ASTM D2784-98(2003)e1

(Test Method)Standard Test Method for Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner or Lamp)

Standard Test Method for Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner or Lamp)

SCOPE

1.1 This test method covers the determination of total sulfur in liquefied petroleum gases containing more than 1 μg/g. Specimens should not contain more than 100 μg/g of halogens.

1.2 To attain the quantitative detectability that the method is capable of, stringent techniques must be employed and all possible sources of sulfur contamination must be eliminated. In particular, cleaning agents, such as common household detergents which contain sulfates, should be avoided.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: D 2784 – 98 (Reapproved 2003)

Standard Test Method for

Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner

or Lamp)

This standard is issued under the fixed designation D 2784; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warning notes were editorially moved into the standard text in July 2003.

1. Scope 2.2 Institute of Petroleum Standard:

IP 181 Sampling Petroleum Gases, Including Liquefied

1.1 This test method covers the determination of total sulfur

Petroleum Gases

in liquefied petroleum gases containing more than 1 µg/g.

Specimens should not contain more than 100 µg/g of halogens.

3. Summary of Test Method

1.2 To attain the quantitative detectability that the method is

3.1 The sample is burned in an oxy-hydrogen burner, or in

capable of, stringent techniques must be employed and all

a lamp in a closed system in a carbon dioxide-oxygen

possiblesourcesofsulfurcontaminationmustbeeliminated.In

atmosphere. The latter is not recommended for trace quantities

particular, cleaning agents, such as common household deter-

ofsulfurduetotheinordinatelylongcombustiontimesneeded.

gents which contain sulfates, should be avoided.

The oxides of sulfur are absorbed and oxidized to sulfuric acid

1.3 The values stated in SI units are to be regarded as the

in a hydrogen peroxide solution. The sulfate ions are then

standard. The values given in parentheses are for information

determined by either of the following finishes:

only.

3.1.1 Barium Perchlorate Titration—The sulfate is titrated

1.4 This standard does not purport to address all of the

with barium perchlorate using a thorin-methylene blue mixed

safety concerns, if any, associated with its use. It is the

indicator.

responsibility of the user of this standard to establish appro-

3.1.2 Turbidimetric—The sulfate is precipitated as barium

priate safety and health practices and determine the applica-

sulfate and the turbidity of a suspension of the precipitate is

bility of regulatory limitations prior to use.

measured with a photometer.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

4.1 It is important to have the sulfur content of liquefied

D 156 Test Method for Saybolt Color of Petroleum Prod-

2 petroleum gases at low enough concentration to meet govern-

ucts (Saybolt Chromometer Method)

3 ment regulations.Thepresenceofsulfur canresultincorrosion

D 1193 Specification for Reagent Water

of metal surfaces. Sulfur can be poisonous to catalysts in

D 1265 Practice for Sampling Liquefied Petroleum (LP)

2 subsequent processing.

Gases (Manual Method)

D 1266 Test Method for Sulfur in Petroleum Products

5. Apparatus

(Lamp Method)

5.1 Oxy-Hydrogen Combustion Assembly— The two types

D 1657 Test Method for Density or Relative Density of

2 listed below are recommended. Any combustion apparatus

Light Hydrocarbons by Pressure Hydrometer

giving equivalent results, however, is satisfactory.

E 11 Specification for Wire Cloth and Sieves for Testing

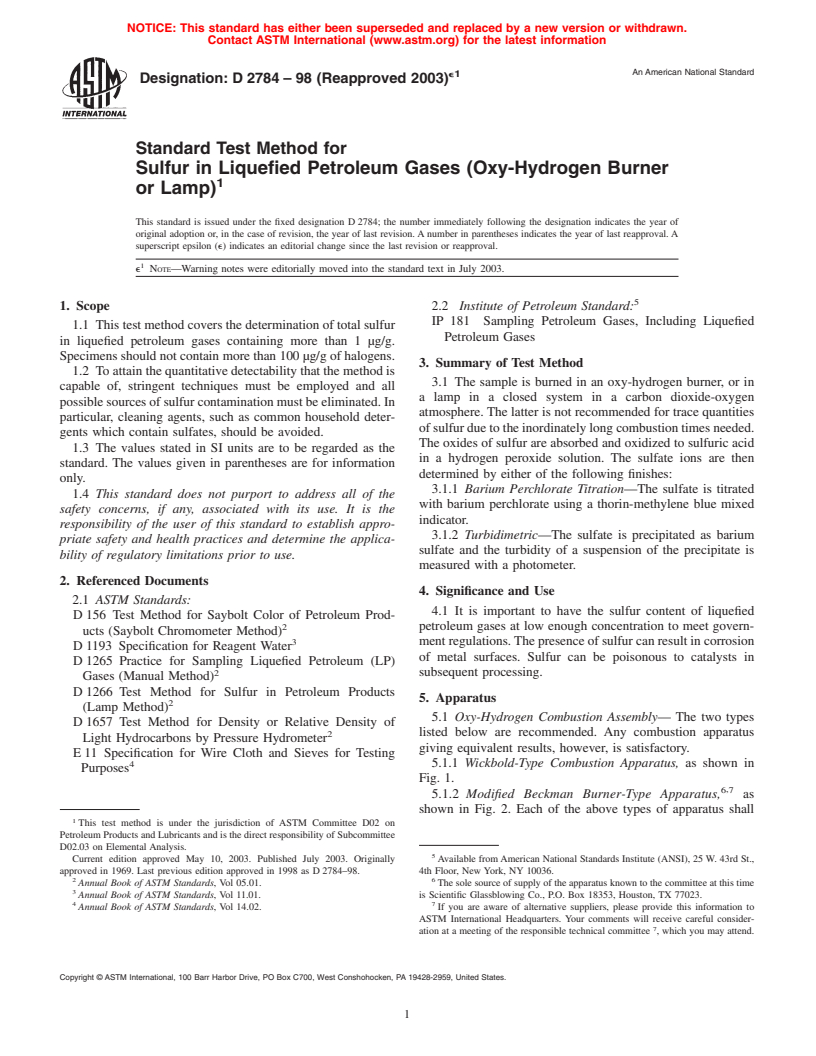

4 5.1.1 Wickbold-Type Combustion Apparatus, as shown in

Purposes

Fig. 1.

,

6 7

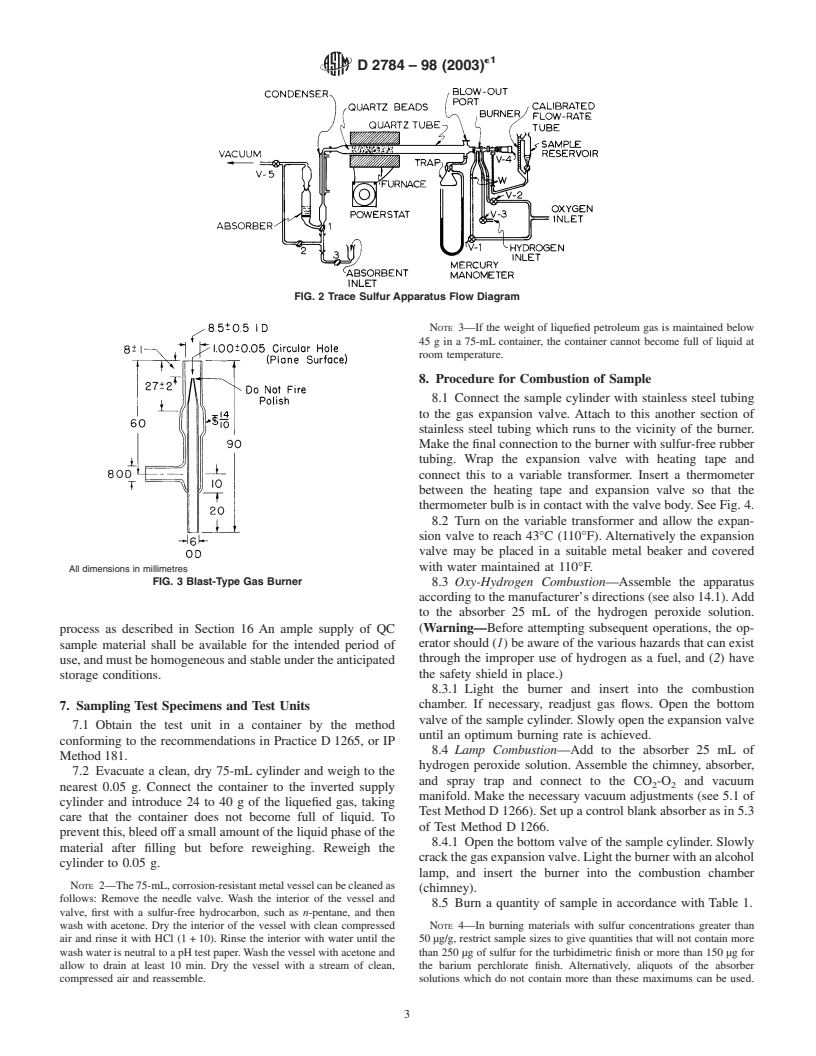

5.1.2 Modified Beckman Burner-Type Apparatus, as

shown in Fig. 2. Each of the above types of apparatus shall

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved May 10, 2003. Published July 2003. Originally Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

approved in 1969. Last previous edition approved in 1998 as D 2784–98. 4th Floor, New York, NY 10036.

2 6

Annual Book of ASTM Standards, Vol 05.01. The sole source of supply of the apparatus known to the committee at this time

Annual Book of ASTM Standards, Vol 11.01. is Scientific Glassblowing Co., P.O. Box 18353, Houston, TX 77023.

4 7

Annual Book of ASTM Standards, Vol 14.02. If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 2784 – 98 (2003)

5.4 Corrosion-Resistant Metal Cylinder,75-mL—Itshallbe

testedatapressureof600psig(4.14MPagage)andshallshow

no leaks when filled with air or nitrogen to this pressure and

submerged in water. It shall be fitted with a needle valve for

connection to the burner assembly.

5.5 Variable Transformer, 0–120 V, 750-W.

5.6 Carbon Dioxide Pressure Regulator— This regulator

should be of a type that eliminates the refrigeration difficulties

7,8

occurring with the pressure reduction of carbon dioxide.

6. Reagents and Materials

6.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

6.2 Purity of Water—Unless otherwise indicated, references

to water shall be understood to mean reagent water as defined

byTypesIIorIIIofSpecificationD 1193.Waterconformingto

the following specification is required. Sulfate-free deionized

1—Atomizer-burner

water prepared by percolation of water through a column of

2—Sample tube

3—Combustion chamber mixed anion and cation exchange resins.

4—Three-way stopcock

NOTE 1—Ameans for determining when to replace the exchange resins

5—Receiver

6—Spray trap shouldbeprovided.Useofasimpleelectricalconductivitymeterhasbeen

found satisfactory for this purpose.

FIG. 1 Flow Diagram of a Typical Oxy-Hydrogen Combustion

Apparatus

6.3 Standard Sulfate Solution (1 mL = 100 µg S)—Dilute

6.24 6 0.01 mL of 1 N sulfuric acid (H SO ) with water to

2 4

exactly 1 L. Check the dilution by titration against standard

consist of three parts: atomizer-burner, combustion chamber,

NaOH solution of about the same normality and adjust the

and absorber with spray trap. A blowout safety port in the

concentration, if necessary, so that each millilitre of this

combustion chamber is desirable. The remainder of the appa-

solution is equivalent to 100 µg of sulfur.

ratusshallconsistofasuitablesupportstandwiththenecessary

6.4 Hydrogen (Warning—Extremely flammable), Carbon

needle valves and flow meters for precise control of oxygen,

Dioxide (Warning—Gas may reduce oxygen available for

hydrogen, and vacuum.

breathing), and Oxygen (Warning—Oxygen accelerates com-

5.1.3 Safety Shield—A transparent shield shall be used to

bustion), meeting the requirement in Note 12.

protecttheoperatorintheeventanexplosivemixtureisformed

6.5 Scavenger-Rinse—Mix equal volumes of low-sulfur

in the combustion chamber.

acetone and isopropanol.

5.2 Apparatus for Lamp Combustion:

6.6 Hydrogen Peroxide Solution (1.5 %) (1 + 19) —Mix 1

5.2.1 Absorbers, Chimneys, and Spray Traps, as required

volume of concentrated hydrogen peroxide (H O =30%)

2 2

are described in detail in Annex A3 of Test Method D 1266.

with 19 volumes of water. Store in a dark-colored, glass-

5.2.2 Manifold System, consisting of a vacuum manifold

stoppered bottle.

with regulating device, valves, etc. (Fig. 2 of Test Method

6.7 Quality Control (QC) Sample(s), preferably are portions

D 1266) and a dual manifold (burner and chimney) supplying

of one or more liquefied petroleum gas materials or product

agasmixtureofapproximately70 %carbondioxide(CO )and

standards of known sulfur content that were not used in the

30 % oxygen (O ) at regulated pressures. The gas mixture in

generation of the instrument calibration curve. These (QC)

the chimney manifold shall be maintained at a nearly constant

samples are to be used to check the validity of the testing

pressure of 1 to 2 cm of water and the burner manifold at

approximately 20 cm of water. A suitable arrangement is

shown in Fig. 2 of Test Method D 1266 and described inA3.6

The sole source of supply of the Victor Type SR 300 regulator known to the

of Annex A3 of Test Method D 1266, but any other similar

committee at this time is Victor Equipment Co., Controls Division, 2336 Auburn

system giving equivalent results can be used.

Blvd., Sacramento, CA 95821.

5.2.3 Blast Type Gas Burner, having dimensions given in

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Fig. 3.

listed by the American Chemical Society, see Annual Standards for Laboratory

5.3 Vacuum Source, having a capacity of at least 1200 L/h.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

If a vacuum pump is used, it should be protected by a suitable

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

trap. MD.

e1

D 2784 – 98 (2003)

FIG. 2 Trace Sulfur Apparatus Flow Diagram

NOTE 3—If the weight of liquefied petroleum gas is maintained below

45 g in a 75-mL container, the container cannot become full of liquid at

room temperature.

8. Procedure for Combustion of Sample

8.1 Connect the sample cylinder with stainless steel tubing

to the gas expansion valve. Attach to this another section of

stainless steel tubing which runs to the vicinity of the burner.

Make the final connection to the burner with sulfur-free rubber

tubing. Wrap the expansion valve with heating tape and

connect this to a variable transformer. Insert a thermometer

between the heating tape and expansion valve so that the

thermometer bulb is in contact with the valve body. See Fig. 4.

8.2 Turn on the variable transformer and allow the expan-

sion valve to reach 43°C (110°F). Alternatively the expansion

valve may be placed in a suitable metal beaker and covered

with water maintained at 110°F.

All dimensions in millimetres

FIG. 3 Blast-Type Gas Burner 8.3 Oxy-Hydrogen Combustion—Assemble the apparatus

according to the manufacturer’s directions (see also 14.1).Add

to the absorber 25 mL of the hydrogen peroxide solution.

(Warning—Before attempting subsequent operations, the op-

process as described in Section 16 An ample supply of QC

erator should (1) be aware of the various hazards that can exist

sample material shall be available for the intended period of

through the improper use of hydrogen as a fuel, and (2) have

use,andmustbehomogeneousandstableundertheanticipated

the safety shield in place.)

storage conditions.

8.3.1 Light the burner and insert into the combustion

chamber. If necessary, readjust gas flows. Open the bottom

7. Sampling Test Specimens and Test Units

valve of the sample cylinder. Slowly open the expansion valve

7.1 Obtain the test unit in a container by the method

until an optimum burning rate is achieved.

conforming to the recommendations in Practice D 1265, or IP

8.4 Lamp Combustion—Add to the absorber 25 mL of

Method 181.

hydrogen peroxide solution. Assemble the chimney, absorber,

7.2 Evacuate a clean, dry 75-mL cylinder and weigh to the

and spray trap and connect to the CO -O and vacuum

2 2

nearest 0.05 g. Connect the container to the inverted supply

manifold. Make the necessary vacuum adjustments (see 5.1 of

cylinder and introduce 24 to 40 g of the liquefied gas, taking

Test Method D 1266). Set up a control blank absorber as in 5.3

care that the container does not become full of liquid. To

of Test Method D 1266.

prevent this, bleed off a small amount of the liquid phase of the

8.4.1 Open the bottom valve of the sample cylinder. Slowly

material after filling but before reweighing. Reweigh the

crackthegasexpansionvalve.Lighttheburnerwithanalcohol

cylinder to 0.05 g.

lamp, and insert the burner into the combustion chamber

NOTE 2—The75-mL,corrosion-resistantmetalvesselcanbecleanedas

(chimney).

follows: Remove the needle valve. Wash the interior of the vessel and

8.5 Burn a quantity of sample in accordance with Table 1.

valve, first with a sulfur-free hydrocarbon, such as n-pentane, and then

wash with acetone. Dry the interior of the vessel with clean compressed NOTE 4—In burning materials with sulfur concentrations greater than

air and rinse it with HCl (1 + 10). Rinse the interior with water until the 50 µg/g, restrict sample sizes to give quantities that will not contain more

wash water is neutral to a pH test paper.Wash the vessel with acetone and than 250 µg of sulfur for the turbidimetric finish or more than 150 µg for

allow to drain at least 10 min. Dry the vessel with a stream of clean, the barium perchlorate finish. Alternatively, aliquots of the absorber

compressed air and reassemble. solutions which do not contain more than these maximums can be used.

e1

D 2784 – 98 (2003)

FIG. 4 Burner Assembly for LPG

TABLE 1 Sample Sizes

the sample. Likewise subtract any sulfur obtained in the lamp

Sample Size, g combustion blank from the total figure.

Sulfur Content, ppm

Turbidimetric Finish Barium Perchlorate Finish

8.11 Disconnect the spray trap from the vacuum line and

1to5 45 30

thoroughly rinse the spray trap and chimney with about 35 mL

5to10 20 10

10 to 50 5 3

of distilled water, collecting the rinsings in the absorber. It is

important that any materials clinging to these parts be trans-

ferred to the absorber to avoid low values for sulfur content.

NOTE 5—Minor adjustment of the gas flow rates can be necessary to

BARIUM PERCHLORATE TITRATION FINISH

maintain those recommended by the manufacturer.

8.6 After a sufficient quantity of sample has been burned,

9. Reagents

turn the bottom valve of the cylinder off. Allow the remaining

9.1 Ion-Free Water—Distill deionized water and store in

gas in the tubing and gas expansion valve to burn itself out.

tightly capped, high-density polyethylene bottles.

Turn the heat off on the gas expansion valve. Disconnect the

9.2 HydrochloricAcid,StandardAlcoholic (0.1M)—Dilute

tubing from the sample cylinder and reweigh the sample

20 mL of aqueous 0.5 M HCl with 80 mL of isopropanol.

cylinder to the nearest 0.05 g. Leave the absorber solution in

9.3 Inhibited Thorin-Methylene Blue Mixed Indicator

the assembled lamp unit. The same absorber solution will be

Solution—The indicator is made up as two solutions and these

used for the scavenger-rinse burning. Allow the expansion

mi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.