ASTM B202-64

(Specification)Specification for Metal Powder Sintered Bearings (Oil Impregnated) (Withdrawn 1965)

Specification for Metal Powder Sintered Bearings (Oil Impregnated) (Withdrawn 1965)

General Information

Standards Content (Sample)

NOTrce: Thi~ matttriai rns be

by copyright law tr,.,.,. 17Y u s"rocieeted

. II~ . • • r Ode>

Standard Specifications for

1\tIETAL POWDER SINTERED BEARINGS

1

(OIL IMPREGNATED)

ASTM Designation: B 202 - 64

•

1

ADOPTED, 1964.

This Standard of the American Society for Testing and Materials is issued

under the fixed designation B 202; the final number indicates the year of orig

inal adoption as standard or, in the case of revision, the year of last revision.

Scope Basis of Purchase

2. Orders for material under these

1. These specifications cover sintered,

specifications shall include the following

metal powder, oil-impregnated bearings

information:

of two types and four classes as follows:

(I) Grade (Section 1),

(a) Grade I, Copper Base:

(2) Dimensions (Note), and

Class A, Copper-Tin

(J) Certification (Section 10 (b)).

Class B, Copper-Lead-Tin

NOTE. -Commercial dimensional tolerances

NoTE.-The compositions included in grade I

are given in Table VI.

are intended to be equivalent so far as appli

cation is concerned, the different compositions

Manufacture

representing the products supplied by different

3. Bearings shall be made by briquet

manufacturers for the same service.

ting and sintering metal powders so as to

(b) Grade II, Iron Base:

produce finished parts conforming to the

Class A, Iron-Carbon

requirements of these specifications.

Class B, Iron-Copper

Chemical Requirements

NOTE.-The compositions in class A repre

4. The material shall conform to the

sent different mechanical properties and must

be identified by subclasses since they constitute

requirements as to chemical composition

separate specifications. The copper content of

prescribed in Table I.

class B may vary over rather wide limits.

Density

1

Under the standardization procedure of the

Society, these specifications are under the juris

5. (a) The density of bearings supplied

diction of the ASTM Committee B-9 on Metal

fully impregnated with lubricant shall be

Powder and Metal Powder Products.

2

Adopted :1.,- standard August :31, 19li-t, 1,_v

within the limits prescribed in Table .II

action of the Society t\t the .-\nn11:.1.l '.\'leeting

for the type and class specified.

and confirming letter ballot.

Prior to adoption as standard, these :specifi

(b) Density shall be determined in ac

cations were published as tentative from 1945

cordance with the Methods or'Test for

to 1964, being published in 1951, H:155, 1958,

Density and Interconnected Porosity of

and HIGO.

,,--,

_.,.,

&-711

Reproduced By GLOBAL

ENGINEERING DOCUMEN'IS

With The Pennission Of ASTM

Under Ro~alty Agreement

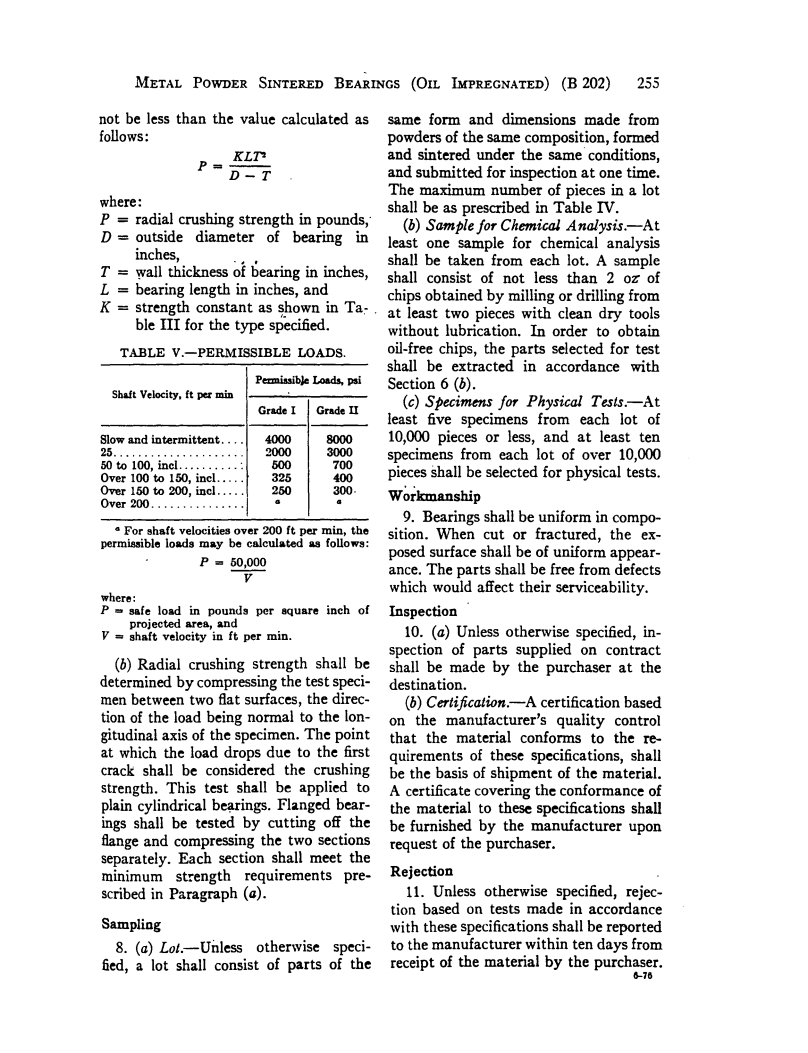

---------------------- Page: 1 ----------------------

254 METAL POWDER SI~TERED BEARINGS (OIL IMPREGNATED) (B 202)

TABLE !.-CHEMICAL REQUIREMENTS.

-

Grade I, Copper Base Grade II, Iron Base

-

Class A

Class A Class B Class B

Al Al

A3

-

Copper, per cent . 82.6

Si.5

{ 1.0 to u.

0

. . . . . . . . .

to 90.5 to 88.5

18.0 to 22.o

Iron, per cent . 1.0 max l.0max 96.25 min 95.9 min 95.6 min remainder-

Tin, per cent . 9.5 9.5 . . . . . . . . . . . . ■ •••

to 10.5 to 10.5

. . . . 2.0

Lead, per cent . . . . . . . . . . . . . . .

to 4.0

Zinc, max, per cent . . . . . 0.75 . . . . . . . . ■ ••• . .

Nickel, max, per cent . . . . . 0.35 . . . . . . . . . . . . . .

Antimony, max, per

cent .

. . . . 0.25 . . . . . . . . . . . .

Silicon, max, per cent . . . . . . . . . 0.3 .

0.3 0.3

Aluminum, max, per

cent . . . . . . . . . 0.2 0.2 0.2 . .

1. 75c

Carbon, max, per cent . 1.75• . . . . . . . . . . . . . .

Total other elements by

difference, max, per

cent . 0.5 0.5 3.0 3.0 3.0 3.0

Combined carbon° (on

basis of iron only) . . . . . . . . .

0.25 max 0.25 0.60 .

to 0.60 to 1.00

a The combined carbon may be a mctallographic estimate of the carbon in the iron.

• Total of iron plus copper shall be 97 per cent, min.

• Commonly graphite. A maximum of 1.5 per cent of another type of solid lubricant may be

substituted when authorized by the purchaser.

TABLE IL-DENSITY REQUIREMENTS.

TABLE IV.-MAXIMUM NUMBEH. OF

PIECES IN LOT.

I Density, i; per

1 cu cm

Maximum

! _____ _

Gra

Weight of 1000 Pieces, lb

Number of

Pieces in Lot

min max

Up to 10, excl . . 60 000

I, Copper base A. (i.4 6.8

10 to 50, excl. . . 30 000

B . ·I 6.5 6.9

50 to 100, e.xcl . .

10 000

I

100 and over . . 5 000

II, Iron base . A . I 5. 7 6.1

6.2

B . ·I 5.8

Sintered Powder Metal Structural Parts

and Oil Impregnated Bearings (ASTM

8

Designation: B 328).

Porosity

TABLE !IL-STRENGTH CONSTANTS.a

6. Porosity in terms of intercon

nected void space shall not be less than

K (strength

Grade I

• Class constant)

18 per cent for all classes when deter

------1-------,----

mined in accordance with AST

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.