthesamplebottleorsamplingapparatuscontactsthe

the mouth of the beaker should face upstream during the

hazardous material, it needs to be cleaned before subsequent

rotation.

steps, such as labelling or sample transfer, are taken.

6.1.2.3 Allow the beaker to fill.

5.3 For samplers with long handles, if high voltage electri-

6.1.2.4 Slowly bring it to the surface.

cal wires could come into contact with the handle, the handle

6.1.2.5 Transfer the sample, usually by gently pouring the

should be made of nonconductive material, such as wood.

dipper’s contents into a clean sample container.

5.4 For guidance in obtaining a representative sample, see

6.1.3 Advantages and Limitations:

Guide D 6044.

Advantages Limitations

5.5 For guidance in how to prepare composite samples and

It is inexpensive. It can be used to obtain only

subsamples in the field, see Guide D 6051.

When attached to a rigid pole, it surface samples.

can reach to4m(10–13 ft) Because the sample collection chamber

5.6 Some discrete samples can be taken using bailers (see

away from the person is always open, it cannot obtain a

Practice D 6699). Additional information on selecting sam-

collecting samples. sample containing the same strata

pling equipment, based on the sample matrix, and the con-

proportions as the strata at the location

being sampled.

straints on the use of equipment, based on the physical and

chemical properties of the equipment, can be found in Guide

6.2 Liquid Grab Sampler:

D 6232.

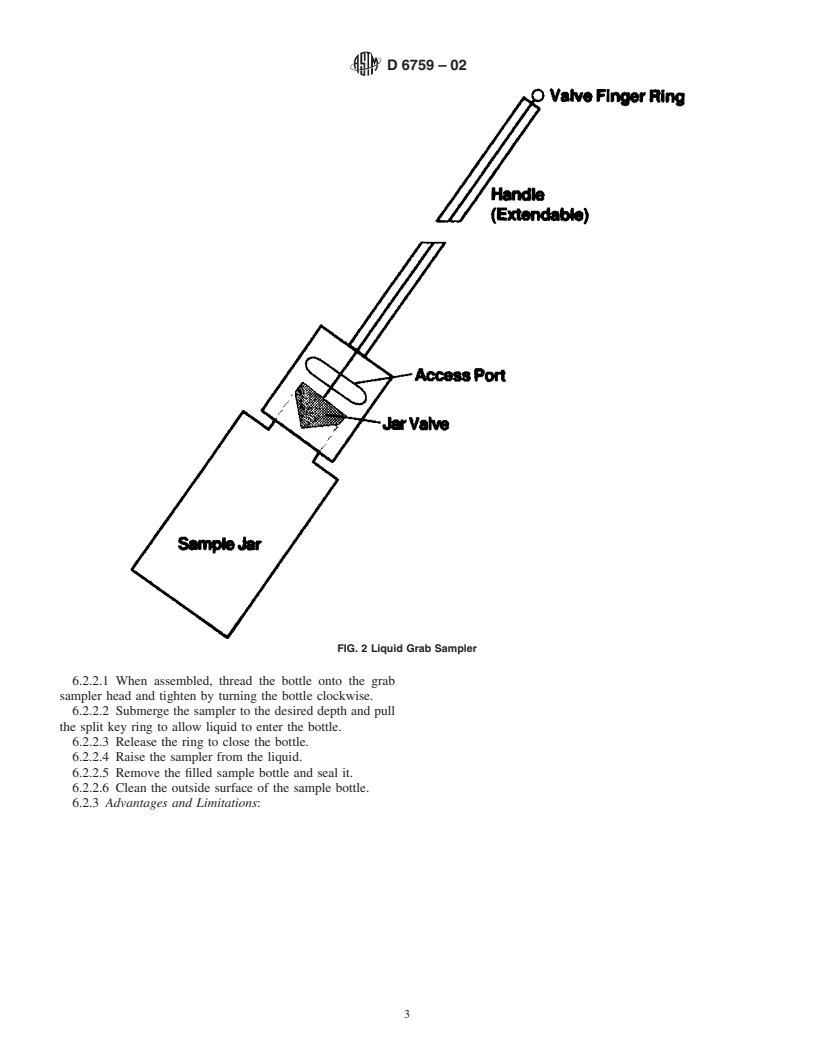

6.2.1 Description—Aliquid grab sampler consists of a rigid

handle with a bottle attached to one end. The bottle is sealed

with a plunger that can be opened or closed by moving the

cable that is attached to it (see Fig. 2).

Occupational Safety and Health Guidance Manual for Hazardous Waste Site

6.2.2 Procedure—Assemble the liquid grab sampler per the

Activities, DHHS (NIOSH) Publication No. 85-115 (NTIS No. PB87-162855/LL),

NIOSH, OSHA, USCG, EPA, October 1985. manufacturer’s instructions.

D6759–02

FIG. 2 Liquid Grab Sampler

6.2.2.1 When assembled, thread the bottle onto the grab

sampler head and tighten by turning the bottle clockwise.

6.2.2.2 Submerge the sampler to the desired depth and pull

the split key ring to allow liquid to enter the bottle.

6.2.2.3 Release the ring to close the bottle.

6.2.2.4 Raise the sampler from the liquid.

6.2.2.5 Remove the filled sample bottle and seal it.

6.2.2.6 Clean the outside surface of the sample bottle.

6.2.3 Advantages and Limitations:

D6759–02

6.3.2.1 Select the bottle clamp that best fits the desired

sample bottle.

6.3.2.2 Connect the pole to the bottle holder and turn it

clockwise until snug.

6.3.2.3 Slide the clamp onto the bottle to a point midway

between the bottle shoulder and heel.

6.3.2.4 Tighten the screw located in the inner pole screw

threads of the bottle holder.

6.3.2.5 Lower the sampler into the liquid slowly with the

bottle facing downward until it is submerged to cause minimal

surface disturbance.

6.3.2.6 Rotate the bottle through 180°.

NOTE 1—If there is a current, the mouth of the bottle should face

upstream during the rotation.

6.3.2.7 Allow the bottle to fill and slowly bring it to the

surface.

6.3.2.8 Loosen the screw holding the bottle to the device.

6.3.2.9 Remove the bottle from the holder.

6.3.2.10 For transport to the laboratory, either seal the bottle

and clean the exterior or transfer the bottle’s contents into a

clean sample container.

6.3.3 Advantages and Limitations:

Advantages Limitations

The sampler can accommodate Not suitable for discrete depth sampling.

different sample bottle sizes Exterior of sample bottle needs

up to 960 mL. cleaning after immersion in

It allows collection from various hazardous waste.

angles, including vertical.

6.4 Bacon Bomb:

6.4.1 Description—The Bacon Bomb sampler consists of a

sealed hollow tube or chamber. It is attached to a primary

cable/line, with length markings and an actuator rod (labeled

FIG. 3 Swing Jar Sampler

Secondary Activation in Fig. 4) connected to a second line,

which opens and closes the chamber’s valves.

Advantages Limitations

6.4.2 Procedure:

The sample jar is available True depth of sample unknown unless

6.4.2.1 Measure and mark the support line or cable with the

commercially in a range of materials, device is vertically deployed.

providing the choice of one that is Not able to collect stratified desired length or depth.

chemically inert to the contaminants samples of proper proportions.

6.4.2.2 Close the chamber.

of interest. Exterior of sample bottle needs

6.4.2.3 Lower the Bacon Bomb sampler using the primary

Handles of various lengths can be cleaning after immersion in

used to obtain samples from hazardous waste. support line or cable to the desired depth, as marked on the

different depths.

support line. Secure the line.

The sample does not need to be

6.4.2.4 Open the chamber by pulling on the actuator rod

transferred to another container

for shipping.

line, thereby allowing the sampler to fill.

The sampler is not opened until

6.4.2.5 When the chamber is full, release the second line to

the desired sampling depth is

close the sampler.

reached, that is, it can be used

as a discrete depth sampler

6.4.2.6 Return the sampler to the surface by raising the

(see Practice D 6699).

primary support line.

6.3 Swing Jar Sampler: 6.4.2.7 Transfer the contents of the Bacon Bomb sampler to

6.3.1 Description—This sampling device consists of a pole a clean dry sample container. Hold the Bacon Bomb sampler

that screws into a bottle holder (see Fig. 3). The angle of the over the sample container. Open the lower stopper by raising

bottle with respect to the pole can be varied. the actuator rod. Drain the contents into a clean sample

6.3.2 Procedure: container(s).

D6759–02

Advantages Limitations

Sampler is closed to the material The lowering and activation lines

being sampled until it has reached tend to cross each other during

its intended depth, that is, it can descent, which could allow

be used as a discrete depth sample collection to occur

sampler. at the wrong depth.

It is available in 250-, 500- and The commercially available stainless

1000-mL volumes in both steel unit has a maximum

PTFE and type 302 capacity of 500 mL.

stainless steel. PTFE device is expensive

The stainless steel unit is relative to stainless steel.

effective for use in high Not effective in turbid sample

viscosity non aqueous media, according to the

liquids, for example, oil. manufacturer.

Slight leakage into the interior

may occur with the stainless

steel unit during descent,

according to the manufacturer

With viscous material, an excess

of the material being sampled

may adhere to the outside of

the Bacon Bomb sampler.

6.5 Syringe Sampler:

6.5.1 Description—The Syringe sampler is a hollow tube

type sampler with a bottom fill valve. A Syringe sampler

normally consists of a piston assembly with a T-handle, safety

locking nut, and control rod (PTFE-covered aluminum to

facilitate operation of the piston), a piston body assembly, a

sampling tube assembly, and a standard bottom valve or coring

bottom (see Fig. 5).

6.5.2 Procedure:

6.5.2.1 Open the bottom valve.

6.5.2.2 Slowly lower the assembled sampler to the desired

depth.

6.5.2.3 Raise the T-handle, drawing the sample into the

sampler body.

6.5.2.4 Close the bottom valve by pressing the sampler

down against the side or bottom of the container being

sampled.

6.5.2.5 Raise th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.