ASTM F722-82(2014)

(Specification)Standard Specification for Welded Joints for Shipboard Piping Systems

Standard Specification for Welded Joints for Shipboard Piping Systems

ABSTRACT

This specification covers typical details of welded joints commonly used in shipboard piping systems. These joints and other joints may be used provided the welding procedures used have been qualified in accordance with the applicable regulatory rules and regulations. The maximum butt weld reinforcement of differnet nominal wall thicknesses of pipe or tube shall be discussed.

SCOPE

1.1 This specification covers typical details of welded joints commonly used in shipboard piping systems. These joints and other joints may be used provided the welding procedures used have been qualified in accordance with the applicable regulatory rules and regulations.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F722 −82 (Reapproved 2014) An American National Standard

Standard Specification for

1

Welded Joints for Shipboard Piping Systems

ThisstandardisissuedunderthefixeddesignationF722;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

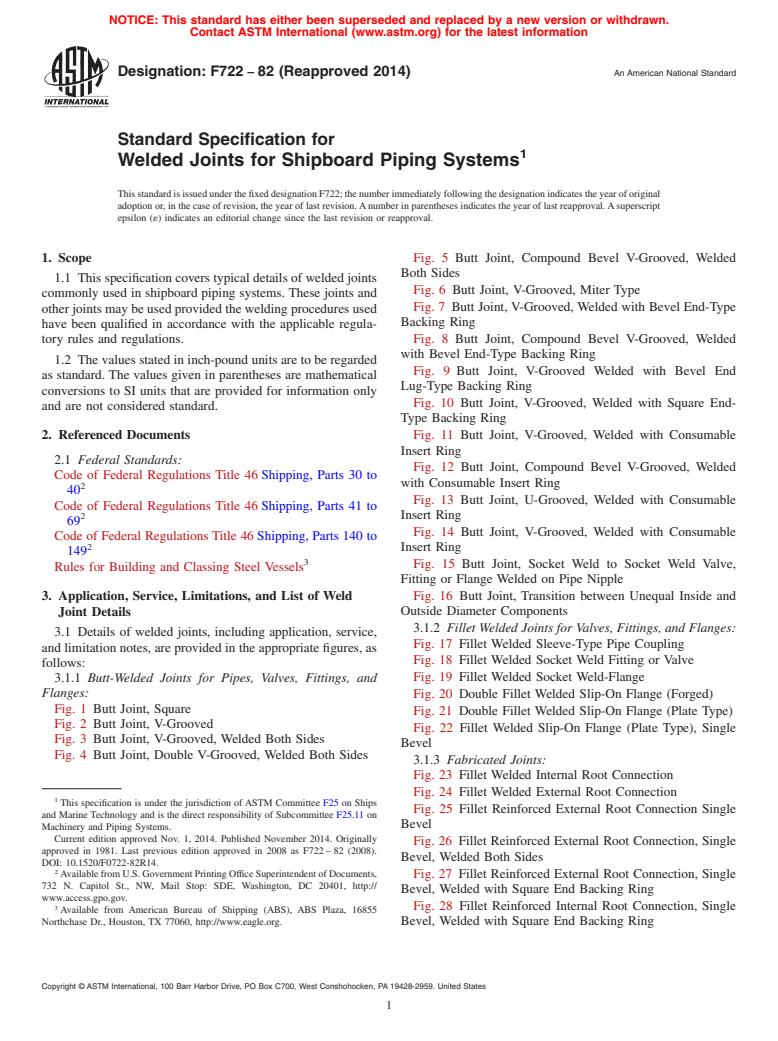

1. Scope Fig. 5 Butt Joint, Compound Bevel V-Grooved, Welded

Both Sides

1.1 This specification covers typical details of welded joints

Fig. 6 Butt Joint, V-Grooved, Miter Type

commonly used in shipboard piping systems. These joints and

Fig. 7 Butt Joint, V-Grooved, Welded with Bevel End-Type

other joints may be used provided the welding procedures used

Backing Ring

have been qualified in accordance with the applicable regula-

tory rules and regulations. Fig. 8 Butt Joint, Compound Bevel V-Grooved, Welded

with Bevel End-Type Backing Ring

1.2 The values stated in inch-pound units are to be regarded

Fig. 9 Butt Joint, V-Grooved Welded with Bevel End

as standard. The values given in parentheses are mathematical

Lug-Type Backing Ring

conversions to SI units that are provided for information only

Fig. 10 Butt Joint, V-Grooved, Welded with Square End-

and are not considered standard.

Type Backing Ring

Fig. 11 Butt Joint, V-Grooved, Welded with Consumable

2. Referenced Documents

Insert Ring

2.1 Federal Standards:

Fig. 12 Butt Joint, Compound Bevel V-Grooved, Welded

Code of Federal Regulations Title 46 Shipping, Parts 30 to

with Consumable Insert Ring

2

40

Fig. 13 Butt Joint, U-Grooved, Welded with Consumable

Code of Federal Regulations Title 46 Shipping, Parts 41 to

2 Insert Ring

69

Fig. 14 Butt Joint, V-Grooved, Welded with Consumable

Code of Federal Regulations Title 46 Shipping, Parts 140 to

2

Insert Ring

149

3

Fig. 15 Butt Joint, Socket Weld to Socket Weld Valve,

Rules for Building and Classing Steel Vessels

Fitting or Flange Welded on Pipe Nipple

3. Application, Service, Limitations, and List of Weld Fig. 16 Butt Joint, Transition between Unequal Inside and

Joint Details Outside Diameter Components

3.1.2 Fillet Welded Joints for Valves, Fittings, and Flanges:

3.1 Details of welded joints, including application, service,

Fig. 17 Fillet Welded Sleeve-Type Pipe Coupling

and limitation notes, are provided in the appropriate figures, as

Fig. 18 Fillet Welded Socket Weld Fitting or Valve

follows:

Fig. 19 Fillet Welded Socket Weld-Flange

3.1.1 Butt-Welded Joints for Pipes, Valves, Fittings, and

Flanges:

Fig. 20 Double Fillet Welded Slip-On Flange (Forged)

Fig. 1 Butt Joint, Square

Fig. 21 Double Fillet Welded Slip-On Flange (Plate Type)

Fig. 2 Butt Joint, V-Grooved

Fig. 22 Fillet Welded Slip-On Flange (Plate Type), Single

Fig. 3 Butt Joint, V-Grooved, Welded Both Sides

Bevel

Fig. 4 Butt Joint, Double V-Grooved, Welded Both Sides

3.1.3 Fabricated Joints:

Fig. 23 Fillet Welded Internal Root Connection

Fig. 24 Fillet Welded External Root Connection

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

Fig. 25 Fillet Reinforced External Root Connection Single

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Bevel

Machinery and Piping Systems.

Current edition approved Nov. 1, 2014. Published November 2014. Originally

Fig. 26 Fillet Reinforced External Root Connection, Single

approved in 1981. Last previous edition approved in 2008 as F722 – 82 (2008).

Bevel, Welded Both Sides

DOI: 10.1520/F0722-82R14.

2

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments, Fig. 27 Fillet Reinforced External Root Connection, Single

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

Bevel, Welded with Square End Backing Ring

www.access.gpo.gov.

3

Fig. 28 Fillet Reinforced Internal Root Connection, Single

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855

Northchase Dr., Houston, TX 77060, http://www.eagle.org. Bevel, Welded with Square End Backing Ring

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F722−82 (2014)

1

⁄8 in. = 3mm

3

⁄16 in. = 5mm

1

⁄16 in. = 2mm

Application—Class II piping

1

⁄8 in. = 3mm

Systems or Service—For services such as gravity drains (including plumbing),

7

⁄8 in. = 22 mm

vents, and overflows.

Remarks—1. Root of weld need not be ground.

Application—Class I and II piping above 2-in. NPS

FIG. 1 Butt Joint, Square

System or Service—All

Remarks—1. Internal weld shall be made first and ground, chipped, or cleaned

by some other means to assure sound welds.

2. The “L” dimension should be held to a minimum to facilitate welding and

inspection on the inside surface of the pipe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F722 − 82 (Reapproved 2008) F722 − 82 (Reapproved 2014)An American National Standard

Standard Specification for

1

Welded Joints for Shipboard Piping Systems

This standard is issued under the fixed designation F722; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers typical details of welded joints commonly used in shipboard piping systems. These joints and other

joints may be used provided the welding procedures used have been qualified in accordance with the applicable regulatory rules

and regulations.

1.2 The values stated in inch-pound units are to be regarded as the standard. standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 Federal Standards:

2

Code of Federal Regulations Title 46,46 Shipping, Parts 30 to 40

2

Code of Federal Regulations Title 46,46 Shipping, Parts 41 to 69

2

Code of Federal Regulations Title 46,46 Shipping, Parts 140 to 149

3

Rules for Building and Classing Steel Vessels

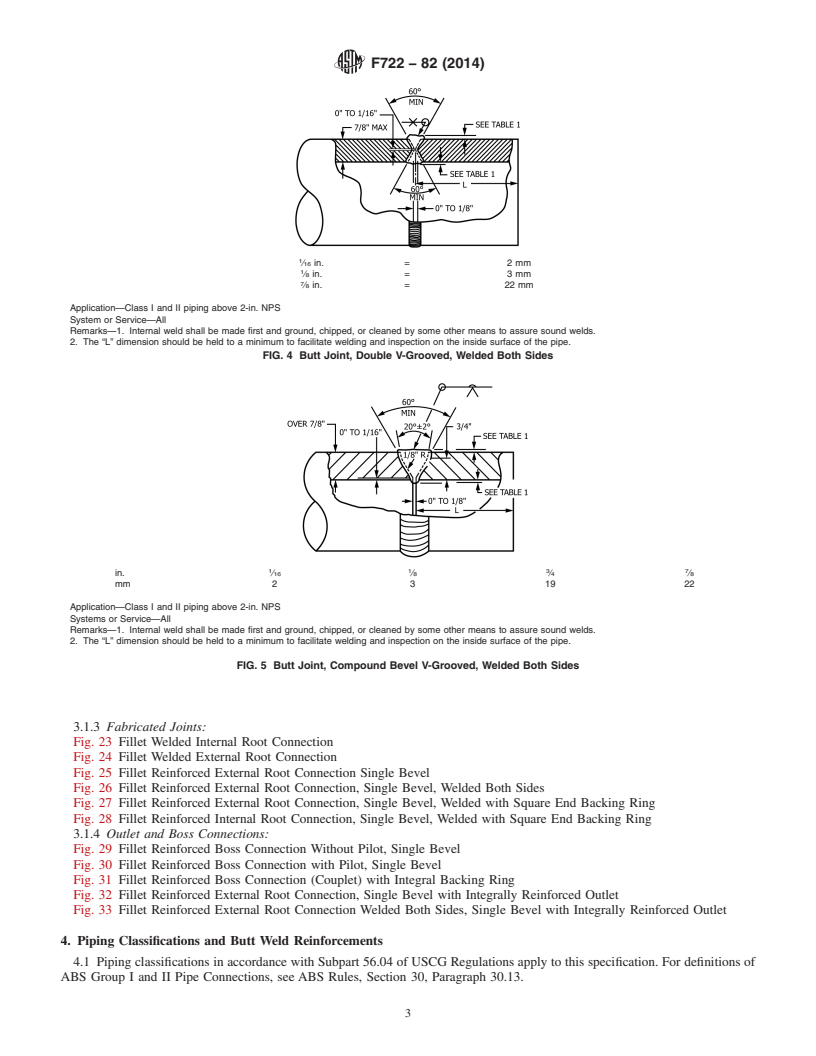

3. Application, Service, Limitations, and List of Weld Joint Details

3.1 Details of welded joints, including application, service, and limitation notes, are provided in the appropriate figures, as

follows:

3.1.1 Butt-Welded Joints for Pipes, Valves, Fittings, and Flanges:

Fig. 1 Butt Joint, Square

Fig. 2 Butt Joint, V-Grooved

Fig. 3 Butt Joint, V-Grooved, Welded Both Sides

Fig. 4 Butt Joint, Double V-Grooved, Welded Both Sides

Fig. 5 Butt Joint, Compound Bevel V-Grooved, Welded Both Sides

Fig. 6 Butt Joint, V-Grooved, Miter Type

Fig. 7 Butt Joint, V-Grooved, Welded with Bevel End-Type Backing Ring

Fig. 8 Butt Joint, Compound Bevel V-Grooved, Welded with Bevel End-Type Backing Ring

Fig. 9 Butt Joint, V-Grooved Welded with Bevel End Lug-Type Backing Ring

Fig. 10 Butt Joint, V-Grooved, Welded with Square End-Type Backing Ring

Fig. 11 Butt Joint, V-Grooved, Welded with Consumable Insert Ring

Fig. 12 Butt Joint, Compound Bevel V-Grooved, Welded with Consumable Insert Ring

Fig. 13 Butt Joint, U-Grooved, Welded with Consumable Insert Ring

Fig. 14 Butt Joint, V-Grooved, Welded with Consumable Insert Ring

Fig. 15 Butt Joint, Socket Weld to Socket Weld Valve, Fitting or Flange Welded on Pipe Nipple

Fig. 16 Butt Joint, Transition between Unequal Inside and Outside Diameter Components

3.1.2 Fillet Welded Joints for Valves, Fittings, and Flanges:

Fig. 17 Fillet Welded Sleeve-Type Pipe Coupling

Fig. 18 Fillet Welded Socket Weld Fitting or Valve

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved Nov. 1, 2008Nov. 1, 2014. Published December 2008November 2014. Originally approved in 1981. Last previous edition approved in 20042008

as F722 – 82 (2004).(2008). DOI: 10.1520/F0722-82R08.10.1520/F0722-82R14.

2

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.20401,

http://www.access.gpo.gov.

3

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 Northchase Dr., Houston, TX 77060.77060, http://www.eagle.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

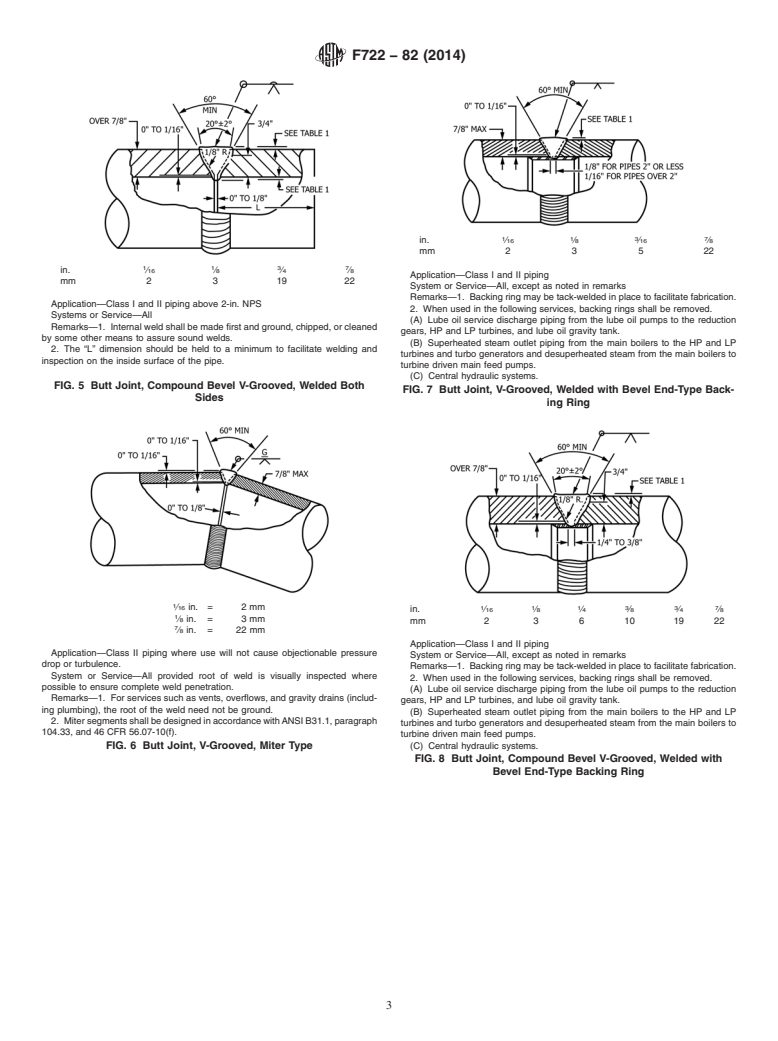

F722 − 82 (2014)

1

⁄8 in. = 3 mm

3

⁄16 in. = 5 mm

Application—Class II piping

Systems or Service—For services such as gravity drains (including plumbing), vents, and overflows.

Remarks—1. Root of weld need not be ground.

FIG. 1 Butt Joint, Square

1

⁄16 in. = 2 mm

1

⁄8 in. = 3 mm

7

⁄8 in. = 22 mm

Application—Class II piping

System or Service—All provided root of weld is visually inspected where possible to ensure complete weld penetration.

Remarks—1. For services such as vents, overflows, and gravity drains (including plumbing) the root of the weld need not be ground.

FIG. 2 Butt Joint, V-Grooved

1

⁄16 in. = 2 mm

1

⁄8 in. = 3 mm

7

⁄8 in. = 22 mm

Application—Class I and II piping above 2-in. NPS

System or Service—All

Remarks—1. Internal weld shall be made first and ground, chipped, or cleaned by some other means to assure sound welds.

2. The “L” dimensi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.