ASTM D7257-06

(Test Method)Standard Test Method for Automated Shelling Two-Piece Child-Resistant Closures That Are Activated by Two Simultaneous Dissimilar Motions

Standard Test Method for Automated Shelling Two-Piece Child-Resistant Closures That Are Activated by Two Simultaneous Dissimilar Motions

SIGNIFICANCE AND USE

This test method of applying force may be used as a standard test to compare the characteristics of a given design of container/child-resistant closure system with a standard or to compare the characteristics of container/child resistant closure systems differing in construction.

It may be used to simulate certain manipulations that may be expected to occur in protocol testing (such as, prying with the teeth, or objects in the room, biting, and pulling with the teeth).

This test may be used to establish performance specifications. Shelling force may vary with cap application torque, bottle design, and other factors. Consequently where precise comparative results are desired, these factors must be carefully controlled.

SCOPE

1.1 This test method covers the measurement of the force required to separate (or "shell") the snap-fitted outer cap from the inner cap of Type IA, IB, or IC child-resistant closures. See Practice D 3475.

1.2 This test method is an alternative to Test Method D 3481, a manual test procedure.

1.3 This test method does not measure the force required to separate parts of a child-resistant closure system that were originally "screwed-on" instead of "snapped-on" (for example, pull a cap over or through continuous or multi-start threads when the cap was originally screwed on).

1.4 The values stated in inch-pound (lbf) units are to be regarded as standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7257–06

Standard Test Method for

Automated Shelling Two-Piece Child-Resistant Closures

That Are Activated by Two Simultaneous Dissimilar

Motions

This standard is issued under the fixed designation D7257; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope With Specified Precision, the Average for a Characteristic

of a Lot or Process

1.1 This test method covers the measurement of the force

required to separate (or “shell”) the snap-fitted outer cap from

3. Terminology

the inner cap ofType IA, IB, or IC child-resistant closures. See

3.1 Definitions:

Practice D3475.

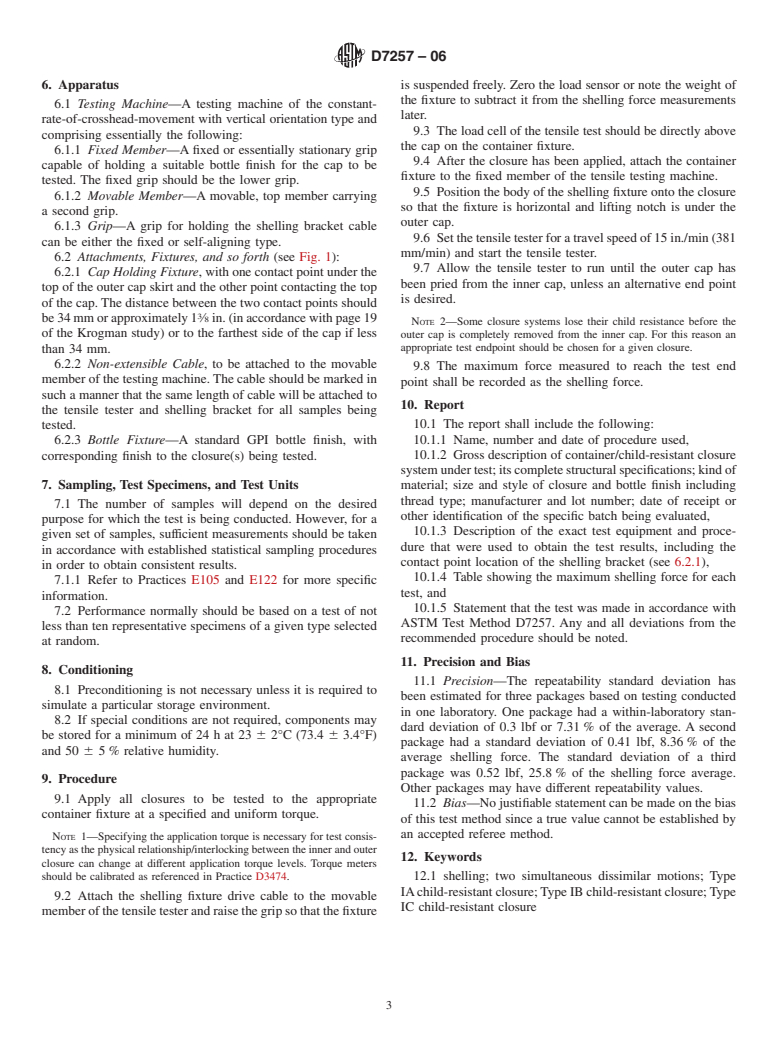

3.1.1 shelling fixture or bracket—a metal bracket that at-

1.2 ThistestmethodisanalternativetoTestMethodD3481,

taches to a two-piece, child-resistant closure and pries an outer

a manual test procedure.

cap from an inner cap. The bracket is shaped to simulate the

1.3 This test method does not measure the force required to

prying action of a child’s teeth. See Fig. 1.

separate parts of a child-resistant closure system that were

3.1.2 drive cable—a non-extensible cable attached from the

originally “screwed-on” instead of “snapped-on” (for example,

shelling fixture to a tensile strength measuring device to

pull a cap over or through continuous or multi-start threads

provide the cap shelling force.

when the cap was originally screwed on).

3.1.3 lifting notch—indentation on the shelling fixture that

1.4 The values stated in inch-pound (lbf) units are to be

lifts the outer cap off the inner cap during the test. See detailA

regarded as standard.

in Fig. 1.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 This test method measures the force required to pry the

priate safety and health practices and determine the applica-

outercapofftheinnercapusingafixturehavingacontactpoint

bility of regulatory limitations prior to use.

under the tip of the skirt of the outer cap and leverage being

placed on that point and the top of the cap. This procedure is

2. Referenced Documents

2 used where a pivotal prying force can be successfully used to

2.1 ASTM Standards:

separate the components of the closure system, thereby dis-

D3474 Practice for Calibration and Use of Torque Meters

abling the child-resistant function.

Used in Packaging Applications

D3475 Classification of Child-Resistant Packages

5. Significance and Use

D3481 Test Method for Manual Shelling Two-Piece Child-

5.1 This test method of applying force may be used as a

Resistant Closures That Are Activated by Two Simultane-

standardtesttocomparethecharacteristicsofagivendesignof

ous Dissimilar Motions

container/child-resistant closure system with a standard or to

E105 Practice for Probability Sampling Of Materials

compare the characteristics of container/child resistant closure

E122 Practice for Calculating Sample Size to Estimate,

systems differing in construction.

5.2 It may be used to simulate certain manipulations that

may be expected to occur in protocol testing (such as, prying

This test method is under the jurisdiction of ASTM Committee D10 on

with the teeth, or objects in the room, biting, and pulling with

Packaging and is the direct responsibility of Subcommittee D10.32 on Consumer,

the teeth).

Pharmaceutical and Medical Packaging.

5.3 This test may be used to establish performance specifi-

Current edition approved April 1, 2006. Published May 2006. DOI: 10.1520/

D7257-06.

cations. Shelling force may vary with cap application torque,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bottle design, and other factors. Consequently where precise

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

comparative results are desired, these factors must be carefully

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. controlled.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7257–06

FIG. 1 Shelling Bracket

D7257–06

6. Apparatus is suspended freely. Zero the load sensor or note the weight of

the fixture to subtract it from the shelling force measurements

6.1 Testing Machine—A testing machine of the constant-

later.

rate-of-crosshead-movement with vertical orientation type and

9.3 The load cell of the tensile test should be directly above

comprising essentially the following:

the cap on the container fixture.

6.1.1 Fixed Member—A fixed or essentially stationary grip

9.4 After the closure has been applied, attach the container

capable of holding a suitable bottle finish for the cap to be

fixture to the fixed member of the tensile testing machine.

tested. The fixed grip should be the lower grip.

9.5 Position the body of the shelling fixture onto the closure

6.1.2 Movable Member—A movable, top member carrying

so that the fixture is horizontal and lifting notch is under the

a second grip.

outer cap.

6.1.3 Grip—A grip for holding the shelling bracket cable

9.6 Setthetensiletesterforatra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.